When it comes to injection molding, one of the key factors that determines the success of the process is clamping force. Clamping force is the force applied by the clamping unit of the injection molding machine to keep the mold closed during the injection and cooling cycles. It is crucial to calculate the right clamping force for a successful and efficient molding process.

Credit: calculator.academy

Why Clamping Force Matters

The clamping force plays a critical role in securing the mold in place and preventing it from opening due to the pressure of the injected molten plastic. Without adequate clamping force, the mold might not be able to withstand the high pressure, leading to defects in the final product and potential damage to the mold itself.

Proper clamping force also ensures that there is no flash or burrs on the final product, which can impact its quality and functionality. Additionally, achieving the right clamping force helps in reducing cycle times and improving overall productivity of the injection molding process.

Credit: www.carrlane.com

Calculating Clamping Force

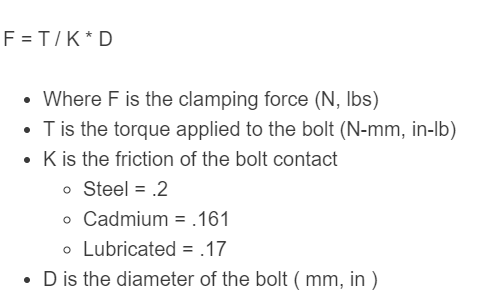

To determine the required clamping force for a specific injection molding job, a clamping force calculator can be used. This tool takes into account several factors including the projected area of the part, the pressure of the material being injected, and the safety factor to determine the optimal clamping force.

Using the Clamping Force Calculator

When using a clamping force calculator, it is essential to input accurate and precise data to obtain reliable results. The projected area of the part, also known as the part area, is a key parameter in the calculation. It is calculated based on the shape and size of the part as well as the mold design.

The material pressure, which is the pressure at which the molten plastic is injected into the mold, is another crucial factor in the calculation. It is important to consider the viscosity and flow characteristics of the material to accurately determine the required pressure.

Moreover, the safety factor is applied to ensure that the calculated clamping force provides a buffer to account for any unexpected variations or fluctuations in the process. This helps in preventing issues such as mold deflection or part deformation due to inadequate clamping force.

Optimizing Clamping Force for Efficiency

Once the clamping force is calculated, it is important to verify that the injection molding machine being used has the capacity to deliver the required force. Proper maintenance and calibration of the machine are essential to ensure consistent and accurate clamping force application.

It is also beneficial to conduct periodic checks and adjustments to optimize the clamping force for different molds and materials. Implementing a systematic approach to clamping force optimization can lead to improved part quality, reduced production costs, and enhanced overall efficiency of the injection molding process.

Conclusion

Clamping force is a critical aspect of injection molding that directly impacts the quality, consistency, and efficiency of the manufacturing process. Using a reliable clamping force calculator and ensuring that the injection molding machine is capable of delivering the required force are essential steps in achieving optimal results.

By understanding the significance of clamping force and its calculation, manufacturers can enhance their molding operations, minimize defects, and ultimately produce high-quality parts with precision and reliability.