Brown Pressure Treated Wood vs Green: Proven Best

Choosing between brown and green pressure-treated wood is a common decision for DIYers. Both offer excellent protection against rot and insects, but their appearance and suitability for certain projects can differ. This guide will help you understand the differences and make the best choice for your next build.

Hey there, fellow woodworkers! Ever stood in the lumberyard, staring at those long boards, wondering if the green ones are better than the brown ones? It’s a common question, and honestly, it can be a bit confusing when you’re just starting out. You want your projects to look great and last a long time, and picking the right wood is a big part of that. Don’t worry, we’re going to break it all down in a way that makes perfect sense. We’ll explore what makes pressure-treated wood turn green or brown, and how that affects your projects. Get ready to feel confident about your next lumber purchase!

Understanding Pressure-Treated Wood

Pressure-treated wood is a fantastic material for outdoor projects because it’s infused with chemicals that protect it from decay, fungi, and insects. This process involves placing the wood in a sealed cylinder and then introducing the wood preservative under high pressure. This forces the chemicals deep into the wood fibers, ensuring long-lasting protection. This treatment makes it ideal for decks, fences, pergolas, and any other structure exposed to the elements or in contact with the ground. Without this treatment, untreated wood would quickly succumb to rot and insect damage, especially in damp environments.

The core of the matter lies in the preservatives used and how they react over time. The color you see is often a result of these chemicals and any added colorants. It’s not necessarily an indicator of better or worse performance, but rather a visual cue to how the wood has been treated and potentially aged.

The “Green” in Pressure-Treated Wood

You’ve likely seen wood with a distinct greenish hue. This color typically comes from copper-based preservatives, such as Alkaline Copper Quaternary (ACQ) or Copper Azole (CA). These are some of the most common and effective preservatives used in the industry today. The copper compounds are what give the wood its characteristic green tint. This color is most noticeable when the wood is freshly treated.

Historically, Chromated Copper Arsenate (CCA) was widely used, and it also imparted a greenish color. However, due to environmental and health concerns, CCA is no longer approved for most residential uses in many countries, including the United States, for applications like decks and play structures. Modern treatments have replaced CCA with safer alternatives that still rely on copper for their protective properties.

When you buy wood treated with these modern copper-based preservatives, it will often have a greenish or sometimes bluish-green color. This color is primarily a visual indicator that the wood has been treated and contains the necessary protective chemicals. It’s important to note that this green color will fade over time as the wood is exposed to sunlight and the elements, usually turning a natural grayish-brown.

Why the Green Color?

- Copper Preservatives: The green color is mainly due to copper compounds in the wood preservative.

- Protection Against Fungi and Insects: Copper is a key ingredient in protecting the wood from rot and insect infestation.

- Visual Indicator: It serves as a visual confirmation that the wood has been pressure-treated.

- Fades Over Time: The green hue will naturally fade to a silvery-gray or brown as the wood weathers.

The “Brown” in Pressure-Treated Wood

Brown pressure-treated wood has typically undergone a similar pressure treatment process but with the addition of a brown stain or dye. This stain is often added at the treatment facility along with the preservative. The goal of this added colorant is twofold: to provide an initial aesthetic appeal that resembles natural wood tones, and to help users easily distinguish treated wood from untreated wood. It also helps to mask the green color that might be present from the copper-based preservatives.

The brown color is a popular choice because it blends well with natural landscaping and can provide a more finished look immediately after installation, reducing the need for staining right away. However, like the green color, this brown stain is also a surface treatment and can fade over time. Many people still choose to stain or seal their brown pressure-treated wood after installation to enhance its color and add another layer of protection.

The underlying preservative is still effective regardless of the added color. Whether it’s copper-based or another type of treatment, the brown color is primarily for aesthetics and identification. It’s important to remember that the color doesn’t necessarily mean it’s treated with a different or more effective preservative. The effectiveness comes from the chemicals forced into the wood fibers.

Why the Brown Color?

- Added Brown Stain/Dye: The brown color is achieved by adding a stain or dye during the treatment process.

- Aesthetic Appeal: It offers a more natural wood look from the start.

- Ease of Identification: Helps distinguish treated wood from untreated wood.

- Can Still Be Stained: While it has a brown tint, you can still apply your preferred stain or sealer for a custom look and added protection.

