What Is The Most Durable Material For A Wooden Handle?

For the most durable wooden handle, choose dense hardwoods like Hickory or Ash, especially for striking tools. For tools needing resistance to moisture and rot, dense woods like Teak or Black Locust are superior choices due to their natural oils and hardness.

Welcome! If you’ve ever had a favorite tool handle snap, crack, or simply feel flimsy after hard use, you know the frustration. A good handle should feel like an extension of your arm, not a weak link in your project. Choosing the right wood seems complicated, but it doesn’t have to be. We are going to look closely at what makes one piece of wood tougher than another.

Don’t worry if you aren’t a lumber expert. I’ll break down the best woods based on what you plan to do with your tool—whether it’s heavy chopping or fine detail work. By the end of this guide, you will confidently pick the perfect, long-lasting wood for your next handle project. Let’s get started on making handles that last!

What Makes a Wooden Handle Durable? The Science of Strength

When we talk about durability in a wooden handle, we are talking about a few key characteristics that prevent failure over time. It’s not just about being hard; it’s about how the wood reacts to stress, moisture, and vibration. Understanding these factors helps us pick the right material for the job, ensuring your tool stays safe and effective for years to come.

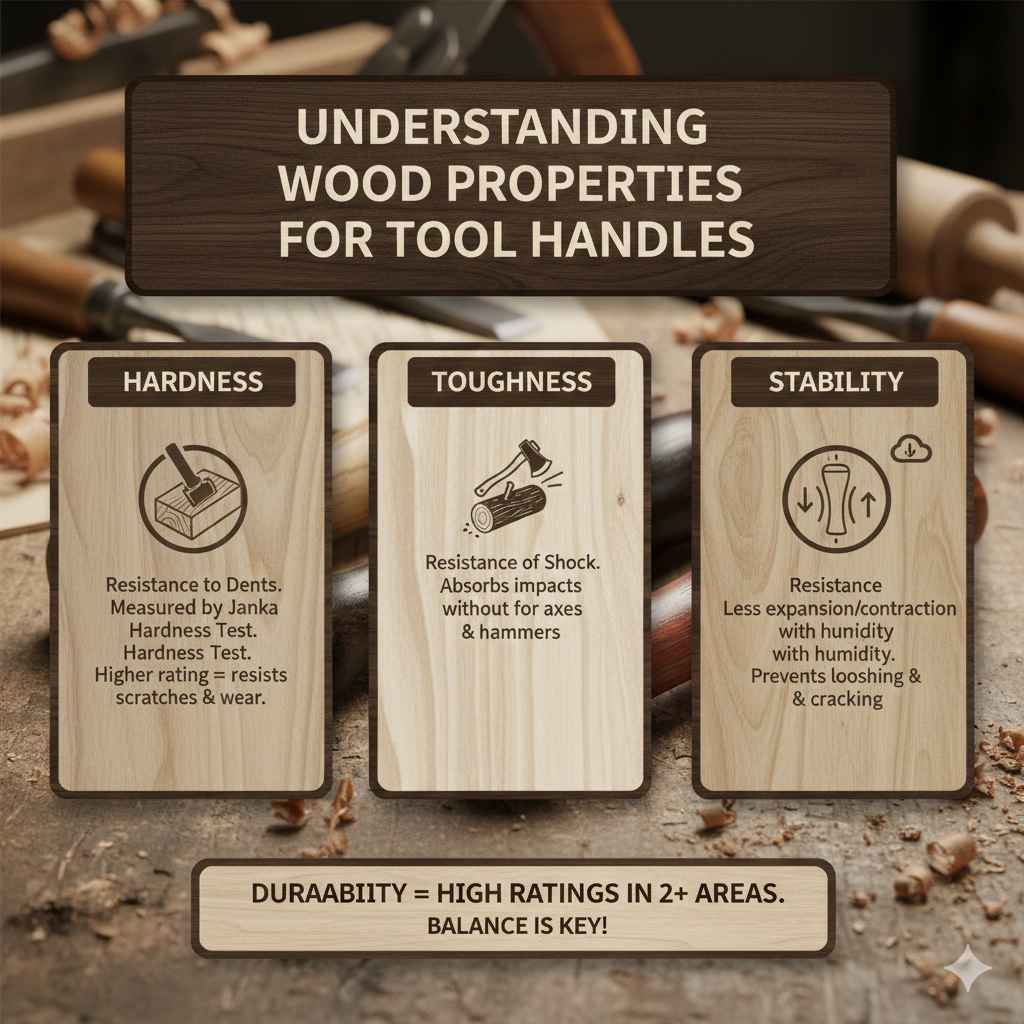

Understanding Wood Properties for Tool Handles

Durability is measured by several factors scientists use to grade timber. For handles, three properties matter most:

- Hardness (Resistance to Dents): This is often measured using the Janka Hardness Test. A higher Janka rating means the wood resists dents, scratches, and general wear and tear better. Think about striking tools—you need high hardness here!

- Toughness (Resistance to Shock): This is crucial for tools that take a beating, like axes or hammers. Toughness means the wood can absorb sudden impacts without shattering or splintering.

- Stability (Resistance to Warping): Wood naturally expands and contracts with changes in humidity. A stable wood changes size less, meaning the handle won’t loosen from its head or crack due to excessive movement.

For DIYers, the best durable woods combine high ratings in at least two of these areas. For example, a very hard wood that shrinks a lot when it dries might crack quickly, making it less durable overall than a slightly softer but much more stable wood.

Why Durability Matters for Safety

