How to Calculate Wood Work Cost: Expert Tips

To calculate woodwork costs, multiply the width and height of all sides to be coated (including the top). Carpenters measure their work using a measuring tape to ensure accuracy and minimize wood waste, resulting in higher productivity.

To determine the price for a woodworking project, use the formula: Labor rate x overhead rate x labor hours + material cost = project price. Calculate the dimensions of your project to estimate the amount of wood needed and determine the cost per square foot.

It’s important to consider labor costs, material costs, and other factors such as overhead and fees when determining the final price.

Factors Affecting Wood Work Cost

Factors Affecting Wood Work Cost include the type of wood used, the complexity of the design, the size of the project, labor costs, and additional materials needed. To calculate wood work cost, multiply the width and height of all sides to be coated, consider labor and overhead rates, and include material costs to determine the project price.

A carpenter measures their work using a measuring tape for precise and efficient results.

Labor Costs

Labor costs play a significant role in determining the overall cost of woodwork projects. Skilled carpenters’ wages vary depending on their experience, locality, and complexity of the project. It is important to accurately calculate labor costs to ensure pricing accuracy and profitability. To determine labor costs:

- Identify the number of hours required to complete the project

- Multiply the number of hours by the hourly rate of the carpenter

Material Costs

Material costs refer to the expenses incurred for purchasing all the necessary materials for the woodwork project. It includes the cost of wood, hardware, finishes, and any other materials required. To calculate material costs:

- Create a detailed list of all the materials needed

- Research and determine the cost of each material

- Sum up the costs of all the materials

Overhead Costs

Overhead costs are the expenses associated with running a woodworking business, such as rent, utilities, insurance, and administrative costs. These costs must be factored into the pricing equation to ensure profitability. To calculate overhead costs:

| Expense | Cost |

|---|---|

| Rent | XX |

| Utilities | XX |

| Insurance | XX |

| Administrative Costs | XX |

| Total Overhead Costs | XX |

By considering these factors, you can accurately calculate the woodwork cost and ensure that your pricing is both competitive and profitable.

Calculating Labor Costs

When it comes to calculating the cost of woodwork projects, labor costs play a crucial role in determining the overall pricing. Whether you are an experienced carpenter or a woodwork enthusiast, understanding how to calculate labor costs accurately is essential for profitability and sustainable business operations. In this section, we will delve into the methods and formulas for calculating labor costs in woodworking projects.

Methods Of Calculating Labor Costs

There are various methods employed to calculate labor costs in woodworking projects. Some of the common approaches include:

- Hourly wage rate

- Piece-rate payment

- Project-based pricing

Formula For Labor Cost Calculation

The formula for calculating labor costs in woodworking projects is as follows:

| Formula |

|---|

| Labor Cost = (Hourly Wage Rate x Labor Hours) + (Piece-rate Payment) + (Project-based Pricing) |

Determining Material Costs

Calculating woodwork costs involves multiplying width and height of all sides, including the top. Carpenters measure accurately with a tape to minimize wood wastage and enhance productivity in woodworking projects. Labor rate x overhead rate x labor hours + material costs determine the overall project price.

Wood Measurement Techniques

Wood measurement techniques are crucial for accurately assessing the materials required for your woodworking project. This includes understanding the dimensions and shapes of the wood pieces needed, which will directly impact the material costs. Precise measurement is essential to ensure that you purchase the correct quantity of wood and avoid wastage.

Calculating Material Cost

Once you have determined the specific measurements for your woodworking project, calculating material costs involves a few key steps. First, you need to identify the type and quantity of wood required. Then, you can estimate the cost per unit of wood and multiply it by the total quantity needed. Be sure to consider any additional materials, such as adhesives or finishing products, when calculating the overall material cost.

It’s important to factor in any potential waste or offcuts when determining the material cost. By accounting for these additional materials, you can ensure that your project stays within budget and avoid unexpected expenses.

Understanding Overhead Costs

When calculating the cost of woodwork, it’s crucial to consider overhead costs. These are the indirect expenses incurred in running your woodworking business beyond the direct materials and labor costs. Understanding and factoring in overhead costs is vital for accurately pricing your woodwork projects and ensuring profitability.

