Planer Helical Vs Straight: Which Offers Superior Precision?

Are you standing at the crossroads of woodworking, trying to decide between planer helical and straight blades? You’re not alone.

This decision can significantly impact the quality of your projects and your overall satisfaction with your woodworking journey. Imagine effortlessly gliding through wood, achieving that smooth finish you’ve always dreamt of. Choosing the right planer blade isn’t just about cutting wood; it’s about enhancing your craftsmanship and elevating your skills.

You’ll discover the key differences between helical and straight planer blades, helping you make an informed decision that aligns with your woodworking needs. Stick around to learn how the right choice can transform your workbench into a haven of efficiency and precision.

Credit: machineatlas.com

Understanding Planer Helical And Straight Gears

Planer helical gears have angled teeth. They look like a spiral. This helps them reduce noise. They also carry more load. Straight gears have straight teeth. They look simple. They are easy to make. But they can be noisy. They also have less load capacity.

Helical gears are great for smooth operations. Straight gears are better for simple machines. Both have their uses. Each serves a purpose in different machines.

Helical gears are used in car transmissions. They are also in factories. Straight gears fit in bicycles. They are in simple toys too. Each gear type works in different settings. Understanding their uses helps in choosing the right gear.

Helical gears handle heavy tasks. Straight gears are for simple tasks. Knowing this helps in machine design.

Mechanics Of Helical Gears

Helical gears transmit torquesmoothly. Their teeth are angled. This helps in continuous contact. Less noise is produced. The force spreads evenly. This reduces wear and tear. Straight gears do not have angled teeth. They can be noisy. Torque transmission is less efficient. Helical gears are often preferred for quiet operations.

Load distribution is crucial in gears. Helical gears offer better load distribution. Their angled teeth help in even spreading. This means less stress on each tooth. Gears last longer due to this. Straight gears focus load on fewer teeth. This can lead to wear faster. Helical gears ensure durability.

Mechanics Of Straight Gears

Straight gears connect directly. They have simple teeth. This makes them easy to understand. The teeth touch each other directly. This gives fast power transfer. No delay in movement. Simple design helps in easy maintenance. Straight gears often make noise. Their teeth hit each other hard. This can create wear and tear.

Straight gears are efficientfor simple tasks. Their design is basic. They work well in low-speedmachines. They don’t slip easily. Gear slippage is rare. Straight gears are affordable. Making them costs less. They are good for budget-friendlyprojects. But they can lose power at high speeds. This affects their efficiency. Not ideal for complex tasks.

Credit: www.findbuytool.com

Precision In Helical Gears

Helical gears offer better alignment. Their angled teeth help in smooth movement. This reduces chances of slippage. Proper alignment means less wear and tear. It increases the life of the gears. Straight gears are simpler but less stable. They may not align as perfectly. This can cause noise and vibration. Helical gears are better for machines needing precision.

Helical gears are quiet. Their angled teeth reduce noise. The contact is gradual, not sudden. This makes them ideal for quiet environments. Straight gears can be noisy. They hit straight on, causing sound. For machines needing low noise, helical is the choice. They keep the machine running smoothly and quietly.

Precision In Straight Gears

Straight gears are known for their precise movement. Each tooth aligns perfectly. This ensures smooth operation. Machines using straight gears work well. They are ideal for exact tasks. Perfect for precise alignments. These gears reduce errors. They offer exactness in every turn.

Manufacturing straight gears is simple. They need less complex machinery. This reduces production time. Costs are lower too. Simple designs mean fewer mistakes. Workers find it easy to make them. Quality control is easier. Straight gears are efficient to produce. This makes them popular in many industries.

Credit: spetools.com

Comparative Analysis

Planer helical gearsexcel in smooth and quiet operations. They handle higher loads with ease. Straight gears work well in simpler tasks. They are better for low-speed applications. Helical gears reduce vibration and noise. This makes them ideal for noisy environments. Straight gears are good for precision tasks. They offer better control at low speeds.

Helical gears are often more expensivedue to complex designs. They require precise manufacturing. Straight gears are cheaper and simpler. They need less maintenance over time. Helical gears may save money in noise reduction. Straight gears save money in initial costs. They are better for budget projects. Helical gears may have higher long-term value.

Choosing The Right Gear

Industry needs guide gear choice. Helical gears are quiet. Straight gears are strong. Noise matters? Choose helical gears. Need power? Go for straight gears. Material affects gear life. Steel lasts long. Plastic is light. Size impacts performance. Big gears? Slow but strong. Small gears? Fast but weak. Cost matters too. Helical gears cost more. Straight gears are cheaper. Space is important. Helical gears need more room. Straight gears fit tight spots. Load capacity is key. Heavy loads need straight gears. Light loads suit helical gears.

Frequently Asked Questions

Is Spiral Or Helical Better?

The choice between spiral and helical depends on your specific needs. Spirals offer flexibility and space efficiency, ideal for compact designs. Helical gears provide better load distribution and quieter operation, suitable for high-speed applications. Consider your project’s requirements to determine which is better for you.

