When Can You Stain Pressure Treated Wood: Expert Timing Guide

You can stain pressure treated wood once it’s dry. This usually takes a few weeks to a few months.

Timing depends on factors like climate and wood type. Staining pressure treated wood can be tricky. It’s vital to wait until the wood is fully dry. If you stain it too soon, the stain won’t adhere properly. This can lead to a patchy, unattractive finish.

Understanding the right time to stain ensures your wood looks great and lasts long. In this guide, we’ll explore how to determine the best time to stain your pressure treated wood. We’ll also share tips on preparing the wood for staining and choosing the right stain. This way, you can achieve a beautiful, durable finish.

Credit: rainonatinroof.com

Introduction To Pressure Treated Wood

Pressure treated wood is wood treated with chemicals. These chemicals protect the wood from rot, insects, and decay. This makes the wood last longer. It is often used in outdoor projects.

This wood is used for decks, fences, and playgrounds. It is also used for picnic tables and garden beds. Many people choose it for its durability. It is great for areas exposed to weather. Builders and homeowners trust this wood for strong, lasting structures.

Why Staining Is Important

Staining pressure treated wood gives it a fresh look. It also adds long-term protection. Staining helps prevent wood decay and rot. It seals the wood against moisture. Moisture can cause wood to swell and crack. Staining also protects against sun damage. UV rays can fade the wood’s color. Staining keeps the wood looking new.

Another benefit is that staining makes the wood easier to clean. Dirt and debris do not stick as easily. Staining also helps to prevent mold and mildew. These can cause health issues. Staining pressure treated wood ensures it lasts longer. It saves money in the long run. Less maintenance is needed when wood is stained.

Ideal Conditions For Staining

Staining pressure treated wood requires the right weather. Avoid rainy days. Dry weather is best for staining. Check the forecast before starting. The wood must be dry for 24-48 hours. This helps the stain to absorb properly.

Humidity should be low. High humidity slows drying time. Aim for humidity levels below 60%. Temperature also matters. Ideal temperature is 50-90°F. Too hot or too cold can affect the stain. Make sure to stain on a cool day. Avoid direct sunlight. This prevents the wood from drying too fast.

Credit: thecraftsmanblog.com

Identifying Wood Readiness

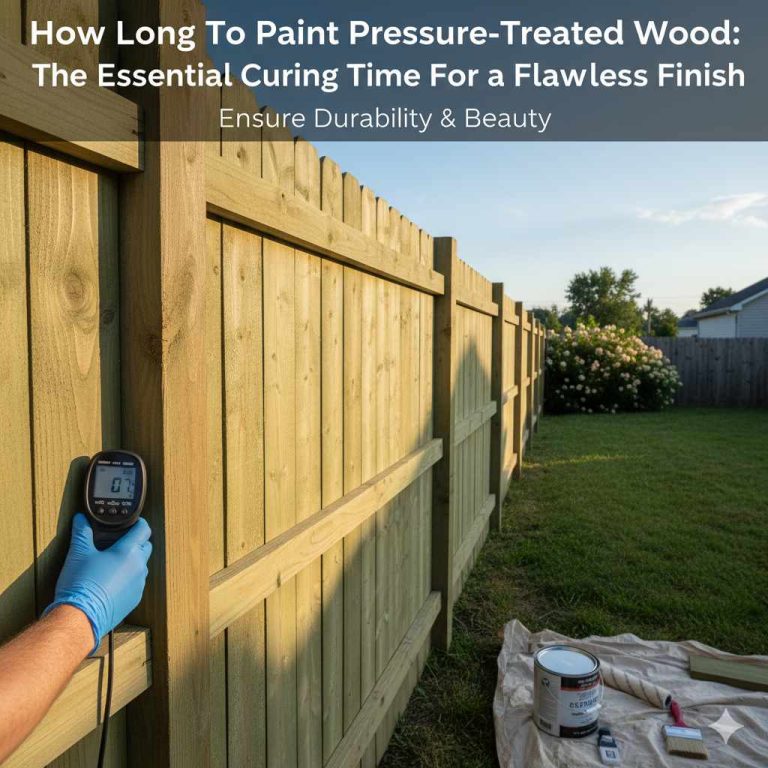

Pressure treated wood has a lot of moisture. To stain it, the wood must be dry. A moisture meter helps check the wood. Insert the meter into the wood. The reading should be below 15%. If it’s higher, the wood is still wet. Wait for the wood to dry before staining.

Look at the surface of the wood. Dry wood looks dull and has cracks. Wet wood looks shiny and smooth. Touch the wood. Dry wood feels rough. Wet wood feels damp and cool. Check for water beads. If you see them, the wood is wet. Wait until the wood is dry to stain it.

Best Time Of Year To Stain

Spring and fall are ideal for staining. The weather is mild. Temperatures should be between 50-80°F. The humidity should be low. This helps the wood absorb the stain.

Avoid staining during extreme weather. Hot summer days can dry the stain too fast. Cold winter days can prevent proper drying. Rainy days are also bad. Wet wood won’t absorb the stain.

Preparing Wood For Staining

Stain pressure treated wood after it dries completely. Drying can take a few weeks to several months. Ensure the wood is clean and smooth before staining.

Cleaning The Surface

Start by cleaning the surface of the wood. This removes dirt and grime. Use a stiff brush to scrub the wood. Warm water and mild soap work well for this. Rinse the wood with clean water. Let it dry fully before staining. Drying can take a few days.

Necessary Tools And Materials

| Tools | Materials |

|---|---|

| Stiff brush | Warm water |

| Bucket | Mild soap |

| Hose | Stain |

| Sandpaper | Rags |

Staining Techniques And Tips

Picking the right stain is crucial. There are two main types: oil-based and water-based. Oil-based stains last longer. Water-based stains dry faster. Both have their own benefits. Think about your needs before you choose.

Apply stain with a brush, roller, or sprayer. Brushes give good control. Rollers cover large areas fast. Sprayers are best for even coats. Always follow the grain of the wood.

Credit: www.sand-stain.com

Maintenance After Staining

Keep the wood clean. Use a mild soap and water. Dry it well after cleaning. Dirt can damage the stain. Sweep leaves and debris regularly. This helps keep the wood looking nice.

Check for mold or mildew. These can harm the wood. Use a solution of water and vinegar. Scrub gently and rinse well. Look for cracks or splits. Fill them with wood filler. Sand the area smooth. This prevents further damage.

Frequently Asked Questions

When Can You First Stain Pressure-treated Wood?

You can stain pressure-treated wood once it is dry, typically after 2-4 months. This allows the wood to absorb the stain properly.

How Do You Know Wood Is Ready To Stain?

Wood is ready to stain when it absorbs water droplets. If the water soaks in, it’s ready for staining.

What Happens If You Stain Pressure-treated Wood Too Soon?

Staining too soon can result in poor adhesion, leading to a blotchy appearance and reduced wood protection.

Can You Stain Pressure-treated Wood In Winter?

Staining in winter is possible, but ensure temperatures stay above 50°F. Cold weather can affect stain absorption.

Conclusion

Staining pressure treated wood requires careful timing. Wait until the wood dries fully. This could take weeks or months. Test the wood’s moisture with a simple water drop test. If it absorbs, it’s ready to stain. Choosing the right stain matters too.

Opt for quality, durable products. Regular maintenance keeps your wood looking fresh and protected. Follow these steps for a successful staining project. Your pressure treated wood will look great and last longer. Happy staining!