Difference Between Engineered Hardwood: Essential Secrets

Engineered hardwood is real wood layered over a stable core, while laminate uses photographic images over HDF. Engineered wood lasts longer and can be refinished; laminate is cheaper and more water-resistant for quick updates.

Choosing new flooring can feel tricky, especially when you see terms like “engineered hardwood” and “laminate.” These two options look surprisingly similar when first installed, but they are built completely differently. It is easy to mix them up, leading to big headaches later when you try to repair or replace them. Don’t worry! I’m here to break down these differences simply. We will look closely at what makes each one unique, so you can choose the best floor with total confidence. Let’s uncover the essential secrets of engineered wood versus its look-alikes.

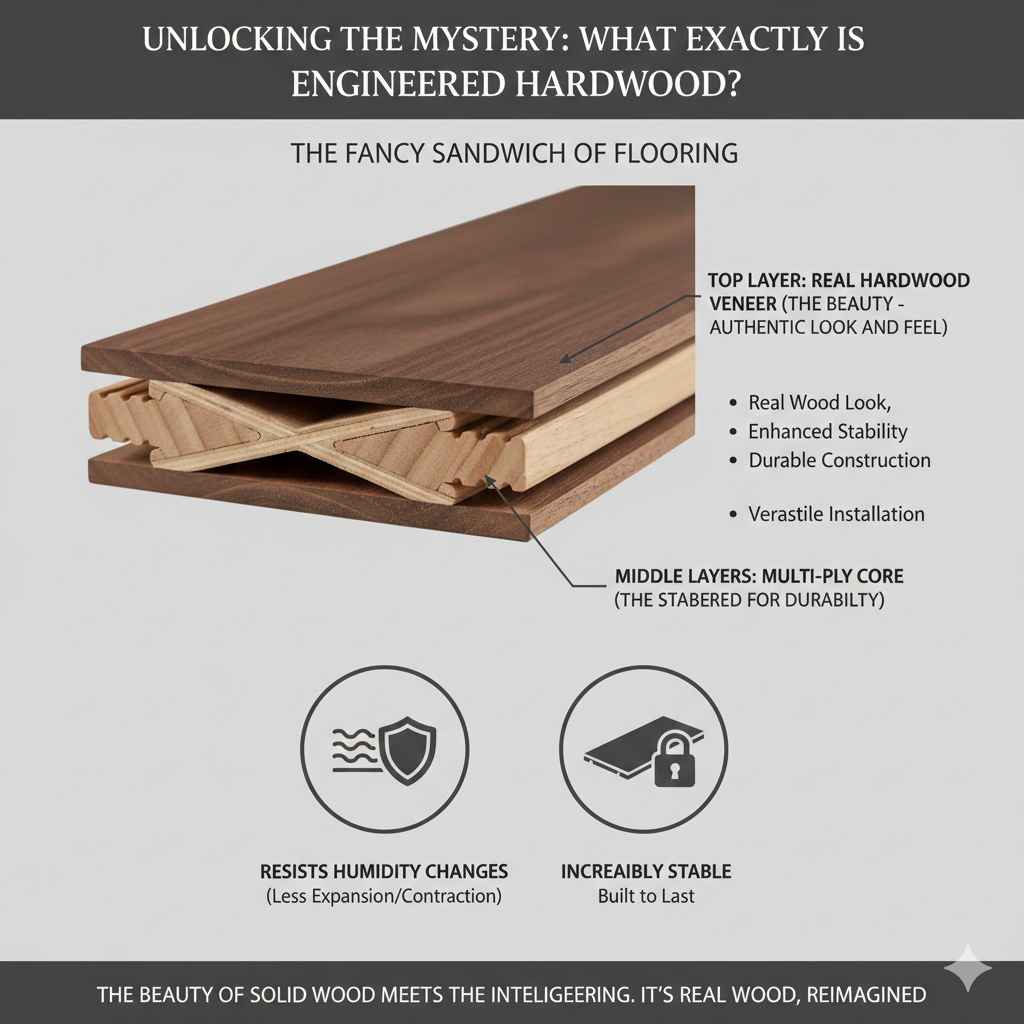

Unlocking the Mystery: What Exactly is Engineered Hardwood?

When you look at engineered hardwood, your eyes are seeing real wood! That is the biggest difference right away. Think of it like a fancy sandwich where every layer matters for strength and beauty. It’s designed to give you the authentic look and feel of solid hardwood but with better stability against humidity swings in your home.

