Wood Screw Diameters: Essential Guide for Secure Fixing

Wood screw diameters typically range from #0 to #14, measured in gauge sizes. The diameter increases as the gauge number decreases.

Understanding wood screw diameters is essential for any woodworking project. Choosing the right diameter ensures strong connections and prevents splitting. Wood screws come in various sizes, making it crucial to select the correct one for your application. The gauge size indicates the screw’s diameter, with lower numbers signifying thicker screws.

This selection impacts the screw’s holding power and the type of wood being used. Whether you’re building furniture or installing cabinetry, knowing the appropriate diameter helps achieve sturdy and reliable results. Always consider the material and purpose when selecting wood screws to enhance the durability of your projects.

Introduction To Wood Screw Diameters

Understanding wood screw diameters is crucial for effective woodworking. The right diameter ensures proper grip and strength.

Different projects require different screw sizes. Thicker screws hold better but may split wood. Thinner screws may not provide enough support.

Choosing the right diameter depends on several key factors:

| Factor | Description |

|---|---|

| Wood Type | Softwoods need smaller screws; hardwoods require larger ones. |

| Screw Length | Longer screws need larger diameters for strength. |

| Load Requirements | Heavy loads need thicker screws for safety. |

Types Of Wood Screws

Wood screws come in many types. Each type serves a specific purpose. Here are some common varieties:

- Flat Head Screws: These screws sit flush with the surface.

- Pan Head Screws: These have a rounded top for a decorative look.

- Round Head Screws: These are fully rounded and provide a classic style.

- Socket Head Screws: These require a special tool for installation.

Some screws have specialized applications:

- Deck Screws: Designed for outdoor use, resistant to rust.

- Drywall Screws: Ideal for attaching drywall to wooden or metal studs.

- Wood Deck Screws: Used specifically for securing wood decking.

- Lag Screws: Heavy-duty screws for thick materials.

Measuring Screw Diameters

Measuring screw diameters requires specific tools for accuracy. Use a caliper for precise measurements. A ruler can also help, but may not be as accurate.

Other tools include a micrometer for small screws and a tape measure for larger ones. Always ensure the tools are calibrated before use.

| Tool | Purpose |

|---|---|

| Caliper | Measure diameter accurately |

| Ruler | Quick measurement |

| Micrometer | Measure small screws |

| Tape Measure | Measure larger screws |

Follow these steps for measuring: first, choose your tool. Next, place the screw in the tool’s jaws or against the ruler.

Read the measurement carefully. Write down the diameter for future reference. Repeat for other screws as needed.

Choosing The Right Diameter

Choosing the right wood screw diameter is important for your project. Material thickness affects which diameter to use. Thicker materials need larger screws for strength. For thinner materials, smaller screws work best.

Joint type also plays a role in your choice. For butt joints, use wider screws. For lap joints, smaller screws may suffice. Pilot holes can help prevent wood splitting, especially with larger screws.

| Material Thickness | Recommended Screw Diameter |

|---|---|

| 1/4 inch | #4 or #6 |

| 1/2 inch | #8 or #10 |

| 3/4 inch | #10 or #12 |

Impact Of Diameter On Screw Performance

The diameter of a wood screw greatly affects its holding strength. A larger diameter provides better grip in the wood. This helps to prevent the screw from pulling out. Smaller screws may not hold as firmly, especially in soft woods.

Holding strength is vital for stability. For heavy objects, a thicker screw is often needed. Thinner screws may lead to failure, especially under stress.

Risk of wood splitting increases with larger screws. Wood may crack if a screw is too thick for the material. Pre-drilling can help reduce this risk. Always choose the right diameter for the project.

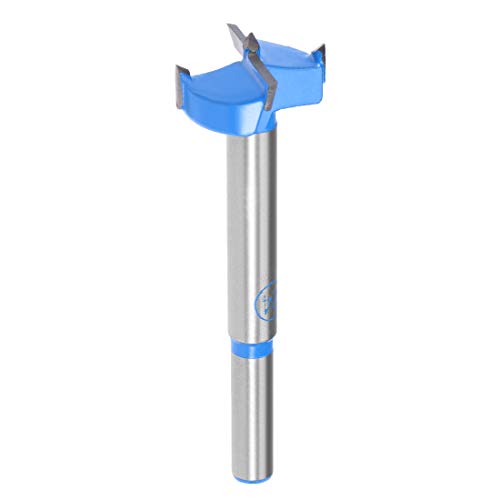

Matching Screw Diameter With Pilot Holes

Choosing the right screw diameter for your pilot holes is very important. It helps in achieving a strong hold. A proper fit reduces the risk of splitting the wood. This ensures that the screws stay in place.

Pilot holes guide screws into the wood. They prevent damage and make installation easier. Each screw size needs a specific hole size. Using the wrong size can lead to problems.

Methods for perfect alignment include measuring carefully. Always use a drill bit that matches the screw diameter. This practice will save time and effort.

Tips For Working With Various Wood Types

Understanding the difference between hardwoods and softwoods is essential. Hardwoods come from trees like oak and maple. These woods are usually denser and stronger. Softwoods, like pine and cedar, are lighter and easier to work with.

Choosing the right screw diameter depends on wood density. For hardwoods, select a larger diameter screw. This helps create a stronger hold. For softwoods, a smaller diameter screw works better. It prevents splitting and damage to the wood.

Always consider the screw length too. A longer screw provides more grip in dense wood. Shorter screws are ideal for lighter woods. This ensures a secure fit without excess strain.

Troubleshooting Common Issues

Stripped screws can cause major problems. Using the wrong size screwdriver leads to this issue. Always choose a screwdriver that fits well. If a screw is stripped, try using rubber bands for grip. This can help you remove the screw easily.

Misalignment happens often during installation. Check the angle before driving screws into wood. Using a pilot hole can prevent misalignment. A pilot hole guides the screw and keeps it straight. Make sure to use the right drill bit size for the screw diameter.

Frequently Asked Questions

What Are Common Wood Screw Diameters?

Common wood screw diameters typically range from #0 to #14. Smaller screws, like #0, are suitable for light applications. Larger screws, such as #14, are ideal for heavy-duty tasks. It’s essential to select the right diameter for your project to ensure a secure fit and optimal performance.

How To Choose The Right Wood Screw Diameter?

To choose the right wood screw diameter, consider the material and load requirements. Thicker screws offer greater strength, while thinner screws work for lighter applications. Always match the screw diameter to the material thickness for the best results. Testing different sizes can help you find the optimal fit.

What Is The Difference Between Gauge And Diameter?

Gauge refers to the screw’s thickness, while diameter measures its width. The gauge system is not linear; larger numbers indicate thinner screws. Understanding both terms is essential when selecting screws for your project. A proper match ensures strong connections and prevents damage to the materials being joined.

Can You Use Different Diameters In The Same Project?

Using different diameters in the same project is possible but should be done carefully. Mixing sizes can affect the integrity of the assembly. It’s best to maintain consistency for strength and stability. If necessary, use smaller screws for lighter components and larger screws for heavier parts.

Conclusion

Understanding wood screw diameters is essential for any woodworking project. Choosing the right diameter ensures a secure fit and optimal strength. Remember to consider the material and application for best results. With this knowledge, you can enhance your craftsmanship and achieve professional-looking results.

Happy woodworking!