Wheels for Table Saw: Enhance Mobility and Efficiency

Wheels for a table saw can make life easier. They add mobility and convenience.

Imagine having the power to move your heavy table saw effortlessly. Wheels transform a stationary tool into a versatile one. This upgrade helps in small workshops and busy workspaces. With wheels, you can rearrange your setup quickly. This flexibility boosts productivity and safety.

You avoid the hassle of lifting and the risk of injury. Plus, it saves time and effort. In this blog, we will explore the benefits and options for adding wheels to your table saw. Get ready to make your woodworking experience smoother and more efficient.

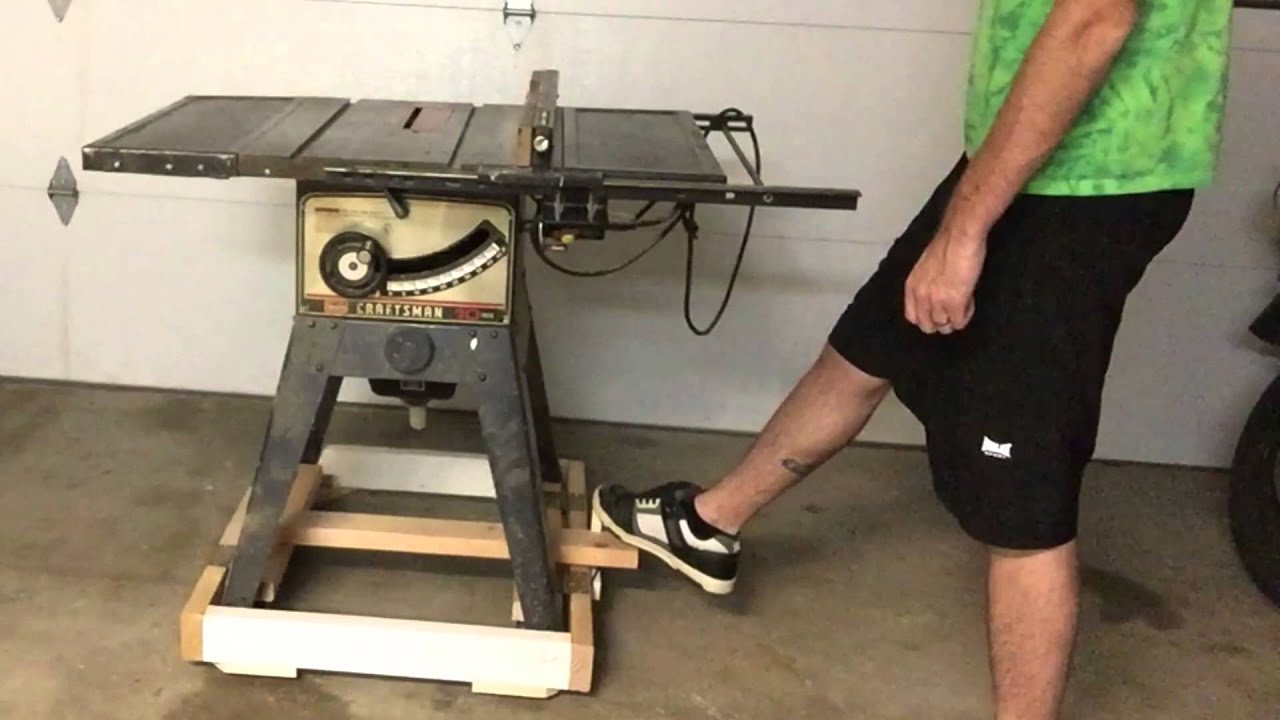

Credit: www.youtube.com

Importance Of Mobility For Table Saws

Wheels on a table saw make work faster. Moving the saw is easy. No heavy lifting. No back pain. You can push the saw to any spot. Cut wood where you need. Save time. Boost productivity.

Workshops can be crowded. A table saw with wheels solves this problem. Move it around freely. Create space when needed. Adjust the layout of your workshop. Keep the area clean. Easy movement means better work flow.

Credit: www.instructables.com

Types Of Wheels For Table Saws

Fixed wheels are great for stability. They do not turn or swivel. They are mounted straight. Easy to move in a straight line. Perfect for straight paths. Fixed wheels keep your table saw steady. They prevent wobbling.

