Mitre Saw Vs Table Saw: Which One Reigns Supreme?

You’re standing in your workshop, eyeing that stack of wood and wondering which tool will make your job smoother and more precise. You’ve heard the names mitre saw and table saw tossed around, but which one truly fits your needs?

It’s a decision every DIY enthusiast and professional woodworker faces. Imagine slicing through wood with ease, creating crisp angles or flawless straight cuts, and ultimately achieving your vision. Choosing the right saw isn’t just about power or brand; it’s about enhancing your craftsmanship and making every project a masterpiece.

Dive into the world of saws and discover which tool will become your trusted companion in the workshop. You deserve to know the difference, and this guide will reveal all. Ready to make an informed choice? Let’s explore!

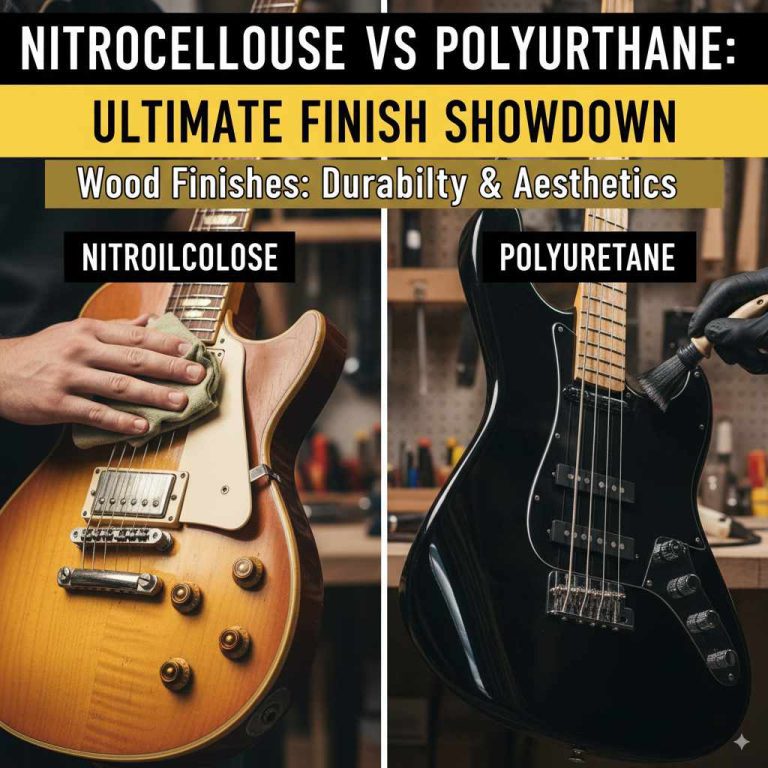

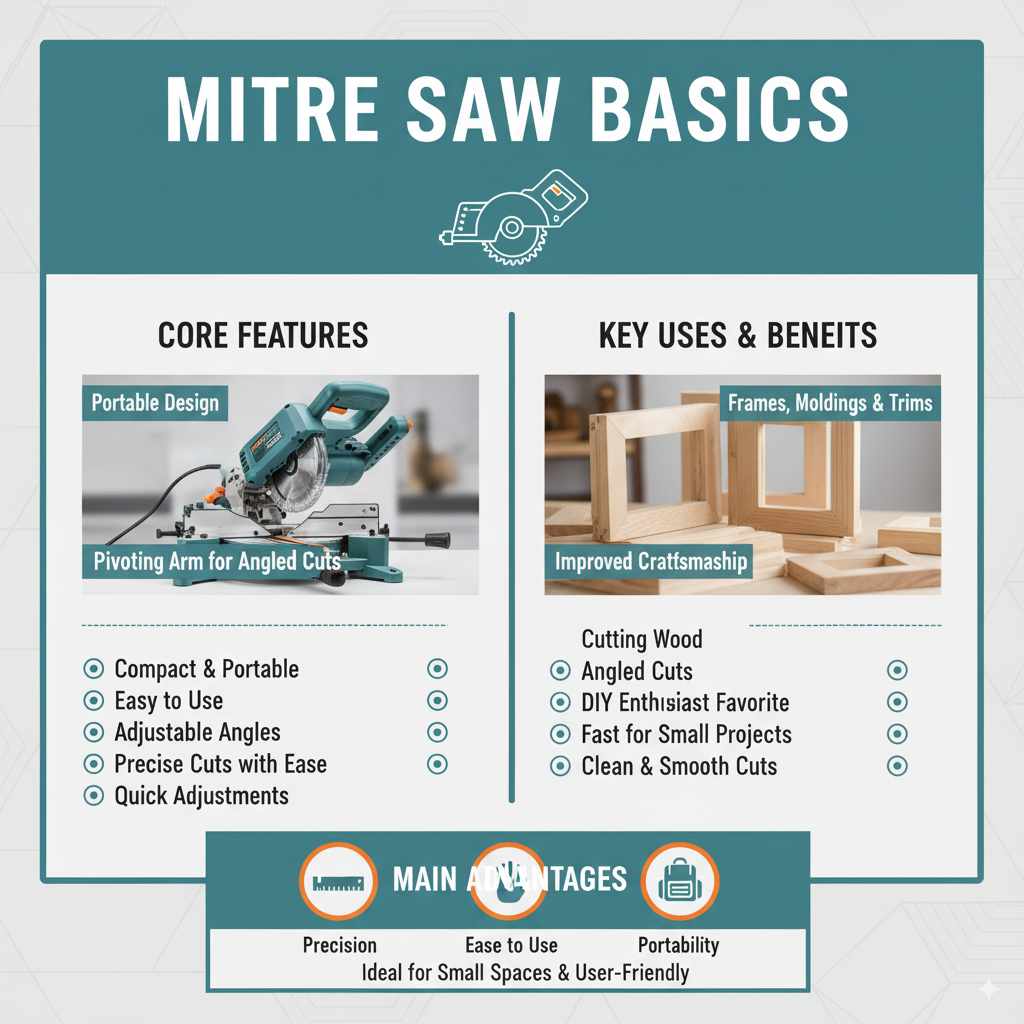

Mitre Saw Basics

Mitre saws are known for their compact design. They are portable and easy to use. The blade is mounted on an arm that can be pivoted. This allows for angled cuts. Precise cuts are made with ease. Users can adjust angles quickly.

Mitre saws are used for cutting wood. They excel at making angled cuts. Perfect for frames, moldings, and trims. Craftsmanship is improved with precision cutting. DIY enthusiasts often prefer them. Fast and efficient for small projects.

The main advantage is its precision. Ease of use makes it popular. Portability is another big plus. It is ideal for small spaces. The saw is safe and user-friendly. Cuts are clean and smooth.

Table Saw Fundamentals

Choosing between a mitre saw and a table saw depends on your cutting needs. Mitre saws excel at angled cuts for moldings and frames. Table saws offer versatility for larger wood pieces and straight cuts. Understanding their strengths helps select the right tool for your project.

Design And Functionality

Table saws have a flat table. The blade is under the table. It comes up through a slot. Users can adjust the blade height. This helps cut materials of different thickness. The blade is circular. It spins fast. This makes cutting quick and easy. Safety is crucial. Many table saws have guards and safety features.

Common Applications

Table saws are used in woodworking. They cut large pieces of wood. They make straight cuts. Perfect for making furniture. Also used in construction. They cut boards, panels, and sheets. They help in making precise cuts. This tool is handy in many projects.

Advantages Of Table Saws

Table saws are versatile. They cut different materials. Wood, plastic, and metal. They offer precision. Cuts are accurate and clean. They save time. Fast cutting speeds. Easy to use. Even beginners can learn quickly. They are durable. Built to last many years. Ideal for both professionals and hobbyists.

