Board Foot Calculator for Insulation: Maximize Savings!

To calculate board feet for insulation, multiply the length, width, and thickness in inches, then divide by 144. This formula provides a quick estimate for insulation needs.

Understanding how to calculate board feet for insulation is essential for efficient project planning. Board feet measures volume and helps determine how much insulation material you need. Accurate calculations ensure you purchase the right amount, reducing waste and saving costs.

Whether you’re working on a DIY project or a professional job, knowing how to use a board foot calculator can simplify the process. This tool allows you to input dimensions and quickly receive an estimate, making it a valuable resource for homeowners and contractors alike. Explore the benefits of using a board foot calculator today for your insulation projects!

Introduction To Insulation Savings

Insulation plays a crucial role in saving money on energy bills. Proper insulation keeps homes warm in winter and cool in summer. This leads to reduced energy consumption. Lower energy costs mean more savings for homeowners.

Using a board foot calculator helps determine the amount of insulation needed. It measures the volume of insulation in a simple way. Knowing the right amount prevents overspending on materials. Proper calculations ensure your home stays energy-efficient.

In areas like Austin, Texas, insulation is essential due to varying temperatures. Effective insulation can significantly cut heating and cooling costs. Investing in quality insulation pays off in the long run.

Board Foot Basics

A board foot is a unit of measurement for lumber. It represents a volume of 1 foot long, 1 foot wide, and 1 inch thick. This measurement is useful in the world of insulation as it helps determine the amount of material needed for a project.

Understanding how a board foot relates to insulation is crucial. For example, insulation materials often come in board foot measurements. When calculating insulation needs, knowing the board foot value helps ensure an accurate estimate. This helps in avoiding waste and ensuring efficiency in insulation projects.

Calculating Insulation Needs

To calculate insulation needs, start by accurately measuring your space. Measure the length and width of each area. Multiply these dimensions to find the total square footage. For example, a room that is 10 feet long and 12 feet wide has a total of 120 square feet.

Next, determine the required thickness for efficiency. This can depend on the desired R-value of the insulation. Generally, thicker insulation provides better thermal resistance. For instance, if your target R-value is 30, you may need around 10 inches of insulation.

Using a board foot calculator can simplify these calculations. This tool helps estimate the amount of insulation needed based on your measurements and desired thickness. It takes the guesswork out of your insulation project.

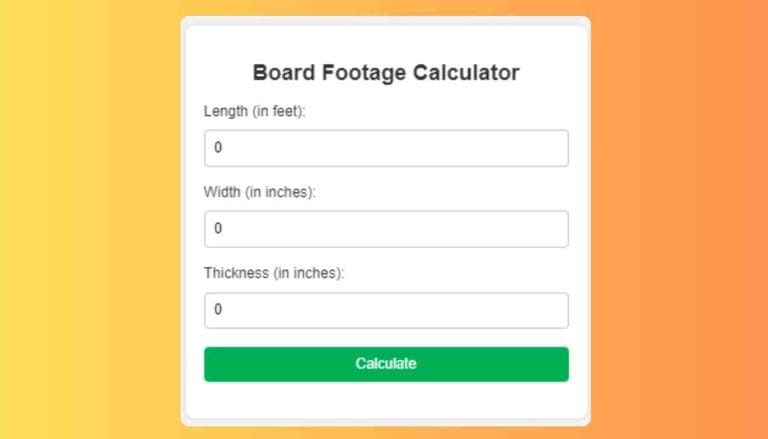

Using A Board Foot Calculator

Using a Board Foot Calculator is easy and helpful. Start by measuring the length, width, and thickness of the insulation. Multiply these numbers to get the total volume in cubic inches. Divide this by 144 to convert to board feet.

Common mistakes often happen during calculations. Here are some to avoid:

- Not measuring correctly. Always double-check your measurements.

- Forgetting to convert units. Ensure all dimensions are in inches.

- Misunderstanding board foot definitions. A board foot equals 1 square foot at 1 inch thick.

Using this calculator correctly saves time and effort. Accurate calculations lead to better project results.

Types Of Insulation Materials

Spray foam insulation is a popular choice for many homeowners. It offers excellent thermal resistance and creates a tight seal against air leaks. This material expands upon application, filling gaps and cracks effectively. It is also moisture-resistant, making it ideal for areas prone to dampness.

