1/8 Maple Plywood Mastery: Tips for Perfect Projects

1/8 maple plywood is a thin, versatile material commonly used in woodworking and crafting. It measures 1/8 inch in thickness and features a smooth surface ideal for various projects.

Maple plywood is highly valued for its durability and attractive appearance. Often used in furniture, cabinetry, and decorative applications, it offers a fine grain and light color. The 1/8-inch thickness makes it suitable for detailed work and projects requiring lightweight materials.

This plywood type is easy to cut, shape, and finish, making it perfect for both amateur and professional woodworkers. Its resistance to warping and splitting enhances its appeal, ensuring projects maintain their integrity over time. Whether you’re building a model or creating intricate designs, 1/8 maple plywood can elevate your craftsmanship significantly.

Introduction To Maple Plywood

Maple plywood is a popular material in woodworking. Its fine grain and smooth finish make it ideal for many projects. One specific thickness, 1/8 inch, has unique benefits. This guide explores the characteristics of maple and why its 1/8 inch thickness stands out.

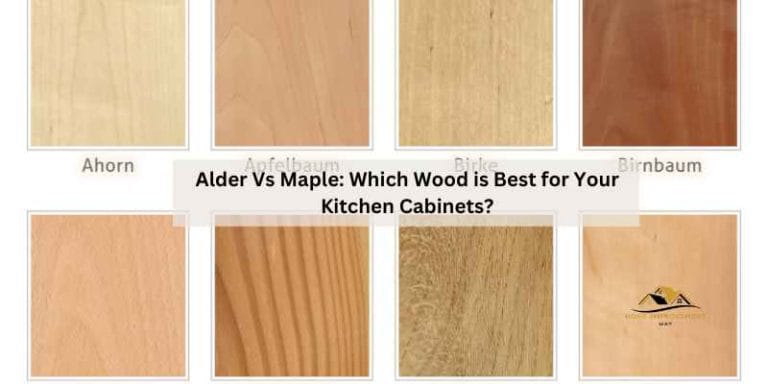

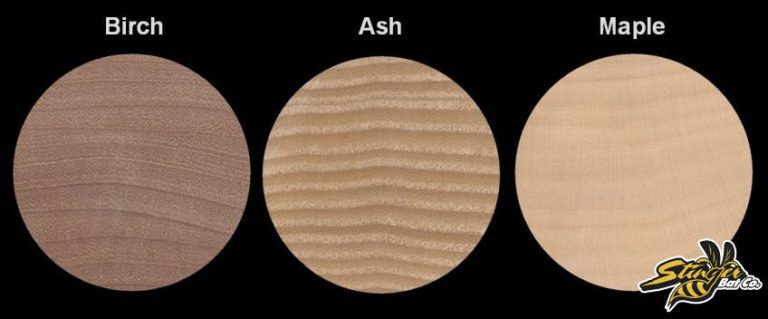

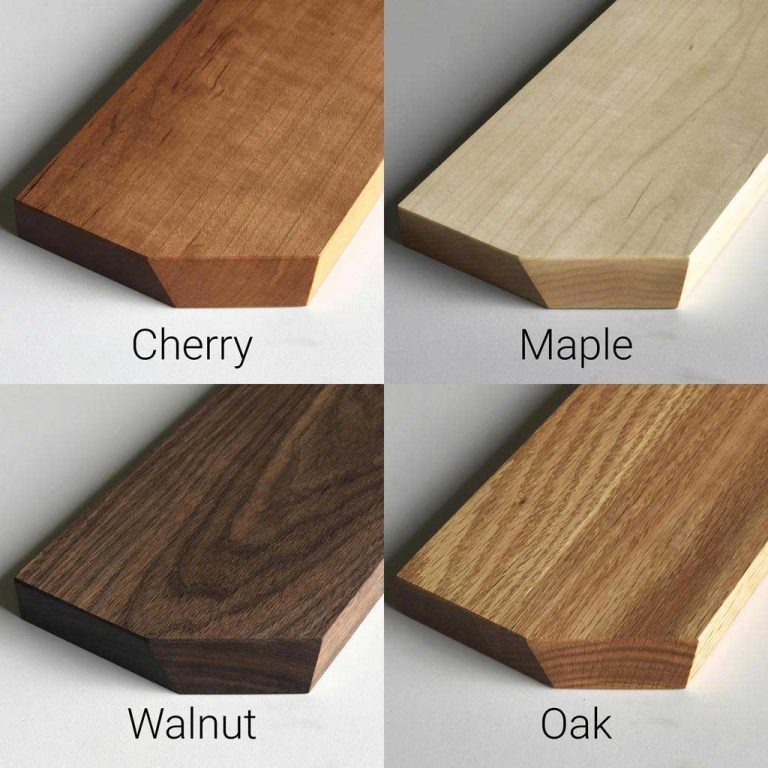

Characteristics Of Maple

Maple wood is known for several key traits:

- Durability: Maple is strong and resistant to wear.

- Aesthetic Appeal: It features a beautiful light color.

- Uniform Texture: The grain is fine and consistent.

- Stability: It holds its shape well over time.

These qualities make maple plywood a favorite among builders and crafters.

Why Choose 1/8 Inch Thickness

The 1/8 inch thickness of maple plywood offers several advantages:

- Lightweight: Easier to handle and transport.

- Flexibility: Suitable for curved or intricate designs.

