Sawzall Vs Angle Grinder: Which Tool Reigns Supreme?

When it comes to tackling DIY projects or professional tasks, choosing the right tool can make all the difference. You might find yourself standing in front of two popular power tools: the Sawzall and the Angle Grinder.

Each has its own strengths and uses, but how do you decide which one is right for your needs? Maybe you’re looking to make precise cuts, or perhaps you need to grind down tough materials. Understanding the differences between these two tools can save you time, money, and effort.

By the end of this article, you’ll know exactly which tool will help you get the job done efficiently and effectively. Are you ready to make the perfect choice for your next project? Let’s dive in and explore what each tool can offer you.

Sawzall Features

The Sawzall is known for its strong motor. It cuts through wood and metal easily. Many users find its power impressive. The tool provides consistent cutting speed. This helps in efficient tasks. It can handle tough jobs without slowing down. It’s a favorite for professionals.

The Sawzall works well for many tasks. It cuts pipes, wood, and metal sheets. This tool is great for demolition jobs. It’s used in construction and home repairs. Its blade options add to versatility. You can switch blades for different materials. This makes it handy for varied projects.

Using a Sawzall is straightforward. It has a comfortable grip. This reduces hand fatigue. Its design helps in safe operation. Quick blade changes make it user-friendly. Many find it easy to operate. Beginners can use it with confidence. Its lightweight build aids in long projects.

Angle Grinder Features

Angle grinders can cut metal, stone, and tiles. They are very versatile. You can also use them for grinding surfaces. This makes them handy for many jobs. The right blade or disc is important. It helps in cutting and grinding properly. Choose wisely for best results.

Angle grinders have a high-speed rotation. This helps in doing tasks quickly. Precision is key for clean cuts. Steady hands are needed. Use the right settings for speed. It helps in achieving precision. Always practice care while using these tools.

Safety is very important. Use protective gear like gloves and goggles. Sparks and debris can fly during use. Keep the tool steady in your hands. Never force the grinder. This can be dangerous. Always unplug when not in use. Safety first for every project.

Comparing Durability

The Sawzall is often made with strong metal parts. This helps it last. The handle is usually covered in rubber. This makes it easy to hold. Angle Grinders also have a tough build. They use metal and plastic parts. This mix keeps them light but strong. Both tools need to be kept clean. Dirt can damage them.

Sawzalls work well in hard jobs. They can cut through wood and metal. They handle drops and bumps. Angle Grinders are tough too. They cut and grind many materials. They can handle heat from long use. Both tools need care. Regular checks help them last longer.

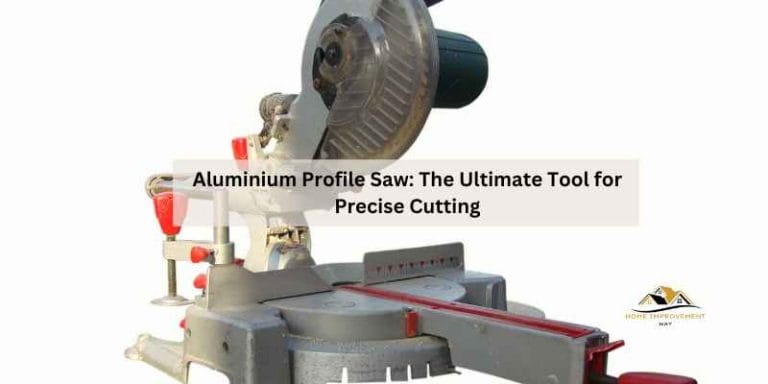

Credit: engineerwarehouse.com

Cost Analysis

Choosing between a sawzall and an angle grinder involves cost considerations. Sawzalls excel in cutting through wood and metal, while angle grinders are versatile for grinding and cutting tasks. Evaluate the specific project needs to determine which tool provides the best value.

Initial Purchase Price

The Sawzalland Angle Grinderhave different costs. A Sawzall may cost more. Angle Grinders are often cheaper. Prices depend on the brand. Quality also affects the price. High-quality tools cost more. Budget options are available for both.

