Forstner Bit vs Hole Saw: Proven Best

Forstner Bit vs Hole Saw: Proven Best for Clean, Precise Holes

Choosing the right tool for drilling clean, accurate holes can make all the difference in your woodworking projects. If you’ve ever faced the frustration of ragged edges or off-center holes, you’re not alone! Many DIYers wonder whether a Forstner bit or a hole saw is the better choice. This guide will break down the differences, show you when to use each, and help you make the best decision for your next project. Let’s get your holes drilled perfectly, every time!

Forstner Bit vs Hole Saw: Understanding Your Hole-Drilling Options

As a woodworker, having the right tools is key to achieving professional-looking results. When it comes to drilling holes, two popular options often come up: the Forstner bit and the hole saw. Both are designed to cut circular holes, but they do so in very different ways and are suited for different tasks. Understanding their unique strengths and weaknesses will help you pick the perfect tool for the job, whether you’re building a birdhouse, installing hardware, or tackling a more complex project.

Let’s dive into what makes each of these tools special and how they stack up against each other in the classic “Forstner bit vs hole saw” debate.

What is a Forstner Bit?

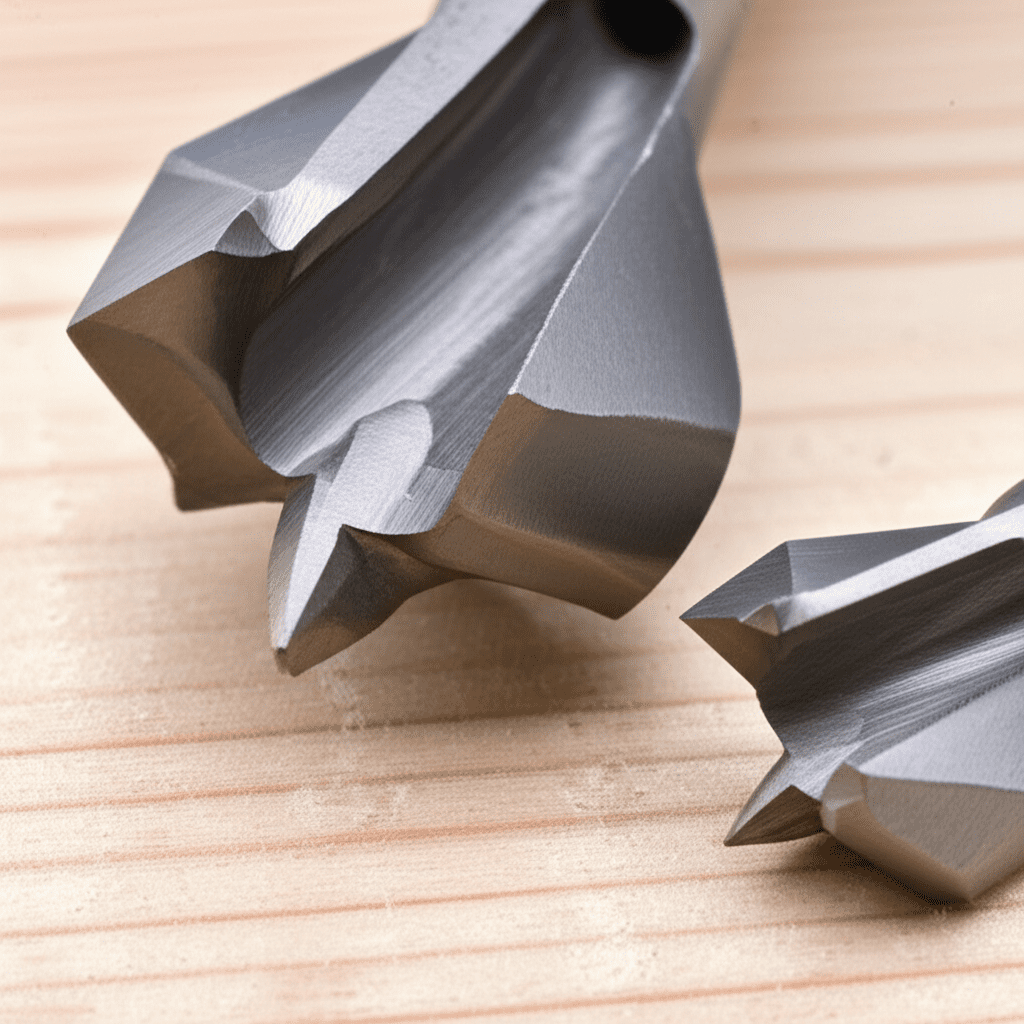

Invented by Benjamin Forstner in the late 19th century, the Forstner bit is a type of drill bit designed to make clean, flat-bottomed holes. Its unique design features a sharp center spur and a raised rim around the cutting edge.

