Helical Vs Spiral Cutter Head: Ultimate Woodworking Guide

When you’re diving into the world of woodworking, the choice between a helical and a spiral cutter head can feel like a pivotal decision. You want smooth surfaces and perfect cuts, but which tool will help you achieve that?

Imagine having a tool that not only enhances your work but also saves time and reduces noise. Intrigued? This is where understanding the differences between helical and spiral cutter heads becomes crucial. Your projects deserve precision, and your time deserves efficiency.

As you read on, you’ll discover how these cutter heads can transform your woodworking experience. Are you ready to make the best choice for your workshop? Let’s explore together.

Helical Cutter Head Basics

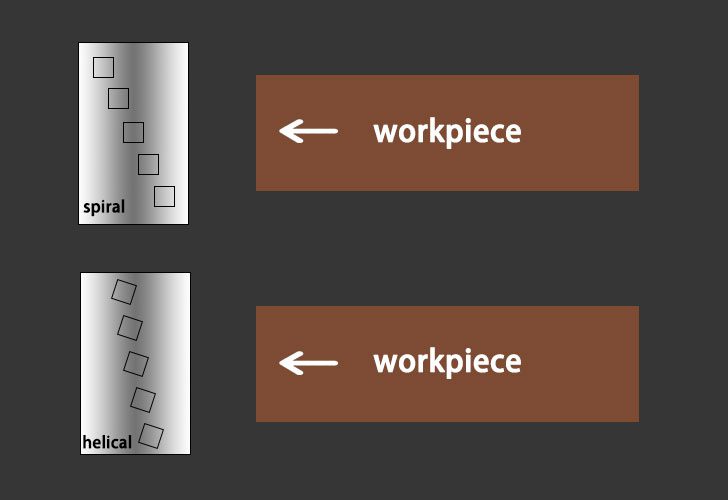

A helical cutter head has a special design. It uses small, square cutters. These cutters are set in a spiral line. Each cutter is slightly angled. This helps in making smooth cuts. The design looks like a twisted line. It is different from straight cutter designs.

Many helical cutter heads use strong materials. Carbide is a common choice. It stays sharp for long. It can cut hard wood easily. Another material is steel. It is also strong and lasts long. These materials ensure the cutter works well.

Helical cutter heads have many benefits. They make less noise. This is good for your ears. They also reduce tear-out. Wood looks smoother with them. Changing blades is easy too. Only one cutter needs replacement at a time. This saves time and money.

Spiral Cutter Head Essentials

Spiral cutter heads are made with small blades. These blades are set in a spiral shape. Each blade works on its own. This makes the cut smooth. Wood pieces look even better. The design helps lower noise. Less noise means a better work environment.

High-quality steel is used for these heads. Steel makes the blades strong. Strong blades last longer. Some heads use carbide. Carbide stays sharp for a long time. This saves time in sharpening. Good materials mean good cuts.

Spiral cutter heads offer many benefits. Smooth cuts are a top benefit. Smooth cuts mean less sanding. Woodworkers save time. These heads also make less noise. Less noise helps focus on work. Less wear on blades means saving money. Blades stay sharp longer.

Comparing Helical And Spiral

Helical cutter heads have angled blades. They cut wood very smoothly. Spiral cutter heads have straight blades. They might leave small lines on wood.

Helical heads are quieter. They make less noise during use. Spiral heads can be louder. They create more sound.

Helical heads are great for hardwoods. They handle tough wood easily. Spiral heads work well with softer woods. They are not as good with hard wood.

Helical heads need less power. They cut more efficiently. Spiral heads use more power. They may be less efficient.

Helical cutter heads can be expensive. They cost more to buy. Spiral heads are cheaperto purchase. They are more budget-friendly.

Helical heads last longer. They need less maintenance. Spiral heads may wear faster. They require more upkeep.

Choosing The Right Cutter Head

Cutter heads come in helical and spiral types. Noise level is a key factor. Helical heads make less noise. Spiral heads are louder. Cut quality matters too. Helical heads leave smooth surfaces. Spiral heads can leave marks. Durability is important. Helical heads last longer. Spiral heads may wear faster. Cost can affect your choice. Helical heads are more expensive. Spiral heads are cheaper.

Small projects might need a spiral head. They cost less. Large projects benefit from helical heads. They work longer. Wood type also matters. Hardwoods work well with helical heads. Softwoods can use spiral heads. Precision cutting needs helical heads. For rough cuts, spiral heads are fine.

