Can You Convert a Propane Fireplace to Wood Burning? Epic?

Yes, you can sometimes convert a propane fireplace to wood-burning, but only if it was originally a traditional masonry fireplace designed for wood. If you have a factory-built gas unit (zero-clearance), it cannot be safely converted. This project requires professional inspection of the chimney, firebox, and flue to ensure it can handle the intense heat of a real wood fire.

There’s nothing quite like the crackle and warm glow of a real wood fire. It feels cozy, timeless, and completely natural. If you have a propane fireplace, you might find yourself looking at the steady, predictable flames and wishing for that rustic charm. You might be wondering, “Can I switch this over? Can I get that authentic wood-burning experience?”

It’s a great question, and you’re not alone in asking it! Many homeowners dream of making this change. The good news is that it’s sometimes possible. The bad news is that it’s not as simple as just taking out the gas logs and tossing in some firewood. Safety is the number one priority here. In this guide, I’ll walk you through everything you need to know, step-by-step, so you can figure out if this project is right for you.

First Things First: Understanding Your Fireplace Type

Before we go any further, we need to solve the most important puzzle: what kind of fireplace do you actually have? The answer to this question determines whether a conversion is a straightforward project or a major, expensive renovation. There are two main types.

Type 1: The Masonry Fireplace with a Gas Insert

This is the best-case scenario. A masonry fireplace is the classic, old-school kind built from brick or stone. It has a solid, built-in chimney that goes right up through the roof. At some point, a previous owner likely installed a gas insert or a set of gas logs for convenience.

How to Spot It:

- Look at the Chimney: Walk outside. Do you see a large chimney made of brick or stone blocks? That’s a great sign.

- Check the Surround: The area around the fireplace opening (the hearth and surround) is usually made of real brick or stone.

- Peek Inside: The inside of the firebox is often lined with firebricks (special, heat-resistant bricks). You might see a metal gas insert box sitting inside this larger brick opening.

If this sounds like your setup, a conversion is often possible! You’re essentially just returning the fireplace to its original purpose.

Type 2: The Factory-Built Gas Fireplace (Zero-Clearance)

This type is very different. These are self-contained metal boxes designed and manufactured in a factory to burn only gas. They are installed inside a wooden frame in your wall. They are called “zero-clearance” because they are engineered with special insulation to be safely placed very close to combustible materials like wood studs.

How to Spot It:

- Look at the Chimney: The “chimney” outside is usually a metal pipe (a vent) sticking out of the roof or an exterior wall, not a big brick structure.

- Check the Surround: While it might have a decorative stone or tile facade, the underlying structure is a framed wall.

- Look for a Label: There is often a metal plate or tag somewhere on the unit (you may need to look around the controls) with the manufacturer’s name and model number. It will state that it is a gas-only appliance.

If you have this type of fireplace, I have to be direct: you cannot convert it to burn wood. It’s not designed for the much higher temperatures of a wood fire and doing so would create an extreme fire hazard.

Weighing the Pros and Cons of a Conversion

Switching from propane to wood is a big decision. It’s not just about changing the fuel source; it changes how you use and maintain your fireplace. Let’s break down the good and the not-so-good to help you decide.

| Pros of Converting to Wood | Cons of Converting to Wood |

|---|---|

| Unbeatable Ambiance: Nothing beats the authentic crackle, smell, and radiant heat of a real wood fire. | Significant Cost: A safe conversion involves professional inspections, repairs, and potentially a new flue liner, which can be expensive. |

| Heat During Power Outages: A wood fireplace provides reliable heat even when the electricity is out. | Major Mess and Maintenance: You’ll have to deal with buying/chopping, storing, and hauling wood, as well as cleaning out ash regularly. |

| Potentially Cheaper Fuel: If you have access to free or low-cost firewood, it can be cheaper than paying for propane. | Requires Annual Inspections: Wood-burning chimneys must be professionally swept and inspected every year to prevent dangerous creosote buildup. |

| The Satisfaction of a Real Fire: Many people find tending a real fire to be a relaxing and rewarding experience. | Not a “Flip a Switch” Solution: Building and maintaining a fire takes time and effort. It’s not instant heat. |

The Conversion Process: A Step-by-Step Guide for Masonry Fireplaces

Okay, so you’ve confirmed you have a true masonry fireplace with a gas insert. Fantastic! Now, let’s talk about the steps to bring it back to its wood-burning glory. Please remember, several of these steps require a certified professional. This isn’t the place to cut corners.

