How to Tap Hardened Steel: Master the Technique for Lasting Results

To tap hardened steel, use a carbide tap and apply steady pressure while cutting the threads. Working with hardened steel requires precision and patience to achieve accurate results.

When tapping the steel, use a cutting fluid to reduce heat buildup and prolong the lifespan of the tap. Additionally, ensure the drill press or tapping machine is securely set to prevent any vibrations that could damage the tap or the workpiece.

Understanding the proper techniques and tools for tapping hardened steel is crucial for achieving successful results in metalworking projects. With the right approach, you can effectively tap hardened steel and create threaded holes for various applications.

Understanding The Characteristics Of Hardened Steel

Hardened steel is known for its exceptional strength and resistance to wear, making it a popular choice for industrial applications such as machining, toolmaking, and automotive manufacturing. Some of the key properties of hardened steel include:

- High tensile strength

- Excellent wear resistance

- Corrosion resistance

- Toughness

- Dimensional stability

These properties make hardened steel a valuable material for producing durable and long-lasting components.

Tapping hardened steel presents unique challenges due to its hardness and toughness. Some of the main challenges include:

- High cutting forces required

- Tool wear and breakage

- Difficulty in chip evacuation

- Heat generation during tapping

- Risk of surface damage

Addressing these challenges requires specialized tools, techniques, and a thorough understanding of the material’s behavior during the tapping process.

Selecting The Right Tools For Tapping Hardened Steel

Tapping hardened steel requires precision and the right tools to achieve accurate and efficient results. Choosing the appropriate tools for tapping hardened steel involves considering the tap material, correct tap geometry, and the importance of lubrication. Each of these factors plays a crucial role in the success of the tapping process.

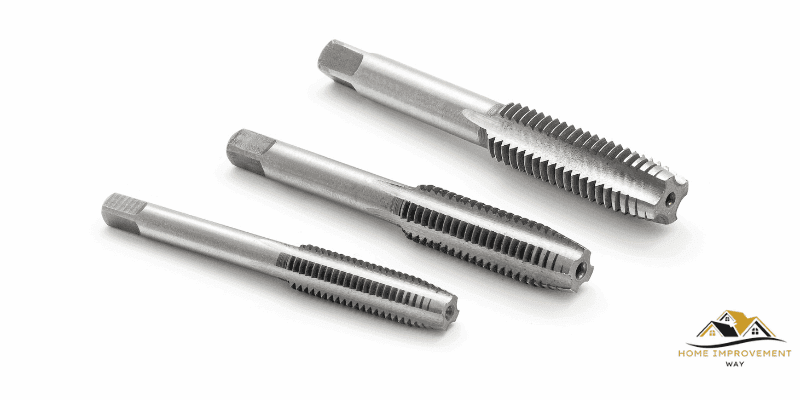

Choosing The Appropriate Tap Material

When tapping hardened steel, selecting the right tap material is essential for achieving the desired outcome. High-speed steel (HSS) taps are commonly used for this purpose due to their durability and heat resistance. Cobalt steel taps are another popular choice for tapping hardened steel, as they can withstand the high cutting forces involved in the process. These materials offer superior hardness and toughness, making them ideal for tapping hardened steel without compromising on the tool’s performance.

Selecting The Correct Tap Geometry

The correct tap geometry is critical for tapping hardened steel with precision. Spiral point taps are well-suited for this application, as they effectively push the chips forward, preventing clogging and ensuring smooth performance. Form taps, on the other hand, create threads through a cold forming process, reducing the risk of chip buildup and tool wear. By selecting the right tap geometry for the specific application, the tapping process can be optimized for efficiency and accuracy.

Understanding The Importance Of Lubrication

Lubrication plays a vital role in tapping hardened steel, as it helps reduce friction and heat generation during the cutting process. Applying a high-quality cutting fluid or tapping oil is crucial for prolonging the tool life and achieving clean, precise threads. Proper lubrication also aids in chip evacuation, preventing chip buildup and potential damage to the workpiece. Understanding the significance of lubrication and using the appropriate lubricants can significantly enhance the performance and longevity of the tapping tools.

Mastering The Technique For Tapping Hardened Steel

When it comes to working with hardened steel, tapping can be a challenging task that requires precision and expertise. Mastering the technique for tapping hardened steel is crucial for achieving clean, accurate threads without damaging the material. In this guide, we’ll explore the essential steps and best practices for tapping hardened steel to ensure successful and efficient results.

Proper Drilling And Hole Preparation

Before tapping hardened steel, it’s important to ensure that the drilling and hole preparation are carried out with utmost precision. First and foremost, the drill bits used for creating pilot holes in hardened steel must be specifically designed for the material. Using high-speed steel or cobalt drill bits can provide the necessary hardness and durability to effectively penetrate hardened steel without getting dull or breaking.

Next, the pilot holes should be drilled at a slower speed, especially when working with highly dense and tough hardened steel. This allows for better control and accuracy while preventing overheating that can adversely affect the hardness of the material.

Best Practices For Tapping Hardened Steel

- Choose the right tap type: When tapping hardened steel, it’s crucial to select taps made from high-speed steel, cobalt, or carbide. These materials offer superior strength and heat resistance, essential for cutting threads into hardened steel without compromising the tool’s integrity.

