Sawmill Vs Lumber Mill: Key Differences Explained

Are you puzzled by the terms “sawmill” and “lumber mill”? You’re not alone.

It’s easy to mix them up, especially when you’re diving into the world of wood processing. Understanding the difference can be crucial, whether you’re building your dream home or simply curious about how wood transforms into the materials we use every day.

Imagine standing in front of a towering stack of timber. You’re about to make a decision that could affect the quality, cost, and even the sustainability of your project. Wouldn’t you want to know exactly what you’re dealing with? This knowledge empowers you to make smarter choices and might even save you money. We’ll break down what each mill does, how they operate, and why it matters to you. By the end of this article, you’ll feel confident in navigating the world of wood processing with ease. So, let’s delve into the differences and discover what sets a sawmill apart from a lumber mill.

Purpose And Function

Sawmills cut logs into boards and planks. They use large, noisy machines. These machines slice logs quickly. A sawmill is where the wood journey starts.

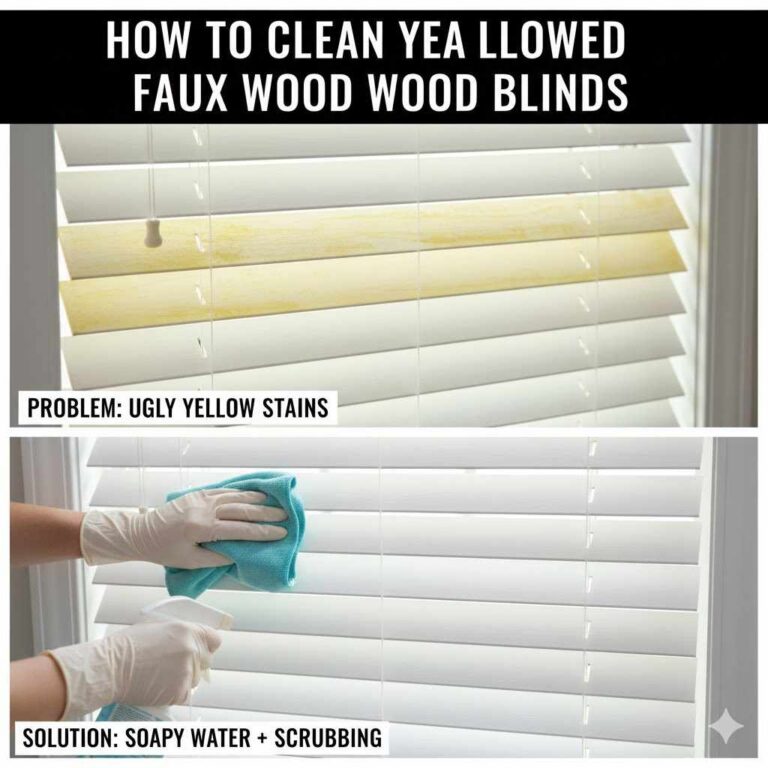

Lumber mills take these boards and make them smooth. They prepare wood for building. Lumber mills handle drying and shaping. This makes wood ready for houses and furniture.

Both mills work with logs. But they do different jobs. Sawmills focus on cutting. Lumber mills focus on shaping. Each mill is important for wood production.

Raw Material Processing

Sawmills and lumber mills both process wood. But they work differently. A sawmill cuts logs into rough pieces. These pieces are called timber. Sawmills use big machines. Blades slice through wood quickly.

A lumber mill makes finished wood products. These products are smooth and ready to use. Lumber mills use machines too. But they also have special tools. These tools make wood look nice.

Wood from sawmills is good for construction. Lumber mill wood is for furniture and floors. Both mills are important for building and creating things.

Equipment And Machinery

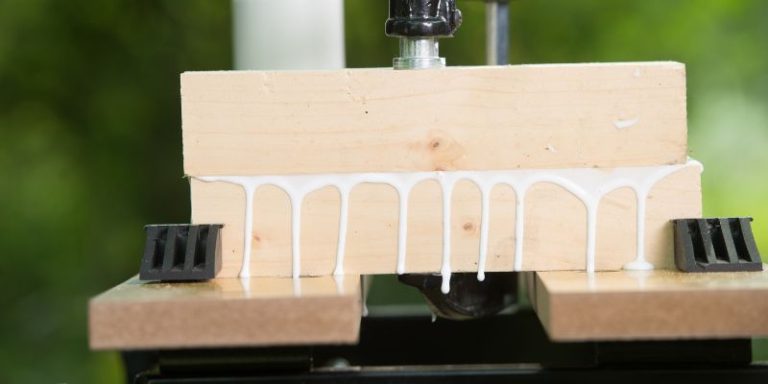

Sawmills use big machines to cut logs into wooden planks. These machines are called saws. They can be circular or band saws. Lumber mills have more machines. They cut, shape, and treat the wood. Planers smooth the wood surface. Dry kilns remove moisture from the wood. This makes wood strong. In sawmills, logs are moved by conveyors. Lumber mills use forklifts to move wood. Both have cranes to lift heavy logs. Safety gear is important. Workers wear helmets and gloves. Machines are noisy. So, workers use ear protection. Both places work with wood but use different tools.