Step 1: Get a Professional Chimney Inspection (Level 2)

This is the most critical step and is absolutely non-negotiable. Before you do anything else, you need to hire a CSIA (Chimney Safety Institute of America) certified chimney sweep to perform a Level 2 inspection. This is more than just a quick look up the flue. The inspector will use a special camera to examine the entire interior of your chimney from top to bottom.

They will check for:

- Cracks in the flue liner: Hot embers can escape through cracks and ignite the structure of your home.

- Blockages: Nests, debris, or collapsed liner sections can block smoke from escaping.

- Structural integrity: They’ll ensure the masonry itself is sound and stable.

- Proper clearances: They check to make sure the chimney is a safe distance from any combustible materials in your walls or attic.

The inspector will give you a detailed report on the condition of your chimney and a list of any necessary repairs.

Step 2: Safely Disconnect and Remove the Gas Line

This is a job for a licensed plumber or gas fitter. Working with gas lines is extremely dangerous if you don’t know what you’re doing. A professional will properly shut off the gas, disconnect the line, and cap it securely to prevent any leaks. Once the gas is safely disconnected, the gas insert or log set can be removed from the firebox.

Step 3: Make All Necessary Repairs

Based on the chimney inspection report, now is the time to fix any issues. This is vital for safety. Common repairs include:

- Installing a New Flue Liner: Many older masonry chimneys either have damaged clay tile liners or no liner at all. Installing a new stainless steel flue liner is often the best solution. It creates a safe, sealed channel for smoke and protects the masonry from the corrosive byproducts of wood smoke.

- Repairing the Firebox: The firebricks inside the firebox can become cracked or loose over time. These must be repaired or replaced (a process called tuckpointing) to safely contain the intense heat of a wood fire.

- Fixing the Damper: The damper is the metal flap that you open and close to control airflow. It must be in good working order to prevent heat from escaping up the chimney when not in use.

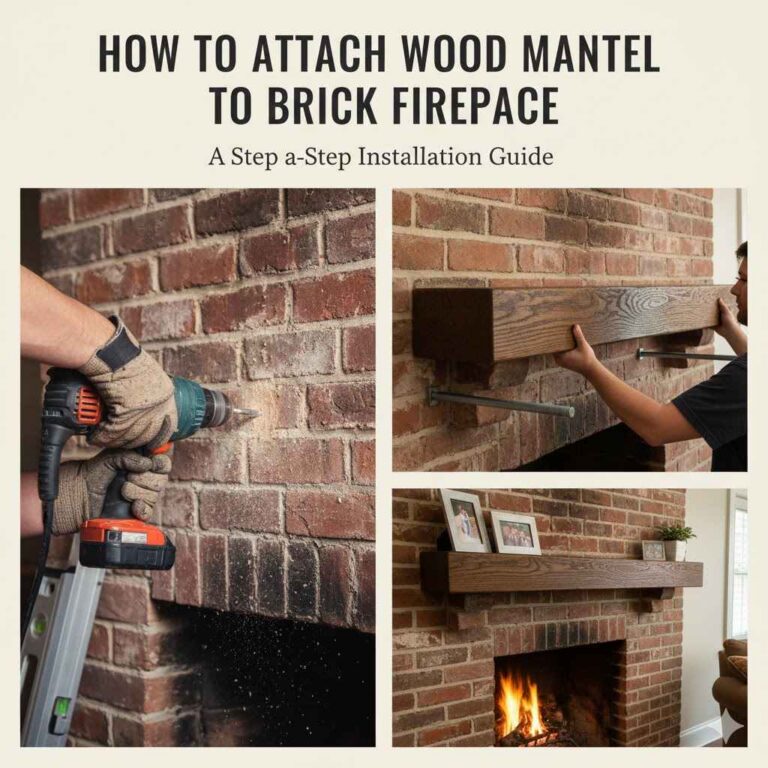

Step 4: Prepare the Fireplace for Wood Burning

With the structure safe and sound, you’re on the home stretch! The final pieces of the puzzle include:

- Install a Chimney Cap: This goes on top of the chimney to keep rain, animals, and debris out. Most also have a screen that acts as a spark arrestor.