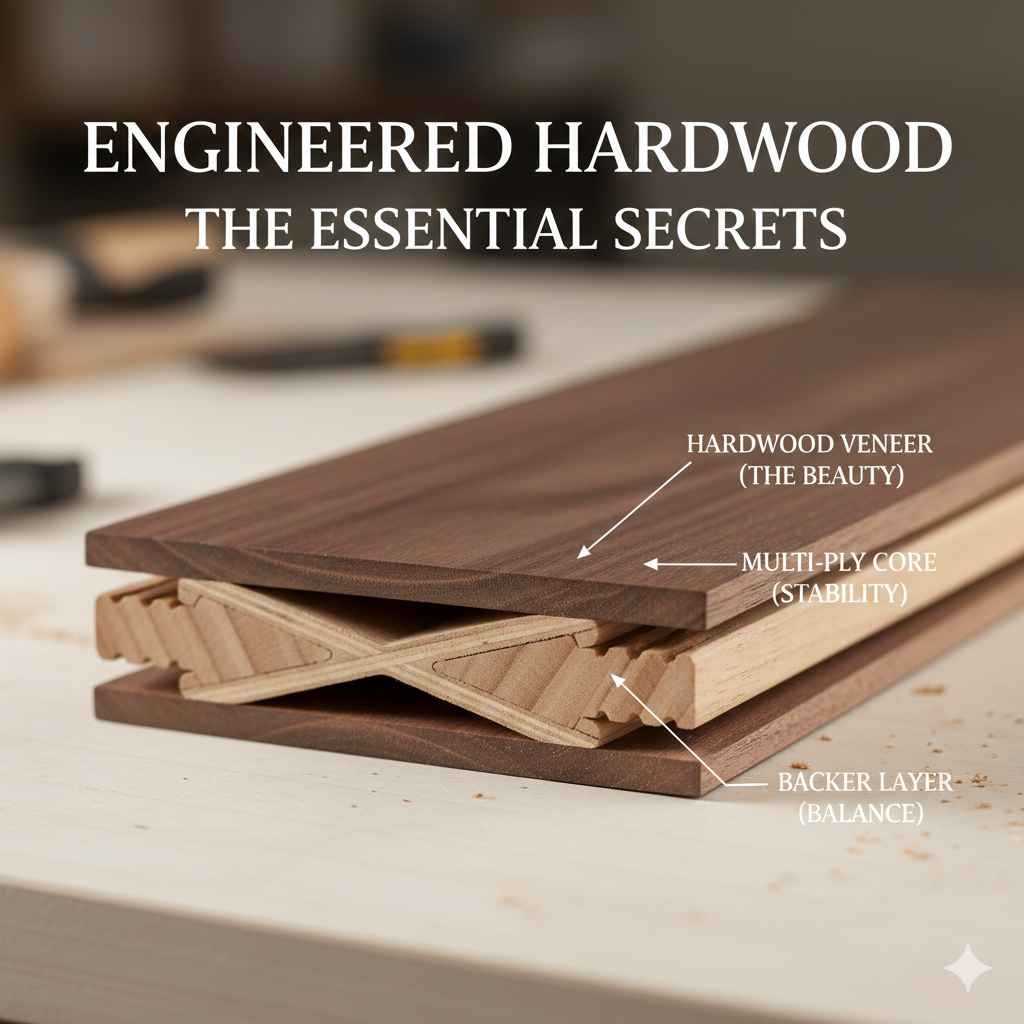

The Blueprint of Engineered Hardwood

Engineered wood is constructed in multiple layers, usually three or more. Understanding this structure is the first step in knowing why it performs differently than other floors. We stack these layers like pancakes, but each layer has a special job.

Layer 1: The Wear Layer (The Beauty)

This top layer is thin, but it is the star of the show. It is made of 100% real hardwood—oak, maple, cherry, whatever look you want. The thickness of this wear layer is super important because it determines how many times you can sand and refinish the floor over its lifetime. A thicker wear layer means a longer life!

Layer 2: The Core (The Strength)

This middle part is the secret weapon against warping. It is usually made from high-quality plywood or High-Density Fiberboard (HDF). These cross-grain layers lock together, which stops the wood from expanding or contracting too much when moisture or temperature changes. Think of it like building a wall with crossed beams—it’s much stronger that way.