- Cost-Effective: Less material means lower costs.

- Easy to Cut: Simple to work with for various projects.

This thickness is perfect for crafts, model-making, and lightweight furniture.

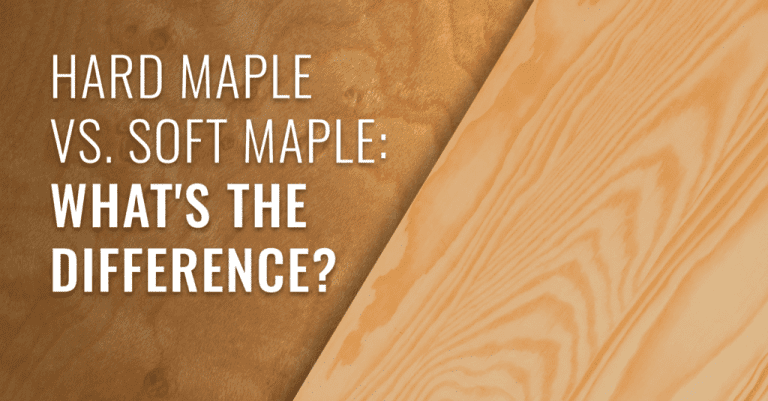

Selecting The Right Maple Plywood

Choosing the right 1/8 Maple Plywood is crucial. It affects your project’s durability and appearance. This guide helps you make informed decisions.

Grades And Quality

Maple plywood comes in different grades. Each grade affects appearance and strength. Here’s a quick overview:

| Grade | Appearance | Uses |

|---|---|---|

| AA | Very smooth, minimal imperfections | Furniture, cabinetry |

| A | Smooth, some minor defects | Visible projects, indoor use |

| B | Some defects, more texture | Hidden parts, structural use |

| C | Noticeable defects, rougher | Non-visible areas, utility |

Choose a grade based on your project needs. Higher grades suit visible projects. Lower grades work for structural components.

Where To Purchase

Finding quality maple plywood is simple. Check local hardware stores. They often stock various grades.

- Home improvement stores

- Specialty woodworking shops

- Online retailers

Online options offer convenience. Compare prices and reviews easily. Look for local suppliers for quick pickups.

- Visit stores to inspect quality.

- Ask for samples if unsure.

- Check for return policies.

Choosing the right source ensures you get the best product. Always prioritize quality over price.

Tools For Cutting And Shaping

Cutting and shaping 1/8 Maple Plywood requires the right tools. Choosing the right tools ensures precision and ease. Here’s a look at essential and advanced equipment.

Essential Tools

Basic projects need only a few essential tools. Here’s a list of must-have tools:

- Hand Saw: Great for straight cuts.

- Jigsaw: Perfect for curves and intricate shapes.

