What Size Air Compressor For Car Painting

Picking the right air compressor can feel tricky when you want to paint cars. Many beginners wonder, What Size Air Compressor Do You Need to Paint Cars? It’s a common question because the wrong one can mess up your paint job or just not work well. Don’t worry, we’ll make it easy.

We’ll walk through everything step-by-step so you can get the perfect compressor for your project. Let’s figure out what you need.

Understanding Air Compressor Basics for Auto Painting

Air compressors are the heart of any spray painting setup. They take in air, compress it, and store it under pressure. This pressurized air is what pushes the paint through your spray gun.

For car painting, you need enough air volume and pressure to keep the gun working smoothly and consistently. Without enough power, your paint won’t atomize properly, leading to drips, uneven coverage, and a less-than-perfect finish. It’s about getting the right flow and steadiness for a professional look.

This section will break down the key numbers and terms you need to know.

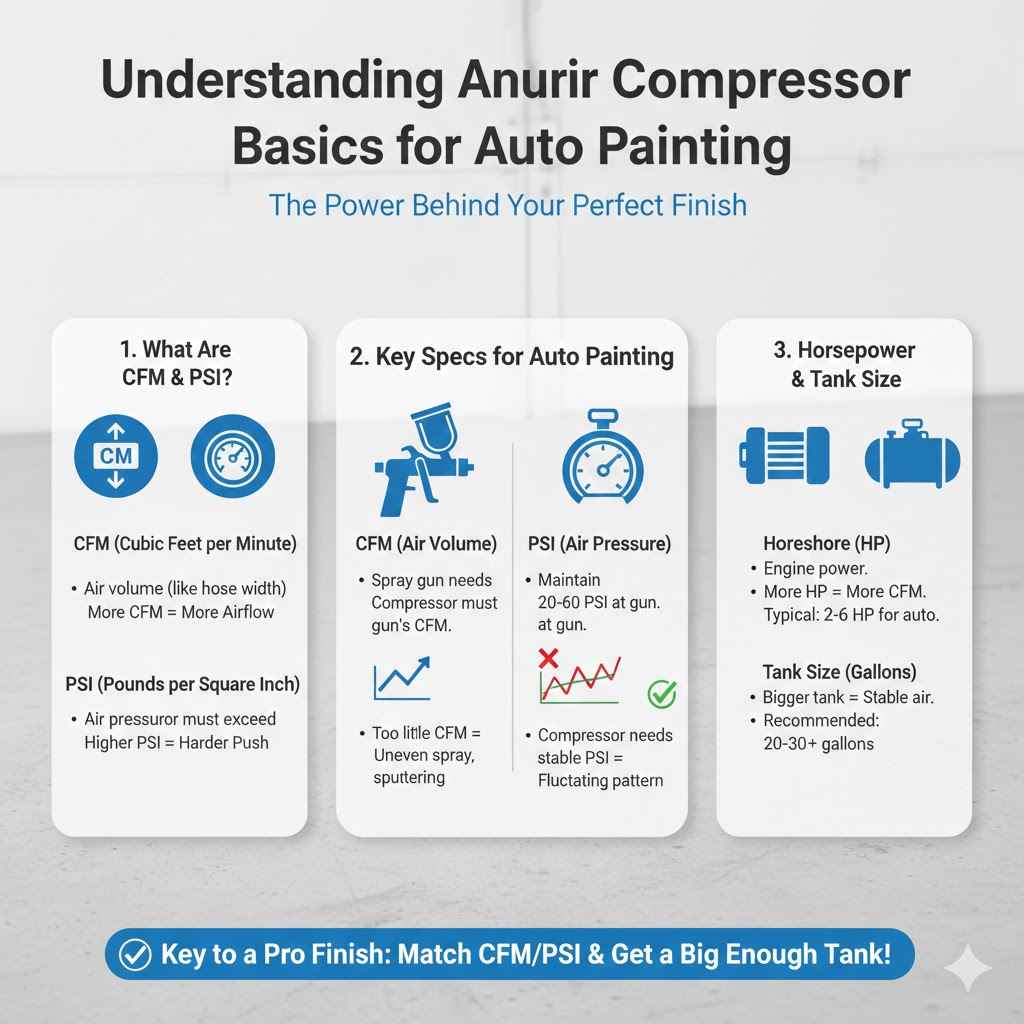

What Are CFM and PSI?

