Wood Cutting Wedge Essentials: Maximize Your Chopping

A wood cutting wedge is a tool used to split logs or wood. It helps to create a gap, allowing for easier splitting.

Wood cutting wedges are essential tools for anyone involved in woodwork or logging. These simple yet effective devices are designed to assist in splitting timber efficiently. By driving a wedge into the wood, users can create leverage that fractures the material along its natural grain.

This method is especially useful for larger logs that are difficult to split with an axe. Available in various sizes and materials, wood cutting wedges cater to different needs and preferences. Whether you’re a seasoned lumberjack or a DIY enthusiast, understanding how to use a wood cutting wedge can enhance your wood cutting experience significantly.

The Role Of Wood Cutting Wedges

Wood cutting wedges are essential tools in lumberjacking and woodworking. They help split logs and direct the fall of trees. A wedge applies pressure to the wood, creating a clean break. This action makes cutting easier and safer.

Types Of Wood Cutting Wedges

There are several types of wood cutting wedges, each designed for specific tasks. Here are the most common types:

- Standard Wedge: Basic shape, ideal for most cutting tasks.

- Felling Wedge: Larger, helps control tree direction during felling.

- Splitting Wedge: Heavy-duty, designed for splitting logs.

- Plastic Wedge: Lightweight, used for delicate tasks.

Benefits Of Using A Wedge

Using a wood cutting wedge offers many advantages:

- Improved Safety: Reduces the risk of injury.

- Increased Efficiency: Cuts logs faster with less effort.

- Better Control: Directs the fall of trees accurately.

- Cleaner Cuts: Produces less splintering and damage.

Wood cutting wedges are a must-have for anyone working with wood. They enhance safety, improve efficiency, and provide better control. Choose the right wedge for your specific needs.

Selecting The Right Wedge

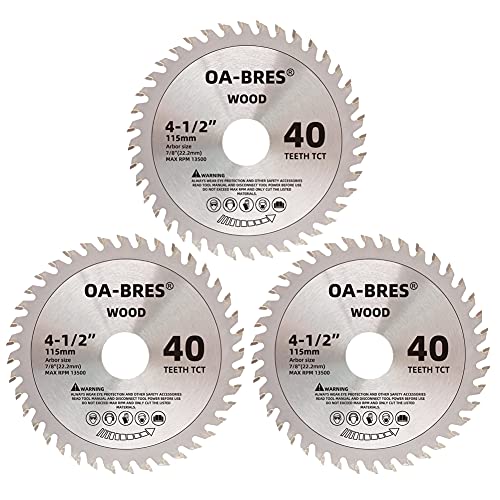

Choosing the right wood cutting wedge is essential for effective splitting. The correct wedge can make your task easier and safer. Focus on two main factors: material and size.

Material Considerations

Wedges come in different materials. Each has its benefits:

- Steel: Very durable. Ideal for heavy-duty tasks.

- Aluminum: Lightweight and easy to carry. Good for quick jobs.

- Plastic: Less durable but safe for small logs. Prevents damage to chainsaws.

Choose a material based on your needs. For heavy logs, steel is best. For lighter tasks, consider aluminum or plastic.

Size And Weight For Efficiency

The size and weight of the wedge affect its performance:

| Wedge Size | Weight | Best Use |

|---|---|---|

| Small (3-5 inches) | Light (1-2 lbs) | Small logs and branches |

| Medium (5-8 inches) | Medium (2-4 lbs) | Most general tasks |

| Large (8+ inches) | Heavy (4+ lbs) | Heavy-duty splitting |

A smaller wedge is easier to handle. Larger wedges provide more splitting power. Choose the right size for your specific needs.

Proper Techniques For Using Wedges

Using wood cutting wedges correctly can improve your splitting efficiency. Mastering these techniques ensures safety and effectiveness. Follow these steps for optimal results.

Positioning For Optimal Splitting

Correct positioning is key for effective splitting. Here are some tips:

- Stand with your feet shoulder-width apart.