Brown Pressure Treated Wood vs Green Pressure Treated Wood: A Comparison

When you’re deciding between brown and green pressure-treated wood, it’s helpful to look at their characteristics side-by-side. The primary difference, as we’ve discussed, is the color, which stems from added dyes or the natural hue of the preservatives. Functionally, both types offer excellent protection against rot and insects, provided they have been treated to the appropriate standards for their intended use.

The choice often comes down to your project’s aesthetic goals and your immediate plans for finishing the wood. If you want a project that looks more “finished” right away or want to avoid the initial green tint, brown-treated wood might be your preference. If you plan to stain or paint your project soon after completion and don’t mind the initial green, then green-treated wood is perfectly fine and often more readily available or cost-effective.

It’s also worth noting that the effectiveness of the treatment itself is dictated by the retention level of the preservative, not the color. For example, wood treated for ground contact will have a higher retention level of preservative than wood treated for above-ground use. Always check the end tag of the lumber to ensure it’s rated for your specific application.

Let’s break down some key differences in a table:

| Feature | Green Pressure Treated Wood | Brown Pressure Treated Wood |

|---|---|---|

| Color Origin | Natural color of copper-based preservatives (e.g., ACQ, CA) | Added brown stain or dye mixed with preservatives |

| Initial Appearance | Greenish or bluish-green hue | Brown or reddish-brown hue |

| Aesthetic Goal | Can be stained or painted to desired color; natural weathered gray look is also common | Provides a more finished, wood-like appearance immediately; can still be stained/painted |

| UV Resistance (Color) | Green color may fade faster than some brown dyes initially | Brown dye helps protect the underlying wood from UV rays, but can also fade |

| Treatment Effectiveness | Dependent on preservative retention level, not color | Dependent on preservative retention level, not color |

| Availability | Often widely available, especially for decking and framing | Availability can vary by region and supplier |

| Cost | Can sometimes be slightly less expensive due to simpler processing | May be slightly more expensive due to the added dyeing process |

What About the Treatment Chemicals?

The actual preservatives used in pressure-treated wood are designed to be highly effective against biological degradation. The most common modern treatments for residential use are copper-based, such as:

- Alkaline Copper Quaternary (ACQ): This is one of the most prevalent treatments. It uses copper in combination with quaternary ammonium compounds. ACQ is effective against a wide range of fungi and insects. It’s considered safe for most outdoor applications.

- Copper Azole (CA): Similar to ACQ, CA also uses copper combined with azole compounds. It offers excellent protection and is approved for various uses, including ground contact.

- Micronized Copper Quaternary (MCQ): This is a newer technology where copper particles are dispersed in a water-based solution. It offers good protection and can sometimes result in a lighter color.

Historically, Chromated Copper Arsenate (CCA) was a dominant treatment. It was highly effective and provided a greenish color. However, due to concerns about arsenic leaching, its use in residential applications like decks, fences, and playgrounds has been significantly restricted or banned in many regions. For more information on wood preservatives and their regulations, you can refer to resources from the U.S. Environmental Protection Agency (EPA).

The color of the wood (green or brown) is usually an indicator of whether a dye has been added, not necessarily a change in the core protective chemicals. Both green and brown treated woods should meet industry standards for preservation if they are intended for outdoor use.

Choosing the Right Treatment Level

Beyond color, the most critical factor in selecting pressure-treated wood is its retention level, which indicates how much preservative is in the wood. This is determined by the intended use of the wood. Always check the end tag on the lumber, which will specify its treatment level and intended application.

Here are common retention levels:

- Above Ground (AG) / General Use: This is suitable for applications like deck framing, railings, and fences that are not in direct contact with the ground.

- Ground Contact (GC): This wood has a higher retention level of preservatives and is designed for applications where the wood will be in direct contact with soil, such as fence posts, deck pilings, or landscaping timbers.

- Below Ground (BG) / Marine Use: The highest retention level, used for wood that will be constantly exposed to moisture or submerged in water, like dock pilings or boat structures.

Using the wrong retention level can lead to premature failure of your project. For instance, using above-ground rated wood for fence posts set in the ground will significantly shorten its lifespan.

Can You Stain or Paint Pressure-Treated Wood?

Yes, absolutely! Both brown and green pressure-treated wood can be stained or painted. However, it’s important to wait for the wood to dry out properly before applying any finish.

When to Stain/Paint

Newly treated lumber contains a significant amount of moisture. Applying a finish too soon can trap this moisture, leading to peeling, bubbling, or poor adhesion. A good rule of thumb is to wait at least a few weeks, and often longer (up to several months), especially if the wood was treated for ground contact or if you live in a humid climate.