CFM stands for Cubic Feet per Minute. This tells you how much air volume the compressor can deliver. Think of it like the width of a water hose.

A wider hose delivers more water. For painting, you need a certain amount of air to push the paint out evenly.

PSI stands for Pounds per Square Inch. This is the pressure of the air. It’s like how hard the water is being pushed out of the hose.

Too little pressure, and the paint won’t spray right. Too much, and you can cause overspray or damage the paint. You need the right balance for a good paint job.

CFM Explained

CFM is super important for painting cars. Your spray gun has a specific CFM requirement listed in its manual. This is the minimum amount of air it needs to work at its best.

If your compressor’s CFM is lower than what your gun needs, the gun will sputter, and your paint job will suffer. You’ll see things like:

- Uneven spray patterns

- Poor atomization (paint not breaking into fine mist)

- The compressor running constantly trying to keep up

- Potential for the compressor to overheat

To get a great finish, you generally want a compressor that can supply at least 10-15% more CFM than your spray gun requires. This gives you a buffer and ensures consistent performance. For most automotive spray guns, you’ll be looking for compressors that offer between 5 to 15 CFM, depending on the specific gun and application.

PSI Explained

PSI is the force behind the air. Most spray guns work best within a certain PSI range, usually between 20 and 60 PSI. This range is controlled at the spray gun itself or at a regulator connected to the compressor.

While the compressor might have a maximum PSI it can produce, what matters more is its ability to maintain a steady PSI at the required CFM.

A compressor that can’t hold its PSI will lead to fluctuating spray patterns. The paint will come out differently from moment to moment. This is just as bad as not having enough CFM.

You need a stable, controlled flow of air at the right pressure to achieve a smooth, even coat of paint.

Horsepower and Tank Size

Horsepower (HP) on an air compressor is like the engine size in a car. More HP generally means more power and the ability to produce more CFM. For car painting, you’ll typically see compressors ranging from 2 HP to 6 HP or more.

A higher HP compressor will be able to deliver higher CFM at lower duty cycles, meaning it won’t have to run as often.

The tank size is measured in gallons. A larger tank stores more compressed air. Think of it as a reservoir.

A bigger tank means the compressor doesn’t have to kick on and off as frequently. This is really helpful during painting because you want a continuous supply of air. If the compressor is constantly stopping and starting, it can interrupt your spray pattern.

For car painting, a common recommendation is a tank size of at least 20 gallons, with 30 gallons or more being ideal for longer spray sessions. A larger tank will help maintain consistent pressure and CFM, especially when using a demanding spray gun.

What Size Air Compressor Do You Need to Paint Cars The Right Way

Now, let’s get to the core of the matter: What Size Air Compressor Do You Need to Paint Cars? This isn’t a one-size-fits-all answer, as it depends on your specific tools and how you plan to paint. However, we can give you clear guidelines. The goal is to match your compressor’s output to your spray gun’s needs.

We’ll look at different types of spray guns and their requirements to help you make the best choice.

Choosing the Right CFM for Your Spray Gun

The most critical factor in selecting an air compressor for car painting is its CFM output. You must know the CFM requirement of your spray gun. This is usually found in the spray gun’s user manual or on the manufacturer’s website.

Let’s consider some common spray gun types and their typical CFM needs.

