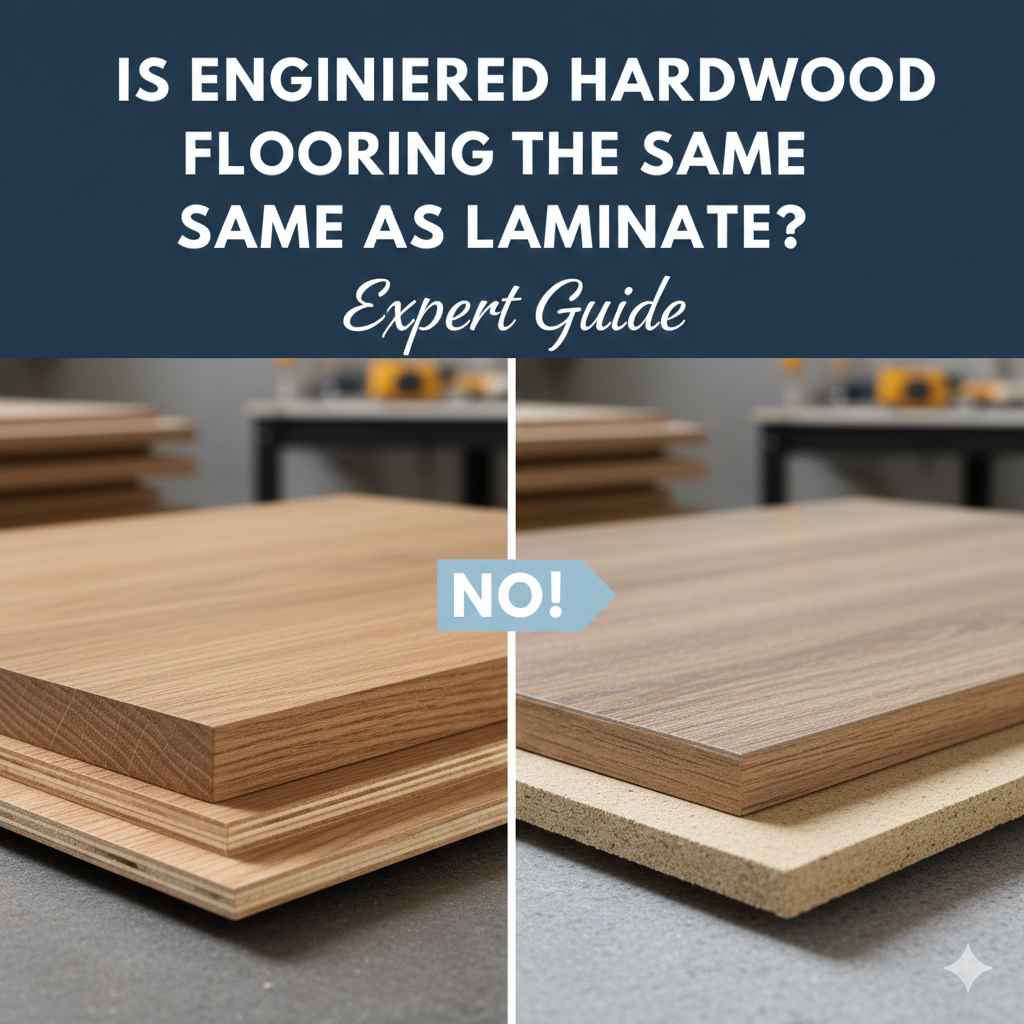

Is Engineered Hardwood Flooring The Same As Laminate?

No, engineered hardwood flooring is NOT the same as laminate flooring. While both offer wood-look options, engineered wood has a real hardwood top layer for authentic appeal and longevity, whereas laminate is an image layer glued onto an HDF core. They differ significantly in composition, feel, and lifespan.

Picking out new flooring can feel like learning a new language. You see terms like “engineered” and “laminate,” and it’s easy to mix them up! They both look nice, but are they twins, or distant cousins? If you are standing in the aisle overwhelmed, you are not alone. We’re going to clear this up right now. Knowing the difference is key to making a smart choice that fits your budget and lasts for years. We will break down exactly what makes each material unique, using simple steps you can follow. Get ready to feel confident about your flooring choice!