Layer 3: The Backer Layer (The Anchor)

This bottom layer stabilizes the whole plank, often made of a thin layer of hardwood or composite material. It helps keep the plank flat against your subfloor.

Because of this stacked design, engineered hardwood is very versatile. You can often install it below grade (in basements) or directly over concrete slabs, which you often can’t do with traditional solid hardwood. For more technical details on wood product stability, you can reference resources like those provided by The Wood Products Information Center.

The Pros and Cons: Is Engineered Wood Right for You?

Every flooring choice has trade-offs. Here is a quick, honest look at what makes engineered wood great and where it might fall a little short for certain projects.

Advantages of Engineered Hardwood:

- Real Wood Aesthetics: It looks, feels, and smells like solid wood because the top layer is genuine.

- Moisture Resistance: The plywood core handles humidity much better than solid wood.

- Versatile Installation: Great for basements, condos, and areas with concrete subfloors.

- Refinishing Capability: Thicker wear layers allow for sanding and refinishing one or more times, extending the floor’s life significantly.

- Investment Value: It generally increases a home’s resale value more than alternative options.

Disadvantages of Engineered Hardwood:

- Cost: It is usually more expensive upfront than laminate or vinyl options.

- Refinishing Limits: You can only refinish it as many times as the wear layer thickness allows. Very thin layers might only be good for one light sanding.

- Damage Depth: Deep gouges that penetrate the thin top veneer cannot be easily repaired like a surface scratch on solid wood.

Decoding Laminate Flooring: The Lookalike Champion

Laminate flooring is the master of disguise. It does a fantastic job of mimicking the look of wood, stone, or tile, but underneath that pretty picture, it is an entirely different animal. If you are looking for budget-friendly durability, laminate is worth understanding.

The Construction Secret of Laminate

Laminate flooring is a synthetic product. It is built for affordability and easy installation, not for long-term structural wood benefits. It typically has four layers, but none of them are real hardwood veneer.

Layer 1: The Wear Layer (The Shield)

This is a clear, highly durable top coating, usually made of aluminum oxide. It resists scratches and fading exceptionally well. This layer protects the image underneath.

Layer 2: The Design Layer (The Image)

This is the magic trick. It’s a high-resolution photograph of wood grain, tile, or stone printed onto paper. This is what gives laminate its visual appeal.

Layer 3: The Core Layer (The Bulk)

The core is typically made from High-Density Fiberboard (HDF) or Medium-Density Fiberboard (MDF). It is essentially wood fibers compressed with resin under heat and pressure. This core is the thickest part of the plank.

Layer 4: The Backer Layer (The Balancer)

This stabilizing bottom layer prevents moisture from seeping up from the subfloor and helps keep the plank flat.

Because laminate’s core is mostly fiberboard, it does not handle standing water well. If water seeps between the seams, the HDF core swells up like a sponge, causing permanent bubbling and warping that cannot be undone.

The Laminate Lowdown: Where It Shines and Where It Fails

Laminate is famous for its accessibility and ease of use for DIYers. Let’s weigh the benefits against its limitations.

Advantages of Laminate:

- Budget-Friendly: It is one of the most affordable flooring options available today.

- Durability (Surface): The aluminum oxide layer is extremely scratch-resistant, making it great for high-traffic homes with kids or pets.

- Easy DIY Install: Most laminate uses a simple click-and-lock floating floor system that’s very forgiving for beginners.

- Water Resistance: While not waterproof, the surface resists spills better than solid wood surfaces.

Disadvantages of Laminate:

- No Real Wood Value: It’s synthetic; it offers minimal resale value compared to true wood products.

- Cannot Be Refinished: Once the image layer is damaged or scratched through, the plank must be replaced.

- Sound: It can sound hollow or “clicky” when walked on, often requiring an extra acoustic underlayment.

- Moisture Sensitivity: Swells permanently if water gets into the seams or edges.

The Core Difference: Structure vs. Image

The most crucial secret separating engineered hardwood and laminate lies in that central layer—what the plank is fundamentally made of. This one factor dictates durability, repairability, and cost.

Think of it this way: Engineered hardwood has a skin of real wood that can be renewed. Laminate has a picture of wood that, once broken, is gone forever.