- Apply cutting fluid: Using a high-quality cutting fluid during the tapping process is essential for maintaining proper lubrication and reducing heat buildup. This not only extends the tool life but also ensures smoother cutting performance while minimizing the risk of tool breakage.

- Use the correct tapping speed: Efficient tapping of hardened steel requires a controlled and consistent tapping speed. Opt for slower rotational speeds to prevent overheating and promote chip evacuation, leading to cleaner and more precise threads.

Importance Of Maintaining Consistent Speed And Pressure

When tapping hardened steel, maintaining a consistent speed and pressure is paramount. Applying uniform pressure throughout the tapping process helps to prevent the tap from binding or breaking, ensuring smooth and uninterrupted cutting. Additionally, adhering to a steady rotational speed prevents overheating and promotes efficient chip evacuation, resulting in clean and accurate threads.

Overcoming Common Challenges When Tapping Hardened Steel

When tapping hardened steel, machinists often encounter various challenges that can affect the efficiency and precision of the process. Overcoming these common hurdles is essential for achieving high-quality results. Understanding how to navigate the obstacles associated with tapping hardened steel can significantly improve the overall efficiency and productivity of the machining process.

Dealing With Tool Breakage And Wear

Tool breakage and wear are common occurrences when tapping hardened steel due to the extreme hardness of the material. To minimize these issues, it is crucial to use high-quality taps specifically designed for tapping hardened steel. Opt for carbide or cobalt taps with appropriate coatings that enhance their durability and resistance to wear. Additionally, ensuring the proper alignment and concentricity of the tapping operation will help prevent excessive tool wear and breakage.

Strategies For Chip Evacuation

Efficient chip evacuation is crucial for successful tapping of hardened steel, as chip accumulation can lead to tool damage and thread imperfections. Utilizing high-pressure coolant systems can aid in chip removal by flushing out debris from the tapping zone. Implementing proper chip evacuation strategies, such as using spiral flute taps or through-tool coolant delivery systems, can help maintain a clean and unobstructed tapping environment, reducing the risk of chip-related complications.

Tips For Avoiding Thread Damage

Protecting the integrity of the threads during the tapping process is essential for ensuring the functionality and strength of the finished components. To avoid thread damage, carefully control the speed and feed parameters to prevent excessive forces that can compromise the thread quality. Additionally, employing thread forming taps instead of traditional cutting taps can minimize the risk of thread distortions and improve the overall thread finish. Prioritizing proper lubrication and tool maintenance also plays a key role in minimizing thread damage and preserving the quality of the tapped threads.

Ensuring Lasting Results When Tapping Hardened Steel

Tapping hardened steel can be a challenging endeavor, but with the right approach, it can yield lasting and efficient results. Proper cleaning and inspection, implementing preventive maintenance strategies, and maximizing tool life and efficiency are crucial elements for achieving success in tapping hardened steel.

Proper Cleaning And Inspection

Before tapping hardened steel, it’s essential to ensure that the workpiece and the tapping tools are thoroughly cleaned and free from any contaminants. Using a mild solvent and a clean cloth, remove any oil, grease, or debris from the workpiece and the tapping tools. Inspect the tools for any signs of wear or damage, and replace them if necessary to prevent any potential issues during the tapping process.

Implementing Preventive Maintenance Strategies

Implementing a proactive approach to maintenance is crucial for ensuring lasting results when tapping hardened steel. Establishing a regular maintenance schedule for the tapping tools and equipment is essential. This includes regularly checking for wear, regrinding and re-sharpening tools as needed, and applying appropriate lubricants to reduce friction and prolong tool life.

Maximizing Tool Life And Efficiency

To maximize the tool life and efficiency when tapping hardened steel, it’s important to use high-quality cutting tools specifically designed for this purpose. Additionally, optimizing cutting speeds and feeds and using the proper cutting fluid can significantly impact the overall performance and longevity of the tools. Regularly monitoring the cutting process and making adjustments as needed can also help in achieving maximum tool efficiency and prolonged lifespan.

Frequently Asked Questions Of How To Tap Hardened Steel

How Can I Tap Hardened Steel Without Breaking The Tool?

To tap hardened steel without breaking the tool, you should use high-speed steel (HSS) taps with a slow speed and plenty of cutting oil. It’s essential to use the right technique and tools, as well as to maintain a straight and steady application of force during the tapping process.

What Are The Best Tapping Techniques For Hardened Steel?

The best tapping techniques for hardened steel involve using slow rotational speeds, plenty of cutting fluid, and a peck tapping method to ensure efficient chip removal and prevent tap breakage. It’s also important to choose the correct tap size, use a high-quality lubricant, and consider pre-drilling a hole to make the process easier.

Why Is It Important To Use Cutting Oil When Tapping Hardened Steel?

Using cutting oil when tapping hardened steel is crucial as it provides lubrication, reduces friction and heat, and helps in chip evacuation. This not only extends the life of the tap but also improves the quality of the threads and reduces the risk of tool breakage.

Conclusion

To sum up, tapping hardened steel requires the right tools, techniques, and patience. By following the steps outlined in this guide, you can successfully tap into hardened steel and complete your projects with precision and efficiency. Remember to use lubrication, work at the right speed, and maintain sharp tools for optimum results in your metalworking endeavors.