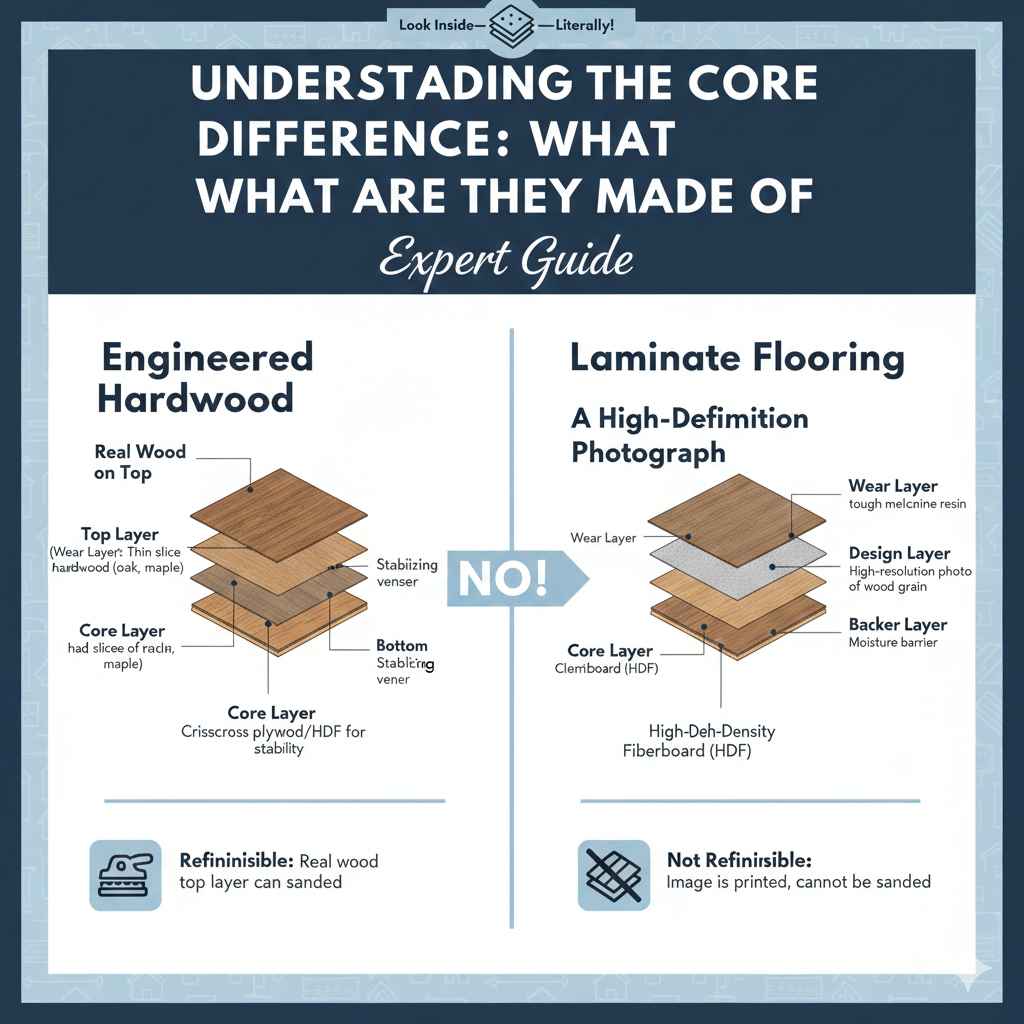

Understanding the Core Difference: What Are They Made Of?

The easiest way to tell engineered hardwood and laminate apart is by looking inside—literally! Think of them like sandwiches. They stack different materials on top of each other, but the ingredients are worlds apart. This composition affects everything from how they feel underfoot to how much they cost.

Engineered Hardwood: Real Wood on Top

Engineered hardwood is the champion when you want the authentic look and feel of solid wood but perhaps need a bit more stability for areas where moisture might be an issue, like a basement. It’s built in layers, like a professional skateboard deck.