Visual Comparison Table: Hardwood vs. Laminate Breakdown

To make this clear, here is a side-by-side comparison focusing on the key structural elements.

| Feature | Engineered Hardwood | Laminate Flooring |

|---|---|---|

| Top Layer Material | Real Solid Wood Veneer (e.g., Oak, Maple) | Photographic Image printed on paper |

| Core Material | Cross-laminated Plywood or HDF | High-Density Fiberboard (HDF) |

| Refinishing Potential | Yes (1 to 5 times, depending on veneer thickness) | No (Must replace planks) |

| Moisture Reaction | Handles humidity well; resists minor warping | Swelling/Bubbling if water penetrates seams |

| Installation Cost | Higher (often requires professional glue-down) | Lower (simple DIY floating install) |

| Resale Value | Adds significant value to the home | Minimal or no added resale value |

Why the Wear Layer Thickness Matters So Much

When shopping for engineered wood, you will see wear layers measured in millimeters (mm). This measurement directly relates to how long your floor will last before needing replacement.

For DIYers, this measurement is key:

- 1.5mm or less: Light-duty traffic. Maybe one light buffing, but generally treated as single-use.

- 2.0mm to 3.0mm: Good residential wear. Allows for one or two professional refinishing jobs over 20–30 years.

- 4.0mm or more: Commercial grade or maximum lifespan. This product can be refinished multiple times, potentially lasting 50 years or more.

With laminate, this thickness measurement is less critical because you can never sand it down, regardless of the layer size. The visual appeal relies entirely on the printed image layer staying pristine.

Installation Nuances: A Beginner’s Guide to Different Needs

The way you install these floors affects your DIY enjoyment and how long the floor stays looking perfect. Engineered wood often requires more specialized techniques, while laminate is often a snap to lay down.

Installing Engineered Hardwood: Glue vs. Nail

Engineered wood offers flexibility, but each method has specific tool requirements. Always check the manufacturer’s guide, as improper installation voids the warranty!

Installation Methods for Engineered Wood:

- Glue Down: This is common over concrete slabs or radiant heat systems. You use a special adhesive and a flooring roller. This creates a very solid bond, minimizing movement. You will need a moisture meter to test the slab first!

- Nail Down: This mimics solid hardwood installation, using pneumatic nailers or staplers driven through the tongue of the plank into the subfloor. This requires the subfloor to be wood (plywood or OSB).

- Float: Sometimes permitted over an existing stable floor. The planks click together and rest freely on an underlayment pad. This is often the easiest DIY approach for engineered wood.

Tool Tip for Beginners: If you are floating engineered wood, you might need a tapping block and rubber mallet to securely lock the edges together without damaging the tongue and groove system.

Installing Laminate: The Floating Master

Laminate’s big win is its floating installation. It doesn’t attach to the subfloor at all.

- Preparation: Lay down a thin foam underlayment pad directly on the subfloor. This handles sound deadening and minor imperfections.

- Click and Lock: The planks connect via an angled tongue-and-groove system. You angle the long edge in, push down, and the short edge often snaps right in place.

- Expansion Gaps: This is critical for laminate. You must leave a 1/4-inch to 3/8-inch gap around all walls and fixed objects. Since laminate is mostly HDF, it needs room to expand slightly if it absorbs humidity. This gap is covered by baseboards or quarter-round molding later.

For safety and precision when cutting laminate, you might consider using a specialized flooring cutter or a jigsaw for the more complex cuts around door jambs. Always wear safety glasses, as cutting fiberboard can throw fine dust.

Addressing Water and Moisture: The Dealbreaker

For many homeowners, especially those finishing basements, bathrooms, or laundry rooms, water resistance is the deciding factor. This is where the biggest functional difference appears.

Engineered Hardwood and Humidity

Engineered wood is moisture-tolerant, not waterproof. Its core construction fights against gradual changes in humidity (like what happens seasonally). If you have a slow, small leak, the product can handle it better than solid wood. However, standing water over several hours will still penetrate the seams, leading to core swelling and irreparable damage.

Laminate and Water Vulnerability

Laminate is highly susceptible to standing water. Because the core is fiberboard, if water reaches that HDF layer, the fibers expand rapidly and irreversibly. If you spill a drink, wipe it up immediately, and you’re fine. If a pipe bursts, the floor is usually ruined.

A Note on “Waterproof” Laminate: Some newer laminate products boast water-resistant cores or sealed edges. While these are much better than older versions, they still aren’t the same as a waterproof vinyl plank (LVP). Always research the specific product warranty regarding moisture.

