Marine Grade Plywood Vs Pressure Treated: Ultimate Guide

Choosing the right type of plywood for your project can make all the difference in durability and performance. When it comes to outdoor or moisture-prone environments, two popular choices often come into play: marine grade plywood and pressure treated plywood.

But how do you decide which one is best for your needs? Imagine investing time and effort into a project, only to see it deteriorate due to the wrong material choice. That’s a scenario no one wants to face. We’ll break down the key differences between marine grade plywood and pressure treated plywood, so you can make an informed decision.

Whether you’re building a boat, a deck, or any structure exposed to the elements, understanding these differences is crucial. You’ll learn about their strengths, weaknesses, and the specific situations each type is best suited for. By the end, you’ll have the confidence to choose the right plywood that ensures your project stands the test of time. Stay with us, and let’s dive into the details that could save you from costly mistakes and enhance your project’s longevity.

Marine Grade Plywood Basics

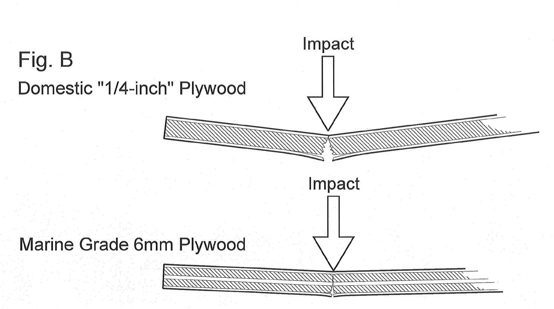

Marine grade plywood uses high-quality wood. It has thin layers called plies. These layers are glued together. The glue is strong and water-resistant. This makes it durable in wet places. The wood has no gaps or holes. This keeps water out and makes it sturdy.

Marine plywood is water-resistant. It can handle wet conditions. The wood is also strong and dense. This makes it last longer. It is smooth and easy to cut. This helps in building things. It does not warp or bend. Even in wet areas.

Boat builders love marine plywood. It is also used in docksand piers. People use it for outdoor furniture. It is good for bathrooms and kitchens. Anywhere water might be a problem. This wood stays strong and reliable.

Pressure Treated Wood Essentials

Pressure treated wood is soaked in chemicals. This prevents rot and bugs. Chemicals make it strong and last long. Wood is put in a big tank. Tank removes air. Then, chemicals go in. Pressure pushes chemicals deep inside. This is why it’s called pressure treated.

Pressure treated wood is tough. It doesn’t rot easily. Bugs don’t like it. It’s strong and durable. Can be used outside. Often has a green or brown tint. Safe for building decks and fences. Needs less care than other wood.

Used mostly outdoors. Perfect for decks, fences, and swings. Also good for garden beds. Helps keep plants safe. Can be used for playhouses. Works well for picnic tables. Not good for inside the house.

Durability And Longevity

Marine grade plywoodis highly resistant to water. It stays strong even in wet conditions. This plywood is made for long-lasting use. It is less likely to rot or decay over time.

Pressure treated woodis also good for wet places. Chemicals in the wood help it resist moisture. This treatment helps prevent rot and decay. The chemicals protect the wood from insects too.

Both materials have different lifespan expectations. Marine grade plywood can last for many years. It is great for outdoor use. Pressure treated wood has a long life too. It is not as durable as marine plywood but still strong.

Credit: www.youtube.com

Cost Comparison

Marine grade plywoodcosts more to buy. It is made for water. This makes it special. It is great for boats. Pressure treated woodis cheaper. It is treated with chemicals. These keep bugs away. Both have different uses.

Marine plywood lasts a long time. It is strong against water. It stays good for many years. This gives good value. Pressure treated wood can rot. It may need replacing sooner. It costs less now. But may cost more later.

Marine plywood needs little care. It stays strong on its own. This saves money over time. Pressure treated wood needs more care. It might need fixing often. This adds to the cost. Think about this when choosing wood.

Environmental Considerations

Marine grade plywood and pressure treated wood both have different impacts. Marine grade plywood uses wood from fast-growing trees. This can be more sustainable. Pressure treated wood often comes from slower-growing trees. It may take more time to replace.

Pressure treated wood uses chemicals to resist bugs and rot. These chemicals can harm nature. Marine plywood uses fewer chemicals. It depends on natural oils to resist water. This makes it a better choice for some.

Some eco-friendly options exist for both types. Look for certified wood. It means the wood came from a good source. Check for labels like FSC or PEFC. These labels help you pick better wood for the planet.

Credit: www.youtube.com

Ease Of Installation

Marine grade plywood is easy to handle. It’s light and smooth. Pressure treated wood can be heavy. It might be more rough. Both can be cut with basic tools. Use saws and drills. Marine plywood cuts cleanly. Pressure treated wood may splinter. Handle with care. Wear gloves. Avoid splinters.