- Add a Fireplace Grate: You’ll need a sturdy cast iron or steel grate to hold the logs. This allows air to circulate underneath the wood for a better, more complete burn.

- Get the Right Tools: Purchase a good set of fireplace tools, including a poker, tongs, a shovel, and a brush. You’ll also want a metal ash bucket for safe ash disposal.

Once these steps are complete, you are finally ready to enjoy your first fire in your newly converted wood-burning fireplace!

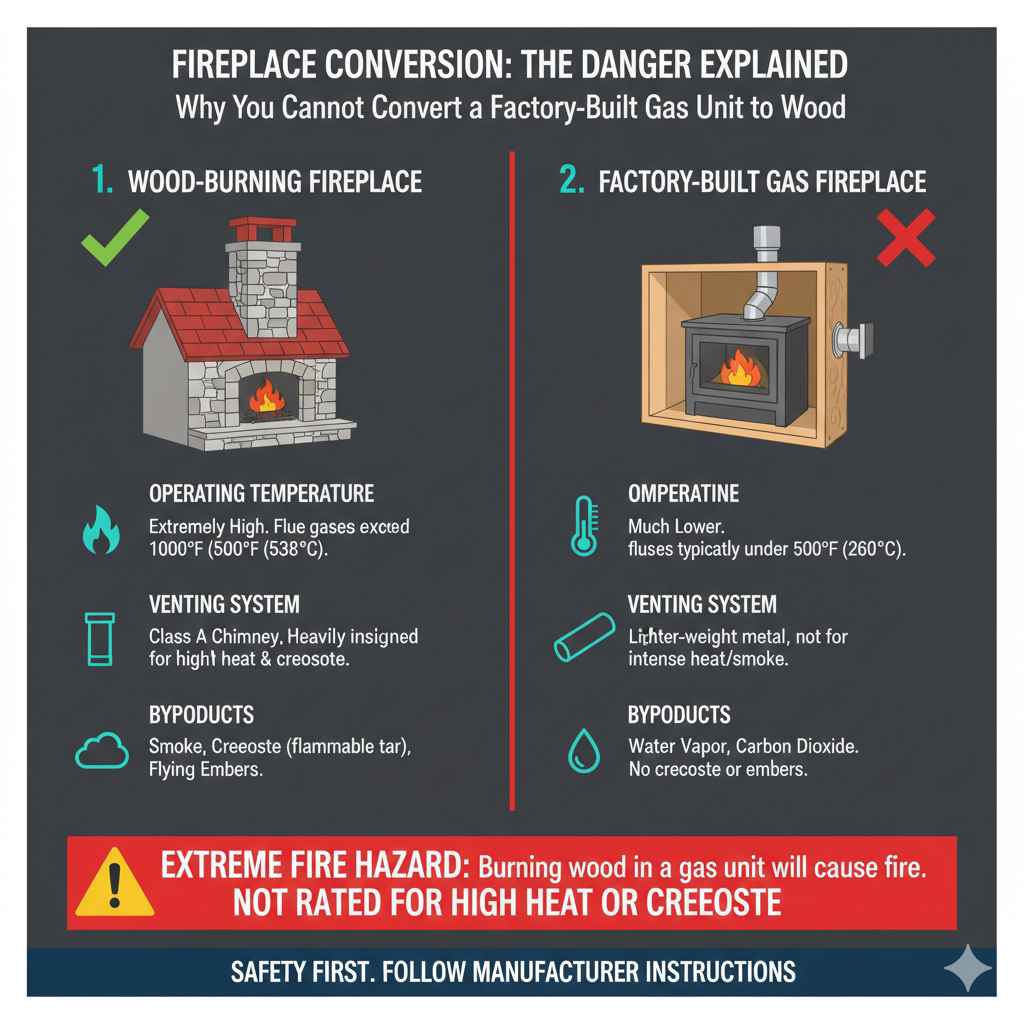

Why You Can’t Convert a Factory-Built Gas Unit

I want to take a moment to really emphasize why converting a zero-clearance gas fireplace is so dangerous. It comes down to two key differences: heat and venting.

