Can You Weld on a Wood Table: Expert Tips for Safe and Effective Wood Table Welding

Yes, you can weld on a wood table using a welding mat to protect the wood from heat and sparks. Welding on a wood table without protection can damage the table and pose a fire hazard.

When considering welding on a wood table, it’s important to take precautions to ensure the safety of the table and the surrounding area. This includes using a welding mat, ensuring proper ventilation, and following all safety protocols. By taking these measures, you can safely weld on a wood table without causing damage or creating safety risks.

Whether you’re a hobbyist or a professional welder, it’s essential to prioritize safety and protection when working with wood surfaces.

Safety Considerations For Wood Table Welding

When considering welding on a wood table, it’s crucial to prioritize safety to protect both the table and yourself. Here are some essential safety considerations to keep in mind:

Material And Equipment Preparation

Before starting the welding process on a wood table, make sure to adequately prepare your materials and equipment. This includes:

- Ensuring your welding equipment is in good working condition and properly set up for the specific welding task.

- Preparing the wood table surface by clearing it of any flammable objects or materials that could pose a fire hazard during the welding process.

- Using appropriate welding materials and tools suitable for wooden surfaces to minimize the risk of damage to the table.

Protecting The Wood Surface

Protecting the wood surface is paramount to prevent any heat damage or marks during the welding process. Here are some methods for protecting the wood surface:

- Utilize a suitable heat-resistant welding blanket or flame-resistant material to cover the wood table around the welding area.

- Consider using a non-flammable barrier such as a sheet of metal or fire-resistant fabric to provide an extra layer of protection for the wood surface.

- Applying a heat-resistant coating or fire-retardant spray designed for wood surfaces can provide an added level of protection against potential heat damage.

Fire Prevention Measures

Welding on a wood table presents a fire hazard, so it’s vital to implement fire prevention measures to safeguard the work area:

- Have a fire extinguisher readily accessible in the vicinity of the welding operation in case of an unexpected fire outbreak.

- Maintain a clean and clutter-free work area to reduce the risk of combustible materials igniting during the welding process.

- Regularly inspect and properly maintain all welding equipment to prevent potential malfunctions or sparks that could ignite the wood surface.

Best Practices For Welding On A Wood Table

When it comes to welding on a wood table, it’s important to follow best practices to ensure both the safety of the table and the quality of your welding work. Proper technique, choosing the right method, and ensuring proper ventilation are essential components of welding on a wood table. Below, we’ll explore these best practices in detail.

Proper Welding Technique

When welding on a wood table, it’s crucial to use proper welding technique to prevent damage to the table. Ensure that the wood surface is clean and free of any flammable materials, such as sawdust or wood shavings, that could ignite during the welding process. To protect the wood from heat and sparks, consider using a welding blanket or fire-resistant barrier to create a protective layer between the wood and the welding sparks.

Choosing The Right Welding Method

Choosing the right welding method is essential when working on a wood table. Consider using methods that produce minimal heat and sparks, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. These methods are less likely to damage the wood surface and reduce the risk of fire hazards. Additionally, using lower amperage settings can help minimize heat transfer to the wood, further protecting the table.

Ensuring Proper Ventilation

Proper ventilation is crucial when welding on a wood table to dissipate fumes and protect the surrounding environment. Set up a well-ventilated area with fans or exhaust systems to remove welding fumes and prevent them from accumulating near the wood table. Additionally, consider using a welding respirator to protect yourself from inhaling harmful fumes while working on the wood table.

Wood Table Welding Alternatives

Welding on a wood table can be risky as it can damage the table and compromise the safety of your work area. Here are some alternatives to welding on a wood table that can provide better support and protection for your projects.

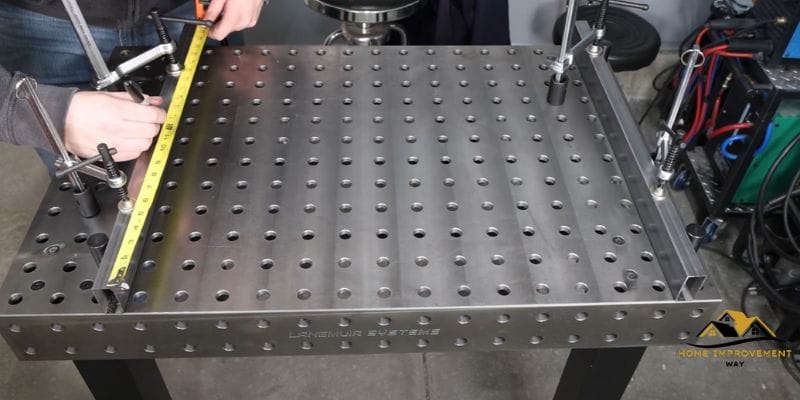

Welding On Sawhorses Or Metal Surfaces

If you’re looking for a sturdy and stable surface for welding, using sawhorses or metal surfaces can be a great alternative to a wood table. Sawhorses are portable and can provide a reliable base for your welding projects. Additionally, metal surfaces offer a heat-resistant and durable option for welding support, ensuring the safety and integrity of your work area.

Using Clamps And Jigs For Welding Support

Clamps and jigs can be indispensable tools for providing support and stability during welding. By securely holding the workpieces in place, clamps and jigs help prevent movement or misalignment during the welding process. These tools are essential for achieving precise and accurate welding results, especially when working on intricate or complex projects.

Temporary Workbenches For Welding Projects

In addition to sawhorses and metal surfaces, temporary workbenches offer a practical solution for welding projects. Constructed from sturdy materials such as steel or aluminum, temporary workbenches provide a reliable and dedicated workspace for welding. Their portability and adjustable features make them versatile options for accommodating various project requirements.