A simple test is to sprinkle a few drops of water on the wood. If the water beads up, the wood is still too wet. If the water soaks in, it’s likely dry enough to finish. You can also use a moisture meter for a more precise reading; aim for a moisture content below 15-20%.

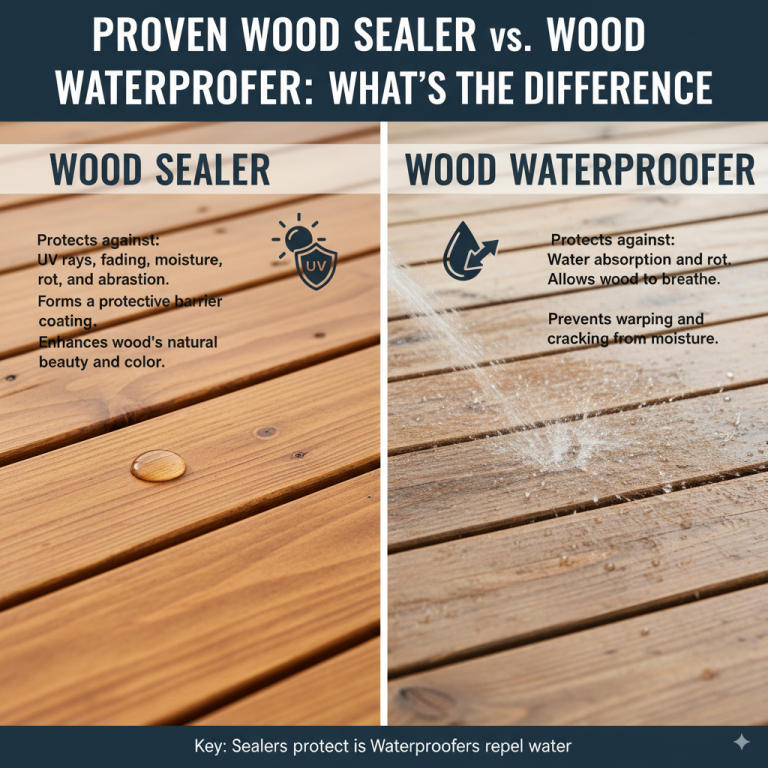

Types of Finishes

- Stains: Available in transparent, semi-transparent, and solid colors. Stains penetrate the wood and highlight the grain (transparent/semi-transparent) or provide a more opaque, paint-like finish (solid). They offer UV protection and help prevent the wood from drying out and cracking.

- Paints: Offer the most complete coverage and a wide range of color options. Like stains, paint provides UV protection and helps seal the wood.

- Sealers: These are typically clear or lightly tinted and provide water repellency and some UV protection without significantly altering the wood’s appearance.

For both brown and green treated wood, applying a good quality exterior stain or paint will enhance its appearance and further extend its lifespan by protecting it from UV rays and moisture. The brown-treated wood might require fewer coats of stain to achieve an opaque finish compared to the green-treated wood, but the end result with either can be beautiful.

Best Practices for Working with Pressure-Treated Wood

Working with pressure-treated wood is similar to working with other dimensional lumber, but there are a few extra precautions and tips to keep in mind:

Cutting and Handling Safety

When you cut pressure-treated wood, the preservative chemicals can be released as dust. It’s crucial to take precautions to avoid inhaling this dust.

- Wear Safety Glasses: Protect your eyes from sawdust and flying debris.

- Wear a Dust Mask or Respirator: Use a P95 or P100 respirator when cutting, drilling, or sanding treated wood to avoid inhaling fine particles.

- Work in a Well-Ventilated Area: Ensure good airflow to disperse any airborne dust.

- Clean Up Properly: Sweep or vacuum sawdust; avoid using compressed air, which can spread dust widely. Dispose of sawdust and scraps responsibly, as they may contain chemicals.

For more on safe handling practices, you can consult resources like the Southern Pine Council, which provides detailed information on the proper use and handling of pressure-treated lumber.

Fasteners

The copper-based preservatives used in modern pressure-treated wood can be corrosive to certain types of metal fasteners. It’s essential to use fasteners that are specifically rated for use with treated lumber. These are often referred to as “hot-dip galvanized” (meeting ASTM A153 standards) or stainless steel fasteners.

Using incompatible fasteners can lead to rust, staining, and eventual failure of the fastener. This is particularly important for structural components like deck joists and beams.