Helical heads are a good long-term choice. They last many years. Spiral heads may need frequent changes. This can add costs over time. Initial cost of helical heads is high. Yet, fewer replacements save money. Maintenance is easier with helical heads. Spiral heads need more care.

Maintenance Tips

Keep your helical heads clean. Use a soft cloth. Wipe away dust and debris. Check the screws regularly. They must be tight. Loose screws cause problems. Lubricate the moving parts. Use light oil. This helps prevent rust. Inspect the blades often. Sharp blades work best. Replace dull blades quickly. This saves time and energy.

Spiral heads need care too. Clean them often. Dust can build up fast. Check for loose screws. Tight screws ensure safety. Blades need checking too. Sharp blades cut better. Use oil for lubrication. It helps parts move smoothly. Regular checks extend the life of the tool. Save money and time with good care.

Sometimes blades become dull. Replace them soon. Dull blades make poor cuts. Tools may vibrate if screws are loose. Tighten them quickly. This stops noise. Rust can appear on metal parts. Use oil to prevent it. Oil keeps metal shiny and smooth. Always store tools in a dry place. This keeps them safe from damage.

Credit: www.konetool.com

Expert Opinions

Woodworkersshare thoughts on cutter heads. Some prefer helical for smooth cuts. Helical headsreduce noise and vibration. Others favor spiral heads. Spiral headsare cheaper and simpler. Experts suggest choosing based on project needs. Many say helical heads are ideal for hardwoods. Spiral heads work well on softer woods. Both types have pros and cons.

Many woodworkerstest both cutter heads. One expert tried helical on oak. He loved the smooth finish. Another used spiral on pine. He found it efficient. A third expert used both heads. He liked helical for high-end work. Spiral was great for quick jobs.

Future Trends In Cutter Head Technology

Exciting changes are coming to cutter head technology. Advanced materials will make them stronger. Smart sensors will be added for better performance. These sensors help in detecting wood density. Energy-efficient designs will save power. This means less electricity use.

New designs will be quieter. They will make less noise. This is good for workshops. Safety features will also improve. Safer for workers. Innovations mean better results. Wood will look smoother. The future is bright for woodworking.

Woodworking will see changes. Tools will be easier to use. Precision will improve. Cuts will be more accurate. This helps in making detailed furniture. Reduced waste is another benefit. Less wood will be wasted. This saves money and resources.

New cutter heads will be more reliable. Less chance of breakdowns. This means more work done in less time. Woodworkers can finish projects faster. These advancements will boost productivity. Woodworking will become more efficient and enjoyable.

Credit: ncwoodworker.net

Frequently Asked Questions

What Is Better, A Helical Or Spiral Cutterhead?

Helical cutterheads provide smoother cuts and less tear-out. Spiral cutterheads are quieter and need less maintenance. Both have advantages, but helical is better for precision and finish. Choose spiral for noise reduction and ease of upkeep. Consider your needs and budget when deciding.

Are Helical Cutter Heads Worth It?

Helical cutter heads provide smoother cuts and reduce tear-out. They offer quieter operation and require less maintenance. Although more expensive initially, they save time and money in the long run. For woodworking enthusiasts and professionals, they are a worthwhile investment.

What Is The Difference Between Helical And Spiral?

Helical shapes wind around a central axis like a spring, while spiral shapes expand outward from a center point. Helical structures maintain consistent distance from the axis; spirals gradually increase distance. Helical is common in DNA structure; spirals appear in galaxies and shells.

Both feature in various scientific and design applications.

What Is The Difference Between Helical And Spiral Cutterhead Reddit?

Helical cutterheads have angled, staggered carbide inserts for smooth cuts. Spiral cutterheads use straight blades, offering less noise but can cause tear-out. Helical is favored for quality finish, while spiral is more affordable. Both reduce noise and chip size compared to traditional straight blades.

Conclusion

Choosing between helical and spiral cutter heads depends on your needs. Helical heads offer quieter cuts and smoother surfaces. Spiral heads excel in heavy-duty tasks and durability. Both options enhance woodworking projects. Consider your budget and specific requirements. Analyze noise levels, finish quality, and material type.

Each cutter head has its unique benefits. Make an informed decision based on your project goals. Both tools improve efficiency and results. Your choice should align with long-term woodworking objectives. Understanding these differences ensures the best investment.