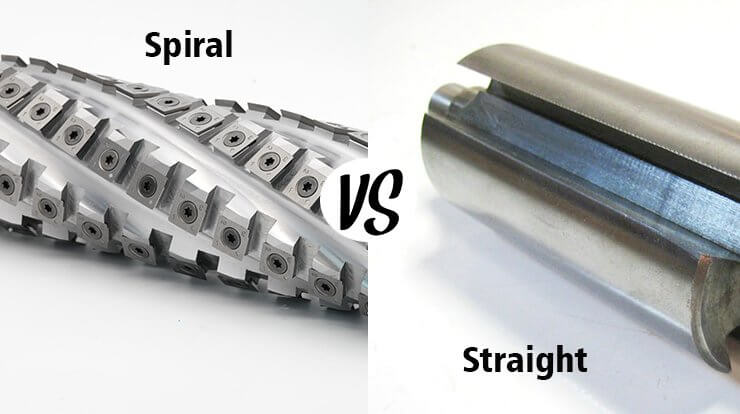

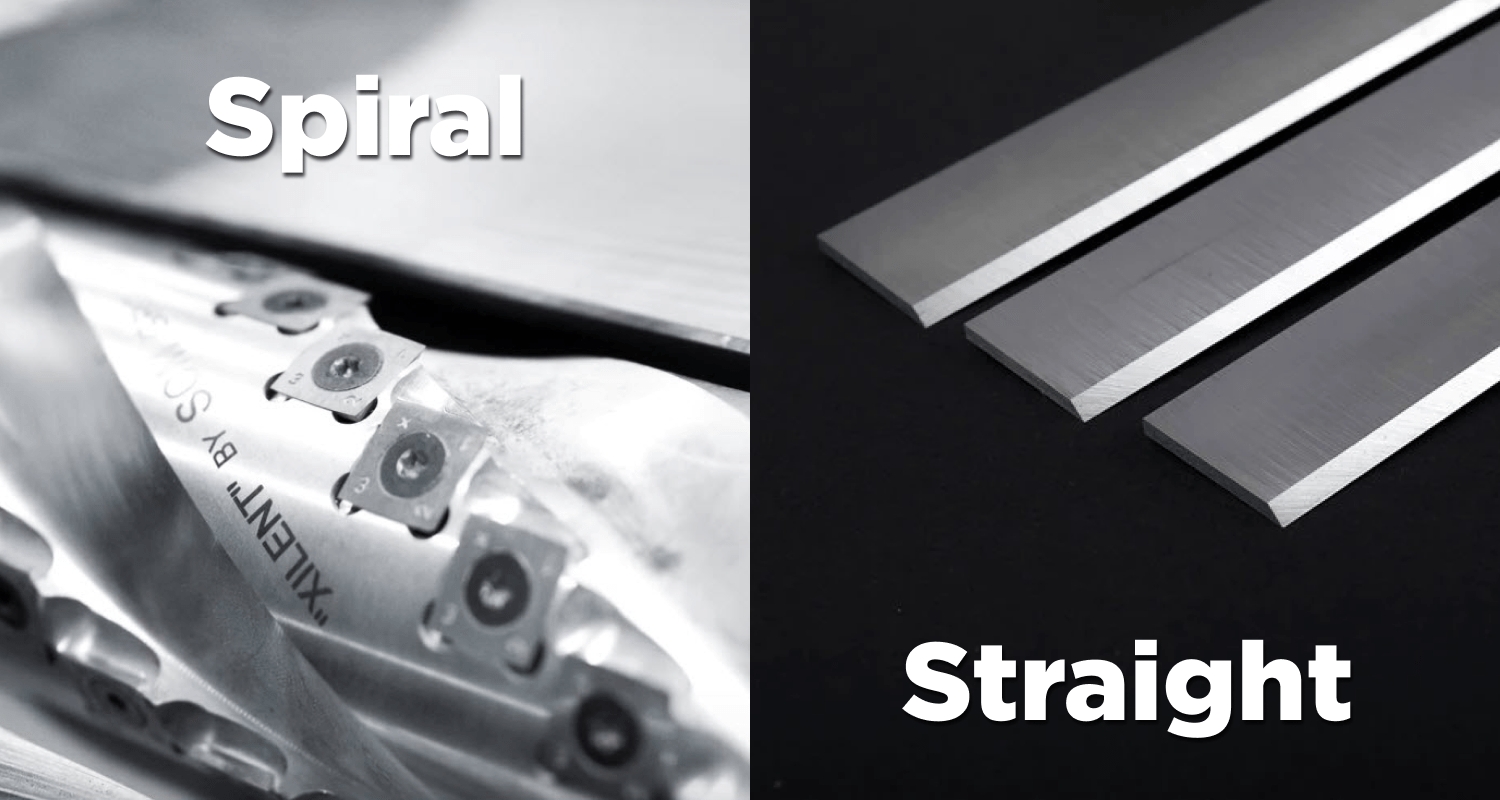

What Is The Difference Between A Spiral And Straight Planer Blade?

Spiral planer blades have a helical design, offering smoother cuts and reduced noise. Straight planer blades are flat, providing faster cuts but can be noisier and less smooth. Spiral blades also require less frequent sharpening and offer better chip evacuation compared to straight blades.

What Type Of Planer Blade Is Best?

Carbide-tipped blades are ideal for planers due to their durability and precision. They last longer than steel blades. High-speed steel blades are cheaper and suitable for softwoods. Choose carbide for hardwoods and frequent use. Ensure compatibility with your planer model for optimal performance.

Can You Put Helical Blades On A Dewalt Planer?

Yes, you can install helical blades on a DeWalt planer. Ensure compatibility with your specific model for optimal performance. Helical blades provide smoother cuts and reduced noise, enhancing the planer’s efficiency. Always follow manufacturer instructions for installation to maintain safety and functionality.

Conclusion

Choosing between planer helical and straight blades depends on your needs. Helical blades offer quiet operation and smooth finishes. Straight blades are affordable and easy to maintain. Consider the type of wood you work with. Also, think about your budget.

Both options have their benefits. Selecting the right one improves your woodworking projects. Evaluate your goals and make the best choice for you. Remember, the right tool makes a difference in quality. Happy woodworking!