- Utility Knife: Useful for scoring and quick cuts.

- Clamps: Hold pieces securely during cutting.

- Ruler and Square: Ensure accurate measurements.

Advanced Equipment

For more complex projects, consider advanced equipment. These tools offer enhanced precision and efficiency:

| Tool | Description |

|---|---|

| Table Saw | Ideal for long, straight cuts and consistent thickness. |

| Router | Shapes edges and creates grooves. |

| Band Saw | Great for cutting curves and thick wood. |

| CNC Machine | Automated cutting for precision and complex designs. |

Using the right tools makes cutting and shaping easier. Choose what fits your project best.

Preparing For Your Project

Starting a project with 1/8 Maple Plywood requires careful preparation. Understanding the wood and its properties is essential. This section covers how to read the wood grain and prepare the surface effectively.

Reading The Wood Grain

Understanding the wood grain helps in achieving better results. Here’s what to look for:

- Grain Pattern: Observe the direction and pattern of the grain.

- Color Variations: Note any changes in color. This indicates different wood characteristics.

- Defects: Look for knots, cracks, or splits. These may affect your project.

Reading the grain helps in planning cuts and finishes. Use this knowledge to enhance your project’s appearance.

Surface Preparation

Proper surface preparation is vital for success. Follow these steps:

- Cleaning: Remove dirt and dust from the surface.

- Sanding: Sand the plywood with fine-grit sandpaper. This smooths the surface.

- Inspecting: Check for any rough patches. Sand them down as needed.

- Sealing: Apply a wood conditioner if staining. This ensures even absorption.

Well-prepared surfaces enhance finishes and durability. Take your time during this step for the best results.

Cutting Techniques

Cutting 1/8 Maple Plywood requires careful techniques for the best results. Proper methods enhance accuracy and reduce waste. This section covers effective cutting strategies.

Precision Cutting

Precision cutting ensures clean, accurate edges. Here are some tips:

- Use a sharp blade. A dull blade tears the wood.

- Measure twice, cut once. Double-check measurements.

- Utilize a straight edge. This keeps cuts aligned.

For intricate designs, consider using a jigsaw. This tool allows for curves and detailed work.

Avoiding Splintering

Splintering can ruin your project. Follow these steps to prevent it:

- Cut with the good side facing up.

- Score the cut line first. Use a utility knife.

- Use painter’s tape on the cut line. This adds support.

These techniques help maintain the integrity of the wood. They ensure a smooth finish for your project.

Joinery And Assembly

Joinery and assembly are vital for working with 1/8 Maple Plywood. Choosing the right joints ensures strong and durable projects. Proper assembly techniques enhance the beauty of your work. This section explores the types of joints and how to secure them effectively.

Types Of Joints

- Butt Joint: Simple and easy to make. Ideal for quick projects.

- Lap Joint: Overlaps two pieces. Provides extra strength.

- Dado Joint: A groove cut into one piece. Excellent for shelves.

- Rabbet Joint: A notch cut along the edge. Great for frames.

- Miter Joint: Cuts at an angle. Perfect for corners.

| Joint Type | Strength | Use Cases |

|---|---|---|

| Butt Joint | Low | Quick repairs |

| Lap Joint | Medium | Frames and boxes |

| Dado Joint | High | Shelves and partitions |

| Rabbet Joint | Medium | Cabinets and frames |

| Miter Joint | Medium | Picture frames |

Securing Joints

Securing joints is essential for lasting projects. Here are some effective methods:

- Wood Glue: Strong adhesive for wooden pieces. Apply evenly for best results.

- Screws: Provide additional strength. Use pre-drilled holes to avoid splitting.

- Nails: Quick and easy to use. Choose the right size for your project.

- Dowels: Wooden pins that align joints. Create a strong connection.

- Biscuits: Small, oval-shaped pieces. Help align and strengthen joints.

Choosing the right securing method depends on your project needs. Strong joints ensure your 1/8 Maple Plywood creations last for years.

Finishing Maple Plywood

Finishing Maple Plywood enhances its beauty and durability. Proper techniques ensure a smooth and attractive surface. Whether you plan to stain, paint, or seal, the right finish brings out the wood’s natural charm.