| Feature | Wood-Burning Fireplace (Masonry or Class A Chimney) | Gas Fireplace (Factory-Built) |

|---|---|---|

| Operating Temperature | Extremely high. Flue gases can exceed 1,000°F (538°C). | Much lower. Flue gases are typically under 500°F (260°C). |

| Venting System | Requires a Class A chimney. This is heavily insulated or made of masonry, designed to handle high heat and resist creosote fires. | Uses a B-Vent or Direct Vent system. These are lighter-weight metal vents not designed for the intense heat or corrosive smoke from wood. |

| Byproducts | Produces smoke, creosote (a flammable tar-like substance), and flying embers. | Produces mainly water vapor and carbon dioxide. No creosote or embers. |

Trying to burn wood in a gas unit would cause the venting system to fail, likely melting or igniting. The extreme heat could transfer to the surrounding wood framing of your walls, starting a devastating house fire. The U.S. Environmental Protection Agency (EPA) offers extensive resources on the importance of proper venting for wood-burning appliances. It’s simply not what the appliance was tested or certified for, and it must never be attempted.

FAQs: Your Questions Answered

Here are some quick answers to common questions I hear about this project.

1. Can I just remove the gas logs from my masonry fireplace and start a fire?

No, you absolutely should not. Even if you have a masonry fireplace, the chimney needs to be professionally inspected first. It may have cracks, blockages, or a damaged liner that would make it unsafe for a wood fire. Always get a Level 2 inspection before burning wood.

2. What is a flue liner and why is it so important?

A flue liner is a clay, ceramic, or metal conduit installed inside a chimney. Its job is to contain the combustion products, direct them outside, and protect the chimney walls from heat and corrosion. A damaged or missing liner is a major fire hazard.

3. How much does a conversion typically cost?

The cost varies widely. A simple conversion where the chimney is in great shape might cost $500 to $1,500 for the inspection and gas line work. If you need significant repairs, like a new stainless steel liner, the cost can easily be $3,000 to $7,000 or more.

4. How often do I need to clean a wood-burning chimney?

The National Fire Protection Association (NFPA) recommends that chimneys, fireplaces, and vents be inspected at least once a year for soundness, freedom from deposits, and correct clearances. Cleaning should be done whenever necessary based on that inspection.

5. Is burning wood bad for the environment?

Modern, EPA-certified wood stoves and fireplaces are much cleaner and more efficient than older models. To minimize your environmental impact, always burn dry, seasoned hardwood and never burn trash, plastics, or treated wood.

6. What kind of wood is best to burn?

Seasoned hardwoods like oak, maple, and hickory are excellent choices. They burn long and hot with less smoke. Avoid softwoods like pine for regular use, as they can produce more creosote. “Seasoned” means the wood has been split and dried for at least 6-12 months.

7. Can I do any part of this conversion myself?

While you can certainly remove old non-essential parts and clean the hearth, the most critical parts of this job—the gas line disconnection and the chimney inspection/repair—should always be left to certified professionals. Your family’s safety is worth the investment.

A Warm and Worthy Project

Converting a propane fireplace back to its wood-burning origins can be a wonderfully rewarding project. That authentic fire brings a warmth and character to a home that’s hard to replicate. But it’s a journey that must start with safety and a clear understanding of what you’re working with.

Remember the key takeaway: if you have a true masonry fireplace, your dream is likely achievable with the help of a few good professionals. If you have a factory-built gas unit, the safe path is to enjoy it for what it is or plan for a larger renovation to replace it entirely. By taking the right steps, getting a thorough inspection, and putting safety first, you can be well on your way to cozying up by that crackling wood fire you’ve been dreaming of. Happy building!