The center spur acts like a guide, keeping the bit centered and preventing it from “walking” or wandering when you start drilling. The outer rim scores the wood fibers cleanly before the cylindrical cutter removes the material. This results in a very precise and clean-edged hole, with no blowout on the exit side if used correctly.

Key Features of a Forstner Bit:

- Center Spur: For precise starting and preventing wandering.

- Raised Rim: Scores the wood for clean edges.

- Cylindrical Cutting Edge: Removes material efficiently.

- Flat Bottom: Ideal for creating recesses or stop holes.

- Versatility: Can drill partially or completely through wood, and even at an angle.

When to Use a Forstner Bit:

Forstner bits excel in situations where precision and a clean finish are paramount. They are your go-to for:

- Creating recesses: Perfect for drilling shallow holes to sink screws, bolts, or other hardware flush with the surface.

- Drilling through-holes with clean edges: Ideal for furniture making, cabinet installation, or anywhere you need a neat, burr-free hole.

- Blind holes: The flat bottom means you can drill a hole to a specific depth without going all the way through.

- Drilling into hardwoods: Their design cuts through dense wood cleanly.

- Drilling at an angle: While tricky, it’s more feasible with a Forstner bit than a hole saw due to its guided center spur.

Forstner bits are also fantastic for drilling overlapping holes to create larger openings or for mortising. Their ability to create a precise, flat-bottomed hole makes them invaluable for joinery and detailed woodworking.

What is a Hole Saw?

A hole saw is a cup-shaped cutting tool that attaches to a drill. It consists of a cylindrical saw blade with teeth on the edge, attached to a mandrel which includes a pilot drill bit in the center.

The pilot bit guides the hole saw to the desired location. As the drill spins, the toothed edge of the cup cuts into the material, creating a circular kerf. The material cut out remains inside the cup until you remove it. Hole saws are designed to cut larger diameter holes quickly and efficiently.

Key Features of a Hole Saw:

- Pilot Drill Bit: Centers the hole saw and prevents it from wandering.

- Cylindrical Blade: Features aggressive teeth for fast cutting.

- Variable Kerf Depth: The depth of the cut is determined by the depth of the hole saw cup.

- Quick Material Removal: Designed for speed and efficiency in cutting larger holes.

- Ideal for Thicker Materials: Can cut through substantial thicknesses of wood, plastic, and even thin metal.

When to Use a Hole Saw:

Hole saws are the champions of speed and efficiency when you need to cut larger diameter holes. They are perfect for:

- Drilling large diameter holes: Think of holes for plumbing pipes, electrical conduit, ventilation ducts, or speaker mounts.

- Cutting through thicker materials: They can handle materials up to several inches thick, depending on the hole saw’s design.

- Roughly cutting larger openings: When precision isn’t as critical as speed and size.

- Cutting through plasterboard or drywall: Excellent for creating openings for light fixtures or electrical boxes.

While hole saws are fast, they can sometimes leave a rougher edge and are prone to blowouts on the exit side if not supported. They are generally not suitable for creating flat-bottomed recesses.

Forstner Bit vs Hole Saw: A Direct Comparison

To truly understand the “Forstner bit vs hole saw” debate, let’s look at how they perform in key areas:

| Feature | Forstner Bit | Hole Saw |

|---|---|---|

| Hole Quality | Very clean, precise, flat-bottomed holes. Minimal blowout. | Can be rougher edges, prone to blowout on exit. |

| Hole Size Range | Typically 1/4 inch to 2 1/2 inches. | Can range from 3/4 inch to 6 inches or more. |

| Depth Control | Excellent, can create precise blind holes. | Limited by the depth of the saw cup; generally for through-holes. |

| Material Removal | Slower, more controlled removal. | Fast and efficient for larger diameters. |

| Best Use Cases | Recesses, clean through-holes, joinery, hardwoods. | Large diameter holes, plumbing, electrical, quick openings. |

| Cost | Can be more expensive for high-quality bits. | Generally more affordable for common sizes. |

Pros and Cons at a Glance:

Forstner Bits:

- Pros: Superior cut quality, flat bottoms, excellent for recesses, precise control, less blowout.

- Cons: Can be slower for large holes, higher cost for premium bits, can be more challenging to drill very thick material cleanly.

Hole Saws:

- Pros: Fast cutting, ideal for large diameters, cost-effective for large holes, good for thicker materials.

- Cons: Rougher edges, potential for blowout, not suitable for flat-bottomed holes, can be difficult to start precisely on curved surfaces.