Swivel wheels can turn in any direction. They are also called caster wheels. Easy to steer and move. Great for small spaces. Perfect for tight corners. Swivel wheels offer flexibility. They can move freely and smoothly.

Material Considerations

Rubber wheels are soft and quiet. They offer a good grip. This reduces slipping and increases control. Rubber wheels are also shock-absorbing. They can handle uneven floors well. These wheels are durable and long-lasting. But they may wear out quickly on rough surfaces.

Polyurethane wheels are strong and hard. They can carry heavier loads than rubber wheels. These wheels are also resistant to chemicals and abrasion. They work well on smooth surfaces. Polyurethane wheels can be noisier than rubber wheels. But they last longer and need less maintenance.

Load Capacity And Stability

Table saw wheels must support the saw’s weight. This ensures stability during use. Choose wheels that can handle the heaviest loads. Lightweight wheels may break or bend. Strong wheels keep your saw safe. They also make moving the saw easier. Check the maximum load capacity. This helps you pick the right wheels.

Wheels must keep the saw balanced. Good balance prevents accidents. Unbalanced saws can tip over. This is dangerous. Wheels with locking mechanisms help. They keep the saw steady when not moving. Brake systems are also useful. They stop the saw from rolling. Always check the balance features before buying wheels.

Installation Process

You need a wrench, a screwdriver, and some bolts. A drill might be useful too. Make sure to have a measuring tape ready.

First, measure the distance between the legs of your table saw. Mark where you need to drill holes. Drill the holes carefully. Attach the wheels using the bolts and a wrench. Tighten the bolts well.

Check if the wheels are secure. Adjust if needed. Make sure your table saw is stable. Test by moving it a bit. If it moves smoothly, the installation is done.

Safety Precautions

Always ensure the table saw is stable. Check the legs and frame for any wobble. Use clamps to secure it tightly. A stable saw is safer to use. Double-check the connections before turning it on. Make sure the saw does not move during cutting.

Wheel locks are very important. Ensure all wheels have a locking mechanism. Press the lock to keep the saw in place. Test each lock before use. If a lock is faulty, replace it. Check the locks regularly for safety.

Maintenance Tips

Check wheels for wear and tear. Look for cracks or dents. Ensure the wheels spin smoothly. Tighten any loose bolts. Inspect the wheel alignment. Misaligned wheels can cause problems. Replace any damaged parts. Regular checks can prevent accidents.

Clean the wheels with a soft cloth. Remove dirt and dust. Use a brush for tough spots. Lubricate the wheels with machine oil. Apply oil to moving parts. Wipe off excess oil. Clean and lubricate monthly. This keeps the wheels working well.

Credit: diy.stackexchange.com

Top Brands And Products

Many brands offer wheel kits for table saws. These kits help in moving the saw easily. Bora Portamate is a well-known brand. Their Mobile Base Kit is popular. POWERTEC also has good options. Their Universal Mobile Base Kit is sturdy and reliable. DEWALT offers strong and durable wheels. Their products are known for quality. HTC has a nice selection too. Their kits are easy to install. Each brand has its strengths. Choose based on your needs and budget.

Customer feedback is very important. Many users like Bora Portamate for its ease of use. Reviews say it is easy to move around. POWERTEC gets praise for its stability. Users feel safe using it. DEWALT is loved for its strength. It handles heavy loads well. HTC gets positive reviews for its easy installation. Users find it simple to set up. Read reviews to make an informed choice. Happy customers often share useful insights.

Frequently Asked Questions

What Are The Benefits Of Table Saw Wheels?

Table saw wheels make your tool mobile and easy to move. They enhance safety by allowing you to reposition your saw effortlessly.

How Do I Install Wheels On A Table Saw?

To install wheels, attach a mobile base kit to the saw’s legs. Follow the manufacturer’s instructions carefully.

Are Table Saw Wheels Safe?

Yes, table saw wheels are designed with safety in mind. They often include locking mechanisms to prevent movement during use.

Can I Add Wheels To Any Table Saw?

Most table saws can accommodate wheels. Check your model’s compatibility with mobile base kits for best results.

Conclusion

Choosing the right wheels for your table saw boosts your woodworking efficiency. Easy mobility ensures convenience and safety in your workspace. Look for durable wheels that fit your table saw model. Regular maintenance keeps the wheels working smoothly. Investing time in selecting the best wheels pays off in the long run.

Better mobility, better workflow. Enjoy safer and more productive woodworking sessions with the right wheels.