Calculate Wood Needed for Project: Quick & Easy Guide

To calculate the wood needed for a project, measure the dimensions of each piece required. Multiply the length, width, and thickness to find the total board feet.

Estimating the amount of wood required for a project can be daunting. Whether you’re constructing furniture or building a deck, precise measurements are crucial. Understanding how to calculate wood requirements not only saves time but also minimizes waste and costs.

Begin by determining the dimensions of each piece you’ll need. Use formulas to convert measurements into board feet, a standard unit of lumber measurement. With accurate calculations, you can confidently purchase the right amount of wood. This guide will help you navigate the process efficiently, ensuring your project runs smoothly from start to finish.

Introduction To Wood Calculation

Calculating the amount of wood needed for a project is crucial. Accurate measurements ensure you buy the right amount. This helps avoid waste and saves money.

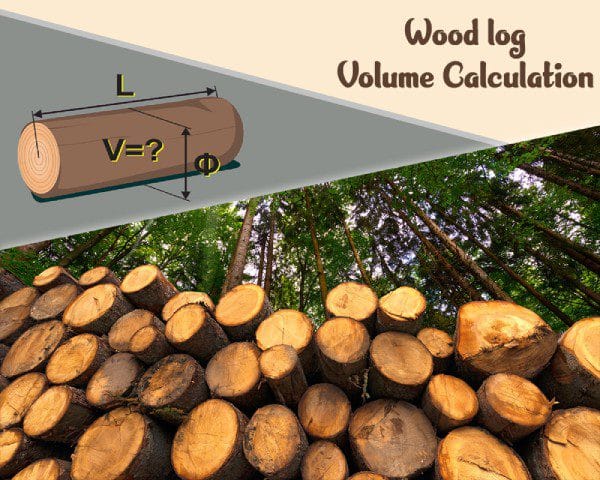

Understanding different measurement units is also important. The three basic units include:

| Unit | Description |

|---|---|

| Board Feet | A volume measurement for lumber, equal to 1 foot long by 1 foot wide by 1 inch thick. |

| Square Feet | A measurement of area, often used for sheet goods. |

| Cubic Feet | A volume measurement useful for logs and bulk wood. |

Using the right units can make the process easier. Always measure twice before cutting.

Determining Your Project’s Wood Requirements

To accurately assess project dimensions, start by measuring the length, width, and height. Use a tape measure for precise results. Write down all measurements on a notepad for reference.

Creating a project materials list is essential. List every piece of wood needed. Include the type of wood, dimensions, and quantity. Use a lumber calculator to help estimate how much wood you will need. Gathering extra wood is wise to account for mistakes.

| Wood Type | Dimensions (inches) | Quantity |

|---|---|---|

| Pine | 2 x 4 | 10 |

| Oak | 1 x 6 | 5 |

| Maple | 3 x 3 | 8 |

Understanding Lumber Dimensions

Understanding lumber dimensions is crucial for any woodworking project. Nominal dimensions refer to the size of the lumber before drying. For example, a 2×4 is actually smaller than its name suggests. It typically measures 1.5 inches by 3.5 inches. This difference is important when planning your project.

Measuring lumber thickness accurately is essential. Always check the actual thickness before purchasing. Lumber can vary slightly due to manufacturing processes. For example, a 1×6 board may be 0.75 inches thick. Knowing these specifics helps prevent mistakes in calculations.

Calculating Board Feet

To calculate board feet, use the formula: Thickness (inches) x Width (inches) x Length (feet) / 12. This gives you the volume in board feet. For example, a board that is 1 inch thick, 12 inches wide, and 10 feet long equals 10 board feet.

Different board sizes affect the calculation. Here are common dimensions and their board feet:

| Thickness (inches) | Width (inches) | Length (feet) | Board Feet |

|---|---|---|---|

| 1 | 6 | 8 | 4 |

| 2 | 4 | 10 | 6.67 |

| 1 | 12 | 10 | 10 |

Gathering a little extra wood is smart. It helps to avoid trips back to the store.

Using Lumber Calculators

Online lumber calculators offer many advantages for woodworkers. They save time by quickly estimating the amount of wood needed for projects. Users can input specific measurements, and the calculator does the rest. This eliminates the risk of miscalculations, ensuring accurate results.

