How Long Should Wood Dry: The Ultimate, Essential Answer

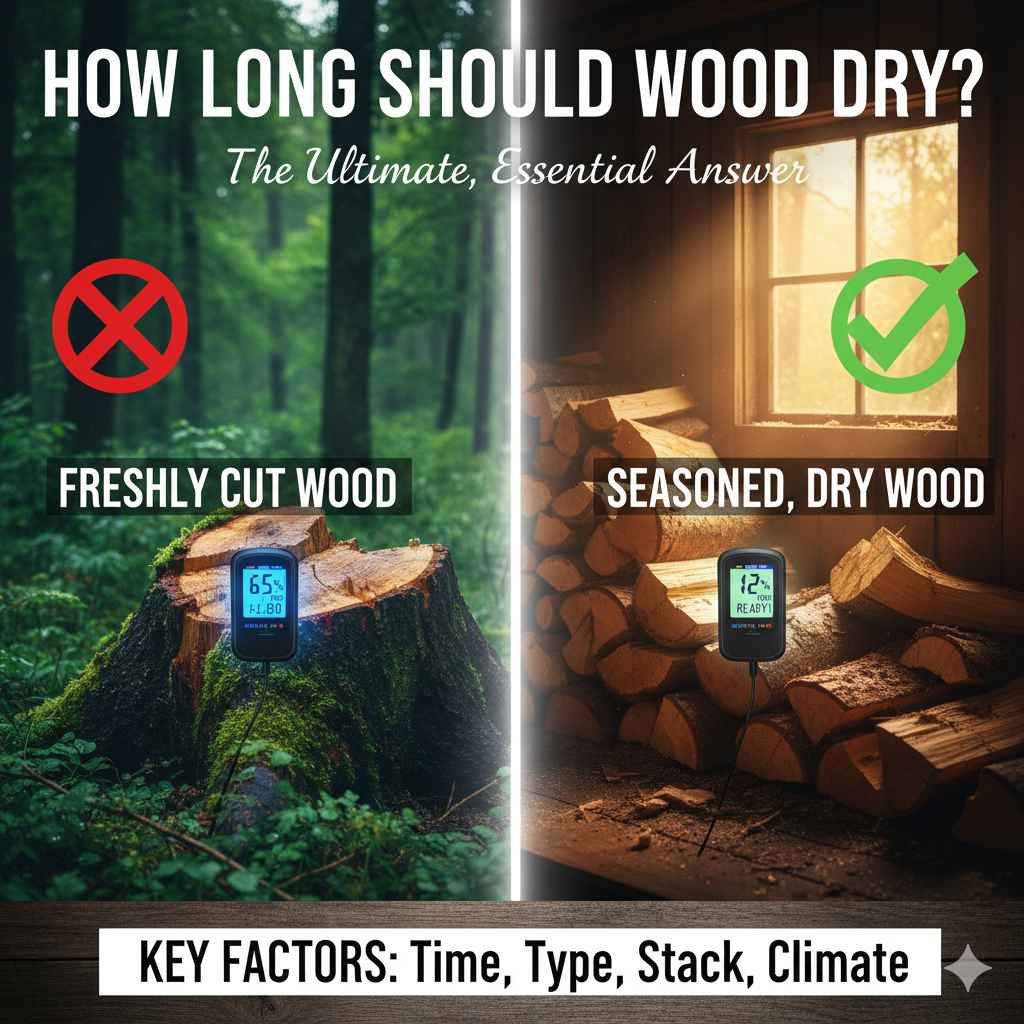

For general woodworking projects, wood should dry until its moisture content is between 6% and 8% for indoor use and 9% to 14% for outdoor use. A common rule of thumb for air-drying is to allow one year per inch of wood thickness, but using a moisture meter is the only way to be certain.

Have you ever built something beautiful with wood, only to see it warp or crack a few months later? Or maybe you painted a deck, and the paint started peeling almost immediately? It’s a frustrating problem, but the cause is often simple: the wood wasn’t dry enough. Knowing how long wood needs to dry can feel like a mystery, but don’t worry. It’s easier than you think!

