Hand Planer Vs Thickness Planer: Ultimate Woodworking Showdown

Are you caught in the woodworking dilemma of choosing between a hand planer and a thickness planer? You’re not alone.

This decision can feel overwhelming, especially when you want to ensure the perfect finish for your projects. Both tools promise to transform your wood surfaces, but they do it in very different ways. Understanding these differences is key to enhancing your craftsmanship and elevating your woodworking game.

Imagine the satisfaction of smooth, even surfaces achieved with the right tool. By the end of this article, you’ll not only know which planer suits your needs best, but you’ll also gain insights into making your woodworking process more efficient and enjoyable. Dive in to discover how you can make the most informed choice for your woodworking arsenal!

Credit: sawsonskates.com

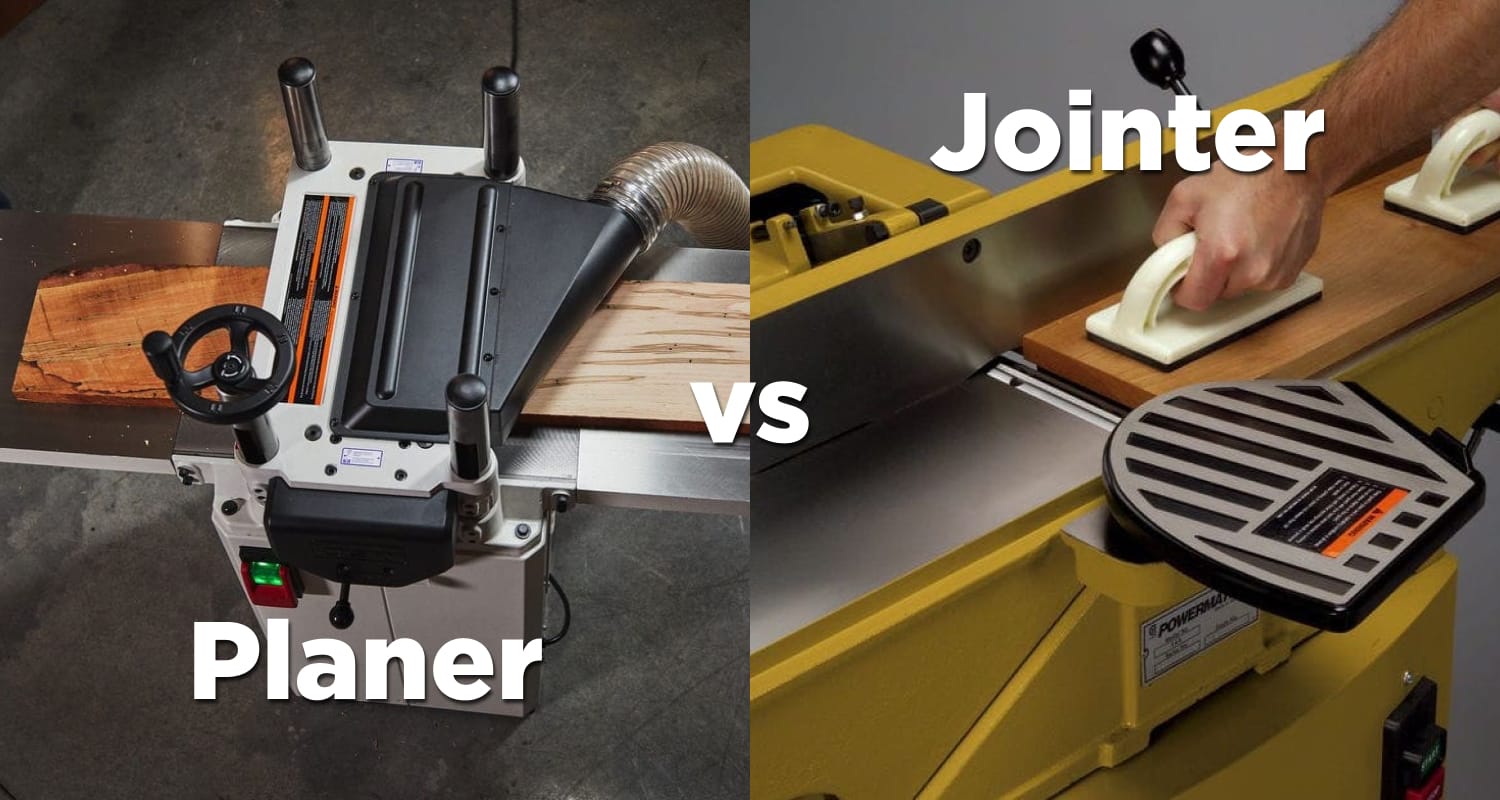

Purpose And Functionality

Hand planers are used for small jobs. They smooth wood surfaces and remove rough edges. Thickness planers help make boards even. They make all boards the same thickness. This is important for big projects. Hand planers are easy to use. They are great for quick fixes. Thickness planers are bigger. They need space and power. Both tools have unique uses. Choosing depends on your project needs.

Credit: machineatlas.com

Design And Features

Hand planers are small tools. They fit in your hand. They are used for smoothing wood surfaces. They have a sharp blade. This blade cuts thin wood shavings. Hand planers need physical strength. Thickness planers are bigger machines. They stand on the floor. They make wood pieces even. These planers have a motor. The motor moves the cutter head. Wood passes through the machine. It becomes the same thickness.

Hand planers are simple. No power needed. You push them with your hand. Thickness planers are complex. They need electricity. They have knobs for settings. You can adjust thickness easily. Hand planers are best for small jobs. Thickness planers are good for large boards. Each tool has its own use.