Credit: www.youtube.com

Product Output

A sawmill cuts logs into raw lumber. This includes planks and boards. These are the first steps in wood processing. A lumber mill, on the other hand, refines wood. It produces finished wood products. Examples are flooring and moldings. Sawmills focus on simple cuts. Lumber mills add more value. They make wood ready for homes and furniture.

Both have important roles. Sawmills start the process. Lumber mills finish it. They work together to supply the wood industry. Each plays a key part in creating useful wood items.

Scale And Capacity

Sawmills are often smallerand handle limited wood. They focus on cutting logs into boards. This makes them ideal for localor small-scaleoperations. Lumber mills, on the other hand, have a largercapacity. They process a vast amount of wood. Their machines are more advanced. This allows them to handle large orders. Sawmills might serve singlecommunities. Lumber mills often cater to multipleregions. Each mill type serves its own market needs. Both have importantroles in the wood industry.

Credit: woodlandmills.com

Environmental Impact

Sawmills and lumber mills both affect the environment. Sawmills often use less energy. They produce less waste. Their process can be simpler. Lumber mills usually need more energy. They may create more waste. This is due to extra steps. Both mills can harm forests. Cutting trees is necessary. It leads to deforestation. This impacts animals. It changes habitats. Replanting trees helps. It reduces damage. Mills can pollute air. Dust and fumes are common. Clean technologies help reduce this. Using renewable energy is important. It can lower pollution. Protecting nature is vital. Saving trees helps the planet. Choosing eco-friendly options is smart.

Economic Contributions

Both sawmillsand lumber millshelp the economy. Sawmills process raw logs into usable lumber. This lumber is used in building and furniture. It gives jobs to many workers. Lumber mills refine and treat wood further. This creates high-quality products. These products are sold at higher prices. The mills boost trade and local businesses. They also support the construction industry.

Sawmills often have lower costs. They focus on simple processing. This makes them vital for small towns. Lumber mills may need more money and skilled workers. They contribute by improving wood quality. Both mills are key in the wood supply chain. They ensure a steady flow of timber products. These mills are important for economic growth. They help communities thrive.

Historical Development

Long ago, people used simple tools to cut trees. These were called sawmills. Sawmills were small and needed a lot of human work. Later, people built bigger machines. These machines were called lumber mills. Lumber mills could cut more wood. They were faster and needed less human work. This helped people get more wood quickly.

Over time, sawmills and lumber mills changed. They used water and wind to work. Then, they used steam and electricity. This made them even faster. Today, lumber mills are very advanced. They use computers to cut wood. This helps us save time and trees.

Current Trends

In today’s world, sawmills and lumber mills play big roles. These mills help in processing wood. A sawmill cuts logs into planks. A lumber mill, on the other hand, processes these planks further. Both are important for the wood industry.

Sawmills use big machines to cut logs. These machines are fast and efficient. Lumber mills make wood smooth and ready for building. Both types of mills use advanced technology now. This technology saves time and reduces waste. Many countries have these mills for local wood needs.

Wood from these mills is used in furniture and houses. It is also used in making paper. With more people building homes, these mills are very important. They help meet the growing demand for wood products.

Industry Challenges

Both sawmills and lumber mills face many challenges. Environmental concerns are a big issue. Cutting trees can harm nature. Mills must find ways to be sustainable. They need to use resources wisely. Regulations can also be tough. Governments set rules for cutting trees. Mills must follow these rules to avoid fines. Technology changes fast. Mills must keep up with new tools. This can be costly. Labor shortages are another issue. Skilled workers are hard to find. Training new workers takes time and money. Mills must balance cost and efficiency. These challenges affect how mills operate. They must plan well to succeed.

Credit: woodmizer.eu

Frequently Asked Questions

What Is A Sawmill Used For?

A sawmill processes raw timber into lumber by cutting logs into various sizes. It focuses primarily on cutting, shaping, and refining wood. Sawmills are crucial in the initial stages of wood processing, preparing wood for further use in construction or manufacturing.

How Does A Lumber Mill Differ?

A lumber mill refines and processes wood into finished products like planks or boards. It may involve further treatment, smoothing, and cutting to precise dimensions. Lumber mills often handle wood that has already been cut by sawmills, enhancing its quality for specific applications.

Which Is More Efficient: Sawmill Or Lumber Mill?

Efficiency varies based on the function; sawmills are efficient in initial log processing. Lumber mills excel in refining and customizing wood products. Both play vital roles in the timber industry, but efficiency depends on the specific requirements of the wood processing stage.

Can A Sawmill Be Part Of A Lumber Mill?

Yes, a sawmill can be integrated within a lumber mill. This setup streamlines operations by combining initial log cutting with subsequent processing. It enhances efficiency and reduces transportation costs, allowing seamless transitions from raw timber to finished wood products.

Conclusion

Choosing between a sawmill and a lumber mill depends on your needs. Sawmills cut logs into rough lumber. Lumber mills process rough lumber into finished boards. Each serves different purposes. Think about your project size and material requirements. Consider costs and available resources.

Both options have unique benefits. Decide based on your specific goals. Evaluate equipment availability and budget constraints. Ensure you understand the processes involved. Make the right choice for your woodworking projects. Happy building!