This isn’t just about saving money on replacements; it’s a major safety issue. A handle failure on a sharp axe or a heavy sledgehammer can cause serious injury. Durable wood ensures a secure grip and prevents the head of the tool from flying off under load. Always prioritize safety when selecting material for high-impact tools.

The Top Contenders: Most Durable Woods for Tool Handles

When woodworkers talk about the best woods for handles—especially for high-stress items like axes, shovels, or mallets—a few species consistently rise to the top. These woods have stood the test of time (and hard labor!) across centuries of toolmaking.

1. Hickory: The King of Shock Resistance

If you need a handle to take a serious beating, Hickory is usually the answer. It’s the traditional wood choice for striking tools in the United States for a reason.

Why Hickory Excels:

- Unmatched Toughness: Hickory has exceptional shock resistance. It flexes rather than breaking when slammed against a hard surface repeatedly.

- Good Hardness: It ranks quite high on the Janka scale (around 1820 lbf), meaning it resists general wear well.

- Affordability and Availability: It is generally easy to source, especially in North America, making it a cost-effective choice for durability.

Best For: Axes, hammers, sledgehammers, and baseball bats.

2. Ash: The Balanced Workhorse

Ash is very similar to Hickory in its toughness and is often used interchangeably, though it typically scores slightly lower on the Janka hardness scale (around 1320 lbf). It has a beautiful grain pattern, making it aesthetically pleasing as well.

Ash Pros and Cons:

Ash is known for its excellent bending strength and shock absorption. However, it can be slightly less resistant to rot than some tropical hardwoods, so it needs good sealing if used outdoors frequently.

Best For: Shovels, rakes, specialized axes, and sporting goods.

3. Hard Maple: Strength Meets Stability

While Maple is often known for fine furniture, the hard varieties (like Sugar Maple) offer excellent durability. They are very hard (around 1450 Janka) and resist wear beautifully.

Maple’s strength lies in its density and low movement when moisture levels change. This means handles stay tight on the tool longer.

Best For: Mallets, chisel handles, plane bodies, and tools requiring a very smooth, non-vibrating surface.

4. Exotic Hardwoods: Durability Through Natural Oils

For tools that face constant exposure to the elements (like garden trowels or outdoor carving knives), certain dense tropical woods offer incredible natural protection.