Storage

Store pressure-treated lumber flat, off the ground, and ideally under cover or wrapped to protect it from excessive moisture and direct sunlight. This helps prevent warping, checking (cracking), and premature fading of any added colorants.

Proven Best: When is Brown or Green the “Proven Best”?

The “proven best” isn’t about the color itself, but about choosing the wood that best suits your project’s needs and your desired outcome. Here’s a breakdown of when each might be considered the “best” choice:

When Green Pressure Treated Wood Might Be “Proven Best”:

- Budget-Conscious Projects: Green-treated wood can sometimes be slightly less expensive, making it a great choice for those on a tighter budget.

- Projects You Plan to Stain Immediately: If your intention is to apply a solid stain or paint very soon after construction, the initial green color is irrelevant.

- Availability: In some regions, green-treated lumber is more commonly stocked, especially for standard framing and decking applications.

- Natural Weathered Look: If you prefer the silvery-gray weathered look of wood left unfinished, the green will fade into that over time.

When Brown Pressure Treated Wood Might Be “Proven Best”:

- Immediate Aesthetic Appeal: If you want your project to look more “finished” right out of the gate without immediate staining, the brown color offers a head start.

- Projects Where Uniformity is Key: The brown dye can help mask minor variations in wood color and provide a more consistent appearance before any additional finishing.

- Reduced Need for Immediate Staining: While still recommended, you might feel less pressure to stain brown-treated wood immediately compared to green-treated wood if you like the initial brown hue.

- UV Protection from the Start: The brown dye can offer a slight advantage in protecting the wood’s surface from UV degradation from day one, although the underlying preservative is the primary protector.

Ultimately, both brown and green pressure-treated woods are excellent choices for durability and protection against the elements. The “proven best” is the one that aligns with your project’s budget, timeline, and aesthetic vision. Always ensure the wood is rated for the intended use (ground contact, above ground, etc.) and that you use appropriate fasteners.

Frequently Asked Questions (FAQs)

Q1: Does the green color in pressure-treated wood mean it’s stronger?

A1: No, the green color itself doesn’t indicate stronger protection. The color is usually from copper-based preservatives, and the strength of the treatment comes from the amount of preservative retained in the wood, not the color.

Q2: Can I use regular screws with pressure-treated wood?

A2: It’s highly recommended to use hot-dip galvanized (ASTM A153) or stainless steel fasteners. The copper in the preservatives can corrode standard fasteners over time, leading to rust and potential structural issues.

Q3: How long should I wait before staining pressure-treated wood?

A3: You should wait until the wood is dry enough for a finish to adhere properly. A good test is to sprinkle water on it; if it soaks in, it’s likely ready. This can take anywhere from a few weeks to several months, depending on weather conditions.

Q4: Is brown pressure-treated wood more expensive than green?

A4: Sometimes brown pressure-treated wood can be slightly more expensive because of the added dyeing process. However, the price difference is often minimal, and availability can vary by region.

Q5: Can I use pressure-treated wood for indoor projects?

A5: While pressure-treated wood is safe for outdoor use, it’s generally not recommended for indoor projects where direct contact with skin is frequent, especially for children. The preservatives are designed for outdoor conditions. If you need a treated wood for indoor applications where moisture is a concern, consult specific product recommendations.

Q6: Will the color of pressure-treated wood affect how well it holds paint?

A6: The color itself shouldn’t significantly affect paint adhesion, as long as the wood is properly prepared (dry and clean). Both green and brown treated woods can be successfully painted or stained.

Q7: What should I do with leftover pressure-treated wood scraps?

A7: Treat sawdust and scraps as you would the larger pieces. Avoid burning them, as this can release chemicals into the air. Dispose of them according to local regulations for treated wood waste.

Conclusion

So, there you have it! The mystery of brown versus green pressure-treated wood is demystified. Remember, the color is primarily an aesthetic choice or an indicator of added dye, not a measure of the wood’s protective capabilities. Both brown and green pressure-treated lumber, when treated to the correct standards for their intended use and fastened with the right hardware, will provide excellent, long-lasting durability against rot and insects for your outdoor projects.

Whether you lean towards the immediate, warm tones of brown-treated wood or the classic greenish hue of green-treated wood, the most important factors are ensuring the lumber is rated for its specific application (like ground contact or above-ground use) and that you follow safe handling and installation practices. With a little knowledge and care, you can confidently select the best pressure-treated wood for your next build and create something beautiful that will stand the test of time. Happy building!