Particle Board Vs Mdf Vs Plywood: Ultimate Material Guide

When you’re diving into a new home improvement project or picking out materials for your next DIY masterpiece, the choices can be overwhelming. You’ve probably come across terms like particle board, MDF, and plywood.

Each of these materials promises durability and aesthetics, but which one is truly right for your needs? Choosing the wrong material can lead to costly repairs or disappointing results. This is why understanding the differences and benefits of each is crucial for making the best decision.

Imagine creating a beautiful piece of furniture that stands the test of time, or completing a home renovation that boosts your property value. By the end of this article, you’ll have a clear understanding of what particle board, MDF, and plywood offer, empowering you to make informed choices for your projects. Let’s unravel the mystery behind these materials and find out which one aligns perfectly with your vision.

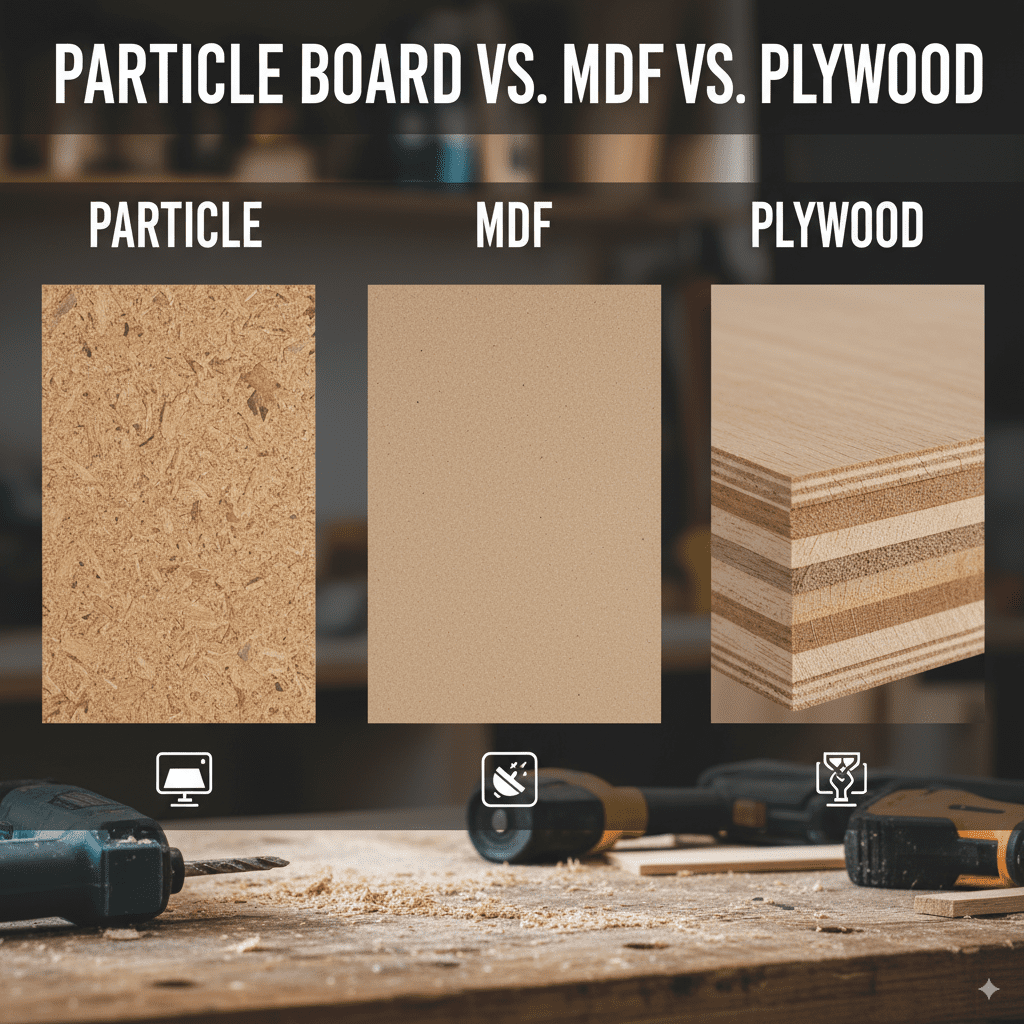

Material Composition

Particle board is made from wood chips and sawdust. These are mixed with glue. The mixture is then pressed into sheets. It is an affordable option. It is less strong than other wood types. It can swell if it gets wet.