Precision And Control

Hand planers offer great control over wood surfaces. They are small and easy to handle. You can shape wood with precision using hand planers. They are ideal for fine-tuning edges and corners. Craftsmen love hand planers for their ease of use. These tools work without electricity, making them quiet. Perfect for detailed work. Hand planers are lightweight and portable.

Thickness planers smooth large pieces of wood quickly. They provide consistent thickness across boards. Electric-powered, they save time and effort. Thickness planers are perfect for big projects. They handle rough wood with ease. These machines are bulky and need space. They ensure uniform surface every time. Best for reducing wood to desired thickness.

Speed And Efficiency

Hand planers are great for small tasks. They work best for minor adjustments. Speed depends on skill level. Hand tools need more effort. This can make them slower. Yet, they offer more control and precision.

Thickness planers are faster for large jobs. They handle big boards with ease. Electric power makes them efficient. You can finish the job quicker. They save time on large projects. However, they lack the fine touch of hand planers.

Both tools have their uses. Hand planers are better for detail. Thickness planers excel in speed. Choosing the right one depends on the task. Think about your needs and project size.

Versatility In Use

Hand planersare small and easy to carry. They help smooth rough wood. Thickness planersare bigger and stay in one place. They make wood even on both sides. Hand planers work well for small tasks. You can use them for edges and corners. Thickness planers are better for big pieces of wood. They save time and effort. Hand planers need more skill to use. Thickness planers are easier for beginners. Both tools have unique roles. Hand planers fit in your toolbox. Thickness planers need a workshop space. Choose based on your project needs.

Credit: www.tylerbrownwoodworking.com

Cost And Investment

A hand planer costs less money. It’s a good choice for small jobs. Thickness planers cost more. They are better for big projects. These machines save time. They can handle large wood pieces. Hand planers take more time. They need more effort. Thickness planers need electricity. Hand planers do not. Think about your budget. Check your needs. Choose the right tool.

Hand planers can be found easily. They are in many stores. Thickness planers need more space. They are bigger. These tools need care. Keep them clean. Lubricate moving parts. This makes them last longer. Good tools help make great work.

Maintenance And Care

Always keep planers clean and dry. Dust can harm the blades. Rust can damage the surface. Regular oiling helps protect metal parts. Check blades for sharpness. Dull blades make work harder. They can also spoil wood. Tighten loose screws. Loose parts can cause accidents.

Store planers in a safe place. Avoid wet areas. Wet places can cause rust. Use protective covers if possible. Covers keep dust away. Inspect planers often. Look for any cracks or damage. Replace worn-out parts quickly. Safety is very important.

Follow instructions in the manual. Manuals have useful tips. They help in keeping planers in good shape. Proper care extends the life of planers. Well-maintained tools work better. They also keep users safe.

Safety Considerations

Both hand planers and thickness planers need careful handling. Fingers should stay clear of blades. Blades are sharp and can cut. Always wear protective gloves. Goggles protect eyes from flying wood chips. Dust masks keep your lungs safe from fine dust. The floor around the planer should be clean. Tripping is dangerous. Keep cords and tools organized. Proper lighting helps you see clearly. Hearing protection is important. Planers are loud. Read and follow safety instructions. Never rush while using tools. Take breaks if you feel tired. Stay focused for safety.

Choosing The Right Tool

A hand planeris small and easy to use. It helps with minor wood adjustments. You can carry it anywhere. It is perfect for small projects. A thickness planeris bigger. It works well for large wood pieces. This tool makes all boards the same thickness. It is great for big jobs.

Both tools have their uses. Choose based on your project needs. Hand planers are good for detail work. Thickness planers save time on big tasks. Think about the size of your workspace too. Small spaces fit hand planers better. Big workshops benefit from thickness planers.

Frequently Asked Questions

Do I Really Need A Thickness Planer?

A thickness planer is essential for achieving precise wood thickness. It enhances woodwork quality by providing smooth surfaces. Ideal for professionals and serious DIY enthusiasts. Without it, maintaining consistent thickness and surface smoothness becomes challenging, impacting overall project results. Consider investing in one for better woodworking outcomes.

When Would You Use A Hand Planer?

Use a hand planer to smooth rough wood surfaces, adjust door edges, or fit wooden joints precisely. It’s ideal for creating beveled edges and leveling uneven boards. Hand planers offer control and precision in woodworking projects, making them essential for detailed craftsmanship and finishing touches.

What Is A Hand Planer Used For?

A hand planer is used for smoothing and shaping wood surfaces. It allows for precise control over material removal. Ideal for small projects and detailed work, it’s perfect for leveling uneven surfaces, creating beveled edges, or adjusting wood thickness manually.

How Does A Thickness Planer Work?

A thickness planer trims boards to a consistent thickness across their length. It uses rotating blades to shave off wood. This tool is great for maintaining uniform thickness and smoothness, making it ideal for preparing lumber for projects requiring exact dimensions.

Conclusion

Choosing between a hand planer and thickness planer depends on your needs. Hand planers offer control and precision for small projects. Thickness planers save time on larger boards. Both tools have unique advantages. Consider the job size and desired finish.

Hand planers suit detailed work. Thickness planers excel in speed. Your workshop space and budget matter too. Each tool enhances woodworking skills. Decide based on your project requirements. Both planers play a vital role. Selecting the right tool ensures efficient and quality woodworking.

Make your choice wisely for the best results.