The Layered Construction of Engineered Wood

An engineered wood plank has three main parts, which gives it strength and beauty:

- Top Layer (The Wear Layer): This is the part you see and walk on. It is a thin slice—usually 1/8 inch to 1/4 inch thick—of real hardwood, like oak, maple, or walnut. This is where the authentic wood grain comes from.

- Core Layer: This middle layer is usually made from plywood or high-density fiberboard (HDF). The layers of this core are glued together in a crisscross pattern. This specialized layering is what gives engineered wood its stability against moisture changes compared to solid hardwood.

- Bottom Layer (Backer): This is a balancing layer, often thin plywood or veneer, which helps prevent the plank from warping or cupping over time.

Because that top layer is real wood, you can refinish engineered hardwood. If deep scratches appear, a professional can sand and reseal that top veneer, making it look brand new again—a huge advantage!

Laminate Flooring: A High-Definition Photograph

Laminate flooring is the budget-friendly, highly durable option designed to mimic wood (or stone) beautifully. However, the look you see is entirely synthetic. It is a fantastic, modern product, but it is constructed completely differently from wood.

The Layered Construction of Laminate

Laminate planks are also layered, but the top layer is the crucial difference:

- Wear Layer: This is a clear, extremely tough topcoat, usually made of melamine resin. It resists scratches, fading, and spills exceptionally well.

- Design Layer: This is the visual star! It is a high-resolution photograph of wood grain, stone, or tile. Modern printing technology makes this layer incredibly convincing.

- Core Layer: This thick middle layer is almost always High-Density Fiberboard (HDF). HDF is wood dust and resin pressed together very tightly.

- Backer Layer: A final layer that helps stabilize the plank and protect it from moisture coming up from the subfloor.

If you’ve ever seen a deep scratch on laminate where you could see white or grey material underneath the picture, you’ve seen the wear layer fail and expose the design layer below. Because the image is printed, you cannot sand or refinish laminate.

Quick Comparison Table: Engineered Wood vs. Laminate

Let’s put the structure side-by-side so you can see the differences at a glance. Remember, the top layer is the deal-maker here!

| Feature | Engineered Hardwood | Laminate Flooring |

|---|---|---|

| Top Material | Real Wood Veneer (Actual Hardwood) | Synthetic Wear Layer over a Printed Image |

| Core Material | Plywood or HDF (Crisscross layers) | High-Density Fiberboard (HDF) |

| Refinishing Potential | Yes (Depending on veneer thickness) | No (Cannot sand the image off) |

| Moisture Resistance | Good (Better than solid wood, but still vulnerable) | Moderate (Resists surface spills, but the HDF core can swell if soaked) |

| Authenticity/Feel | Authentic wood feel and texture | Mimics wood; can sound hollow underfoot |

Deep Dive into Performance: What This Means for Your Home

Knowing the layers is one thing, but how do these differences affect your daily life? As a DIY homeowner, you need flooring that can handle traffic, kids, and the occasional spill without major drama.

Durability and Wear

This is often where homeowners get confused. Both are durable, but in different ways.

Engineered Hardwood Durability

Since engineered wood has real wood on top, its durability depends heavily on the thickness of that veneer. A thicker veneer means you can refinish it more times over the decades, extending its life significantly. However, if you have pets with long claws or heavy furniture dragging across it, that top wood layer can dent or scratch more easily than laminate’s tough synthetic layer.

Laminate Durability

Laminate excels at resisting superficial damage. That top resin layer is often harder than natural wood, making it excellent at resisting scratches from daily foot traffic, small toys, and everyday bumps. However, if a very sharp object punches through that wear layer, the printed image underneath is exposed, and the damage is permanent—you can’t repair it beyond maybe using a specific touch-up kit.

Moisture Resistance: A Crucial Factor

If you are installing flooring in a kitchen, laundry room, or bathroom, moisture matters a lot. Neither material is truly waterproof like tile, but one handles humidity better than the other.