Importance Of Overhead Costs

Overhead costs play a significant role in determining the overall expenses of your woodworking projects. They encompass various expenses such as rent, utilities, insurance, equipment maintenance, and administrative costs. Failing to account for these expenses could lead to underpricing your projects, ultimately impacting your bottom line and sustainability of your business.

Including Overhead Costs In Pricing

Integrating overhead costs into your pricing strategy is essential to cover all expenses and generate a reasonable profit margin. To incorporate overhead costs, calculate the total expenses over a specific period and allocate them to individual woodwork projects based on their share of the overall business activities. This ensures that overhead costs are distributed proportionally, enabling you to set competitive yet profitable prices for your woodworking services.

Price Calculation Strategies

To calculate woodwork costs, multiply the width and height of all sides to be coated, including the top. Carpenters can measure work using a measuring tape for accuracy and productivity. Labor rate x overhead rate x labor hours + material cost equal the project price for pricing woodworking projects efficiently.

Formula For Pricing Woodworking Projects

Labor rate x overhead rate x labor hours + material cost = project price.

To determine your hourly rate, multiply your overhead rate by your labor rate and add that number back to the labor rate.

Determining Project Price

Carpenters use a measuring tape to measure length to complete the work clean and accurately.

This results in less wood loss, high productivity, and accuracy in woodwork projects.

Effective Wood Work Pricing

Tips For Accurate Cost Estimation

Accurately estimating the cost of woodwork projects is crucial for both carpenters and clients. To ensure you calculate the cost of woodwork accurately, consider the following tips:

- Measurements: Take precise measurements of the woodwork project using a measuring tape. Multiply the width and height of all sides to be coated, including the top.

- Material Cost: Determine the cost of materials required for the woodwork project. Consider the type of wood, quality, and quantity needed.

- Labor Hours: Estimate the labor hours required for the project. Factor in the complexity of the design, construction techniques, and any additional customization.

- Overhead: Consider the overhead costs such as utilities, rent, tools, and equipment maintenance. Calculate the overhead per unit to include in the final pricing.

- Fees: Factor in any additional fees or charges, such as permits, transportation, or subcontractor fees that may be applicable.

Avoiding Underpricing And Overpricing

It is essential to strike the right balance when pricing your woodwork projects to avoid underpricing or overpricing. Underpricing can undermine your profitability, while overpricing can lead to losing potential clients. Consider the following to ensure you set the right pricing:

- Market Research: Conduct thorough market research to determine the average rates for similar woodwork projects in your area. This will provide a benchmark to set competitive pricing.

- Calculate Costs: Calculate all the costs involved in the project, including materials, labor, overhead, and fees. Use a formula such as labor rate x overhead rate x labor hours + material cost to determine the project price.

- Value Proposition: Highlight the unique value you bring to the table, whether it’s exceptional craftsmanship, attention to detail, or timely delivery. Emphasize these factors when discussing pricing with clients.

- Client Budget: Understand the client’s budget and expectations. Tailor your pricing accordingly, taking into consideration the quality and complexity of the woodwork project.

- Communication: Clearly communicate the cost breakdown and justification for your pricing to clients. Address any concerns or questions they may have to build trust and transparency.

By following these tips and avoiding underpricing or overpricing, you can ensure accurate cost estimation for your woodwork projects. Remember, accurate pricing is key to a successful and profitable woodworking business.

Utilizing Tools For Cost Calculation

Calculating the cost of woodwork projects can be made easier by utilizing labor rates, overhead costs, material expenses, and hourly rates. By using a labor rate multiplied by the overhead rate and labor hours, along with material costs, you can accurately determine the project price.

For precision, carpenters use measuring tapes to minimize wood waste and ensure high productivity.

