Calculate Wood for Project: The Ultimate Guide

To calculate wood for a project, measure the dimensions of your project area and determine the wood type. Use a lumber calculator to convert these measurements into board feet.

Calculating the amount of wood required for any project can seem daunting, but it doesn’t have to be. Knowing the dimensions of your project area is the first step. This includes length, width, and thickness of the wood needed. It’s also crucial to consider the waste factor, as some material may be lost during cutting and shaping.

Using a lumber calculator can streamline the process, offering precise measurements in board feet. This tool simplifies estimating costs and ensures you purchase the right amount of wood, minimizing excess and saving you money. Understanding these basics empowers you to tackle your woodworking projects with confidence.

Introduction To Wood Calculation

Calculating wood for a project is essential for success. Accurate measurements save time and money. Incorrect calculations may lead to wasted materials. Understanding the importance of precise measurements helps prevent mistakes.

Familiarity with common terms in wood measurement is vital. Board feet measure wood volume, while linear feet refer to length. Square footage helps determine area coverage. Knowing these terms ensures effective planning.

| Term | Description |

|---|---|

| Board Feet | Measures the volume of lumber. |

| Linear Feet | Measures the length of lumber. |

| Square Footage | Measures the area coverage of wood. |

Types Of Wood And Their Uses

Hardwoods and softwoods serve different purposes in woodworking. Hardwoods come from deciduous trees. They are typically denser and more durable. Common examples include oak, maple, and cherry. These woods are ideal for furniture and cabinetry. Their strength makes them perfect for long-lasting projects.

Softwoods come from coniferous trees. They are usually lighter and easier to work with. Pine, cedar, and fir are popular softwoods. These woods are great for building frames and outdoor projects. They tend to be more affordable than hardwoods. Selecting the right type depends on your project’s needs.

Measuring Techniques

Using the right tools is crucial for accurate wood measurement. Start with a tape measure for precise lengths. A square helps ensure corners are perfect. Calipers can measure thickness for fine adjustments. Consider a laser distance measurer for larger spaces.

Follow this simple step-by-step guide for measuring wood:

- Measure length with a tape measure.

- Check width using the square.

- Use calipers for thickness.

- Double-check all measurements.

- Record your numbers for reference.

Using these techniques will greatly improve your project’s accuracy and efficiency.

Calculating Board Feet

To calculate board feet, use the formula: (Thickness (inches) x Width (inches) x Length (feet)) / 12. This will give you the total board feet needed for your project.

Understanding the conversion to square feet is also essential. To convert board feet to square feet, divide the total board feet by the thickness of the wood in inches. For example:

| Board Feet | Thickness (inches) | Square Feet |

|---|---|---|

| 12 | 1 | 12 |

| 24 | 2 | 12 |

| 30 | 3 | 10 |

Knowing these calculations can save you time and money in your woodworking projects.

Estimating Additional Wood For Waste

Estimating wood for a project requires careful planning. Cutting mistakes can lead to waste, so an allowance is essential. Aim to add about 10-15% more wood to your calculations. This extra wood compensates for errors.

Defects in wood also impact your project. Not all boards are perfect. Some may have knots or cracks. Always inspect your wood before use. Adding an extra 5-10% for defects is wise. This approach ensures you have enough material.

| Type of Allowance | Percentage |

|---|---|

| Cutting Mistakes | 10-15% |

| Defects in Wood | 5-10% |

Project Planning And Layout

Creating a sketch of your design is vital for project planning. Begin with a clear layout to visualize dimensions. This helps in understanding how much wood is needed. Ensure to include all measurements accurately. Consider the scale of your project for better results.

Maximizing wood use involves careful planning. Group similar cuts to reduce waste. Use a lumber calculator to estimate your needs. This tool can help you determine the total board feet required. Always account for scraps and potential errors in your calculations.

By sketching your design and planning effectively, you enhance efficiency. A well-organized approach saves time and money in the long run.

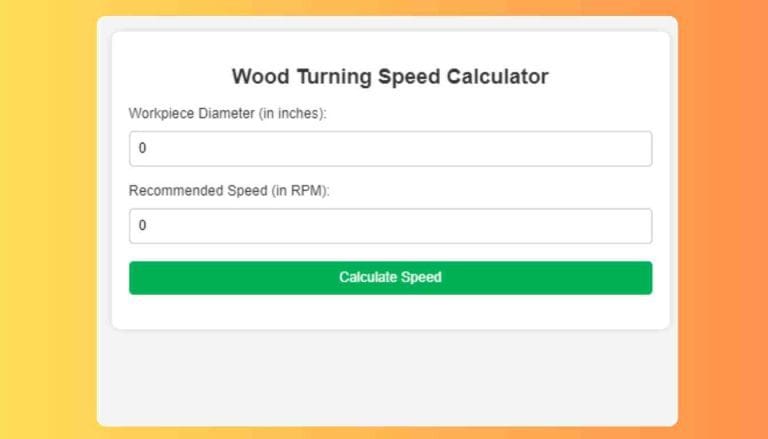

Online Calculators And Apps

Using online calculators and apps can greatly simplify your wood project planning. They provide quick and accurate measurements, saving you valuable time. These tools can help you avoid costly mistakes in material purchases.