Refinishing Reality Check: Longevity and Maintenance

How long will the floor look good, and what work will it take to keep it that way? This is where engineered wood often wins out in the long run.

Refinishing Engineered Hardwood

Refinishing involves sanding off the old top layer and applying a new stain and finish. This is expensive but returns the floor to looking brand new. You must know the wear layer thickness beforehand:

- If you have a thick wear layer (3mm+), you can probably refinish it 2–3 times over decades.

- If you have a thin wear layer (1.5mm), you may only be able to buff the surface lightly one time, or not at all.

This refinishing capability means a high-quality engineered floor can outlive two generations of homeowners.

Laminate Maintenance

Laminate requires almost zero maintenance beyond sweeping and damp mopping. You never need to sand or reseal it. However, if a plank gets damaged, you must locate and replace that single plank—which can be tricky if you didn’t save your spares. Finding an exact color match years later is often impossible, meaning you might have to replace an entire section of the room.

The Hidden Cost: Comparison of Long-Term Value

While laminate seems cheaper at the hardware store, the total cost of ownership might surprise you. Consider the lifespan.

| Factor | Engineered Hardwood (3mm Wear Layer) | Laminate (Standard) |

|---|---|---|

| Initial Material Cost (Per Sq. Ft.) | $5.00 – $15.00 | $1.50 – $4.00 |

| Estimated Lifespan (Years) | 30 – 50 Years (With Refinishing) | 10 – 25 Years (No Refinishing) |

| Cost of Refinishing (One time, per Sq. Ft.) | $3.00 – $5.00 | N/A |

| Total Potential Value | High return on investment | Low initial cost, must be replaced entirely |

If you plan to stay in your home for 20 years or more, paying more for engineered wood often makes financial sense because you are buying a floor that can be renewed, rather than one that must be thrown away.

Key Takeaways for the DIY Homeowner

To wrap up our guide, here are the non-negotiable facts you must remember before heading to the flooring aisle:

Ask Yourself These Three Questions:

- Is this a high-spill area (like a main entryway or basement)? If yes, laminate might offer better surface scratch protection, but engineered wood handles humidity better. Neither is truly ideal for a bathroom.

- How long do I plan to live here? If less than 10 years, laminate is affordable and beautiful for the time you need it. If 15+ years, invest in engineered wood for the ability to refinish.

- Is my subfloor concrete? If yes, engineered hardwood (especially glued down) is usually the better structural match, provided you check moisture readings first.