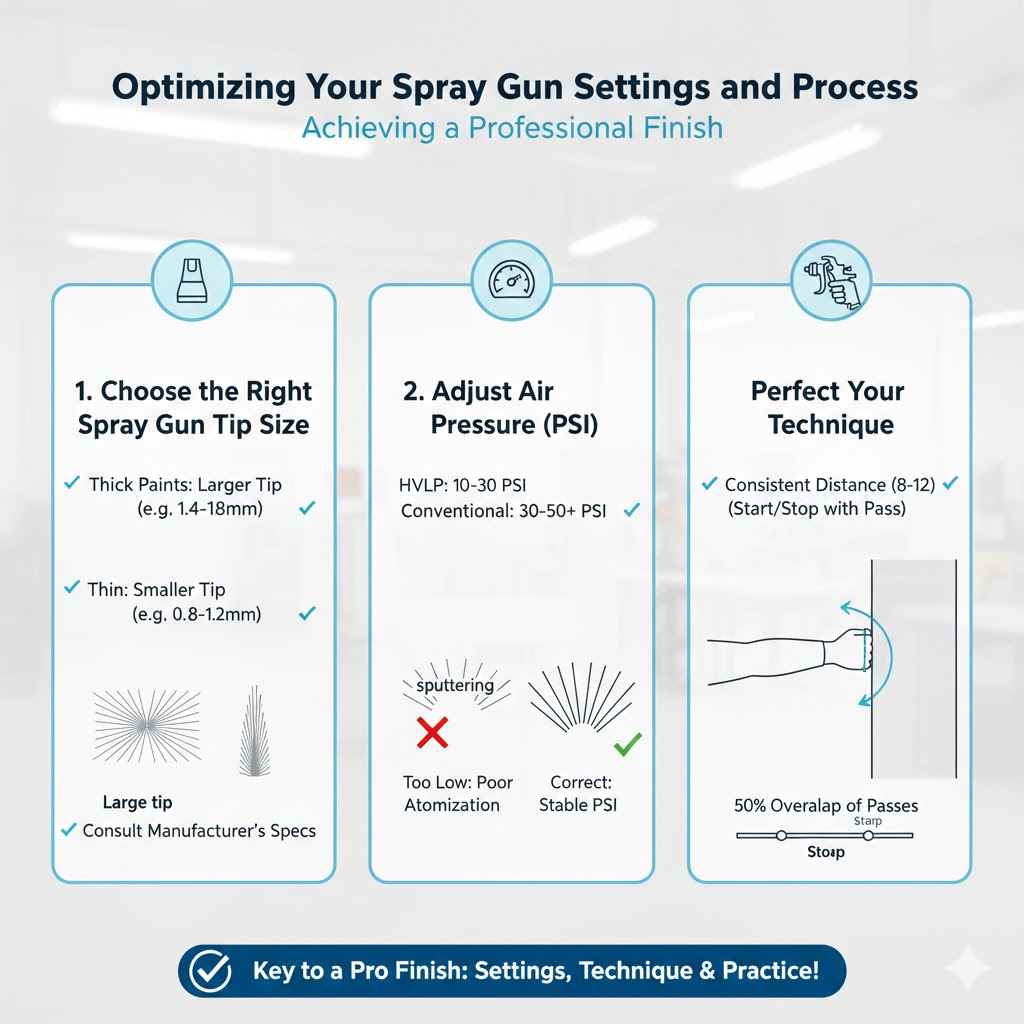

High-Volume Low-Pressure (HVLP) Spray Guns

HVLP spray guns are very popular for car painting because they are efficient with paint and reduce overspray. They typically require a good amount of CFM, but at lower pressures. A common requirement for a good HVLP gun might be around 8 to 12 CFM at 40 PSI.

Some high-performance HVLP guns can even go up to 15 CFM or more.

If you are using an HVLP gun, you’ll need a compressor that can consistently deliver at least 10-14 CFM. To be safe and ensure good performance, aim for a compressor that offers 15-20% more CFM than your gun specifies.

Gravity Feed Spray Guns

Gravity feed spray guns use gravity to feed paint into the air stream. They are versatile and can be used for various applications, including auto body work. Their CFM requirements can vary more widely.

Smaller gravity feed guns might need around 5-8 CFM, while larger ones could require 8-12 CFM.

For general-purpose gravity feed painting of cars, a compressor that can provide 8-10 CFM at the gun is usually sufficient. Again, it’s best to have a little extra CFM to ensure smooth operation.

Conventional Spray Guns

Conventional spray guns are older technology but can still be effective. They typically require higher pressures and can use more air than HVLP guns. A conventional spray gun might need 6-10 CFM, but often at higher PSI settings, which the compressor must be able to handle.

When looking at conventional guns, ensure your compressor can not only meet the CFM but also maintain the necessary pressure. A compressor rated for 8-12 CFM at around 90 PSI would be a good starting point for many conventional spray guns used in auto painting.

