Is There a White Stain for Pressure-Treated Wood

Many folks wonder, is there a white stain for pressure-treated wood? It can seem tricky to find the right finish for this type of wood, especially when you want a bright, clean look. Beginners often feel confused about what works best.

Don’t worry! This guide will show you exactly how to achieve that look simply and effectively. We’ll walk through everything you need to know to make your wood project beautiful.

Understanding White Stains for Pressure-Treated Wood

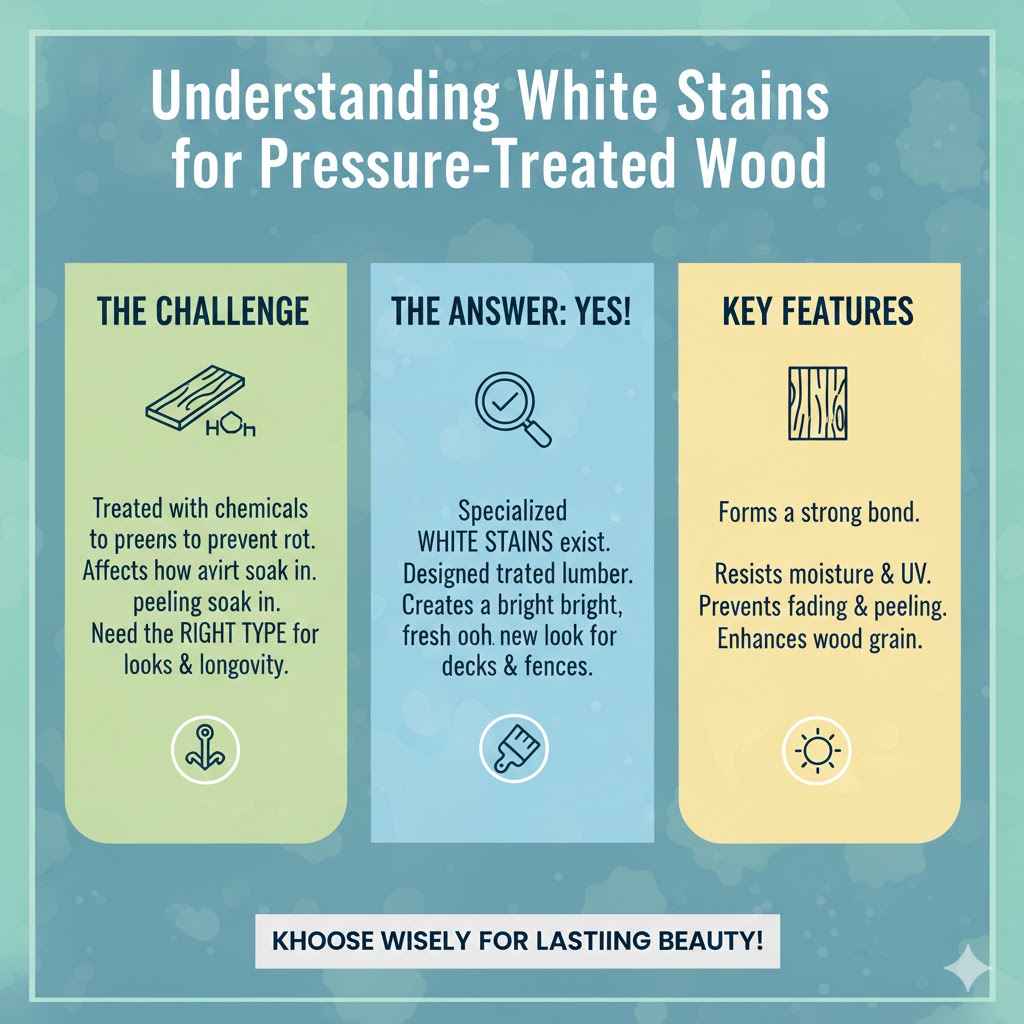

When you’re working with pressure-treated wood, you might want to give it a fresh look. One popular choice is a white stain. This can make decks, fences, or other outdoor structures look bright and new.

But, it’s important to know that not all stains are created equal, especially when it comes to pressure-treated lumber.