Another benefit is the cost estimation feature. Many calculators provide a breakdown of costs based on local prices. This helps in budgeting for projects effectively. Accessibility is also a key advantage. These tools are available on various websites, allowing users to calculate anytime, anywhere.

| Calculator Tool | Website |

|---|---|

| HomeAdvisor Lumber Calculator | homeadvisor.com |

| Lumber Capital Calculator | lumbercapital.com |

| ConCalculator Lumber Calculator | concalculator.com |

Estimating Additional Materials

Estimating additional materials is crucial for any wood project. Waste occurs during cutting and fitting, so plan for extra wood. A common rule is to add 10% to your total estimate for waste. This ensures you have enough materials to complete the project.

Including fasteners and hardware is equally important. Consider the type of joints you will use. For example, screws, nails, or brackets all require different quantities. Always check the manufacturer’s recommendations for the correct number of fasteners needed. This helps avoid shortages and delays.

| Material | Estimated Quantity |

|---|---|

| Wood | Original Estimate + 10% |

| Screws | Depends on joint type |

| Nails | Depends on joint type |

| Brackets | Check manufacturer’s specs |

Cost Estimation Tips

Researching lumber prices helps you find the best deals. Check local hardware stores and online suppliers. Compare prices for different types of lumber. Always consider the quality of wood when estimating costs. Look for sales or discounts to save money.

Budgeting for the unexpected is very important. Projects can go over budget due to hidden costs. Set aside an extra 15-20% of your budget for surprises. This will ensure you can finish your project without stress. Keep a close eye on your spending to avoid surprises.

Finalizing The Wood Order

Review the lumber order list carefully. Ensure you have all required pieces. Check sizes, types, and quantities. Mistakes can lead to delays and extra costs.

Communicate clearly with your suppliers. Confirm the order details before finalizing. Ask about delivery dates and availability. Discuss any potential issues that might arise.

| Action | Details |

|---|---|

| Review Order | Check sizes, types, and quantities. |

| Confirm Details | Verify with suppliers about order specifics. |

| Delivery Inquiry | Ask about delivery dates and potential issues. |

Tips For Efficient Wood Usage

To maximize lumber cuts, plan your project layout carefully. Use a sketch to visualize pieces before cutting. Group smaller parts together to save wood. This helps minimize waste and makes the most of each board.

Design is key for minimizing waste. Consider using modular designs that fit standard board sizes. Avoid complicated shapes that require many cuts. Stick with simple patterns that use full boards. This reduces leftover pieces and saves money.

Always measure twice and cut once. Accurate measurements lead to better cuts. Keep track of your materials and plan ahead. This helps prevent running out of wood during your project.

Frequently Asked Questions

How Do You Calculate How Much Wood You Need For A Project?

To calculate the wood needed for a project, measure the dimensions of each piece. Use the formula: Length x Width x Thickness. Convert to board feet by dividing by 144. Always add extra for mistakes or adjustments, typically around 10-15%.

Use a lumber calculator for convenience.

How Do You Calculate Wood Requirements?

To calculate wood requirements, measure the area in square feet. Multiply the length, width, and thickness of each piece. Use the formula: Board Feet = (Thickness x Width x Length) / 12. Sum the board feet for all pieces to determine total wood needed.

How Do You Calculate Board Feet Needed For A Project?

To calculate board feet, use the formula: Thickness (inches) × Width (inches) × Length (feet) ÷ 12. This formula gives you the board feet required for your project. Measure accurately to ensure you order the right amount of lumber. Adjust for any waste or errors in measurement.

What Is The Formula For Determining The Amount Of Wood?

To determine the amount of wood needed, use the formula: **Board Feet = (Thickness in inches × Width in inches × Length in feet) ÷ 12. ** This calculates the volume of lumber required for your project accurately.

Conclusion

Calculating the wood needed for your project is essential for success. Accurate measurements save time and money. Always consider potential errors by adding a little extra. Use reliable tools and calculators for precise estimates. With proper planning, your project will turn out just as you envisioned.

Happy woodworking!