- Position the wedge at the natural crack in the wood.

- Ensure the wedge is angled slightly downwards.

Check the following table for ideal wedge placement:

| Wedge Type | Ideal Placement |

|---|---|

| Plastic Wedge | Near the center of the log |

| Metal Wedge | At existing splits |

| Wood Wedge | In larger knots |

Striking Accurately

Accurate strikes maximize wedge effectiveness. Follow these steps:

- Use a heavy mallet or maul for striking.

- Aim for the center of the wedge.

- Maintain a steady grip on the mallet.

- Strike with controlled force, not too hard.

Practice will improve your accuracy. Focus on your swing rhythm. This will help split wood more efficiently.

Safety Measures During Chopping

Chopping wood can be fun and rewarding. However, it also has risks. Safety is crucial to prevent injuries. Follow these measures to stay safe while using a wood cutting wedge.

Personal Protective Equipment

Always wear the right protective gear. This equipment reduces the risk of injury. Essential items include:

- Safety goggles: Protect your eyes from flying debris.

- Hard hats: Shield your head from falling branches.

- Ear protection: Guard against loud noises.

- Gloves: Protect your hands from cuts and splinters.

- Steel-toed boots: Prevent foot injuries from heavy objects.

Wearing this gear is vital. It keeps you safe and comfortable while working.

Wedge Handling And Storage

Proper handling and storage of wood cutting wedges is essential. Follow these guidelines:

- Inspect the wedge: Check for cracks or damage before use.

- Use the right wedge: Choose a wedge that fits the job.

- Store wedges safely: Keep them in a dry, secure place.

- Keep out of reach: Store wedges away from children.

- Don’t leave wedges on the ground: This prevents tripping hazards.

Proper handling and storage prevent accidents. Take these steps seriously for a safer chopping experience.

Maintaining Your Wood Cutting Wedges

Proper maintenance of your wood cutting wedges ensures they work effectively. A well-maintained wedge helps in making clean cuts. Regular care extends their lifespan and enhances safety.

Cleaning Best Practices

Keeping your wood cutting wedges clean is essential. Dirt and debris can affect their performance. Follow these best practices for effective cleaning:

- Use a soft brush to remove dirt.

- Soak in warm, soapy water for stubborn grime.

- Rinse with clean water and dry thoroughly.

Regular cleaning prevents rust. Always inspect for any signs of damage after cleaning.

Sharpening Your Wedges

Sharp wedges cut through wood easily. Dull wedges require more force and can be dangerous. Follow these steps to sharpen your wedges:

- Use a sharpening stone or file.

- Hold the wedge securely in one hand.

- Sharpen at a consistent angle, usually 30 degrees.

- Check for a smooth edge after sharpening.

Regular sharpening ensures safe and effective cuts. Aim to sharpen after every few uses, or as needed.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning | After each use | Prevent rust and damage |

| Sharpening | Every few uses | Maintain cutting efficiency |

Troubleshooting Common Issues

Using a wood cutting wedge can lead to some challenges. Knowing how to troubleshoot these issues can make your task easier. Here are two common problems and their solutions.

Stuck Wedges And Removal

Wedges can sometimes get stuck in the wood. This can happen for several reasons:

- Wood is too dense.

- The wedge is driven too deep.

- Improper angle during insertion.

To remove a stuck wedge, follow these steps:

- Assess the situation carefully.

- Use a hammer to tap the wedge gently.

- Try wiggling the wedge side to side.

- Apply lubricant like WD-40 around the wedge.

- Use a pry bar for extra leverage, if needed.

Always wear safety gear during this process. Protect your eyes and hands.

Dealing With Tough Wood

Tough wood can make cutting challenging. Here are tips to handle it effectively:

- Choose the right type of wedge.

- Ensure your tools are sharp.

- Moisten the wood slightly for easier cutting.