MDF stands for Medium-Density Fiberboard. It is made from wood fibers. These fibers are combined with resin. They are pressed into solid panels. MDF is smooth and easy to paint. It can chip or break easily if handled roughly.

Plywood is made of thin layers of wood. These layers are called veneers. They are glued together in layers. The grain of each layer is different. This makes plywood very strong. It can be used for many things, like furniture and floors.

Manufacturing Process

Particle board, MDF, and plywood differ in their manufacturing processes. Particle board uses wood chips bonded with resin. MDF is made from wood fibers and wax. Plywood consists of thin wood layers glued together. Each material offers unique properties suited for various applications.

How Particle Board Is Made

Particle board is made from wood chips. These chips are mixed with glue. The mixture is pressed into sheets. Heat is used to dry the sheets. The board is trimmed to size. It is sanded for smoothness. This board is used in furniture. It is cheaper than other boards. The board is lightweight. It is easy to cut and shape.

Mdf Production Techniques

MDF stands for Medium Density Fiberboard. It is made from wood fibers. Fibers are mixed with resin glue. The mix is pressed into sheets. High pressure is used for strength. The sheets are dried with heat. The edges are smoothened. MDF is strong and dense. It is great for painting and carving. MDF is popular in cabinets and doors.

Plywood Manufacturing Steps

Plywood is made from thin wood layers. These layers are called veneers. Veneers are glued together. Heat and pressure make them strong. Layers are placed at angles. This gives plywood strength. Plywood is cut to size. It is used in construction. It is strong and durable. Plywood is resistant to bending. It is used in floors and walls.

Strength And Durability

Particle board is weak. It cannot hold heavy loads. MDF is stronger. It can hold more weight. Plywood is the strongest. It carries heavy loads easily. Builders often choose plywood for strength. MDF is good for light shelves. Particle board is best for small items.

Particle board breaks easily. It cannot handle hits. MDF is better. It resists small impacts. Plywood is the toughest. It withstands heavy hits. Plywood is ideal for floors. MDF suits furniture. Particle board suits simple crafts. Choose plywood for long-lasting items.

Particle board swells in water. It is weak in rain. MDF handles moisture better. But it is not waterproof. Plywood resists water well. It does not swell easily. Plywood is best outdoors. MDF suits indoor projects. Particle board is for dry areas. Select wisely based on needs.

Environmental Impact

Particle board is made from wood scraps and sawdust. It uses materials that might be wasted. This helps save more trees. Making particle board recycles wood waste. This is good for the environment. But, it may contain glues that are not eco-friendly. These glues can release bad chemicals. Still, using scraps makes it a sustainable choice.

MDF uses wood fibers and resins. It’s smooth and easy to paint. MDF can be made from recycled wood. This helps reduce waste. Yet, some resins may have toxic chemicals. These can harm the air quality. Still, MDF saves many trees. It uses less solid wood than other products. This makes it a greener option.

Plywood is made of thin wood layers. These layers come from logs. It’s strong and lasts long. Plywood uses more wood than particle board or MDF. This can lead to more tree cutting. But, it lasts a long time. This reduces the need for replacements. Using sustainable forests can help. It makes plywood more eco-friendly.

Cost Analysis

Particle board is very affordable. It is often the cheapest. Many people choose it for budget projects. It costs less than other materials. Yet, it may not last as long. It is made from wood chips. These chips are glued together. This makes it light and easy to handle.

MDF costs more than particle board. But it is still affordable. It is made from wood fibers. These fibers are very fine. They make MDF smooth and strong. Many people use it for furniture. It is good for indoor use. MDF does not handle water well. Keep it dry to last longer.