Damage Prevention And Maintenance

When it comes to welding on a wood table, preventing damage and maintaining the table’s integrity are crucial aspects to consider. Proper inspection, maintenance, and repair methods can help preserve the wood table’s quality and prevent potential hazards.

Wood Table Inspection And Maintenance

Regular inspection of the wood table is essential to identify any existing damage and prevent further deterioration. Inspect the table for cracks, splits, or any weakened areas before proceeding with welding. Additionally, maintaining the table by keeping it clean and well-treated with appropriate wood sealants or finishes can help protect it from potential damage during welding and regular usage.

Repairing Minor Damage From Welding

If minor damage occurs during welding, immediate attention is necessary to prevent further issues. Repair minor damage such as scorch marks or superficial burns by lightly sanding the affected area and applying suitable wood fillers or finishes to restore the table’s surface. This proactive approach can help maintain the table’s aesthetic appeal and structural integrity.

Preventing Heat And Fire Damage

Precautions to prevent heat and fire damage are vital when welding on a wood table. Use heat-resistant materials such as welding blankets or fire-resistant barriers to protect the table’s surface from direct heat exposure. Additionally, placing a metal or heat-resistant sheet underneath the welding area can offer further protection against potential heat transfer and sparks, thus minimizing the risk of fire damage.

Expert Tips For Safe And Effective Wood Table Welding

When it comes to welding on a wood table, it’s essential to take the necessary precautions to ensure safety and protect the table’s surface. By following some expert tips, you can effectively weld on a wood table without causing damage. Let’s dive into the key considerations for safe and efficient wood table welding.

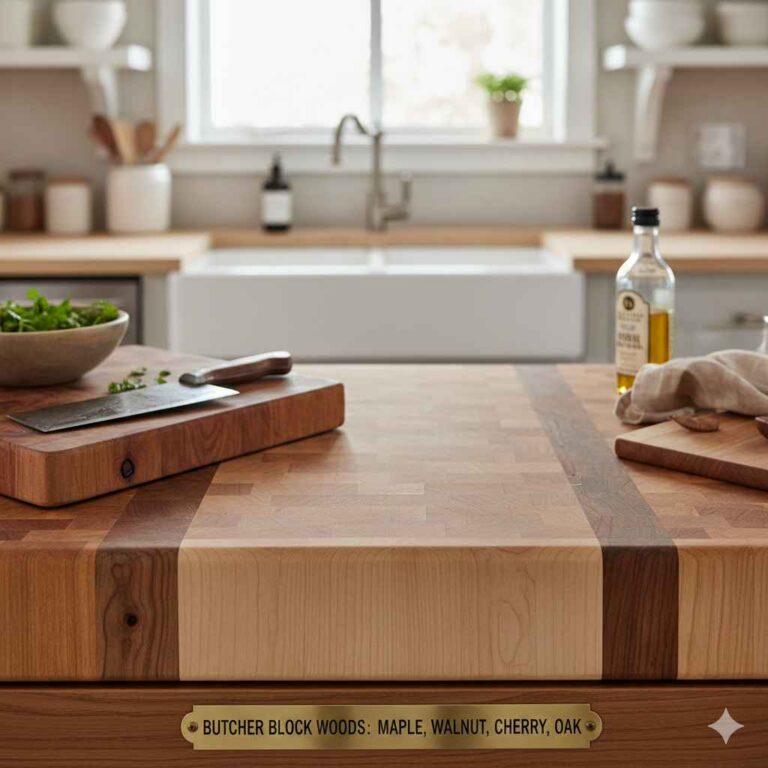

Choosing The Appropriate Wood Table

When selecting a wood table for welding, it’s crucial to choose a table made from sturdy and heat-resistant wood, such as oak or maple. These types of wood can withstand the heat generated during the welding process, reducing the risk of damage. Additionally, make sure the table is stable and level to provide a secure working surface.

Using Heat-resistant Protective Mats

To safeguard the wood table during welding, consider using heat-resistant protective mats specifically designed for welding purposes. These mats act as a buffer between the welding equipment and the table’s surface, minimizing the risk of scorching or burning. A silicone-coated fiberglass welding mat is an excellent choice for protecting the wood table from heat and sparks.

Cleaning And Restoring Wood Tables After Welding

After completing the welding process, it’s essential to clean and restore the wood table to maintain its appearance and longevity. Utilize a non-abrasive cleaner and a soft cloth to remove any welding residue or stains from the table’s surface. Following cleaning, apply a high-quality wood polish or wax to restore the table’s luster and provide an added layer of protection against future welding activities.

Frequently Asked Questions For Can You Weld On A Wood Table

Can You Weld Metal On A Wood Table?

Yes, it is possible to weld metal on a wood table. However, it is important to take precautions to protect the wood from damage. Using a welding blanket or fire-resistant material to cover the table can help prevent any potential harm to the wood surface.

What Precautions Should Be Taken When Welding On A Wood Table?

When welding on a wood table, it’s crucial to protect the table surface from heat and sparks. Using a welding blanket or fire-resistant material can shield the wood from damage. Additionally, positioning the workpiece on a non-flammable surface and ensuring proper ventilation are important safety measures to consider.

Are There Any Potential Risks In Welding On A Wood Table?

Welding on a wood table poses risks such as heat damage, fire hazards, and potential harm to the wood surface. It’s important to take necessary precautions to avoid these risks, such as using protective materials and ensuring proper ventilation to minimize the impact on the wood table during the welding process.

Conclusion

Welding on a wood table is possible, but it requires caution and preparation. It is important to protect the wood from heat and sparks, and to consider the potential risks involved. By following safety guidelines and using the right equipment, you can safely weld on a wood table and complete your projects with ease.