Getting this step right is the secret to strong, beautiful, and long-lasting projects. I’m here to walk you through it, step by step. We’ll break down everything you need to know in plain, simple language. You’ll learn why dry wood is so important, how to tell when it’s ready, and the best ways to dry it. Let’s build your confidence and make sure your next project is a huge success.

Why Waiting for Wood to Dry is Non-Negotiable

Patience is a virtue, especially in woodworking. Using wood that is still wet, or “green,” is a recipe for disappointment. Think of wood like a sponge. When it’s full of water, it’s swollen. As it dries, it shrinks. If you build with it while it’s still swollen, things are going to move around as it dries out.

Here’s what can happen if you use wet wood:

- Warping and Twisting: As the wood shrinks unevenly, boards can twist, cup, or bow. That perfectly flat tabletop you built could end up looking like a potato chip.

- Cracking and Splitting: The stress of shrinking can cause the wood to crack and split open, ruining the look and strength of your project.

- Weak Joints: Glue doesn’t bond well with wet wood fibers. Joints that seem strong at first can fail over time as the wood dries and pulls apart.

- Mold and Mildew: Trapped moisture is a breeding ground for mold and mildew, which can stain the wood and even cause health issues.

- Failed Finishes: Paint, stain, and sealers can’t soak into wet wood properly. This leads to peeling, blistering, and an uneven, blotchy finish.

Taking the time to ensure your wood is properly dried is the most important first step you can take. It’s the foundation for a project you can be proud of for years to come.

Understanding Wood Moisture Content (MC)

Okay, let’s talk about the key to all of this: “Moisture Content,” or MC. It sounds technical, but the idea is very simple.

Moisture Content is just a measurement of how much water is inside a piece of wood, expressed as a percentage of the wood’s total weight. A piece of freshly cut wood can have an MC of 100% or even higher! That means the water in the wood weighs as much as the wood fibers themselves.

Our goal is to get that number way down before we start building. We want the wood’s moisture level to match the environment where it will live. This is called reaching its Equilibrium Moisture Content (EMC). Wood for an indoor dining table needs to be drier than wood for an outdoor fence because the air inside your home is usually much drier than the air outside.

The Magic Numbers: Ideal Moisture Content for Your Projects

So, what percentage should you aim for? It depends on what you’re making. Here are the simple, reliable targets to remember:

| Project Type | Ideal Moisture Content (MC) | Why It Matters |

|---|---|---|

| Indoor Furniture & Cabinetry | 6% – 8% | The controlled environment inside a home is very dry. Wood dried to this level will be stable and less likely to warp or crack. |

| Hardwood Flooring | 6% – 9% | Flooring needs to be extremely stable to prevent gaps from opening up between boards during dry winter months. |

| Outdoor Projects (Decks, Fences, Siding) | 9% – 14% | Outdoor wood needs to be balanced with the higher humidity of the outside air. If it’s too dry, it will swell and buckle. |

| Framing & Construction Lumber | 15% – 19% | Lumber used for framing is often sold “kiln-dried” to this level. It’s stable enough for construction and will continue to dry after it’s installed. |

Trying to guess the MC is like trying to bake a cake without measuring the flour. You might get lucky, but you’ll get much better results with a proper tool.

How to Measure Moisture Content Like a Pro (It’s Easy!)

The single best tool you can own for this job is a moisture meter. It takes all the guesswork out of the equation and gives you a clear, simple number. It’s a small investment that will save you from major headaches down the road. For a DIYer, a quality meter is affordable and incredibly easy to use.

There are two main types:

- Pin Meters: These have two small metal pins that you press into the wood. They measure the electrical resistance between the pins to determine the moisture content. They are very accurate but do leave tiny pinholes.

- Pinless Meters: These use a sensor pad that you press against the wood’s surface. They send out an electromagnetic signal to read the moisture without making any marks. They’re great for finished or expensive wood.

Using Your Moisture Meter: A Simple 3-Step Guide

Don’t be intimidated by this tool! Here’s all you need to do:

- Set Your Meter: Turn it on and, if it has the option, select the correct wood species group. The instruction manual will have a chart. If you’re not sure, a general setting will get you very close.

- Take a Reading: For pin meters, gently push the pins into the wood, parallel to the grain. For pinless meters, press the sensor pad flat against the board. Check a few different spots on the board, not just one.