Real-World Example: Painting a Car Door

Let’s say you have a popular HVLP spray gun that lists its requirement as 10 CFM at 40 PSI. To paint a car door smoothly without interruption, you should look for a compressor that can reliably deliver at least 12 CFM (10 CFM + 20% buffer). A compressor with a 20-30 gallon tank and a 3-5 HP motor that can provide 12-15 CFM would be an excellent choice for this task.

This setup would allow you to paint the entire door without the compressor constantly cycling on and off.

Matching Horsepower and Tank Size to CFM Needs

The horsepower (HP) and tank size of an air compressor are closely related to its CFM output and how well it can sustain that output. You can’t just look at HP alone, but it’s a good indicator of potential performance.

Horsepower Guide

For car painting, especially if you plan to do it regularly or on larger projects, a compressor with at least a 3 HP motor is recommended. However, HP ratings can be a bit misleading. Some manufacturers list “peak” HP, which is not the same as continuous operating HP.

Always look for the compressor’s actual CFM rating at a specific PSI.

- 1-2 HP Compressors: These are generally too small for effective automotive painting. They might be suitable for very light tasks like inflating tires or using small brad nailers, but they will struggle to keep up with a spray gun. Their CFM output is typically below 5 CFM.

- 3-5 HP Compressors: This range is where you start getting into suitable territory for car painting. A good 3-5 HP compressor, especially an oil-lubricated model, can often deliver 8-15 CFM, which is enough for many HVLP and gravity feed spray guns.

- 5 HP and Above: These larger compressors are ideal for serious enthusiasts and professional work. They can deliver higher CFM (15-25+ CFM) and are often equipped with larger tanks, allowing for longer, uninterrupted spray sessions.

Tank Size Guide

The tank size affects how often the compressor motor needs to run. A larger tank acts as a buffer, storing compressed air. This means less frequent cycling of the motor, which leads to more consistent air delivery and less wear and tear on the compressor.

- Up to 10 Gallons: These are very small tanks, often found on portable compressors. They are not suitable for car painting as the compressor will run almost constantly, leading to heat buildup and inconsistent air supply.

- 10-20 Gallons: This is the minimum size to consider for occasional, small touch-up jobs. However, you will likely experience frequent cycling, and it might not be enough for a full paint job.

- 20-30 Gallons: This is a good starting point for hobbyist car painters. It provides a reasonable air reserve to complete sections of a vehicle without excessive compressor cycling.

- 30-60 Gallons: Ideal for enthusiasts and semi-professionals. These larger tanks offer a significant air reserve, allowing for extended spraying periods and more consistent performance. They are well-suited for painting entire cars or larger projects.

- 60+ Gallons: These are professional-grade compressors. They offer the largest air reserves and the highest CFM outputs, suitable for continuous heavy use and the most demanding spray guns.

Table: Recommended Compressor Specs for Car Painting

| Application | Typical Spray Gun CFM Needed | Recommended Compressor CFM Output | Recommended Tank Size | Recommended Horsepower |

|---|---|---|---|---|

| Light Touch-ups / Small Parts | 3-5 CFM | 5-7 CFM | 10-20 Gallons | 1.5-2.5 HP |

| Partial Panels / Hobbyist Use | 6-10 CFM | 8-12 CFM | 20-30 Gallons | 2.5-4 HP |

| Full Car Paint Job / Enthusiast | 8-15 CFM | 10-18 CFM | 30-60 Gallons | 4-6 HP |

| Professional / Heavy Duty | 15+ CFM | 20+ CFM | 60+ Gallons | 5+ HP |

It’s important to note that these are general guidelines. Always check the specifications of your particular spray gun and choose a compressor that exceeds those needs slightly to ensure optimal performance and longevity of your equipment.

Oil vs. Oil-Free Compressors for Painting

When selecting an air compressor, you’ll encounter two main types: oil-lubricated and oil-free. For automotive painting, an oil-lubricated compressor is generally the preferred choice.

Oil-Lubricated Compressors

These compressors use oil to lubricate the pistons and cylinders. This lubrication process helps to reduce wear and tear, leading to a longer lifespan for the compressor. Oil-lubricated models tend to be quieter and run cooler than their oil-free counterparts.