- Engineered Hardwood: Due to its plywood core, engineered wood handles humidity fluctuations better than solid hardwood. This means it’s less likely to expand and contract significantly with seasonal changes in the air. However, standing water or chronic dampness will ruin the real wood veneer and swell the core.

- Laminate: The HDF core of laminate is essentially compressed wood fiber. If water sits on the seams or seeps into the core, the fibers will swell up, creating raised, ruined edges that cannot be flattened again.

Pro Tip: Always check the manufacturer’s specifications. Some newer, premium laminate products now include water-resistant cores, which perform better than older standard versions. Always research the specific product you are buying.

Installation Ease for the DIYer

Most homeowners tackle flooring installation to save money, so ease of installation is a major win. Both materials have vastly improved over the years.

- Click-Lock Systems: Both modern engineered hardwood and laminate flooring usually use a click-and-lock floating floor system. This means the planks snap together edge-to-edge without needing glue or nails down into the subfloor (though some engineered options can still be glued down).

- Subfloor Prep: For both types, preparing a clean, level subfloor is the most important—and often most time-consuming—step. You can find excellent guides on subfloor preparation from organizations like the National Wood Flooring Association (NWFA).

- Tools: Both usually require a simple chop saw or circular saw to cut planks to size. For laminate, you can often use a specialized scoring knife for straighter cuts, which creates less dust than sawing.

Overall, laminate is often considered slightly easier to install because the planks are generally thinner and the locking mechanism might be more forgiving than the thicker engineered wood layers.

Aesthetics and Authenticity: Which Looks More Real?

This is where the “real wood vs. image” difference becomes obvious to the eye and the touch.

The Engineered Hardwood Advantage

If you value authentic depth and texture, engineered hardwood wins every time. Because the top layer is wood:

- The grain patterns are natural and non-repeating.

- You can feel the slight natural variations in texture.

- It ages gracefully. Over time, it may deepen in color (patina) just like a solid wood floor.

When you sell your home later, buyers often perceive engineered wood as a higher-value upgrade compared to laminate.

The Laminate Look

Modern high-definition printing has made laminate look astonishingly real from a distance. However, up close, or in rooms with a lot of natural light:

- You might notice a repeating pattern in the grain if you look at several planks side-by-side.

- The surface texture is usually very uniform, lacking the slight imperfections and depth of real wood.

- Laminate can sometimes sound hollow or clicky when walked on, especially if the underlayment padding isn’t thick enough.

Laminate offers incredible style variety—you can get convincing dark slate or highly distressed barn wood looks that would be very expensive or impossible to find in real engineered wood.

Cost Considerations: Budgeting Your Project

When comparing flooring options, price is usually a major deciding factor for DIYers. Generally, materials break down like this, from least to most expensive (per square foot, installed): Laminate < Engineered Hardwood < Solid Hardwood.

Laminate Flooring Costs

Laminate is typically the most affordable wood-look option available. Entry-level laminate might cost just $1.50 to $3.00 per square foot for materials. High-end, very thick, textured laminate can push closer to $5.00 per square foot, but it remains a fantastic value proposition.

Engineered Hardwood Costs

Engineered wood costs more because you are paying for a real slice of lumber. Expect prices to range widely based on the quality of the veneer:

- Entry-level engineered wood with a very thin veneer might start around $4.00 per square foot.

- High-quality, thicker veneer options (which can be refinished multiple times) often cost $7.00 to $12.00 per square foot or more.

Financial Confidence Note: While laminate saves money upfront, remember that engineered wood has potential resale value and the ability to be refinished, offering better long-term value if properly maintained. Consult local real estate resources on how different flooring materials affect home appraisals.

Where Should You Install Each Type? (Room-by-Room Guide)

Deciding where to use which product makes your project much simpler. The location of the room often dictates the best choice based on potential moisture and wear.

Best Spots for Engineered Hardwood

Because it offers true wood aesthetic and greater stability than solid wood, engineered hardwood is great for areas where you want luxury without the extreme sensitivity of solid planks:

- Living Rooms and Dining Rooms: Where appearance matters most.

- Bedrooms: Low spill risk, high comfort factor.