Sanding Tips

Sanding is a crucial step in finishing maple plywood. It prepares the surface for the finish. Follow these tips for the best results:

- Start with coarse grit: Use 80 to 100 grit sandpaper.

- Progress to finer grits: Move to 120 and then 220 grit.

- Sand with the grain: Follow the wood’s natural pattern.

- Keep the surface clean: Wipe off dust after sanding.

- Check for imperfections: Fill any holes or cracks before finishing.

Choosing The Right Finish

Selecting the right finish is essential for maple plywood. Different finishes create different looks. Here are common options:

| Finish Type | Characteristics | Best Use |

|---|---|---|

| Polyurethane | Durable and water-resistant | High-traffic areas |

| Varnish | Glossy and protective | Furniture and decorative items |

| Oil | Enhances natural grain | Indoor projects |

| Stain | Color enhancement | Customizing appearance |

Consider your project’s purpose. Think about the look you want. Each finish serves a different purpose. Choose one that suits your needs.

Troubleshooting Common Issues

Working with 1/8 Maple Plywood can present challenges. This section addresses common issues and their solutions. Proper knowledge helps ensure a smooth project.

Warping And How To Prevent It

Warping is a common problem with plywood. It can occur due to humidity changes or improper storage. Here are some tips to prevent warping:

- Store sheets flat, not on their edge.

- Avoid direct sunlight exposure.

- Keep in a climate-controlled environment.

- Use weights to hold the sheets down.

If warping occurs, try these solutions:

- Moisten the concave side slightly.

- Place it under a heavy object.

- Allow it to dry slowly.

Dealing With Glue Stains

Glue stains can mar the finish of your project. To effectively deal with them, follow these steps:

- Use a clean cloth with warm water.

- Gently scrub the stained area.

- Apply a small amount of vinegar if stains persist.

For tougher stains, consider these options:

| Stain Type | Recommended Solution |

|---|---|

| Fresh Glue | Warm water and cloth |

| Old Glue | Vinegar and cloth |

| Heavy Stains | Fine sandpaper |

Always test solutions on a small area first. This prevents damage to the plywood.

Advanced Techniques

Exploring advanced techniques with 1/8 Maple Plywood opens new creative possibilities. These methods enhance projects and showcase craftsmanship. Let’s dive into some popular techniques.

Inlays And Veneering

Inlays add unique designs to your projects. They involve embedding materials into the surface of plywood. Common materials for inlays include:

- Wood – Use different types for contrast.

- Metal – Adds a modern touch.

- Resin – Bright colors can enhance designs.

Veneering involves applying a thin layer of wood over plywood. This technique provides a stunning finish with less weight. Choose high-quality veneer for the best results.

Follow these steps for inlays:

- Design your pattern.

- Cut the shape from the plywood.

- Prepare the inlay material.

- Glue the inlay into the cutout.

- Sand the surface for a smooth finish.

Creating Curves

Curves can transform simple designs into stunning works. 1/8 Maple Plywood is flexible enough to create various shapes. Here’s how to create curves:

- Steam bending: Use steam to soften the wood.

- Kerf cutting: Make cuts along the curve for flexibility.

- Layering: Glue multiple layers for a thicker curve.

For precise curves, use a template:

- Draw the curve on the plywood.

- Cut along the line using a jigsaw.

- Sand the edges for a smooth finish.

These advanced techniques with 1/8 Maple Plywood unlock creativity. Experiment with inlays and curves to elevate your projects.

Project Ideas

1/8 Maple Plywood is versatile and easy to work with. It opens up many creative possibilities. Here are some exciting project ideas to inspire you.

Home Decor

Enhance your living space with these simple projects:

- Wall Art: Create unique designs or shapes.

- Shelves: Build floating shelves to display items.

- Plyboard Signs: Make personalized signs for rooms.

- Picture Frames: Craft custom frames for your photos.

- Decorative Panels: Use panels to add texture to walls.