Consider the following table for wedge types:

| Wedge Type | Best For |

|---|---|

| Standard Wedge | General use |

| Splitting Wedge | Hardwood |

| Wedge with Handle | Heavy-duty tasks |

Using the right wedge can make a big difference. It helps you cut through tough wood more efficiently.

Advanced Wedge Techniques

Mastering advanced wedge techniques can enhance your wood cutting skills. These methods increase efficiency and safety. Let’s explore two key techniques: combining wedges for large logs and creating kindling efficiently.

Combining Wedges For Large Logs

Using multiple wedges can break down large logs effectively. This method distributes the pressure evenly. Here’s how to do it:

- Select the right wedges. Choose sturdy materials.

- Position the first wedge at the center of the log.

- Drive the first wedge into the log using a sledgehammer.

- Insert additional wedges on either side of the first.

- Continue hammering until the log splits.

Benefits of combining wedges:

- Increased splitting force.

- Faster log breakdown.

- Reduced effort for the user.

Creating Kindling Efficiently

Creating kindling helps start fires quickly. Wedges are excellent tools for this task. Follow these steps for efficient kindling production:

| Step | Description |

|---|---|

| 1 | Choose small, dry logs. |

| 2 | Place the log on a stable surface. |

| 3 | Use a wedge to split the log into smaller pieces. |

| 4 | Repeat until you have enough kindling. |

Benefits of using wedges for kindling:

- Faster fire-starting process.

- Consistent size for easy burning.

- Less waste compared to traditional chopping.

Innovations In Wood Cutting

Wood cutting has evolved significantly over the years. New technologies and designs enhance efficiency and safety. Innovations in materials and environmental considerations are crucial today. Let’s explore these advancements.

New Materials And Designs

Wood cutting wedges have seen exciting changes. Manufacturers now use advanced materials for better performance. Here are some key innovations:

- High-Strength Plastics: Lightweight and durable, these wedges reduce fatigue.

- Aluminum Alloys: These are strong yet lightweight, perfect for heavy tasks.

- Ergonomic Designs: Modern shapes fit comfortably in the hand.

These innovations lead to better cutting accuracy. Users can complete tasks faster and with less effort.

Environmental Considerations

Today’s wood cutting tools focus on sustainability. Here are some important factors:

- Recycled Materials: Many wedges now use recycled plastics.

- Sustainable Sourcing: Manufacturers prioritize eco-friendly resources.

- Minimal Waste: New designs reduce material waste during production.

These steps help protect our forests and nature. Eco-friendly products attract more consumers. Innovations in wood cutting reflect a commitment to the environment.

Frequently Asked Questions

What Is A Wood Cutting Wedge Used For?

A wood cutting wedge is primarily used to split logs and firewood. It helps create a gap in the wood, making it easier to break apart. This tool is essential for anyone working with wood, whether for construction or recreational purposes.

How Do You Use A Wood Cutting Wedge?

To use a wood cutting wedge, first, position it at the desired spot on the log. Strike the wedge with a hammer or mallet to drive it into the wood. Repeat as necessary until the log splits. Always wear safety gear during this process for protection.

What Materials Are Wood Cutting Wedges Made From?

Wood cutting wedges are typically made from metal, plastic, or wood. Metal wedges are durable and effective for heavy-duty tasks. Plastic wedges are lightweight and ideal for smaller jobs. Each material has its own advantages, depending on the intended use.

How Do You Choose The Right Wood Cutting Wedge?

Choosing the right wood cutting wedge depends on your task. Consider the size and type of wood you’ll be splitting. A wider wedge works well for larger logs. For precision, a narrower wedge may be more effective. Always assess your needs before making a purchase.

Conclusion

A wood cutting wedge is an essential tool for any woodworker or outdoor enthusiast. It enhances safety and efficiency during cutting tasks. Choosing the right wedge can make a significant difference in your woodworking projects. Invest in quality wedges to streamline your work and achieve better results every time.