Key Differences

Miter saws excel at making precise angled cuts, ideal for trim work. Table saws provide versatility with straight cuts, perfect for larger wood pieces. Both tools serve distinct purposes, enhancing woodworking efficiency.

Cutting Capacity

A mitre saw is ideal for cutting angles. It works best with smaller pieces. Table saws handle larger wood. They cut long, straight lines well. Choose a miter saw for detailed cuts. Pick a table saw for big projects.

Portability And Space

Mitre saws are easy to move. They fit in small spaces. Table saws are bigger and heavier. They need more space. A mitre saw is good for tight workshops. A table saw stays in one spot.

Precision And Versatility

Mitre saws offer precise angle cuts. They are great for trim work. Table saws are more versatile. They cut different shapes and sizes. Mitre saws focus on angles. Table saws handle varied tasks.

Choosing The Right Tool

Each tool is best for different tasks. A mitre saw is great for cutting angles. It’s best for trim and moldings. A table saw is useful for long, straight cuts. It’s perfect for ripping wood. Think about what your project needs most. Choose the tool that fits the job.

Tool prices can vary a lot. A mitre saw might cost less. Table saws can be more expensive. Look at your budget first. Think of what you can spend. Consider any extra costs too. Blades and accessories can add up. Pick a tool that fits your wallet.

Safety is very important. Both saws have safety features. Look for blade guards and safety switches. Some tools have emergency stops. These features help keep you safe. Always wear safety gear too. Choose the tool with the best safety options.

Expert Opinions

Many experts love using a mitre saw for angled cuts. It’s fast and precise. A carpenter said, “Mitre saws are great for frames.” They are easy to use and save time. Another expert mentioned, “For straight cuts, a table saw is better.” It is strong and cuts large pieces of wood.

Both tools have their uses. A woodworker said, “I need both for my work.” Each tool has its strengths. It depends on what you need to cut. Using the right tool makes work easier and faster.

Many users find the mitre saw easy to handle. It is not too heavy. One user said, “I can carry it to different sites.” Others like the table saw for its power. It cuts through thick wood easily.

Users often switch between the two tools. They use the mitre saw for quick jobs. The table saw is used for big projects. Both have a place in the workshop.