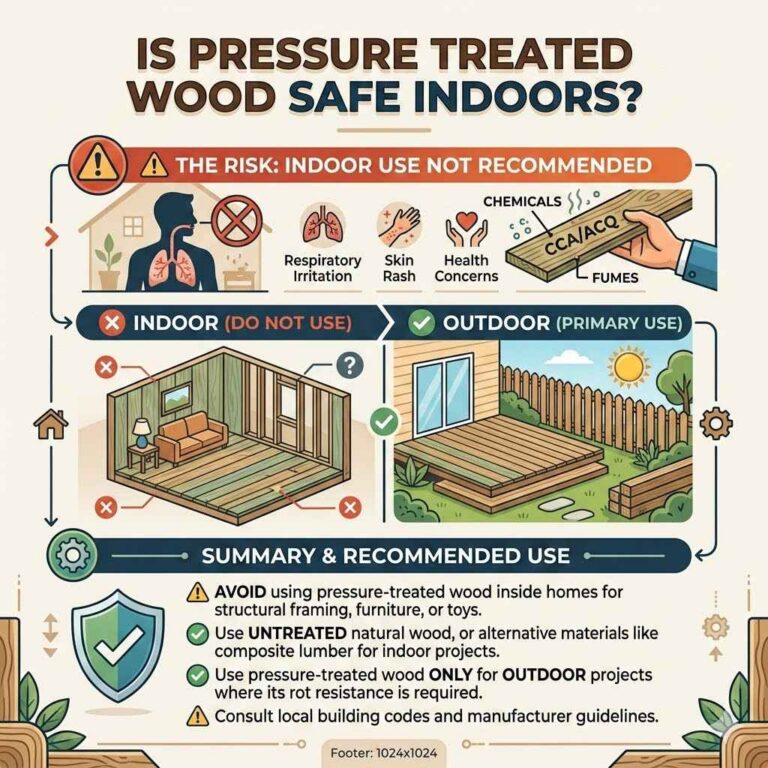

The wood is treated with chemicals to protect it from rot and insects. These chemicals can affect how stains soak into the wood and how they look once applied. This is why knowing the right type of stain to use is key.

You want a finish that looks good and lasts a long time.

So, the question Is There a White Stain for Pressure-Treated Wood? has a simple answer: yes, but you need to pick the right kind. Let’s explore what makes certain stains suitable and what to avoid.

Types of Stains and Their Suitability

There are a few main types of wood stains: penetrating stains, surface stains, and solid stains. Each works differently on wood. For pressure-treated wood, we need to consider how these interact with the treatment process.

Penetrating Stains

Penetrating stains soak into the wood fibers. This gives a natural look and allows the wood grain to show through. They are great for a more natural finish.

However, they might not cover the green tint that some new pressure-treated wood has. They also require more frequent reapplication than other types.

Surface Stains

Surface stains create a thin layer on top of the wood. They offer more color than penetrating stains but still allow some wood grain to be visible. They can provide better coverage for imperfections or unwanted color.

For white stains, a surface stain can give a more opaque look.

Solid Stains (Opaque Stains)

Solid stains are like a thin paint. They completely hide the wood grain and the natural color of the wood. This makes them an excellent choice if you want a uniform white finish and want to cover up any variations in the pressure-treated wood, including the greenish hue.

When looking for a white stain for pressure-treated wood, solid stains are often the best bet for a true white appearance. They provide the most coverage and a clean, painted-like finish.

Why Solid Stains Work Best for White Finishes

Pressure-treated wood often has a greenish tint from the treatment chemicals. This tint can show through lighter stains, giving them a less-than-pure white appearance. Solid stains, by their nature, completely cover the underlying wood.

This means they can effectively hide the green color and provide a bright, consistent white surface.

Solid stains also offer good protection against UV rays and weather. This is important for outdoor projects like decks and fences that are exposed to the elements. When you choose a quality solid stain, you’re getting both a beautiful color and a protective layer.

Preparing Pressure-Treated Wood for Staining

Proper preparation is crucial for any staining project, especially with pressure-treated wood. Rushing this step can lead to a finish that doesn’t look good or doesn’t last. Following these steps will help ensure your white stain looks its best.

Allowing the Wood to Dry

This is a very important first step. New pressure-treated wood is wet from the treatment process. You need to let it dry out completely before you can stain it.

Staining wet wood can cause problems like peeling, flaking, and an uneven finish.

How long does it take to dry? This can vary a lot depending on the weather, humidity, and how much treatment the wood absorbed. A good rule of thumb is to wait at least 48 hours after installation in dry, sunny weather.

For more humid or cooler conditions, you might need to wait several weeks, or even a couple of months.

A simple test is to place a few drops of water on the wood. If the water beads up, the wood is still too wet. If the water soaks in quickly, it’s likely ready.

You can also use a moisture meter to get a precise reading. The moisture content should be below 15% before you stain.

Cleaning the Wood

Once the wood is dry, it needs to be cleaned. Over time, wood can collect dirt, mildew, and mold. This debris can prevent the stain from adhering properly and can show through the finished coat.

You can use a stiff brush and a cleaning solution. There are special wood cleaners available, or you can make your own with mild detergent and water. For tougher jobs, a pressure washer on a low setting can be used, but be careful not to damage the wood fibers.

Always rinse the wood thoroughly after cleaning.