- Main Floor Hallways: Needs durability, but you still want that real wood look.

Best Spots for Laminate Flooring

Laminate thrives in high-traffic, high-activity areas where scratch resistance and budget are top priorities:

- Playrooms: Excellent resistance to toys and general wear.

- Home Offices: Good stability for rolling chairs (use floor mats for chairs with hard wheels!).

- Below-Grade (Basements): While not completely waterproof, modern laminate is often preferred over real wood products in areas with minor humidity risks, provided the concrete subfloor is properly vapor-sealed.

Caution: While many manufacturers make water-resistant laminate, it is still generally recommended to avoid using any wood-based floating floor in full bathrooms where the floor may be constantly wet or directly exposed to standing shower water.

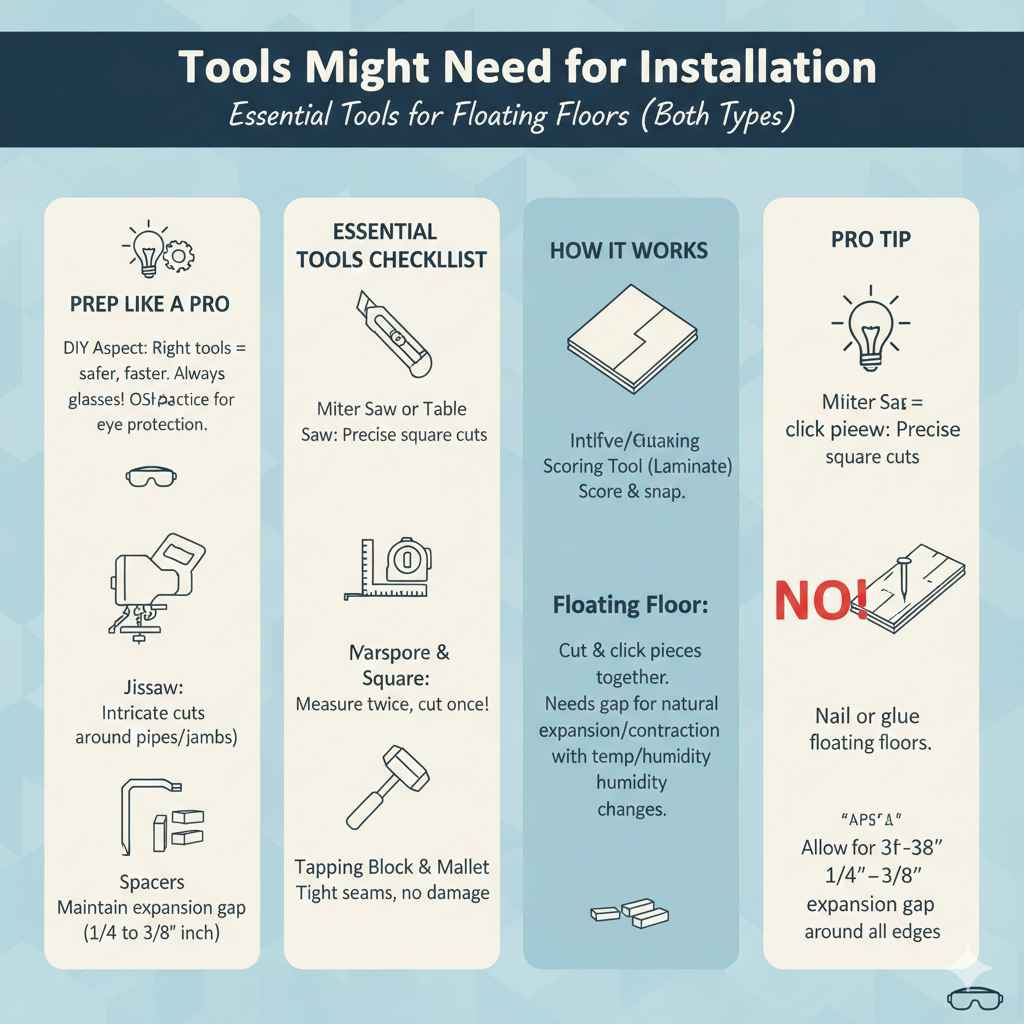

Tools You Might Need for Installation (The DIYer’s Checklist)

Since we are focusing on the DIY aspect, having the right tools makes the job safer and faster. Whether you choose engineered wood or laminate, the installation process is very similar, following the steps of cutting and clicking pieces together.