- Teak: Famous for boat decking, Teak contains natural oils that repel water and resist fungal decay. It’s hard, stable, and lasts almost indefinitely outdoors, though it is more expensive.

- Lignum Vitae: This is perhaps the densest wood available (often over 2800 Janka). It is incredibly durable but is very difficult to work with and often protected or expensive due to its slow growth.

Durability Comparison Table (Key Woods)

Here is a quick comparison of the top choices for handling real-world stress:

| Wood Type | Primary Strength | Approximate Janka Hardness (lbf) | Best Application |

|---|---|---|---|

| Hickory | Shock Resistance/Toughness | 1820 | Axes, Sledgehammers |

| Ash | Toughness & Flexibility | 1320 | Shovels, Rakes |

| Hard Maple | Density & Stability | 1450 | Mallets, Fine Tool Handles |

| White Oak | Water Resistance | 1360 | Outdoor/Damp Environments |

Woods to Approach with Caution for Handles

Just as some woods are champions of durability, others are famous for being brittle, soft, or prone to splitting along the grain. Knowing what not to use is just as important as knowing what to use, especially when safety is on the line.

Softwoods are Not Recommended

Woods like Pine, Fir, and Cedar are excellent for construction framing or decorative trim, but they are terrible for handles. They lack the density to resist impacts. A Pine handle on a hammer will quickly dent, compress, and eventually fail catastrophically under heavy striking force.

Avoid Brittle Hardwoods

Some hardwoods are very hard but lack toughness. This means they resist scratching but shatter easily when hit hard. For example, certain types of exotic woods might look amazing but will snap suddenly under the lateral stress a handle experiences.

Understanding Grain Direction is Critical

Even the most durable wood can fail if the grain is oriented incorrectly. When shaping a handle, the grain must run perfectly parallel to the length of the handle, following the line of force. A diagonal or cross-grain section is a guaranteed weak point where the handle will split, no matter how strong the species is. Always inspect your lumber to ensure the grain lines up straight along the handle blank.

How to Finish a Durable Handle for Maximum Lifespan

You can choose the toughest wood available, but if you don’t protect it, moisture, sweat, and oils from your hands will degrade it over time. Proper finishing seals the wood and keeps it stable.

The Importance of Curing and Drying

Before you even start shaping, the wood must be properly dried, or “seasoned.” Wood that is too wet will shrink significantly after you finish the handle, causing it to loosen or crack. Always use wood that is kiln-dried or air-dried for at least one year per inch of thickness. For the most stable results, look for wood with a moisture content below 10%.

Recommended Finishes for Durability

We want a finish that soaks in to provide internal protection while creating a slight barrier on the surface, without making the handle slippery.

- Boiled Linseed Oil (BLO) or Tung Oil: These are the traditional favorites for tool handles. They penetrate deep into the wood fibers, hardening them from the inside out and repelling water. They offer a natural, grippy feel.

- Polyurethane (Wipe-on): If you need maximum water resistance (like for an outdoor shovel), a wipe-on polyurethane can offer a tougher surface seal. However, it can feel slick when hands get sweaty, so use sparingly or lightly sand after the first coat.

- Wax Finishes: A final coat of beeswax or a specialized paste wax gives excellent water resistance and a comfortable, traditional feel. This is often applied over an oil base.

Safety Note on Oils: Rags soaked in Boiled Linseed Oil can spontaneously combust as they cure and generate heat. Always soak used rags in water or lay them flat outside to dry completely before disposing of them safely. For more detailed safety guidelines on finishing oils, consult resources like those provided by national safety organizations.

Application Tips for Longevity

Apply several thin coats rather than one thick coat. For oil finishes, let the wood soak up the oil for 15–20 minutes, then wipe off all excess thoroughly. Reapply coats until the wood stops absorbing the oil. This process locks the wood structure down for years of hard use.

Project Spotlight: Choosing Wood for Specific Tools

The “most durable” wood depends entirely on the stress the handle will endure. Let’s break down material selection based on common DIY tool projects.