How to Use a Forstner Bit Safely and Effectively

Using a Forstner bit is straightforward, but a few tips will ensure you get the best results and stay safe:

Step-by-Step Guide:

- Select the Right Bit: Choose a Forstner bit of the desired diameter and ensure it’s sharp.

- Mark Your Hole: Clearly mark the center point of your hole on the workpiece. Use a pencil and a ruler or measuring tape. For extra precision, you can use a center punch to create a small indentation.

- Secure Your Workpiece: This is crucial for safety and accuracy. Use clamps to firmly hold your workpiece to a workbench or stable surface. Never try to hold the wood with your hand while drilling.

-

Set Up Your Drill:

- Insert the Forstner bit shank securely into your drill’s chuck.

- If using a drill press, ensure the bit is properly seated and the speed is appropriate for the bit size and wood type. A slower speed is often better for larger Forstner bits.

- If using a hand drill, set it to a lower speed and consider using the side handle for better control.

- Position the Bit: Place the center spur of the Forstner bit precisely on your marked center point.

- Start Drilling Slowly: Begin drilling at a slow speed. Let the center spur guide the bit into the wood. Apply steady, consistent pressure.

- Maintain Control: As the bit cuts, keep the drill perpendicular to the surface. If you’re using a hand drill, maintain a firm grip with both hands.

- For Through-Holes: If you’re drilling all the way through, you can reduce the pressure as you near the exit point to minimize tear-out. Alternatively, you can drill partway through, flip the workpiece, and finish the hole from the other side, aligning with your initial entry point. A common technique is to drill about 80-90% of the way through, then flip the piece and finish from the backside to prevent blowout.

- For Blind Holes: Stop drilling when you reach your desired depth. You can use a depth stop on your drill press or wrap tape around your drill bit as a visual indicator.

- Clean Up: Once the hole is drilled, slowly back the bit out of the workpiece while it’s still spinning at a low speed to help clear the chips and leave a clean hole.

A key benefit of Forstner bits is their ability to create flat-bottomed holes, perfect for sinking hardware. You can also drill overlapping holes to create larger openings or mortises for joinery, a task much more difficult with a hole saw.

How to Use a Hole Saw Safely and Effectively

Hole saws are designed for speed, but proper technique ensures good results and safety:

Step-by-Step Guide:

- Choose the Right Hole Saw: Select a hole saw of the correct diameter for your needs. Ensure the pilot bit is sharp. For wood, a bi-metal or carbide-tipped hole saw is usually best.

- Mark Your Hole: Mark the center of the desired hole on your workpiece.

- Secure Your Workpiece: As with Forstner bits, always clamp your workpiece securely.

-

Set Up Your Drill:

- Attach the hole saw and pilot bit securely to your drill. Most hole saws use a standard mandrel.

- Use a powerful drill, preferably a corded one, as hole saws can draw a lot of power. A drill press can offer more stability for larger hole saws, but it’s often used with hand drills for on-site work.

- Set your drill to a medium to high speed, depending on the material and hole saw size.

- Position the Pilot Bit: Place the pilot bit’s tip on your marked center point.

-

Start Drilling with Caution:

- Begin drilling at a slower speed to let the pilot bit establish its position and the teeth start to engage.

- Once the pilot bit has penetrated slightly, increase the speed and apply steady, firm pressure.

- Keep the drill perpendicular to the surface.

- Manage Chip Ejection: Periodically pull the hole saw back slightly while still drilling to clear sawdust and debris from the cut. This prevents the saw from binding and overheating.

- For Through-Holes: As you approach the end of the cut, reduce the pressure significantly. This helps minimize blowout on the exit side. If possible, support the exit side of the workpiece with a scrap piece of wood clamped tightly against it.

- Remove the Plug: Once the hole is cut, you may need to gently pry the cut-out plug from inside the hole saw. Sometimes, it will fall out on its own.

A helpful tip for reducing blowout with hole saws is to drill about 80% of the way through, then stop, flip the workpiece over, and carefully finish the cut from the other side, aligning with your initial hole. This often results in a cleaner exit.

When Each Tool Shines: Scenarios

Let’s look at some practical scenarios where one tool clearly outshines the other:

Scenario 1: Installing Cabinet Hinges

You need to create shallow recesses for the circular part of a cabinet hinge to sit flush with the door. A Forstner bit is the perfect tool here. Its ability to create a flat-bottomed hole to a precise depth makes for a clean, professional installation.

Scenario 2: Running a 2-inch PVC Pipe Through a Wall Stud

You need to drill a 2-inch diameter hole through a wooden stud to pass a pipe. A hole saw is the ideal choice. It will cut through the wood quickly and efficiently, and the slightly rougher edge is perfectly acceptable for this application.