Essential Tools for Floating Floors (Both Types)

Before you start, make sure your workspace is ready. Always wear safety glasses when cutting! This simple gear is your most important tool for eye protection, following best practices emphasized by safety organizations like OSHA.

- Miter Saw or Table Saw: Necessary for making precise, square cuts across the plank width. A miter saw is often easier for beginners.

- Utility Knife/Scoring Tool: Essential for laminate; used to score the top surface before snapping the plank.

- Jigsaw: Needed for making intricate cuts around door jambs, pipes, or irregularly shaped areas.

- Tape Measure and Square: Measure twice, cut once! A speed square helps ensure your cuts are perfectly 90 degrees.

- Tapping Block and Mallet: Used gently to tap the locking edges of the planks together tightly without damaging the bevels.

- Pry Bar (or Pull Bar): Essential for those last row cuts where you need to pull the plank tight against the wall.

- Spacers: Small wedges used to maintain the necessary expansion gap (usually 1/4 to 3/8 inch) between the floor and all walls or fixed objects.

Remember, never nail or glue a floating floor directly to the subfloor. The floor needs a small gap around the edges to expand and contract naturally as temperature and humidity shift.

Frequently Asked Questions (FAQ)

Q1: Can engineered hardwood flooring truly last as long as solid hardwood?

A: It depends on the veneer thickness. If the veneer is thick (say, 4mm or more), and you take good care of it, it can last 40 to 70 years and be refinished several times. Thinner veneers might only last 10–20 years before they can no longer be sanded.

Q2: If I get a scratch on laminate, can I fix it?

A: Minor surface scratches can often be hidden using specific laminate repair kits, which involve melting wax filler into the scratch. However, deep gouges that penetrate the image layer cannot be truly restored; the plank usually needs to be replaced.

Q3: Which flooring feels warmer underfoot?

A: Engineered hardwood generally feels slightly warmer because the top layer is actual wood, which is a natural insulator. Laminate, with its high-density fiberboard core, can sometimes feel cooler, especially over a cold concrete slab.

Q4: Can I install engineered wood over a radiant heat system?

A: Yes, many engineered hardwood products are specifically designed to work with radiant (in-floor) heating systems, provided you follow strict temperature guidelines from the manufacturer. Standard laminate is often okay, but you must verify its specific installation guidelines.

Q5: Is laminate completely waterproof against big spills?

A: No. Standard laminate is highly water-resistant on the surface, meaning it handles quick spills well. However, the HDF core will swell and buckle if water is left pooled on it for hours. Look for “Waterproof Laminate” options for better protection in kitchens.

Q6: How much more expensive is engineered wood than the cheapest laminate?

A: Typically, engineered hardwood costs about 1.5 to 3 times more than basic, budget laminate per square foot for materials. The price gap closes significantly when comparing high-end laminate to standard engineered wood.

Conclusion: Making Your Confident Choice

So, is engineered hardwood flooring the same as laminate? Absolutely not. They are fundamentally different materials serving slightly different purposes in the world of home design. Engineered hardwood offers authentic, refinishable real wood beauty, making it an investment in the long-term look and feel of your home.

Laminate offers superb, cost-effective durability, relying on modern technology to mimic wood convincingly while resisting many daily surface hazards better than real wood. Your choice boils down to what you value most: real wood authenticity and refinish potential (Engineered Hardwood), or budget-friendly, high-scratch resistance (Laminate).

Take your time to look at samples in the light where you plan to install them. Feel the texture, listen to how they sound when you tap them, and know that no matter which path you choose, with careful preparation and attention to the expansion gaps, you are installing a beautiful, functional floor you built yourself. That feeling of accomplishment is always the best part of any DIY project!