Benefits of using technology include:

- Instant calculations for lumber requirements

- User-friendly interfaces that even beginners can navigate

- Access to multiple formulas for different wood types and project sizes

- Ability to track costs and budget effectively

- Convenient access from any device, anywhere

Recommended lumber calculators include:

| Calculator Name | Website |

|---|---|

| HomeAdvisor Lumber Calculator | homeadvisor.com |

| WoodMizer Board Feet Calculator | woodmizer.com |

| ConCalculator Lumber Calculator | concalculator.com |

| Lumber Capital Calculator | lumbercapital.com |

Cost Estimation

Understanding lumber pricing is crucial for your budget. Prices vary based on wood type, quality, and market demand. Hardwoods like oak or maple often cost more than softwoods like pine. Seasonal changes can also affect prices significantly.

Using tools for budgeting helps manage costs effectively. Consider using a lumber calculator to estimate the amount of wood needed. This tool can help avoid overestimating or underestimating your project’s requirements.

Compare prices from different suppliers to find the best deal. Keep an eye on local sales or discounts. Always factor in additional costs like delivery and taxes when planning your budget.

Practical Tips And Tricks

Buying wood strategically can save time and money. Always check local suppliers for the best prices. Consider purchasing in bulk to get discounts. Look for clearance sales or discounted lots for even better deals.

Storage and handling of excess wood is important for maintaining quality. Store wood in a dry, cool area to prevent warping. Use stacks or racks to keep wood off the ground. Cover wood with a tarpaulin to protect it from moisture.

Inspect wood regularly for damage or pests. Proper handling helps avoid scratches and dents. Always wear gloves to protect your hands while moving wood. This ensures your project materials remain in great condition.

Common Pitfalls To Avoid

Overbuying material can lead to wasted money and excess wood. Always calculate the amount needed carefully. Consider the dimensions of your project. Include any cuts that may be necessary. Double-check your measurements to avoid mistakes.

Underestimating project complexity is another common mistake. Some projects may seem simple but can be tricky. Take time to plan each step thoroughly. Break down tasks into smaller parts. This will help you manage your time and resources better.

Advanced Techniques

Working with irregular wood shapes can be challenging. First, measure each section carefully. Use a tape measure to capture the length and width. Calculate the area by multiplying these dimensions. For complex shapes, break them into smaller, manageable sections. This method makes it easier to estimate the total wood needed.

For custom wood orders in large projects, communicate clearly with suppliers. Provide them with precise measurements and specifications. Discuss the type of wood, desired finishes, and any unique features. This ensures you receive the correct materials for your project. Always allow extra wood to account for mistakes or adjustments.

Case Studies

Real-life examples show important lessons in woodworking. Many woodworkers share their experiences, which help others avoid mistakes. For instance, one project involved building a deck. The woodworker underestimated the amount needed, leading to extra trips to the store. Accurate measurement is crucial for success.

Another example highlights the importance of planning. A furniture maker had to adjust designs mid-project due to miscalculations. This caused delays and frustration. Careful planning prevents these issues and saves time.

| Project Type | Key Lesson |

|---|---|

| Deck Building | Measure twice, buy once. |

| Furniture Making | Plan ahead to avoid changes. |

Frequently Asked Questions

How To Calculate How Much Wood You’ll Need For A Project?

To calculate wood needed for a project, measure the dimensions of each piece. Multiply length, width, and thickness to find the volume. Add 10-15% for waste. Use online lumber calculators for accuracy. Always double-check measurements to ensure you purchase enough wood for your project.

How To Calculate Wood Requirement?

To calculate wood requirement, measure the area in square feet. Consider the thickness of the wood. Use the formula: Board Feet = (Length x Width x Thickness) / 12. Always account for waste in your calculations. Use online calculators for accuracy and convenience.

How To Calculate Board Feet Needed For A Project?

To calculate board feet, use the formula: Width (inches) x Length (inches) x Thickness (inches) ÷ 144. Measure each piece of wood and sum the board feet for the total. Always account for waste when estimating your project needs.

What Is The Formula For Determining The Amount Of Wood?

To determine the amount of wood, use the formula: Length × Width × Thickness. This calculates the volume in cubic feet. Convert to board feet by multiplying by 12. Always account for waste and inefficiencies in your project planning.

Conclusion

Accurate wood calculation is essential for any project. It saves time, money, and resources. By measuring dimensions and factoring in waste, you can ensure a successful outcome. Utilize online calculators for efficiency. With the right preparation, your woodworking project can flourish.

Start calculating today and enjoy the results!