- Check the Core (If Possible): The outside of a board always dries faster than the inside. To get the most accurate picture, check the end grain of the board or, if you can, cut a small piece off the end and measure the freshly exposed center.

Once the reading on your meter matches the target MC for your project, you’re ready to build with confidence!

Factors That Control How Fast Wood Dries

Why does one board dry in a few months while another takes years? Several factors are at play. Understanding them helps you manage the drying process.

1. Wood Species

Different types of wood dry at different rates. Generally, softwoods like Pine or Cedar dry much faster than dense hardwoods like Oak or Hickory. The cellular structure of hardwoods is more complex, making it harder for water to escape.

2. Thickness of the Wood

This is the most significant factor. The “one year per inch of thickness” rule of thumb exists for a reason. Water has to travel from the center of the board to the surface to evaporate, so a 2-inch thick slab will take much more than twice as long to dry as a 1-inch thick board.

3. Airflow

Good airflow is your best friend when drying wood. Moving air wicks moisture away from the wood’s surface, encouraging more moisture to move out from the core. Stagnant, damp air will slow the process dramatically and can even lead to mold.

4. Stacking (Stickers are Key!)

Never stack wet lumber in a solid pile. You need to stack it with spacers between each layer to allow for airflow. These spacers are called “stickers.” They should be dry, of uniform thickness (usually ¾-inch to 1-inch), and placed every 12-16 inches along the length of the boards.

5. Environment (Humidity and Temperature)

Wood dries faster in warm, dry conditions. A hot, low-humidity summer day is perfect for drying. In contrast, wood will dry very slowly (or not at all) during a cool, rainy season. Trying to dry wood in a damp basement is a slow and often moldy process.

Your Guide to Air-Drying Lumber at Home

Air-drying is the most common, affordable, and accessible method for DIYers. It relies on natural airflow to slowly and gently dry the wood. It requires patience, but the results are fantastic. Here’s how to set up your own air-drying stack.

Step-by-Step Guide to Stacking Wood for Air-Drying

- Find a Good Location: Choose a flat, level spot that is covered from rain but open to breezes. A shed with open sides, a carport, or even a covered patio works well. Avoid fully enclosed spaces with no airflow, like a garage with the door always closed.

- Build a Solid Base: Get the stack off the ground! Use concrete blocks or sturdy wood beams to create a level base at least 12 inches off the ground. This prevents ground moisture from wicking up and allows air to flow underneath.

- Place Your Stickers: Lay your first layer of stickers across the base, perpendicular to the direction your boards will run. Space them every 12-16 inches.

- Lay the First Layer of Lumber: Place your first layer of boards on top of the stickers, leaving a 1-inch gap between each board for vertical airflow.

- Add More Stickers and Layers: Place the next layer of stickers directly on top of the first layer. It’s crucial to keep your stickers aligned vertically in perfect columns. This keeps the boards straight and prevents warping. Continue stacking layers of boards and stickers.

- Protect the Top: Place a final layer of stickers on your top course of lumber. Then, cover the stack with a sheet of plywood or corrugated metal. This keeps direct rain and sun off the wood. Let the cover overhang the stack by several inches on all sides, but do not drape a tarp down the sides—this will trap moisture and prevent airflow.

- Weigh It Down: Place some heavy weights, like concrete blocks or large rocks, on top of the cover. This weight helps keep the top layers of boards flat as they dry.

For more detailed information on the science behind air drying, the U.S. Forest Service’s Drying Hardwood Lumber guide is an excellent technical resource.

Estimated Air-Drying Times

Remember, the “one year per inch” rule is just a starting point. Your climate and wood species will make a big difference. Here is a very general guide for some common woods.

| Wood Species | Estimated Time to Air-Dry (Per Inch of Thickness) |

|---|---|

| Pine | 4-6 months |

| Poplar | 6-8 months |

| Maple | 9-12 months |

| Cherry | 10-14 months |

| Red Oak | 12-16 months |

| White Oak | 14-20 months |

Always trust your moisture meter over a calendar!

The Big Question: How Long Should Wood Dry After Rain Before Painting?

