Cutting Board Board Foot Calculator: Maximize Your Material

A Cutting Board Board Foot Calculator estimates the amount of lumber needed to create a cutting board. It calculates board feet based on the dimensions of the wood.

Understanding how to calculate board feet is essential for woodworking projects, especially when crafting cutting boards. Board feet is a unit of measurement for lumber volume, allowing you to estimate material needs accurately. Whether you’re making a simple or intricate design, knowing the right amount of wood prevents waste and saves costs.

Various online calculators simplify this process by requiring just the dimensions of your materials. With the right tools, you can confidently plan your woodworking project, ensuring you have enough wood for your cutting board while also keeping your budget in check.

Maximizing Material With The Right Calculations

Understanding board foot calculations is essential for any woodworking project. This measurement helps determine the amount of lumber needed, ensuring efficient use of materials. A board foot is defined as a volume of wood measuring 1 foot long by 1 foot wide by 1 inch thick.

Accurate measurements prevent waste and save money. Knowing how to calculate board feet allows woodworkers to plan better. For example, a cutting board’s dimensions can significantly affect the total board feet required. Always measure length, width, and thickness precisely to get accurate results.

Using an online board foot calculator can simplify this process. Enter the dimensions, and the tool will do the math for you. This ensures you have the right amount of wood for your project, minimizing leftovers.

Essential Measurements For Cutting Boards

Understanding thickness, width, and length is vital for cutting boards. Each dimension affects the overall size and usability. Thickness determines how sturdy the board feels. Width impacts how much space you have while cutting. Length influences how easily you can maneuver food.

Different wood species significantly affect these calculations. Some woods are denser, while others are lighter. For example, maple is popular for its durability. Walnut offers a beautiful finish but can be heavier. Choosing the right wood helps achieve the desired look and feel.

| Wood Species | Density (lbs/ft³) | Common Uses |

|---|---|---|

| Maple | 45 | Durable cutting boards |

| Walnut | 38 | Elegant cutting boards |

| Cherry | 38 | Beautiful, medium-density boards |

The Board Foot Formula Explained

The board foot formula is essential for calculating lumber. A board foot equals 144 cubic inches of wood. The formula is:

Board Feet = (Thickness × Width × Length) / 144

Each dimension must be in inches. For example, a board that is 1 inch thick, 12 inches wide, and 8 feet long equals:

Board Feet = (1 × 12 × 96) / 144 = 8

Converting dimensions from inches to board feet is simple. Just divide the total cubic inches by 144. Use this method for any project requiring accurate lumber calculations.

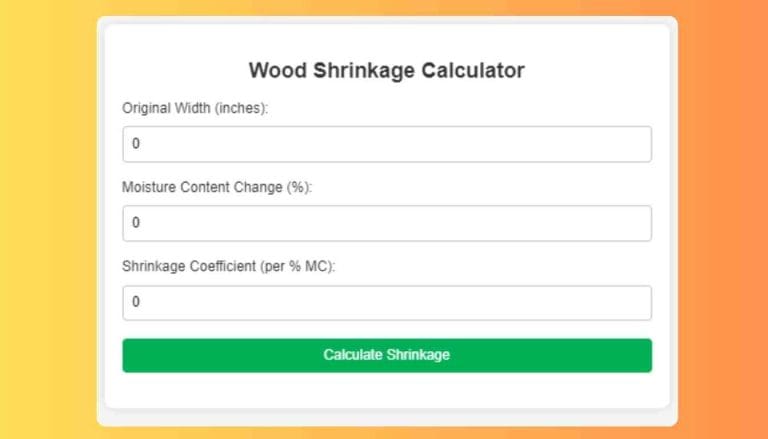

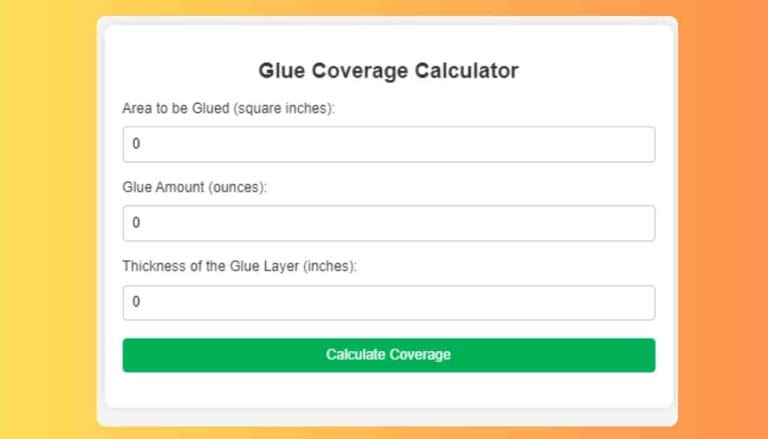

Online Tools For Board Foot Calculations

Online tools for board foot calculations simplify the process of estimating wood needs. Various cutting board calculators are available, each offering unique features.