Plywood is more expensive. It is strong and durable. Many layers of wood make plywood. These layers make it sturdy. It is good for both indoor and outdoor projects. Plywood can handle water better. It is a good choice for many uses. But it costs more than MDF and particle board.

Applications And Uses

Particle board is often used for making cheap furniture. It is lightweight and easy to cut. This board is good for cabinets and shelves. Many people use it in low-cost housing. It is also used in flat-pack furniture. Particle board is not very strong. It swells when wet. Use it indoors to keep it safe.

MDF stands for Medium Density Fiberboard. It is smooth and easy to paint. MDF is used for making stylish furniture. It is often seen in modern decor. This board is good for doors and panels. It does not have knots or grains. MDF is not water-resistant. Keep it dry for long life.

Plywood is strong and durable. Builders use it for floors and walls. It is also used for roofs. Plywood can handle moisture better than others. It is made of thin layers glued together. This board is popular in construction projects. Plywood is good for making outdoor furniture too.

Aesthetic Considerations

Choosing between particle board, MDF, and plywood involves aesthetic considerations. Each offers distinct finishes and textures. Particle board is often covered with veneer, while MDF provides smooth paint-ready surfaces. Plywood showcases natural wood grain, adding warmth and character.

Surface Finish Options

Particle boardoffers a smooth surface. It’s often covered with laminates. These add color and texture. MDFis smooth too. It takes paint well. It can be finished with veneersfor a wood look. Plywoodhas natural wood grains. It can be stainedor painted. Each material has its unique charm.

Customization And Design Flexibility

Particle board is easy to cut. It’s good for simple designs. MDF is versatileand can be shaped. It’s great for detailed designs. Plywood is strong. It supports complex structures. You can create varied designs. Each material offers different design possibilities.