Handles for Striking Tools (Axes, Hammers)

These demand high toughness** to absorb shock without vibrating too much up your arm. The constant impact will quickly destroy less resilient woods.

- First Choice: Hickory

- Second Choice: Ash

The flexibility of Hickory is key here; it flexes slightly upon impact, absorbing energy that would otherwise cause a brittle wood to split.

Handles for Digging and Gardening Tools (Shovels, Hoes)

These tools face two major enemies: constant abrasion from soil and exposure to moisture/rot.

- Best Overall: Ash or White Oak. White Oak has better rot resistance than Ash due to its closed-cell structure, making it excellent for tools left outside occasionally.

- Premium Choice (If outdoors always): Teak or Black Locust (extremely rot-resistant).

Handles for Fine Detail or Ergonomic Tools (Chisels, Knives)

For tools held for long periods, durability means resisting sweat, oil absorption, and providing a comfortable, non-slip grip.

- Best Choice: Hard Maple or Beech. They are dense, smooth, and stable.

- Finish Tip: Use a very light oil finish and keep them clean. A dense wood like Maple resists moisture ingress even without a heavy plastic-like coating.

The Durability of Laminated Handles (Plywood/Strips)

Sometimes, you can boost durability beyond a solid piece of wood by using laminated construction, particularly for tools that need extreme width or unique curves, like mallets.

By gluing several thin strips of wood together (often using a high-quality epoxy), you create a composite material that is often stronger than a single piece of solid wood. This is because the grain direction in adjacent layers runs in different directions, canceling out weak points and preventing a single crack from running the length of the handle.

For laminated handles, woods like Birch plywood (which is engineered for high strength) or Maple strips work exceptionally well. Always use a high-strength wood glue, like Titebond III, which offers good water resistance.

DIY Guide: How to Shape a Durable Handle Safely

Even the best wood needs careful handling during shaping to maintain its strength. Remember, we are protecting that straight grain we discussed earlier!

Tools Needed for Handle Shaping

Keep it simple. You don’t need a full woodshop to shape a handle blank.

- Pencil and Template

- Bandsaw or Jigsaw (for rough cuts)

- Spokeshave or Drawknife (for shaping curves)

- Rasps and Files

- Sandpaper (starting around 80 grit, moving to 220 grit)