Crucially for painting, oil-lubricated compressors produce drier air. The oil helps to reduce moisture buildup. However, there is a small risk of oil vapor escaping into the air line, which can contaminate your paint job.

To combat this, it is essential to use an in-line air filter or an air purification system designed for painting.

Oil-Free Compressors

Oil-free compressors are generally lighter, more portable, and require less maintenance. They are often a good choice for DIY tasks where pristine air quality isn’t as critical. However, they tend to be louder, run hotter, and may have a shorter lifespan compared to oil-lubricated models.

The main drawback of oil-free compressors for painting is the higher potential for moisture and oil contamination in the air. While some oil-free models are designed to minimize this, it’s still a significant concern for achieving a flawless paint finish. If you opt for an oil-free compressor, investing in a high-quality air dryer and moisture traps is absolutely essential.

Recommendation for Painting Cars

For professional-looking results and to protect your paint job, choose an oil-lubricated compressor. Always pair it with an appropriate air filtration system. This combination provides the best balance of performance, longevity, and air quality for automotive painting.

An oil-lubricated compressor with a good filtration system will help you avoid common painting problems like fisheyes, runs, and uneven finishes.

Understanding Duty Cycle

The duty cycle of an air compressor refers to the percentage of time the compressor motor can run within a given period (usually 10 minutes) without overheating. For example, a compressor with a 50% duty cycle can run for 5 minutes and must then rest for 5 minutes. A 100% duty cycle means it can run continuously.

Why Duty Cycle Matters for Painting

When you’re spray painting a car, you need a continuous and steady supply of air. If your compressor has a low duty cycle, it will be constantly stopping and starting. This interruption can cause fluctuations in air pressure and flow, leading to inconsistent paint application.

You might notice the spray pattern changing, which can result in an uneven finish, runs, or sags in the paint.

For automotive painting, especially for longer sessions like painting an entire car panel or multiple coats, you want a compressor with a high duty cycle, ideally 75% or even 100%. A compressor with a 100% duty cycle can run continuously without needing to stop, ensuring a stable air supply throughout your painting process.

How Duty Cycle Relates to Compressor Size

Larger, more powerful compressors, particularly those with higher horsepower and larger tanks, generally have higher duty cycles. A small 1-2 HP compressor might only have a 25-50% duty cycle, making it unsuitable for painting. A 3-5 HP compressor with a 20-30 gallon tank will likely have a 75% duty cycle, which is much better.

A larger 5+ HP compressor with a 60+ gallon tank will typically have a 100% duty cycle.

When you are looking at compressor specifications, don’t just focus on the CFM. Pay close attention to the duty cycle, especially if you plan on extended painting sessions. A compressor that can maintain its CFM output without overheating is crucial for a quality paint finish.

Essential Accessories for Your Air Compressor Setup

Having the right air compressor is only part of the equation for successful car painting. You also need a few essential accessories to ensure you get clean, dry air at the right pressure.

Air Regulators

An air regulator controls the output pressure of air from the compressor to the spray gun. Most spray guns have a recommended operating pressure range. The regulator allows you to set and maintain this precise pressure, which is vital for achieving consistent atomization and spray patterns.

You will typically set the regulator at your spray gun, not at the compressor itself, as pressure can drop over the length of the hose.

Moisture Separators/Filters

Air compressors compress air, which naturally contains moisture. As the air cools, this moisture can condense into water. Water in your airline can cause serious problems for your paint job, leading to spots, sags, and poor adhesion.

A moisture separator or in-line filter removes this water before it reaches your spray gun. For automotive painting, it’s highly recommended to use a good quality filter, or even a combination filter that also removes oil and particulates.

Air Hoses

The air hose connects your compressor to your spray gun. The diameter and length of the hose can affect airflow. For painting cars, you’ll want a hose with an inner diameter of at least 3/8 inch to ensure sufficient airflow without significant pressure drop.

The length should be sufficient to comfortably move around the vehicle without being restrictive, typically 25-50 feet.