Maintenance Costs

Maintaining tools costs money. Sawzalls need new blades often. Angle Grinders need new discs. Sawzall blades are sometimes pricey. Grinder discs are usually less expensive. Regular cleaning is important for both. Clean tools last longer. Dirty tools may break down. Proper care saves money over time.

User Experience

The Sawzall is often heavier than the Angle Grinder. It can tire hands quickly. Gripping it feels firm, but can be tiring. The Angle Grinder is usually lighter. Easier to hold for a long time. Design of handles matters. Sawzall has a straight handle. Angle Grinder has a pistol grip. Easier for long work.

Noise levels differ. Sawzalls can be loud. They vibrate a lot. Angle Grinders are quieter. Less vibration felt. Ear protection helps with both tools. Vibration can cause hand fatigue. Angle Grinders have less vibration. This makes them less tiring.

Best Use Cases

Sawzall is great for cutting wood and pipes. It works fast and easy. Angle Grinder is best for metal and stone. Use it for polishing or cutting tiles. Both tools help with DIY projects. Choose the right tool for the job. Sawzall is safe for beginners. Angle Grinder needs care. Always wear safety gear. Keep kids away when using tools.

Professionals use Sawzalls for plumbing and demolition. It cuts through tough materials. Angle Grinders are used in construction. They shape and grind metal. Both tools are essential in workshops. Skilled workers use them daily. They save time and effort. Safety is important with these tools. Training is needed for safe use. Quality tools last longer.

Environmental Impact

Sawzall tools use electricity to cut things. They need more power when cutting thick materials. Angle grinders also use electricity. They are efficient for grinding and cutting tasks. They may need less power than Sawzall. Both tools can save energy by using them smartly.

Using Sawzall can create dust and debris. This waste can affect the air. Angle grinders produce sparks and metal dust. They also add particles to the air. Both tools can make noise. This noise can disturb animals. Using these tools carefully can help reduce waste.

Credit: www.youtube.com

Expert Opinions

Industry professionals often choose tools based on the task. Sawzall is great for cutting through thick materials. It is often used in demolition tasks. The angle grinder, on the other hand, is used for smoothing surfaces. It is also effective in cutting metal and tiles. Each tool has its own strengths and limitations. Professionals suggest using the tool that fits the job best. Proper use ensures safety and efficiency.

Many users love the Sawzall for its power. They say it’s good for heavy-duty jobs. The angle grinder is praised for its versatility. It can cut, grind, and polish. Consumers appreciate its multi-purpose use. Both tools get positive reviews for reliability. Users highlight the need for proper training. Learning to use each tool safely is important.

Credit: www.reddit.com

Frequently Asked Questions

What Is A Sawzall Used For?

A Sawzall is primarily used for cutting through materials like wood, metal, and plastic. It’s ideal for demolition work and remodeling tasks. Its reciprocating blade allows for precision cutting in tight spaces. It’s a versatile tool, suitable for both DIY enthusiasts and professional contractors.

How Does An Angle Grinder Work?

An angle grinder works by spinning a disc at high speeds to grind, cut, or polish surfaces. It’s commonly used for metalworking, but can also handle masonry and wood tasks. The tool’s versatility depends on the type of disc attached.

It’s essential for both construction and automotive work.

Which Tool Is Safer To Use?

Safety depends on proper use and precautions. Both tools can be hazardous if misused. Sawzalls have less risk of flying debris, but require careful handling. Angle grinders can produce sparks, so protective gear is crucial. Always follow safety guidelines and wear appropriate protection when using either tool.

Can Sawzall Cut Through Metal?

Yes, a Sawzall can cut through metal efficiently. With the right blade, it slices through metal pipes, sheets, and bars. It’s perfect for demolition and renovation projects. Choose a blade designed for metal to ensure clean cuts. It’s a favorite among professionals for its cutting capabilities.

Conclusion

Choosing between a Sawzall and an angle grinder depends on your needs. Sawzall excels in cutting wood and metal with precision. It’s perfect for demolition tasks. On the other hand, an angle grinder is versatile. It grinds, cuts, and polishes various materials.

Ideal for metalwork and masonry projects. Both tools have unique strengths. Consider your project requirements. Safety is also crucial. Always wear protective gear. Assess your budget and tool familiarity. This will guide your decision. Both tools serve different purposes. Choose wisely for efficient work.