Use screws or nails for both. Marine plywood holds screws well. It’s stable. Pressure treated wood might need special screws. Rust-proof ones work best. Glue works for marine plywood. Pressure treated needs more. Secure tightly. Check for loose parts. Adjust if needed.

Basic skills are enough. Marine plywood is simple to work with. Pressure treated wood needs some care. Measure before cutting. Align parts well. Hammer and screw safely. Check your work. Fix mistakes soon. Seek help if unsure. Practice makes it easier.

Aesthetic And Design Options

Surface finishesvary greatly between marine grade and pressure treated plywood. Marine grade often has a smooth finish. This makes it ideal for painting or staining. Pressure treated wood has a rough surface. It is usually left natural or painted.

Color and grain variationsare noticeable. Marine plywood is consistent in color. Its grain is even, offering a clean look. Pressure treated wood shows more grain variation. It might have dark spots from the treatment process.

The custom design potentialis different for each type. Marine plywood can be cut and shaped easily. It is suitable for intricate designs. Pressure treated wood is harder to shape. It is better for simple structures.

Suitability For Different Projects

Marine grade plywood excels in water resistance, ideal for boats and humid areas. Pressure treated wood suits outdoor structures, resisting decay and insects. Each type offers unique benefits, ensuring project needs are met efficiently.

Outdoor Structures

Marine grade plywoodworks well for outdoor structures. It resists water and weather. It’s a good choice for boats and docks. Pressure treated woodis also strong outdoors. It fights rot and insects. Use it for fences, decks, and garden beds.

Marine Applications

Marine grade plywoodPressure treated wood is not the best for marine use. It can warp or rot in water.

Indoor Use Cases

Safety And Health Concerns

Marine grade plywood is made without harmful chemicals. It is safe for indoor use. Pressure treated wood can have chemicals like arsenic. These chemicals can be dangerous. Breathing or touching treated wood can be risky. Always handle with care.

Wear gloves when cutting treated wood. Gloves keep chemicals off your skin. Use a mask to avoid breathing dust. Dust can carry chemicals. Keep treated wood away from food or water. This stops contamination.

Regulations ensure wood safety. Marine plywood meets strict standards. It is safe for boats and homes. Pressure treated wood also follows rules. These rules aim to reduce health risks. Always check labels for safety info.

Credit: www.lbifiberglass.com

Expert Recommendations

Marine grade plywood is best for wet environments. It is used for boats and docks. This plywood does not rot easily. It is stronger than regular plywood. Marine grade plywood lasts for many years. It is a good choice for outdoor projectsthat need to be strong.

Pressure treated wood is good for building fences. It helps to keep bugs away. This wood is also used for decks. Pressure treated wood does not cost much. It is cheaper than marine grade. It works well for garden bedsand other yard projects.

Experts know more about wood types. They help with the right choice. Professionals give advice for big projects. They make sure wood is safe and strong. It is smart to ask them before starting work. This can save time and money.

Frequently Asked Questions

Is Marine Plywood Better Than Pressure Treated?

Marine plywood excels in water resistance, ideal for wet environments. Pressure-treated plywood resists insects and decay, suitable for outdoor use. Choose based on project needs.

What Are The Disadvantages Of Marine Plywood?

Marine plywood is expensive compared to regular plywood. It can be heavy and difficult to work with. Vulnerable to wood-boring pests if not properly treated. Requires regular maintenance to prevent moisture damage. Not eco-friendly due to chemical treatments used for water resistance.

Is Marine Grade Plywood Waterproof?

Marine grade plywood is highly water-resistant but not fully waterproof. It withstands moisture better than regular plywood. Proper sealing and treatment enhance its durability against water exposure. Ideal for boats and outdoor projects, it offers reliable performance in wet environments.

Always check specifications for complete waterproofing needs.

How Long Will Marine Plywood Last Outdoors?

Marine plywood can last 15 to 25 years outdoors with proper maintenance. Regular sealing and varnishing extend its lifespan. Quality marine plywood resists moisture and decay. Ensure proper installation and drainage to prevent water damage. Routine inspections help identify signs of wear early.

Choose high-grade marine plywood for best durability.

Conclusion

Choosing between marine grade plywood and pressure treated wood depends on your needs. Marine plywood resists water well, ideal for boats and docks. Pressure treated wood suits outdoor projects like decks and fences. Both options offer durability, but in different environments.

Consider cost, environment, and specific project requirements. Think about exposure to elements and longevity needs. Each material has its strengths and weaknesses. Make sure to evaluate your project carefully. This ensures you pick the right material. A proper choice guarantees a successful project.

Always prioritize quality and suitability for best results.