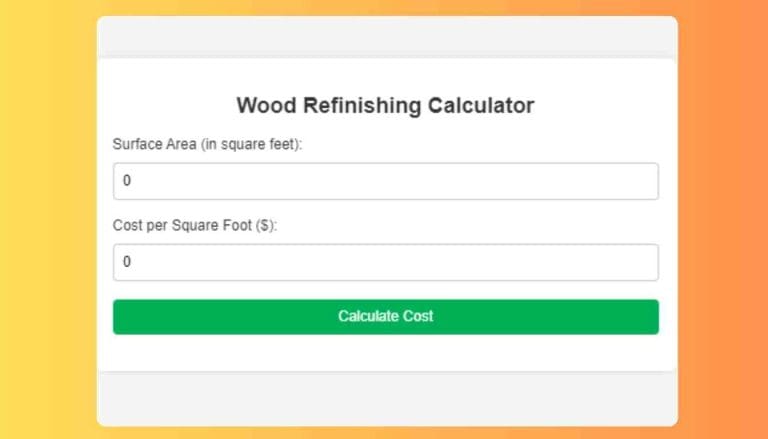

Calculating the cost of woodwork projects can be a challenging task. Fortunately, there are several tools available that can assist you in estimating costs accurately. By utilizing tools such as woodworking pricing calculators, hourly rate calculators, and online resources for pricing guidance, you can ensure that you are charging fair and competitive prices for your woodworking services.

Woodworking Pricing Calculators

Woodworking pricing calculators are valuable tools that can help you determine the appropriate price for your woodworking projects. These calculators take into account factors such as materials, labor hours, overhead costs, and profit margins to generate a comprehensive pricing estimate. By inputting the relevant details of your project into the calculator, you can obtain a realistic cost estimation that takes various factors into consideration.

Hourly Rate Calculators

Hourly rate calculators are useful tools that can help you determine the appropriate hourly rate for your woodworking services. These calculators consider factors such as your desired profit margin, overhead costs, and estimated labor hours to calculate the ideal hourly rate that allows you to cover your expenses and generate a reasonable profit. By using an hourly rate calculator, you can ensure that you are charging a fair price for your time and expertise.

Online Resources For Pricing Guidance

There are various online resources available that can provide valuable guidance and insights into pricing your woodworking projects. These resources include industry websites, forums, and blogs where experienced woodworkers share their knowledge and expertise. By exploring these online resources, you can gather useful tips and advice on how to calculate costs, set prices, and navigate the woodworking market effectively.

In conclusion, utilizing tools for cost calculation is essential for accurately pricing your woodworking projects. Woodworking pricing calculators, hourly rate calculators, and online resources for pricing guidance can help you determine fair and competitive prices. By utilizing these tools, you can ensure that you are charging appropriately for your services and maximizing your profitability in the woodworking industry.

Frequently Asked Questions For How To Calculate Wood Work Cost

How Do You Calculate Wood Work?

To calculate woodwork, multiply the width and height of all sides to be coated (including the top). Carpenters use measuring tape to measure length for accurate work and less wood loss, resulting in higher productivity. To price woodworking projects, use the formula: labor rate x overhead rate x labor hours + material cost = project price.

How Do Carpenter Measure Their Work?

Carpenters measure their work using a measuring tape to ensure precision and efficiency.

How Do You Calculate Wood For A Project?

To calculate wood for a project, multiply the width and height of all sides to be coated. Carpenters use measuring tape for accuracy and efficiency. For pricing, use the formula: Labor rate x overhead rate x labor hours + material cost = project price.

How Can I Accurately Calculate The Cost Of Woodwork?

To accurately calculate the cost of woodwork, multiply the width and height of all sides to be coated (including the top) to get the total surface area. Then, multiply by the cost per square foot to get the total cost.

Conclusion

Calculating the cost of woodwork is an essential step in any woodworking project. By understanding the labor, material, overhead, and fees involved, you can accurately price your projects. Remember to consider factors such as the dimensions and type of wood you’ll be using to determine the total cost.

Using the formula of labor rate x overhead rate x labor hours + material cost, you can calculate the project price. By following these guidelines, you’ll be able to estimate the cost of your woodworking projects more effectively and ensure that you’re pricing your work accurately.