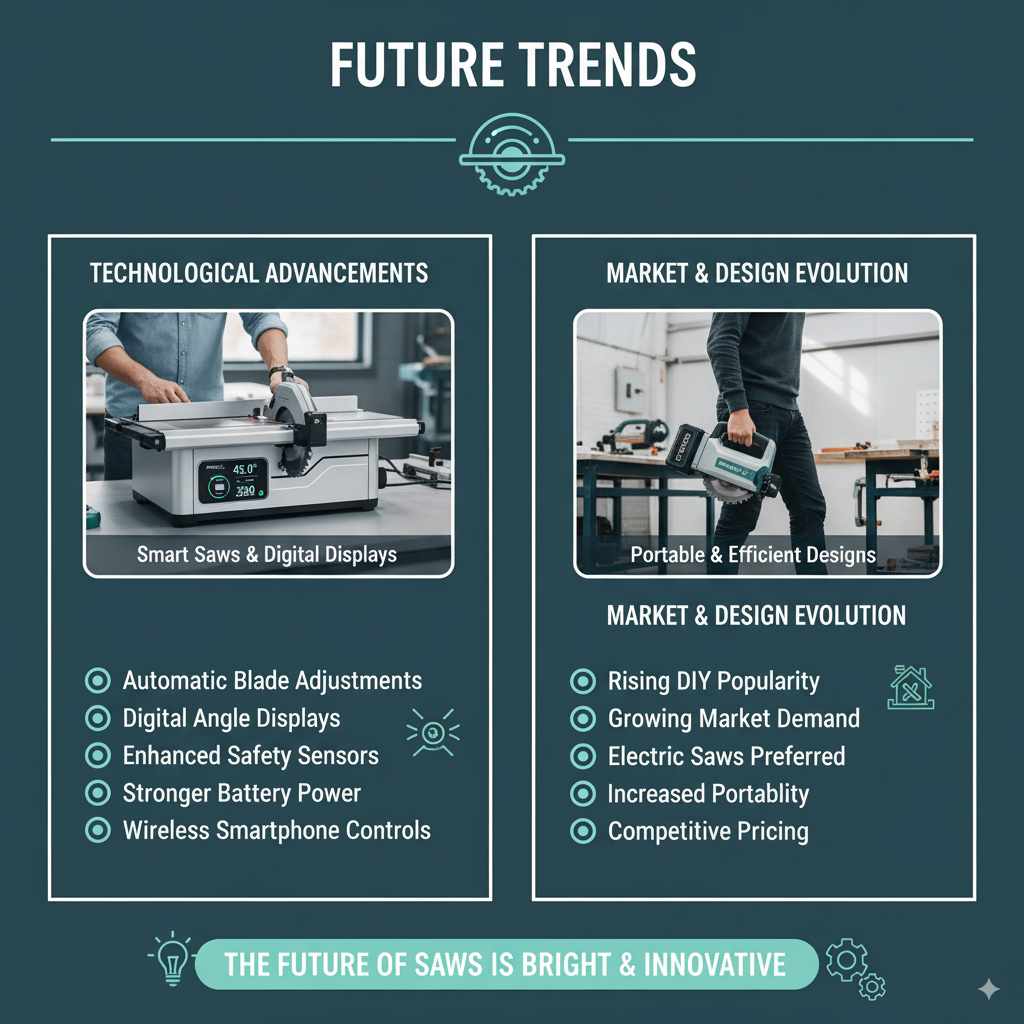

Future Trends

Saws are getting smarter. New saws have automatic blade adjustments. This helps users cut more accurately. Some saws also have digital displays. Displays show cutting angles. Safety features are improving too. Sensors can detect hand positions. They stop the saw if a hand is too close. Battery-powered saws are now stronger. They can last longer and cut better. Wireless controls are becoming popular. Users can control saws with smartphones. This makes work easier and faster.

Demand for saws is rising. More people are doing DIY projects. The market for saws will grow. Electric saws are preferred now. They are easy to use. Portable saws are in demand. People want saws that are easy to carry. Prices may go down. More companies are making saws. Competition will lower prices. Expect more innovations in saw design. New models will be lighter and more efficient. The future of saws looks bright and exciting.

Frequently Asked Questions

Can A Table Saw Do Everything A Miter Saw Can?

A table saw can perform many miter saw tasks but lacks precision for angled cuts. Miter saws excel at quick, accurate crosscuts and angles. Choose a miter saw for detailed angle work and a table saw for versatile straight cuts.

Both tools complement each other in woodworking projects.

Can I Use A Table Saw As A Mitre Saw?

No, a table saw cannot replace a mitre saw. Table saws cut straight lines, while mitre saws make angled cuts. Using a table saw for angles requires complex setups and isn’t precise. For accurate mitre cuts, use a mitre saw designed specifically for this purpose.

What Should You Never Cut With A Miter Saw?

Do not cut metal, stone, or glass with a miter saw. These materials can damage the blade. Always use the correct tool for the material to ensure safety and precision. Miter saws are designed for wood and soft materials.

Can You Cut A 4×4 With A 10 Miter Saw?

Yes, a 10-inch miter saw can cut a 4×4. Make sure the blade is sharp and the saw is properly aligned for precise cuts. Always follow safety precautions and use the appropriate techniques to ensure a clean cut through the wood.

Conclusion

Choosing between a mitre saw and a table saw depends on your needs. Mitre saws excel at precise angled cuts. Perfect for frames and molding. Table saws offer versatility and power. Great for larger cuts and ripping wood. Consider your projects before deciding.

Space and budget also play roles. Each saw has its strengths. Both are valuable in woodworking. Prioritize your tasks and space. Make an informed decision based on your goals. Happy woodworking!