Quick Connect Fittings

These fittings allow you to easily connect and disconnect your air hose from the compressor and spray gun. They are a convenience item, but they are very practical when you need to switch tools or move your setup.

Air Dryer/Aftercooler (Optional but Recommended)

For serious painters, an air dryer or aftercooler can be a valuable investment. An aftercooler cools the air coming directly from the compressor, which helps to condense more moisture before it even reaches your tank. An air dryer then further dries the air, providing the cleanest, driest air possible for your paint job.

This is especially important in humid climates or for high-quality finishes.

Investing in these accessories will not only improve the quality of your paint job but also protect your tools and ensure your compressor lasts longer. They work together with the compressor to create a complete, functional painting system.

How to Calculate Your Air Compressor Needs

To avoid confusion when asking What Size Air Compressor Do You Need to Paint Cars?, you can do a simple calculation. This ensures you get a compressor that’s powerful enough without overspending. The main thing is matching your spray gun’s requirements.

Step-by-Step Calculation Guide

Here’s a straightforward way to figure out the CFM you need:

- Find Your Spray Gun’s CFM Requirement: Look for the CFM rating on your spray gun. This is often labeled as SCFM (Standard Cubic Feet per Minute) or CFM. It’s usually specified at a particular PSI. If it says, for instance, “8 CFM @ 40 PSI,” that’s your baseline.

- Add a Buffer for Efficiency: It’s wise to have a compressor that can deliver more air than your gun’s minimum requirement. This ensures consistent pressure and prevents the compressor from working too hard. A common recommendation is to add 10-25% to your spray gun’s CFM requirement. Let’s use 20% for our example.

- Calculate Your Target CFM: Take your spray gun’s CFM and multiply it by 1.20 (which represents 100% + 20% buffer).

Example Scenario:

Let’s say your chosen HVLP spray gun requires 10 CFM at 40 PSI.

Your calculation would be:

10 CFM (gun requirement) x 1.20 (buffer) = 12 CFM

This means you should look for an air compressor that can reliably deliver at least 12 CFM at 40 PSI. It’s better to have a bit more CFM than not enough. If you find a compressor that offers 15 CFM, that’s even better and will provide a comfortable margin.

Considering Multiple Tools

If you plan to use other air tools while painting, like an air sander or an impact wrench, you’ll need to factor their CFM requirements into your decision. Each tool has its own CFM needs, and you’ll need a compressor that can handle the highest CFM tool you’ll be using, potentially at the same time if you plan to run them together.

Scenario: Painting and Sanding Simultaneously

Imagine you have an HVLP spray gun needing 10 CFM @ 40 PSI and an air sander needing 8 CFM @ 90 PSI.

For the spray gun, you need about 12 CFM (10 x 1.20).

For the sander, you need about 9.6 CFM (8 x 1.20).

If you plan to use both tools at the same time, you’d need a compressor that can deliver the sum of their required CFM, or more accurately, the highest CFM requirement at the pressure it needs. In many cases, you wouldn’t sand and spray at the exact same moment. You’d paint, then let the air pressure build, then sand.

The critical factor is the peak demand. If you are painting and someone else is sanding, you need enough total output. For most DIY auto painting, you’ll likely be using one tool at a time, so focus on the spray gun.

Common Mistakes to Avoid

When choosing an air compressor for car painting, it’s easy to make mistakes that can cost you time and money. Understanding these common pitfalls can save you a lot of frustration.

- Ignoring Spray Gun CFM: The most frequent mistake is not checking the CFM requirement of the spray gun. Buying a compressor based only on its horsepower or tank size without considering CFM can lead to inadequate performance.

- Not Enough CFM Buffer: Relying on a compressor that just meets the minimum CFM requirement of the spray gun is risky. Without a buffer, the compressor will work harder, leading to overheating, reduced lifespan, and inconsistent air supply.

- Buying an Oil-Free Compressor Without Proper Filtration: While oil-free compressors are convenient, they can introduce moisture and contaminants into the air. For painting, this is a major problem. If you must use an oil-free model, invest heavily in dryers and filters.

- Underestimating Tank Size: A small tank means frequent cycling of the compressor motor. This interrupts your painting flow and can lead to pressure drops. For automotive painting, a larger tank is almost always better.

