Cut List Calculator for Lumber: Maximize Your Wood Use

A Cut List Calculator for lumber is a tool that helps you determine the most efficient way to cut wood for your projects. It optimizes material usage, minimizing waste and saving costs.

Creating a cut list is essential for any woodworking project. It ensures that you have a clear plan for the pieces you need, along with their dimensions. Using a cut list calculator can greatly simplify this process. These tools analyze your project requirements and generate optimized cutting plans.

Whether you are a professional carpenter or a DIY enthusiast, a cut list calculator streamlines your workflow. With accurate measurements and efficient layouts, you can reduce material waste and improve project efficiency. Discovering the right calculator can transform your woodworking experience.

Introduction To Cut List Calculators

Cut list calculators play a significant role in modern woodworking. They help save time and reduce waste. With these tools, woodworkers can easily plan their cuts. This ensures efficient use of materials. Technology makes the process simpler and more accurate.

Benefits of using a cut list calculator include:

- Efficiency: Quickly find the best cutting layouts.

- Accuracy: Minimize errors in measurements and cuts.

- Time-saving: Less time spent on planning and more on building.

- Cost-effective: Reduce material waste and save money.

Embracing these tools can elevate any woodworking project. A cut list calculator is essential for both beginners and pros.

Choosing The Right Cut List Calculator

Choosing the right cut list calculator can greatly enhance your woodworking projects. Look for user-friendly interfaces that simplify calculations. A good app should support various materials, from plywood to MDF. Ensure it provides detailed measurements for length, width, and thickness.

Opt for calculators that allow you to save and organize your projects. This feature helps in tracking multiple jobs efficiently. Some popular cut list calculator apps include:

| App Name | Platform | Key Feature |

|---|---|---|

| SheetCut Optimizer | Mobile | Efficient cutting layouts |

| CutList Plus fx | Desktop | Optimized sheet layouts |

| OptiCutter | Online | Free cut list optimizer |

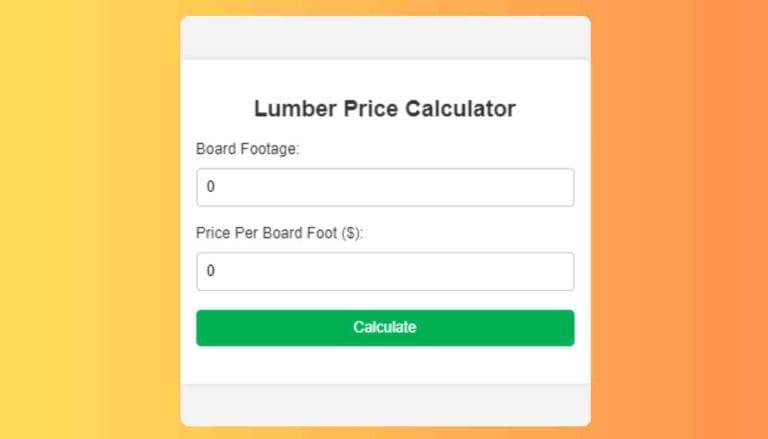

Inputting Your Lumber Measurements

Understanding standard lumber dimensions is essential for accurate measurement. Common sizes include 1×2, 1×4, 2×4, and 2×6. Each dimension represents the nominal size of the wood. Actual sizes may differ due to milling processes.

Measuring and recording your stock is crucial. Use a tape measure for precise measurements. Write down the length, width, and thickness of each piece. Keeping a clear record helps in planning your cuts effectively.

| Nominal Size | Actual Size (inches) |

|---|---|

| 1×2 | 0.75 x 1.5 |

| 1×4 | 0.75 x 3.5 |

| 2×4 | 1.5 x 3.5 |

| 2×6 | 1.5 x 5.5 |

Maximizing Material Efficiency

Understanding wood grain and cuts is essential for maximizing material efficiency. Properly analyzing the wood grain helps in determining the best cutting direction. This can prevent splitting and tearing during the cutting process.

Choosing the right cuts reduces waste significantly. Consider using efficient cutting patterns to make the most out of your lumber. Planning a cut list ensures all pieces fit together perfectly.

- Start with a detailed cut list.

- Group similar pieces to minimize setup changes.

- Use software tools for optimal layouts.

Working With Sheet Goods

Optimizing plywood and MDF cuts is essential for reducing waste. Large panels can be tricky to manage. Use a cut list calculator to determine the best cuts. This tool helps maximize material use while minimizing offcuts.

For effective handling of large panels:

- Measure dimensions accurately before cutting.

- Plan cuts in a logical order to avoid mistakes.

- Use a straight edge for cleaner cuts.

- Consider using a table saw or circular saw for precision.