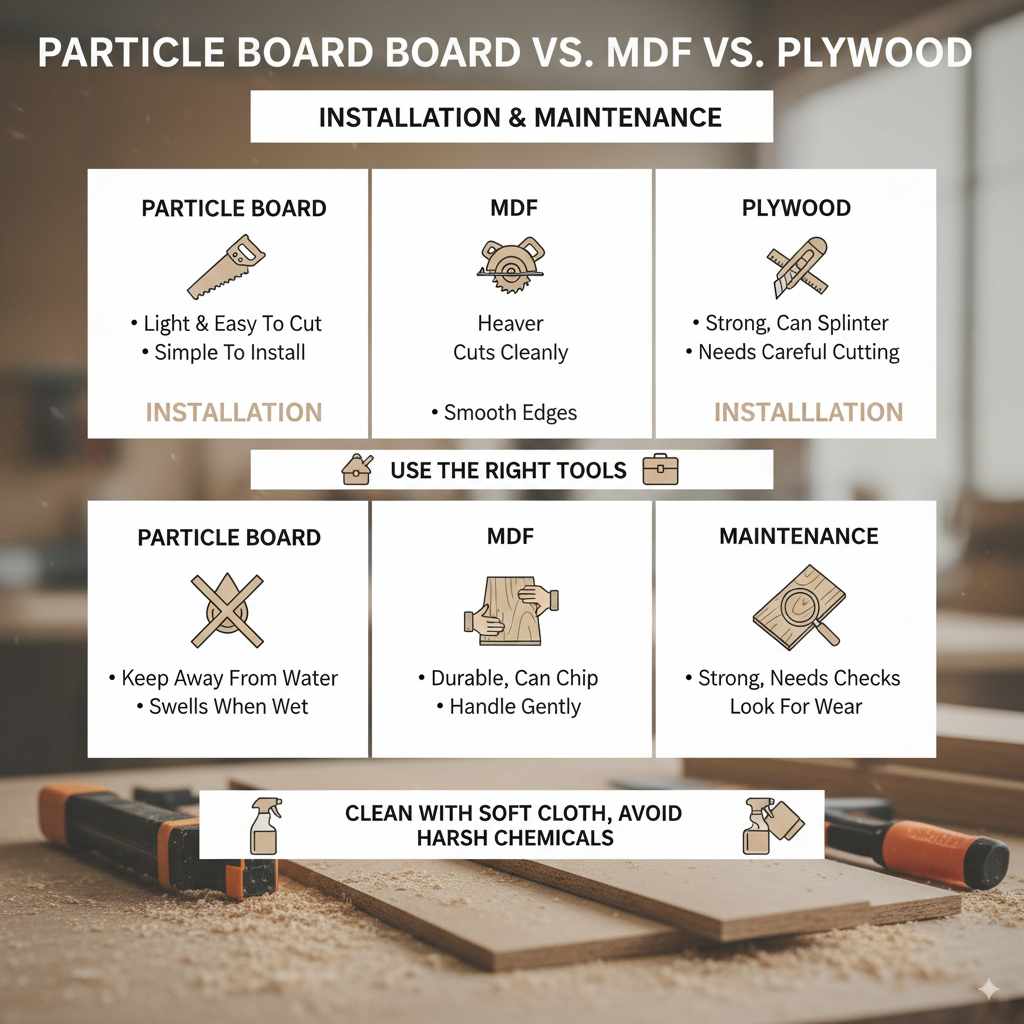

Installation And Maintenance

Particle board is light and easy to cut. This makes it simple to install. MDF is heavier but cuts cleanly, ensuring smooth edges. Plywood is strong but can splinter. This needs careful cutting. Use the right tools for each material. This helps in avoiding mistakes.

Keep particle board away from water. It swells when wet. MDF is durable but can chip. Handle it gently to avoid damage. Plywood is strong but needs regular checks. Look for signs of wear. Always clean surfaces with a soft cloth. Avoid harsh chemicals on all three materials. This keeps them looking new.

Choosing The Right Material

Cost is a big factor in choosing materials. Particle board is often the cheapest option. MDF costs a bit more. Plywood can be the most expensive. Durability is another thing to think about. Plywood is strong and lasts long. MDF is strong too, but less so than plywood. Particle board is the weakest of the three. Weight matters if you need to move it. Particle board and MDF are heavier than plywood. Finish is important for looks. MDF and particle board are smooth and easy to paint. Plywood can show wood grain, which some people like.

| Material | Pros | Cons |

|---|---|---|

| Particle Board |

|

|

| MDF |

|

|

| Plywood |

|

|

Frequently Asked Questions

Are Mdf And Particleboard The Same Thing?

MDF and particleboard are not the same. MDF is denser, smoother, and made from wood fibers. Particleboard is lighter and made from wood chips. Both serve different purposes in furniture and construction. MDF offers better finishing, while particleboard is more affordable.

Choose based on your project’s needs.

Which Is Better, Mdf Board Or Plywood?

MDF board offers a smooth finish, ideal for painting, while plywood provides superior strength and moisture resistance. Choose MDF for indoor projects like cabinets; opt for plywood for outdoor or structural applications. Consider cost and specific project requirements to determine the best choice for your needs.

What Is A Particle Board Called Now?

Particle board is now commonly called “chipboard” or “fiberboard”. It’s made from wood chips and resin. This engineered wood product is often used in furniture and construction due to its affordability and versatility. Chipboard is a cost-effective alternative to solid wood.

Is Particle Board The Same Thing As Plywood?

Particle board and plywood are not the same. Particle board is made from wood chips and adhesive. Plywood consists of thin wood layers bonded together. Plywood is generally stronger and more durable than particle board. Both materials serve different purposes in construction and furniture making.

Conclusion

Choosing the right material depends on your needs and budget. Particle board is affordable but less durable. MDF offers a smooth finish for painting. Plywood stands strong with its durability and versatility. Consider the environment where you’ll use these materials.

Moisture-prone areas may need plywood. For furniture, MDF might be best. Particle board fits well in temporary setups. Assess your project requirements carefully. Each material has its strengths and weaknesses. Make an informed choice for the best results. Your project success hinges on selecting the right material.

Choose wisely for lasting satisfaction.