Lvp Flooring Tools: Essential Picks for Perfect Installation

LVP flooring tools include essential equipment like cutters, spacers, and adhesive products. These tools ensure a smooth and efficient installation process.

Luxury Vinyl Plank (LVP) flooring has gained immense popularity due to its durability and aesthetic appeal. Proper installation is crucial for achieving a flawless finish, and using the right tools can make all the difference. Essential tools for LVP flooring projects include utility knives for precise cuts, spacers for maintaining even gaps, and tapping blocks to secure planks snugly together.

A measuring tape is also vital for accurate dimensions, while a flooring roller helps ensure proper adhesion. Investing in quality tools not only simplifies the installation but also enhances the longevity of your flooring. Selecting the right equipment sets the stage for a professional-looking result.

Introduction To Lvp Flooring

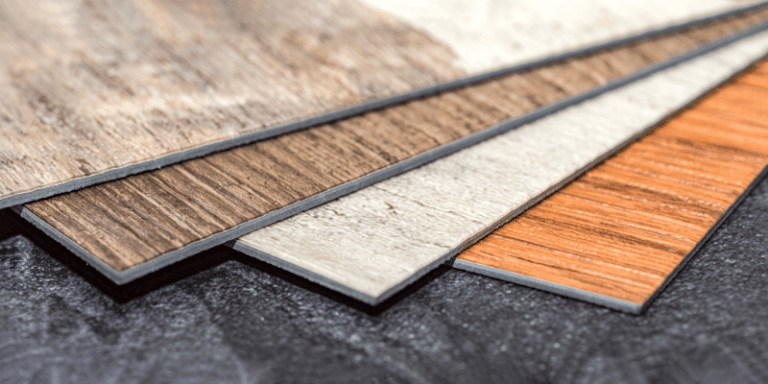

LVP flooring is gaining popularity for its many advantages. It offers a great look while being affordable. Homeowners love its durability and ease of maintenance. Many choose LVP because it can mimic natural wood or stone.

Installation of LVP flooring is straightforward. It often requires just a few basic tools. A utility knife, tape measure, and straight edge are essential. Most people can install it without professional help.

With a click-lock system, LVP is easy to assemble. No glue or nails are needed. This makes it an excellent choice for DIY projects.

Preparation Essentials

Using a measuring tape is crucial for accurate calculations. Measure the length and width of the area. Write down your measurements for reference. Always double-check your numbers to avoid mistakes.

A chalk line helps create straight and precise layouts. Snap the line to mark where the flooring will go. This ensures every plank is placed correctly. A good layout makes installation easier and faster.

Cutting Tools For Precision

A utility knife is perfect for quick cuts. It allows for easy adjustments and sharp blades. This tool is great for trimming edges and making precise cuts.

A flooring cutter offers efficiency and speed. It can handle large pieces of LVP flooring with ease. This tool reduces the need for multiple cuts. It provides a clean finish on edges, making installation smoother.

Both tools are essential for a successful flooring project. Choosing the right one can make all the difference.

Adhesive Application Gear

A notched trowel is essential for applying adhesive evenly. It helps create the right texture. This ensures proper bonding with LVP flooring. Choose a trowel with the right notch size for your adhesive.

The adhesive roller is another important tool. It helps create strong bonds between the flooring and the subfloor. Use a roller to ensure full contact with the adhesive. This tool helps remove air bubbles too.

Using both tools correctly leads to a successful installation. Always follow the manufacturer’s guidelines for best results.

Alignment And Placement Aids

Using spacers is essential for creating consistent gaps between LVP flooring planks. They help maintain even spacing, which is crucial for a professional look. Place spacers at the edges to ensure proper alignment.

A tapping block is another important tool. It helps to minimize gaps between planks. By gently tapping the block, you can ensure a snug fit without damaging the edges. This technique keeps your flooring looking smooth and neat.

Finishing Touch Tools

A pull bar is essential for installing LVP flooring in tight spaces. It helps fit planks snugly without damaging them. Use it at the end of rows or near walls. This tool ensures a clean finish and prevents gaps.

A rubber mallet is another important tool. It helps secure the fit of the planks. Gently tap the planks to lock them in place. This prevents any shifting during installation. Using a rubber mallet avoids damage to the flooring.

Safety And Comfort Equipment

Knee pads are essential for anyone working on long flooring projects. They protect your knees from hard surfaces. Wearing these pads makes it easier to stay comfortable. Choose knee pads with good cushioning and support.

Safety glasses are crucial for protecting your eyes. Dust and debris can cause serious harm. Look for glasses that fit well and provide clear vision.

Gloves are important for hand protection. They help you grip tools better and prevent cuts. Select gloves that offer durability and comfort. This way, you can work safely and efficiently.

Cleanup And Maintenance Supplies

Using the right cleaning supplies helps keep your LVP flooring beautiful. Flooring rollers are essential for a smooth finish. They help remove air bubbles and ensure proper adhesion. Always apply firm pressure while using the roller.

Cleaning solvents are necessary for maintaining the floor’s shine. Choose gentle solvents that won’t harm the surface. Use soft cloths for wiping away dirt and stains. Microfiber cloths work best for this task.

| Tool | Purpose |

|---|---|

| Flooring Roller | Final touch for smoothness |

| Cleaning Solvents | Remove dirt and stains |

| Microfiber Cloths | Wipe surfaces without scratching |

Professional Tips For Installation

To install LVP flooring, proper tools are essential. Use a circular saw for cutting planks. A tapping block helps fit pieces snugly together. Measuring tape ensures accurate cuts and placements.

Avoid common mistakes to ensure a smooth installation. Always acclimate the flooring for at least 48 hours. Check the subfloor for cleanliness and levelness before starting. Use a level to spot any uneven areas.

To ensure longevity of LVP floors, maintain them well. Regularly sweep or vacuum to remove dirt. Use a damp mop with mild cleaner for deeper cleaning. Avoid harsh chemicals that can damage the surface.

Frequently Asked Questions

What Tools Do I Need For Lvp Flooring?

To install LVP flooring, you’ll need essential tools like a utility knife, measuring tape, and a tapping block. A pull bar and a foam underlayment are also important. For cutting, a straight edge or saw is useful. These tools ensure a smooth and professional installation process.

How To Cut Lvp Flooring Accurately?

Cutting LVP flooring accurately requires a sharp utility knife and a straight edge. Measure the area carefully before cutting. Score the plank along the measurement, then snap it along the line. For intricate cuts, use a jigsaw or a circular saw.

Always wear safety goggles for protection.

Can I Install Lvp Flooring Myself?

Yes, you can install LVP flooring yourself. Many homeowners find it manageable due to its click-lock design. However, proper preparation is key. Ensure the subfloor is clean and level. Following manufacturer guidelines will help you achieve a professional finish. Consider watching tutorials for additional guidance.

What Is The Best Underlayment For Lvp Flooring?

The best underlayment for LVP flooring is foam or cork material. Foam underlayment provides sound absorption and thermal insulation. Cork underlayment offers additional moisture protection. Choose one that matches your specific flooring type and local climate conditions. A proper underlayment enhances the longevity and comfort of your flooring.

Conclusion

Choosing the right tools for LVP flooring installation is crucial for a successful project. Quality tools enhance precision and efficiency. Investing in the best equipment saves time and effort. With the right resources, anyone can achieve professional-looking results. Start your flooring journey today with the right LVP tools in hand.