Sanding

Sanding helps create a smooth surface for the stain to adhere to. It also removes any loose fibers or rough spots. For pressure-treated wood, especially if it’s been exposed to the elements for a while, a light sanding is usually enough.

Use medium-grit sandpaper (around 80-100 grit) to start. Sand in the direction of the wood grain. After sanding, clean away all the dust with a broom, shop vacuum, or a damp cloth.

A clean surface is essential for a smooth stain application.

Choosing the Right White Stain Product

When you’re looking for a white stain specifically for pressure-treated wood, here’s what to keep in mind:

- Product Label: Always check the product label. Look for stains that are specifically recommended for decks, fences, or outdoor wood structures. Many products will state if they are suitable for pressure-treated wood.

- Solid or Semi-Solid: As discussed, solid stains offer the best coverage for a true white. If you want a little bit of wood texture to show, a semi-solid stain might work, but it will offer less opacity.

- Water-Based vs. Oil-Based: Both have pros and cons. Water-based stains are easier to clean up and often have lower VOCs. Oil-based stains can penetrate deeper and sometimes offer more durability. For white stains, water-based solid stains are very popular and effective.

- UV Protection: Look for stains that offer UV protection. This will help prevent the white color from fading or turning yellow when exposed to sunlight.

Don’t be afraid to ask for help at your local paint or hardware store. They can often recommend specific brands or types of white stains that work well for pressure-treated wood.

Application Tips for a Flawless White Finish

Applying the stain correctly is just as important as choosing the right product. These tips will help you get a beautiful, even white coat.

Test Area

Before you stain your entire project, always test the stain in an inconspicuous area. This allows you to see how the color looks on your specific wood and check for any unexpected reactions. It also gives you a chance to practice your application technique.

Application Tools

You can use a brush, roller, or sprayer for staining. For solid stains, a good quality synthetic brush or a roller designed for exterior use works well. If you’re using a sprayer, make sure it’s set up for stain and that you have an even spray pattern.

Always back-brush or back-roll to ensure the stain is worked into the wood.

Staining Technique

Work in small sections. Apply the stain evenly, brushing or rolling in the direction of the wood grain. Avoid applying too much stain at once, as this can lead to drips and an uneven finish.

If you see any drips, brush them out immediately.

For solid stains, you’ll likely only need one coat. However, if the wood is very absorbent or the coverage isn’t complete after the first coat, you might need a second. Apply the second coat after the first has dried according to the manufacturer’s instructions.

Drying Time

Always follow the drying and recoating times recommended by the stain manufacturer. Proper drying is essential for the stain to cure and provide its best protection and appearance. Avoid walking on or placing items on the stained surface until it is completely dry and cured.

Maintaining Your Stained Wood

Once your pressure-treated wood is stained white, it will look great. But like any outdoor surface, it will need some care to keep it looking its best. Regular maintenance will extend the life and beauty of your stain.

Periodically clean your stained wood. A soft brush and mild soap and water should be enough for most dirt and grime. For tougher spots, you might need a dedicated wood cleaner.

Rinse thoroughly after cleaning.

Inspect the stain every year. Look for any signs of wear, fading, or peeling. If you notice areas that need touching up, address them promptly.

You may need to reapply a coat of stain every few years, depending on the climate and the amount of wear the surface receives.

Frequently Asked Questions

Question: Can I stain pressure-treated wood immediately after buying it

Answer: No, you should not stain pressure-treated wood immediately. It needs to dry out first. Waiting for the wood’s moisture content to drop below 15% is crucial to prevent staining issues like peeling and poor adhesion.

Question: Will a white semi-solid stain work on pressure-treated wood

Answer: A white semi-solid stain can work, but it will offer less coverage than a solid stain. You might still see some of the wood’s original color or green tint through a semi-solid stain, making a solid stain a better choice for a pure white look.

Question: How do I know if my pressure-treated wood is dry enough to stain

Answer: You can test it by dripping water on the surface. If the water soaks in quickly, it’s likely dry. For a more accurate reading, use a wood moisture meter.

The moisture content should be below 15%.

Question: Can I use a regular house paint as a white stain on pressure-treated wood

Answer: It is not recommended to use regular house paint as a stain. Exterior stains are formulated to penetrate wood and flex with temperature changes. House paint can crack and peel more easily on outdoor wood surfaces.

Question: How often should I reapply white stain to my pressure-treated deck

Answer: The frequency of reapplication depends on the climate, sun exposure, and foot traffic. Generally, you might need to reapply every 2-5 years. Inspect the stain annually for signs of wear and tear.

Final Thoughts

Yes, there is a white stain for pressure-treated wood, and solid stains are your best option for a pure, bright white finish. Proper preparation, including drying, cleaning, and sanding, is key. Choose a quality solid stain designed for outdoor use, and apply it carefully.

With the right steps, you can achieve a beautiful and lasting white look for your wood projects.