- Clamps and a sturdy workbench

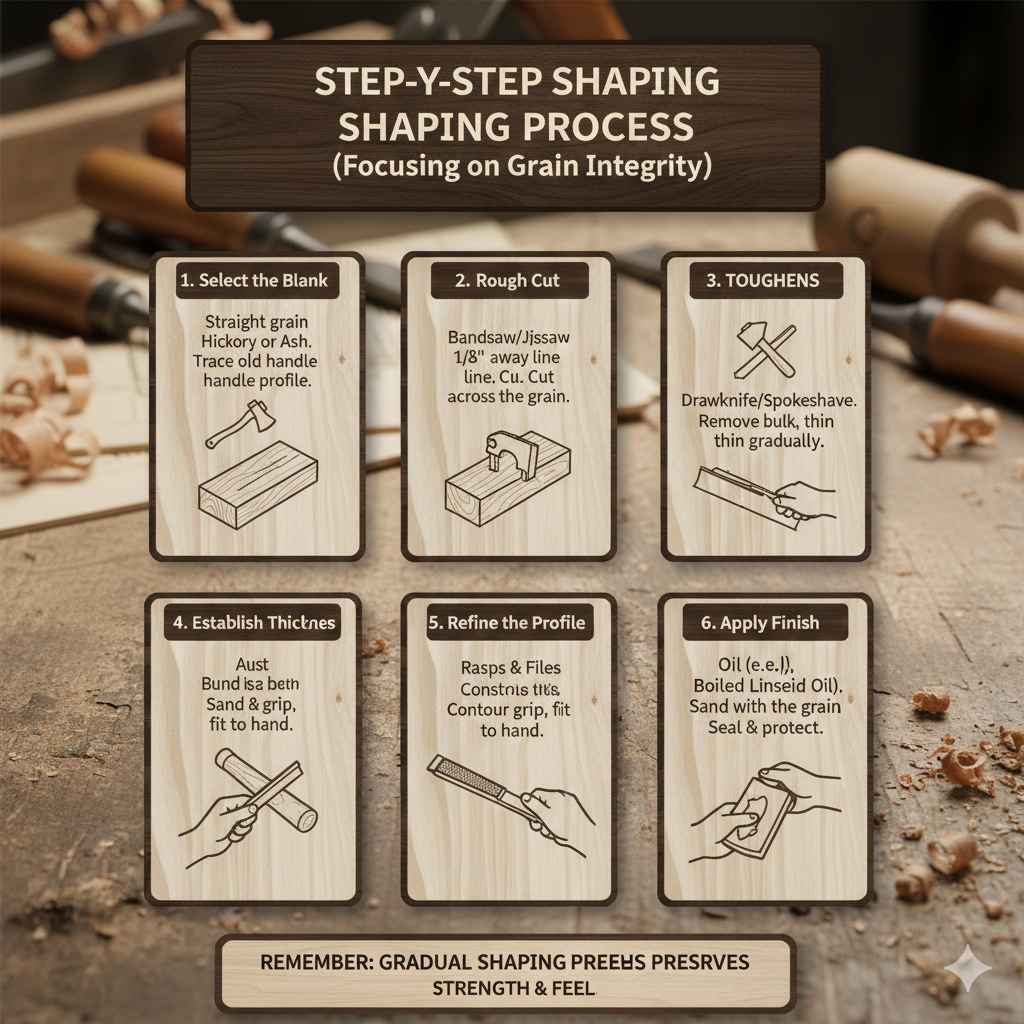

Step-by-Step Shaping Process (Focusing on Grain Integrity)

- Select the Blank: Choose a piece of wood (Hickory or Ash) where the straightest possible grain runs the entire length of the piece. If you are replacing an existing handle, trace its profile onto your new blank.

- Rough Cut: Use your bandsaw or jigsaw to cut the rough profile, staying about 1/8 inch away from your drawn lines. Always feed the wood so the saw blade cuts across the grain, not along it, if possible, to prevent tearing.

- Establish Thickness: Use a drawknife or spokeshave to remove the bulk of the material, thinning the handle down to just slightly thicker than your final dimension. Work slowly, taking off thin shavings at a time.

- Refine the Profile: Switch to rasps and files to refine the curves, paying special attention to the areas where the handle meets the tool head and where your hands grip. Make sure the grip areas are comfortable and contoured to your hand.

- Sand Smoothly: Start sanding with a medium grit (like 80 or 100) to remove rasp marks. Gradually move to finer grits (150, then 220). Sand with the grain direction as much as possible.

- Apply Finish: Once completely dust-free, apply your chosen oil finish (like Boiled Linseed Oil) following the instructions above for sealing and protection. Allow ample time to cure before mounting the tool head.

Remember, shaping is about taking wood away gradually. Rushing this process often leads to over-cutting or creating flat spots where the natural curves should be, which weakens the overall feel and longevity of the handle.

Frequently Asked Questions (FAQ) for Handle Durability

Q1: Is Oak a durable wood for tool handles?

A: Yes, White Oak is very durable, especially for outdoor tools. It has good hardness (1360 Janka) and its closed-cell structure makes it naturally resistant to moisture and rot compared to Red Oak, which is porous.

Q2: What is the cheapest durable wood for a handle?

A: Ash is often the best balance of low cost and high durability, particularly for standard tool handles like shovels. Hickory might be slightly more durable for impact tools but can sometimes be pricier depending on local availability.

Q3: Can I use synthetic materials instead of wood for durability?

A: Absolutely. Fiberglass handles (like those often found on modern sledgehammers) offer superior resistance to rot and weather, and are often tougher than wood. However, they don’t absorb vibration as well as Hickory.