Taking these steps ensures a more efficient project. Enjoy the satisfaction of creating with minimal waste!

The Optimization Process

The optimization process for cut list calculators involves complex algorithms. These algorithms analyze the dimensions of each lumber piece. They aim to minimize waste and maximize efficiency. By inputting sizes and quantities, users receive optimal cutting patterns. This method ensures the best use of materials.

Interpreting the results is crucial. Results usually include a detailed cutting plan. Users can see how to arrange each piece. The layout shows where to make cuts. This clarity helps in executing projects accurately. Proper understanding leads to less wasted wood and cost savings.

Practical Tips For Using Cut Lists On The Job

Organizing cut pieces can save time and reduce mistakes. Start by listing all parts needed for the project. Arrange them by type, such as solid wood and sheet materials. Use a code system for easy identification. Write these codes on each board.

Marking and labeling for accuracy is crucial. Use a pencil or marker to clearly write measurements. Label each piece with its corresponding code. This step ensures everyone knows where each part fits. Always double-check measurements before cutting.

Advanced Features And Customization

Custom cuts allow users to create unique shapes for projects. This feature is perfect for those who need specific dimensions. A cut list calculator makes it easy to input these custom measurements. Users can visualize how the pieces fit together.

Integrating with project design software enhances functionality. This integration streamlines the process, making it quicker and easier. Users can import designs directly into the calculator. The software then provides optimized cut layouts based on the input dimensions.

| Feature | Benefit |

|---|---|

| Custom Cuts | Creates unique project shapes |

| Software Integration | Streamlines design and cutting process |

Cost-saving Benefits And Roi

Calculating material savings is essential for both businesses and hobbyists. Using a cut list calculator helps optimize lumber usage. This tool minimizes waste and ensures cost efficiency. Accurate calculations can lead to significant savings on materials. A well-planned cut list prevents unnecessary purchases. It also reduces the need for excess inventory.

Long-term advantages come from effective planning. Businesses can improve their profit margins by minimizing waste. Hobbyists save money for future projects. Efficient use of materials contributes to a sustainable approach. This practice supports environmental conservation efforts. Ultimately, a cut list calculator enhances overall project efficiency.

Troubleshooting Common Issues

Discrepancies in cuts can arise for many reasons. Always double-check your measurements before cutting. Small errors can lead to significant waste. If parts don’t fit, re-measure and adjust your cut list accordingly.

Material defects can also affect your projects. Inspect each piece of lumber carefully. Look for knots, warping, or cracks. These defects may require adjustments to your cut list. Consider using a cutting diagram to visualize the best approach.

| Issue | Solution |

|---|---|

| Measurement Errors | Re-measure and adjust cut list |

| Material Defects | Inspect lumber and adjust cuts |

| Inaccurate Cuts | Use a cutting diagram for clarity |

The Future Of Cut List Software

Emerging technologies are transforming woodworking. Automation and AI are leading this change. These tools can simplify the cutting process significantly. Software now helps woodworkers optimize their cuts. This means less waste and better efficiency.

Woodworking software can analyze designs quickly. It provides a precise cut list based on user input. This reduces time spent on planning. Machine learning can even predict material needs. Such advancements will make projects faster and more accurate.

New apps are available for mobile devices. These tools allow users to calculate cuts on-the-go. Woodworkers can make real-time adjustments to their plans. The future looks bright for those in the woodworking industry.

Frequently Asked Questions

Is There An App To Calculate Wood Cuts?

Yes, several apps can help calculate wood cuts. The SheetCut Optimizer is a popular choice for maximizing material efficiency. Other options include CutList Plus and OptiCutter. These tools assist in planning and optimizing your cuts effectively.

How To Plan A Cut List?

To plan a cut list, start by listing all required parts. Organize them by material type, prioritizing solid wood first. Assign a unique code to each part for easy identification. Include dimensions and quantities for accuracy. Review and adjust for efficiency before finalizing.

What Is A Lumber Cut List?

A lumber cut list details all necessary parts for a woodworking project. It includes dimensions like thickness, width, and length for each piece. This list acts as a bill of materials, guiding the cutting process without cost information.

What Program Is Used To Layout Plywood?

CutList Plus fx is a popular program for laying out plywood. It optimizes sheet layouts to minimize waste and calculates material costs. Other options include SheetCut Optimizer and OptiCutter, both designed for efficient cutting of plywood and similar materials.

Conclusion

Using a cut list calculator for lumber streamlines your woodworking projects. It helps you minimize waste and save time. With the right tools, you can achieve precise measurements and ensure efficient cuts. Embrace these calculators to enhance your woodworking experience and achieve professional results.

Start calculating and see the difference today!