Scenario 3: Creating a Shelf Support with Dowels

You’re building shelves and need to drill precise, clean holes into the sides of cabinet boxes to insert wooden dowels for shelf support. A Forstner bit will give you the clean, accurate holes needed for a strong and neat fit.

Scenario 4: Installing a Doorknob

Doorknobs typically require two holes: a larger one for the main body of the knob and a smaller one for the bolt. The larger hole, often around 1 1/2 to 2 inches, is best drilled with a hole saw for speed. The smaller bolt hole, usually 1 inch or less, can be drilled with a Forstner bit or a standard twist bit, depending on the depth required.

Scenario 5: Building a Custom Speaker Enclosure

You need to cut precise holes for speaker drivers (e.g., 6-inch diameter) into the front baffle of a speaker box. While a hole saw can do this, a large Forstner bit will often provide a cleaner edge and better control, especially if the material is valuable or visible.

Choosing the Right Size and Type

Both Forstner bits and hole saws come in a wide range of sizes. When selecting, consider:

- Diameter: Measure the opening you need. Forstner bits typically go up to about 2 1/2 inches, while hole saws can go much larger.

- Material: For wood, standard steel or bi-metal hole saws work well. For harder materials or more frequent use, carbide-tipped versions offer greater durability. Forstner bits are generally made of high-speed steel (HSS).

- Shank Type: Ensure the bit or saw fits your drill’s chuck. Most have round or hex shanks.

- Brand and Quality: Investing in quality tools will pay off in terms of performance, durability, and safety. Reputable brands often offer better-balanced bits and sharper cutting edges.

Forstner bits can be a bit pricier, especially in larger sizes or when buying a set. Hole saws are generally more economical for larger diameters.

Maintaining Your Tools for Longevity

To ensure your Forstner bits and hole saws perform at their best:

- Keep them Sharp: Dull bits require more force, produce poorer results, and are more dangerous. Sharpen them regularly or replace them when they become too dull.

- Clean After Use: Remove wood dust and debris after each use. A stiff brush works well.

- Prevent Rust: Store your bits and saws in a dry place. A light coating of oil can help prevent rust on bare metal parts.

- Proper Storage: Use a bit organizer or a case to protect the cutting edges from damage.

Proper maintenance not only extends the life of your tools but also ensures you get cleaner cuts and a safer drilling experience. For more on tool maintenance, resources like Popular Mechanics offer great tips.

Frequently Asked Questions (FAQ)

Q1: Can I use a Forstner bit for large holes?

Yes, you can. Forstner bits are available in larger sizes, up to about 2 1/2 inches. However, for very large holes (3 inches and above), a hole saw is generally more efficient and cost-effective.

Q2: Can I use a hole saw to create a recess for hardware?

No, a hole saw is not suitable for creating recesses. It cuts a full-depth hole with a curved bottom, not a flat-bottomed recess.

Q3: Which tool is better for drilling through plywood?

For a clean hole with minimal blowout on the exit side of plywood, a Forstner bit is generally preferred, especially if you’re careful with the exit. However, a hole saw can also be used, but be sure to support the exit side of the plywood to reduce tear-out.

Q4: Do I need a special drill for Forstner bits or hole saws?

No, standard corded or cordless drills are suitable. However, for larger diameter bits or hole saws, a more powerful drill (often corded) or a drill press will provide better control and efficiency.

Q5: What is the best way to avoid blowout when drilling with a hole saw?

The best method is to drill about 80-90% of the way through, then stop, flip the workpiece, and carefully finish the cut from the other side, aligning with the initial hole. Supporting the exit side with a scrap piece of wood also helps significantly.

Q6: Which tool is better for drilling clean holes in hardwood?

Forstner bits are generally superior for drilling clean holes in hardwoods. Their design allows for a precise cut with minimal tear-out, even in dense woods.

Conclusion: Making the Right Choice for Your Project

So, when it comes down to Forstner bit vs hole saw, there’s no single “best” tool—the ideal choice depends entirely on your project’s specific needs. For precision, clean edges, flat-bottomed holes, and recessed hardware, the Forstner bit is your clear winner.

If you need to quickly cut larger diameter holes through materials, especially for functional purposes like running pipes or conduits, the hole saw is the more efficient and practical option. Understanding these differences will empower you to select the right tool, leading to better results, less frustration, and a safer woodworking experience.

Keep both tools in your arsenal, and you’ll be well-equipped to tackle a wide range of drilling tasks with confidence. Happy drilling!