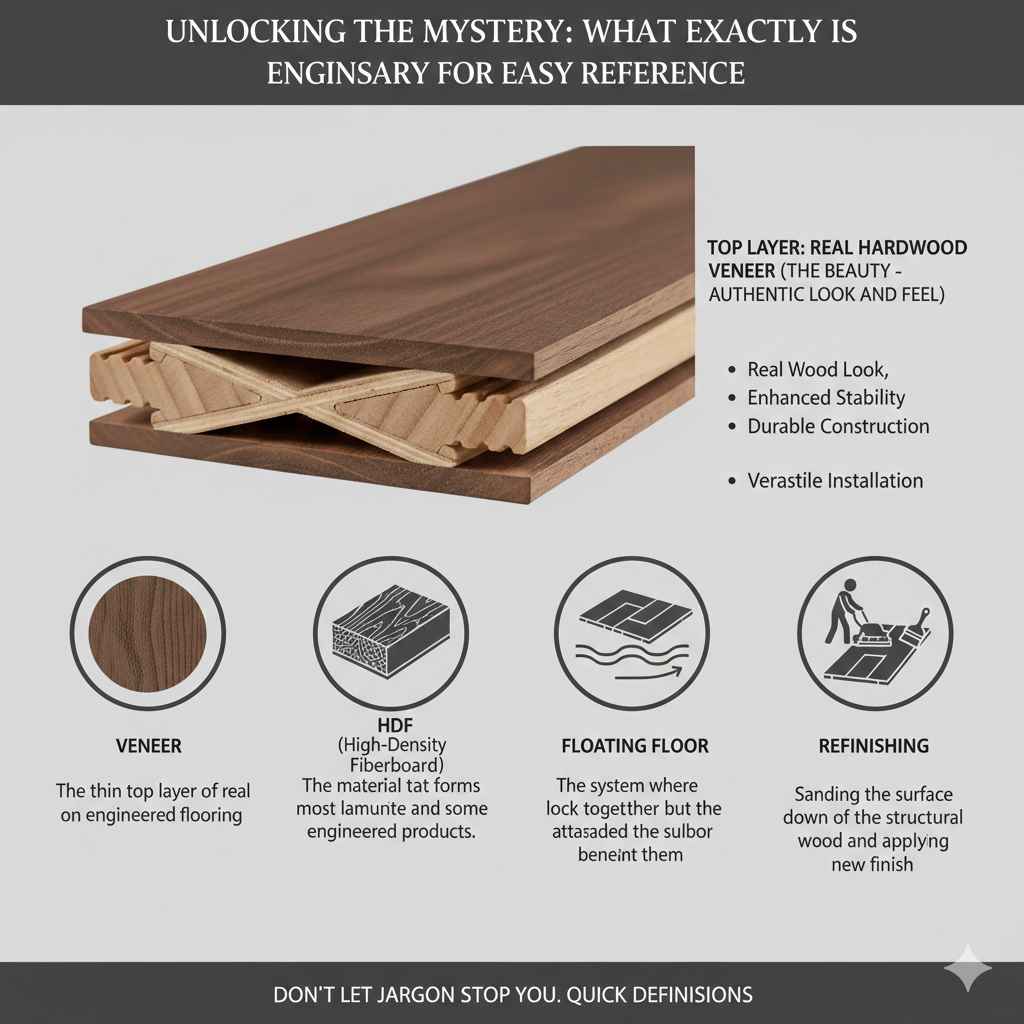

Glossary for Easy Reference

Don’t let jargon stop you. Here are quick definitions for the terms we used:

- Veneer: The thin top layer of real wood on engineered flooring.

- HDF (High-Density Fiberboard): The material that forms the core of most laminate and some engineered products.

- Floating Floor: A system where planks lock together but are not attached to the subfloor beneath them.

- Refinishing: Sanding the surface down to the structural wood and applying a new finish.

Frequently Asked Questions (FAQ)

Q1: Can I install engineered hardwood in my basement?

A: Yes, engineered wood is often ideal for basements because its layered core resists moisture changes better than solid wood. However, you must use a glue-down or float installation method over a moisture barrier if installing over concrete.

Q2: Will my laminate floor look cheap after a few years?

A: Modern, high-quality laminate (AC4 or AC5 rating) holds up very well against surface scratches. It will only look ‘cheap’ if the surface image layer is severely damaged, or if moisture causes the edges to lift or swell.

Q3: How can I tell if a floor is engineered wood or laminate just by looking at a sample?

A: Look at the side profile! If you see multiple layers of plywood stacked like a thin sandwich with a solid-looking wood cap, it’s engineered. If you see a thick, uniform brownish-gray core beneath a thin image layer, it is laminate.

Q4: Is engineered hardwood quieter underfoot than laminate?

A: Generally, yes, especially if installed using a glue-down method. Laminate almost always requires an extra acoustic underlayment pad to reduce the hollow sound common with HDF cores.

Q5: If I get a deep scratch on engineered wood, can I fix it?

A: For small, light surface scratches, you can often use a furniture touch-up kit or wax filler stick matching your stain color. If the scratch goes all the way through the veneer, you would need to sand that specific plank down (if enough veneer remains) or replace the plank entirely.

Q6: Which one is better if I have pets that scratch the floor often?

A: Laminate often wins in scratch resistance due to its tough aluminum oxide wear layer protecting the image. However, if the pet scratches deep enough to hit the HDF core, the plank must be replaced.

Putting It All Together: Making Your Confident Choice

Stepping into the flooring section can feel overwhelming, but you now hold the essential secrets to these two popular choices. Remember this simple guide: Engineered hardwood offers the soul of real wood with modern stability and the chance to renew its beauty years down the road. Laminate offers an incredibly durable, beautiful facade for a lower initial price tag, perfect for quick, budget-conscious updates.

As a DIY guide, my advice is always to match the floor to your lifestyle and your timeline. If the look of genuine wood grain texture and the idea of a long-term investment motivate you, go with engineered wood—you are installing real equity into your home. If affordability, speed, and maximum surface scratch resistance in a rental or short-term home are your main goals, laminate provides unbeatable value.

Take your time. Order samples, put them through the coffee spill test, drop a key on them, and see which one feels right underfoot. With this knowledge, you are ready to select your perfect floor with the confidence of an experienced pro. Happy renovating!