Some calculators allow you to input dimensions easily. Most provide cost estimates based on your inputs. Others may offer design options for both edge and end grain styles.

| Calculator Name | Features |

|---|---|

| Hammock Dave | Design generation and cost estimates |

| Omni Calculator | Quick volume estimation |

| Woodworkers Source | Detailed board foot calculation |

| BeauBilt | End grain cutting board calculator |

Choosing the right calculator can save time and enhance your woodworking projects.

Calculating Costs And Material Efficiency

Estimating lumber cost using board feet is essential for any woodworking project. A board foot is a unit of measure for lumber. It represents a volume of wood that is 1 foot long, 1 foot wide, and 1 inch thick. To calculate the number of board feet, use the formula: (Thickness x Width x Length) / 144. This formula helps in determining how much wood is needed.

Strategies for minimizing waste are crucial in any project. Always measure twice before cutting to ensure accuracy. Use leftover pieces for smaller projects or even as firewood. Consider using a cutting diagram to plan cuts efficiently. This helps utilize more of the wood and reduces waste.

Design Considerations For Cutting Boards

End grain cutting boards feature the ends of wood pieces facing up. This design enhances durability and allows for easier knife maintenance. It helps to minimize knife marks and scratches. However, end grain boards often require more labor and are usually more expensive.

Edge grain cutting boards display the long edges of wood pieces. They are simpler to make and generally less costly. These boards offer good durability but may show knife marks more readily than end grain.

Incorporating wood species variations can impact the board’s appearance and performance. Hardwoods like maple and walnut are popular choices for their strength. Softwoods, while less durable, can offer unique looks. Always consider the wood’s density and maintenance requirements when selecting materials.

Practical Tips For Woodworkers

Measuring lumber accurately is vital for any woodworking project. Use a tape measure for precise measurements. Always measure length, width, and thickness in inches. This helps in calculating the board feet correctly.

Common pitfalls can lead to errors in calculations. Forgetting to convert measurements into the same units can confuse results. Miscalculating the dimensions of the lumber is another frequent mistake. Always double-check your work to ensure accuracy.

Using a calculator can simplify the process. Input the measurements to find the board feet needed. This tool saves time and reduces human error. Be consistent with your measuring tools for the best results.

Advanced Techniques For Professional Results

To enhance cutting board aesthetics, consider using different wood types. Combining hardwoods like maple and walnut creates stunning visual contrasts. Finishing techniques like oil or wax add shine and protection. Use food-safe finishes for safety.

For unique projects, complex calculations are essential. Determine the board feet needed by multiplying thickness, width, and length. Divide by 144 to convert to board feet. This ensures accurate estimates for materials required.

| Wood Type | Visual Effect |

|---|---|

| Maple | Light and elegant |

| Walnut | Rich and dark |

| Cherry | Warm and inviting |

Frequently Asked Questions

How Many Board Feet To Make A Cutting Board?

To make a standard cutting board, you typically need about 2 to 3 board feet of wood. This amount may vary based on the board’s size and thickness. Always calculate based on your specific design and dimensions for accuracy.

How Do You Calculate How Much Wood You Need For A Cutting Board?

To calculate the wood needed for a cutting board, determine the dimensions: length, width, and thickness. Use the formula: (Length x Width x Thickness) / 144 to find board feet. Adjust for any specific design or style. Always round up to account for imperfections.

How Do I Calculate How Many Board Feet I Need?

To calculate board feet, use this formula: (Thickness in inches × Width in inches × Length in feet) ÷ 12. This gives you the total board feet needed for your project. Always round up to ensure you have enough material for cuts and mistakes.

How Do You Calculate Board Feet For A Butcher Block?

To calculate board feet for a butcher block, use the formula: (Length in inches × Width in inches × Thickness in inches) ÷ 144. This gives you the total board feet. Ensure to measure accurately for precise results.

Conclusion

Understanding how to calculate board feet for your cutting board project is essential. This knowledge not only saves you time and money but also ensures you have the right amount of material. By using a board foot calculator, you streamline the process.

Start your woodworking journey today with confidence and precision!