This is a common question, especially for outdoor projects like decks, fences, and siding. You’ve waited for a stretch of good weather, but then a surprise shower passes through. How long do you have to wait now?

Painting or staining damp wood traps moisture underneath the finish. As the sun heats the wood, that moisture tries to escape, pushing the paint right off the surface. This is what causes blistering and peeling.

The answer depends on three things:

- How much did it rain? (A light mist or a downpour?)

- How much sun and wind is the wood getting now?

- What is the humidity?

As a rule of thumb, you should wait at least 24 to 48 hours after rain before painting. The wood surface should feel completely dry to the touch, with no cool or damp spots. However, the best and only way to be 100% sure is to use your moisture meter. For painting, you want the wood’s MC to be below 15%.

Quick Guide: Drying Time After Rain

| Weather Conditions After Rain | Estimated Waiting Time | Md’s Pro Tip |

|---|---|---|

| Hot, Sunny, and Breezy | 1 full day (24 hours) | These are perfect drying conditions. The surface will dry quickly, but give it a full day for the moisture just below the surface to escape. |

| Warm and Overcast (No Sun) | 2 full days (48 hours) | Without direct sun, evaporation is much slower. Be patient and give it an extra day. |

| Cool and Humid | 3-4 days or more | In these conditions, the wood might not dry at all. It’s best to wait for a better stretch of weather. Painting now is asking for trouble. |

When in doubt, wait one more day. It’s always better to be safe than sorry.

Frequently Asked Questions (FAQ)

1. What happens if I use wood that is too wet?

Using wood with a high moisture content will cause major problems. As it dries, it will shrink, leading to warping, cracking, and twisting. Glue joints can fail, and any paint or finish you apply will likely peel and blister.

2. Can wood be too dry?

Yes, it can. If you dry wood to 6% MC and then place it in a humid outdoor environment, it will absorb moisture from the air and swell, which can cause boards to buckle and joints to crack. The goal is to match the wood’s moisture content to its final environment.

3. What is the difference between “air-dried” and “kiln-dried” wood?

Air-dried (AD) wood is dried naturally using airflow. It’s a slow process that typically brings the wood’s MC down to about 12-15%. Kiln-dried (KD) wood is dried in a large, heated oven called a kiln, which controls temperature and humidity. This is a much faster process and can bring the MC down to the 6-8% range needed for indoor furniture.

4. How do I know if my firewood is dry enough to burn?

Properly “seasoned” firewood should have a moisture content below 20%. The ends of the logs will have visible cracks or “checks,” the wood will feel light, and it will make a sharp “clink” sound when two pieces are knocked together, rather than a dull “thud.” Wet firewood is hard to light, smokes a lot, and creates creosote buildup in your chimney.

5. Can I speed up the wood drying process at home?

You can help it along, but be careful. Increasing airflow with a fan can speed up drying. Placing the wood in a warmer, less humid room also helps. However, trying to dry wood too quickly (for example, by putting it in an oven or next to a furnace) can cause severe cracking and warping. Slow and steady wins the race.

6. Do I need a moisture meter for small projects?

For any project where you want a quality, long-lasting result, a moisture meter is highly recommended. It’s the only way to know for sure that your wood is ready. For rough projects where appearance and stability don’t matter as much, you might get by without one, but it’s always a gamble.

7. What does “seasoned wood” mean?

“Seasoned” is a term most often used for firewood. It simply means the wood has been left to air-dry for a long time, usually 6 months to a year or more, until its moisture content is low enough (under 20%) to burn efficiently.

Your Path to Woodworking Success

Working with wood is incredibly rewarding. It connects us to a natural, beautiful material, and lets us create things that are both useful and personal. Understanding how wood behaves, especially when it comes to moisture, is the key that unlocks its full potential.

Don’t let the science intimidate you. At the end of the day, it’s all about one simple goal: making sure your wood is stable before you start. Let it acclimate, use a moisture meter to check its progress, and have patience. By mastering this one fundamental step, you are setting yourself up for a lifetime of successful, beautiful projects that you and your family can enjoy.

So next time you bring home a stack of lumber, you’ll know exactly what to do. You have the knowledge and the tools to get it right. Now go on and build something amazing!