- Confusing Peak HP with Running HP: Many compressors advertise a high “peak” horsepower. This is a temporary maximum, not the sustained power. Always look for the CFM rating at your desired operating pressure.

By understanding these points, you can make a more informed decision and select an air compressor that will truly meet your automotive painting needs.

Maintenance and Best Practices

Once you’ve selected the right air compressor, proper maintenance is key to ensuring it runs efficiently and lasts for a long time. This is especially true for applications like car painting where air quality is critical.

Regular Draining of the Tank

Compressors build up moisture in the tank as they operate. This water can cause the tank to rust from the inside and can also contaminate your air supply. It’s crucial to drain the water from your compressor’s tank regularly.

Most compressors have a drain valve at the bottom of the tank. For best practice, drain it after every use. This simple step prevents corrosion and ensures cleaner air.

Checking and Replacing Air Filters

Air filters on your compressor prevent dust, dirt, and other particles from entering the compression chamber and your air lines. Over time, these filters can become clogged. A clogged filter restricts airflow, reducing the compressor’s efficiency and potentially causing it to overheat.

Refer to your compressor’s manual for the recommended filter cleaning or replacement schedule. For painting, it’s often a good idea to replace filters more frequently than recommended for general use. Some systems have multiple stages of filtration, including ones right before the spray gun.

Ensure these are clean and in good condition.

Monitoring Oil Levels (for Oil-Lubricated Models)

If you have an oil-lubricated compressor, regularly checking the oil level is essential. Low oil levels can lead to excessive wear and damage to the compressor’s internal components. Use the type and grade of oil recommended by the manufacturer.

Most compressors have a sight glass or dipstick to check the oil level easily. Make sure the compressor is turned off and has cooled down before checking.

Inspecting Air Hoses and Fittings

Regularly inspect your air hoses for any signs of wear, cracks, or leaks. A leaky hose wastes air, reduces pressure, and can be a safety hazard. Also, check your quick-connect fittings to ensure they are creating a tight seal.

Damaged hoses or fittings can compromise your entire air system.

Proper Storage

When not in use, store your air compressor in a clean, dry area. Protect it from extreme temperatures and moisture. If you live in an area with very cold winters, you may need to take precautions to prevent the air and any residual water from freezing within the tank and lines.

Frequent Asked Questions

Question: What is the minimum CFM for painting a car?

Answer: The minimum CFM depends on your spray gun, but generally, for automotive painting, you should aim for at least 8-10 CFM at 40 PSI. However, it’s always best to have a buffer and look for a compressor that can deliver 10-25% more CFM than your spray gun’s requirement.

Question: Can I use a small portable compressor for car painting?

Answer: Small portable compressors with low CFM output (under 5 CFM) are typically not suitable for painting cars. They don’t have enough air volume to properly atomize paint, leading to poor finishes. They also tend to cycle on and off too frequently.

Question: How important is the tank size for painting cars?

Answer: Tank size is very important. A larger tank stores more compressed air, which acts as a buffer. This means the compressor motor runs less often, providing a more consistent air supply and preventing pressure drops that can ruin a paint job.

Aim for at least 20 gallons, with 30-60 gallons being ideal.

Question: Do I need an oil-lubricated or oil-free compressor for car painting?

Answer: For car painting, an oil-lubricated compressor is generally preferred because it produces drier air and tends to last longer. However, you must use an in-line air filter to prevent oil contamination. Oil-free compressors can be used, but require more robust filtration systems.

Question: What PSI should my air compressor deliver for car painting?

Answer: The compressor itself might produce higher PSI, but you will use an air regulator to set the pressure at your spray gun. Most automotive spray guns operate effectively between 20 and 60 PSI, depending on the type of gun and paint being used. Your spray gun manual will specify the optimal range.

Summary

When asking What Size Air Compressor Do You Need to Paint Cars?, focus on CFM output. Aim for a compressor that provides 10-25% more CFM than your spray gun requires. A 3-5 HP compressor with a 20-30 gallon tank is a good starting point for hobbyists, while larger setups are better for enthusiasts.

Always use oil-lubricated models with good filtration for the best results. This ensures a smooth, professional finish.