Functional Furniture

Combine beauty and utility with these functional furniture ideas:

- Small Tables: Perfect for coffee or side tables.

- Stools: Build lightweight and portable seating.

- Storage Boxes: Create stylish storage solutions.

- Bookshelves: Design simple yet elegant book storage.

- Benches: Make a bench for your entryway or garden.

These projects are fun and achievable. Start exploring the possibilities with 1/8 Maple Plywood today!

Care And Maintenance

Proper care and maintenance of 1/8 Maple Plywood enhances its durability. Simple steps can keep it looking great. Regular cleaning and preservation techniques are essential for longevity.

Cleaning Tips

Keeping your maple plywood clean is easy. Use these tips for effective cleaning:

- Dust regularly: Use a soft, dry cloth.

- Wipe spills: Clean spills immediately with a damp cloth.

- Avoid harsh chemicals: Use mild soap and water.

- Dry thoroughly: Always dry the surface after cleaning.

Follow these steps to maintain the shine and appearance of your plywood.

Long-term Preservation

Preserving 1/8 Maple Plywood ensures it lasts longer. Consider these methods:

| Method | Description |

|---|---|

| Sealants | Apply a wood finish or sealant to protect the surface. |

| Climate Control | Keep plywood in a stable environment, away from moisture. |

| Avoid Direct Sunlight | Store away from direct sunlight to prevent warping. |

Using these preservation methods will enhance the lifespan of your plywood.

Resource And Material Sustainability

Resource and material sustainability plays a crucial role in today’s world. It helps conserve our planet while meeting material needs. Choosing materials wisely impacts both the environment and future generations.

Eco-friendly Practices

Using 1/8 maple plywood supports eco-friendly practices. This material comes from renewable sources. Manufacturers often use advanced methods to minimize waste.

- Low VOC emissions during production

- Efficient use of wood resources

- Recycling programs for leftover materials

These practices ensure that the environment remains protected. They also promote a healthier living space. Choosing sustainable materials benefits both you and the planet.

Sourcing Responsibly

Responsible sourcing is vital for sustainability. Many suppliers of 1/8 maple plywood commit to ethical practices. They source wood from well-managed forests.

| Certification | Description |

|---|---|

| FSC Certified | Forest Stewardship Council ensures sustainable forestry practices. |

| PEFC Certified | Programme for the Endorsement of Forest Certification promotes sustainable forest management. |

Choosing certified plywood helps protect forests. It reduces deforestation and preserves habitats. Responsible sourcing creates a positive impact on local communities.

Frequently Asked Questions

What Is 1/8 Maple Plywood Used For?

1/8 maple plywood is commonly used in cabinetry, furniture making, and craft projects. Its thin profile makes it ideal for applications requiring lightweight materials. Additionally, it offers a smooth surface, making it perfect for veneer and decorative finishes. It’s versatile and easy to work with for various DIY projects.

How Thick Is 1/8 Maple Plywood?

1/8 maple plywood is precisely 1/8 inch thick, which is approximately 3. 175 mm. This thickness provides a balance between strength and flexibility, making it suitable for many applications. It’s often chosen for projects that need lightweight materials without sacrificing durability.

It’s a popular choice in woodworking and craft projects.

Is 1/8 Maple Plywood Durable?

Yes, 1/8 maple plywood is quite durable. Its construction combines multiple layers of wood, enhancing its strength and resistance to warping. Maple wood is known for its toughness, making this plywood suitable for various applications, including furniture and cabinetry. Proper sealing can further increase its longevity and performance.

Can I Paint 1/8 Maple Plywood?

Absolutely! 1/8 maple plywood can be easily painted. Its smooth surface allows for even application of paint, ensuring a professional finish. For the best results, use a primer first to enhance adhesion. This plywood is also suitable for staining, allowing for versatile design options in your projects.

Conclusion

1/8 maple plywood stands out for its versatility and strength. Whether for furniture, cabinetry, or crafts, it delivers excellent results. Its smooth surface makes finishing easy, enhancing any project. Choosing the right plywood can elevate your work. Embrace the benefits of 1/8 maple plywood for your next creative endeavor.