Fiberglass insulation is another common option. It consists of tiny glass fibers that trap air, providing good insulation. It comes in batts or loose-fill forms. Cellulose insulation is made from recycled paper products. It is treated for fire resistance and is eco-friendly. Both fiberglass and cellulose are effective in reducing energy costs.

Cost Estimation With Board Foot Calculator

Using a board foot calculator can help estimate costs effectively. Inputting material prices is crucial for accurate calculations. Begin by entering the cost per board foot for the insulation materials you plan to use.

Adjusting for local cost variations is essential. Prices can differ based on location and supplier. Always check local market rates to ensure your estimates are realistic. Consider factors such as transportation fees and taxes that may apply.

Here’s a quick overview of factors to consider:

- Material Type: Different insulation materials have varying costs.

- Local Suppliers: Prices may vary from one supplier to another.

- Regional Demand: High demand can increase prices in your area.

Maximizing Insulation Savings

Maximizing insulation savings starts with understanding your needs. Proper insulation reduces energy costs and improves comfort. When looking for cost-effective insulation, consider various materials. Fiberglass, cellulose, and spray foam all have unique benefits. Choose the one that suits your budget and home design.

For long-term benefits, invest in quality insulation. It may cost more upfront, but savings accumulate over time. Higher R-values mean better energy efficiency. Measure your space accurately to avoid overbuying or underestimating your needs.

| Insulation Type | Cost per Board Foot | R-Value |

|---|---|---|

| Fiberglass | $0.25 | 2.9 |

| Cellulose | $0.35 | 3.7 |

| Spray Foam | $1.00 | 6.5 |

Advanced Considerations

Understanding R-Value is crucial for effective insulation. R-Value measures insulation’s thermal resistance. Higher R-Values mean better insulation performance. For optimal results, choose insulation that meets or exceeds local building codes.

Insulation codes vary by region. Local regulations ensure safety and efficiency. Always check requirements before starting any project. Compliance with these codes helps in achieving energy efficiency and cost savings.

| R-Value Range | Insulation Type |

|---|---|

| R-13 to R-15 | Fiberglass Batts |

| R-19 | Blown-in Cellulose |

| R-30 | Spray Foam |

Diy Vs. Professional Installation

Deciding between DIY or hiring a pro for insulation can be tricky. DIY projects can save money but require skills and tools. Professional installers offer expertise and often ensure better results. Consider your comfort level with tools and complex tasks.

Hire a pro when the project is large or complicated. Issues like roofing, walls, or basements may need expert attention. Professionals can also help with tricky materials like spray foam or blow-in insulation.

For those keen on DIY, many resources exist. Online calculators can help estimate materials. Local hardware stores offer guidance and tools. Always check for safety tips and installation guides before starting.

Frequently Asked Questions

How To Calculate Board Feet For Insulation?

To calculate board feet for insulation, use this formula: Board Feet = (Length in feet x Width in feet x Thickness in inches) / 12. Multiply the length, width, and thickness, then divide by 12. This gives you the total board feet needed for your insulation project.

How Do I Calculate How Much Insulation I Need?

To calculate insulation needs, measure the square footage of the area. Divide this figure by the insulation’s thickness or desired R-value. This will give you the total amount of insulation required for your project. Use an insulation calculator for precise estimates.

How Do I Calculate How Many Board Feet I Need?

To calculate board feet, use the formula: Length (in feet) x Width (in inches) x Thickness (in inches) ÷ 12. This gives you the total board feet needed. Ensure all measurements are accurate for best results. Use an online calculator for convenience.

How Much Insulation Do I Need For A 1000 Sq Ft House?

For a 1,000 sq ft house, you typically need between 10 and 15 bags of insulation, depending on the type and R-value. Calculate based on the desired R-value for your region. Consult local building codes for specific requirements. Always consider professional advice for accurate estimates.

Conclusion

Calculating board feet for insulation is essential for any construction project. A precise measurement helps ensure you purchase the right amount of materials. This not only saves money but also enhances energy efficiency. With the right board foot calculator, you can confidently tackle your insulation needs and make informed decisions for your home or project.