Difference Between A Hammer Drill And Impact Driver: Proven

The core difference is function: A hammer drill is designed for drilling into hard materials like concrete using a pounding action, while an impact driver is designed for driving screws quickly and powerfully, delivering rotational force rather than hammering.

Welcome to the workshop! If you’ve ever stood in the tool aisle feeling confused about whether you need a hammer drill or an impact driver, you are certainly not alone. These two powerful tools look somewhat similar, but they handle totally different jobs around your home. Choosing the wrong one can mean sore arms or just not getting the job done right. Don’t worry—we are going to clear up the difference between a hammer drill and impact driver today. By the end of this guide, you will know exactly which tool to grab for driving deck screws or drilling into that tough brick wall. Let’s make your next DIY project smoother and more successful!

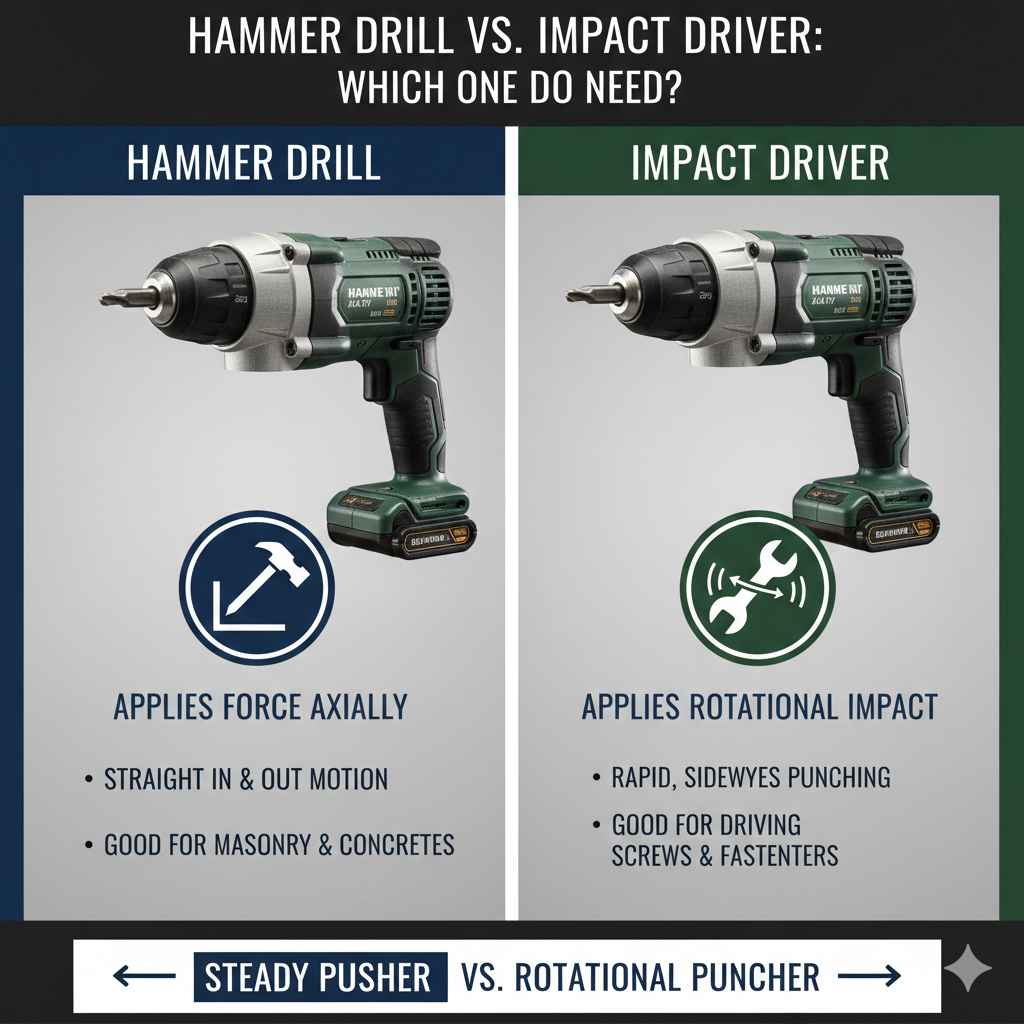

Hammer Drill vs. Impact Driver: Which One Do I Need?

When you are starting a home improvement project, having the right tool makes all the difference between a quick success and a frustrating afternoon. The main confusion comes because both tools spin, and both often use battery power. However, their internal mechanisms and the jobs they excel at are worlds apart. Think of it this way: one is a steady, strong pusher, and the other is a rapid, rotational puncher.

Understanding the fundamental difference boils down to how they deliver force:

- Hammer Drill: Applies force axially (straight in and out, like hammering a nail).

- Impact Driver: Applies rotational force combined with quick, sideways rotational impacts (hammering sideways).

Deep Dive: What is a Hammer Drill?

The hammer drill is the true workhorse when you face tough, dense materials. It’s a beefed-up standard drill that gains an extra capability—the hammer action. This feature is what lets you tackle masonry work that would burn out a regular drill in seconds.

How the Hammer Drill Works

Imagine a standard drill, but inside, two serrated metal discs are placed face-to-face. As the motor spins, these discs move rapidly in and out of contact with each other. This movement creates thousands of small, rapid hammer blows along the axis of the drill bit every minute. This pounding action pulverizes the concrete, stone, or brick just enough so the sharp edges of the drill bit can chew away material.

You can usually use a hammer drill in two modes:

- Drill Mode: This works exactly like a regular drill for wood, plastic, or metal.

- Hammer Mode: This engages the internal hammering mechanism for masonry tasks.

When You Should Always Choose a Hammer Drill

If your project involves making a hole where there is no existing pilot hole in something exceptionally hard, reach for the hammer drill. This is the specialized tool for breaking through hard surfaces.

- Mounting a heavy TV bracket into a brick exterior wall.

- Drilling holes in concrete slabs for anchoring posts or heavy machinery.

- Installing sleeves or Tapcons screws into solid cinder block or stone.

- Any time you are working with tile that requires drilling through the hard glaze.

Pros and Cons of the Hammer Drill

While fantastic for masonry, the hammer drill has limitations compared to its impact counterpart.

| Pros (Hammer Drill) | Cons (Hammer Drill) |

|---|---|

| Excellent for drilling large holes in concrete or stone. | Heavier and bulkier than impact drivers. |

| Versatile—can drill wood, metal, and masonry (three tools in one). | The hammering action can make driving long screws slow and imprecise. |

| Consistent, steady pressure ideal for clean holes in hard materials. | Can often strip screw heads when driving long fasteners due to lack of torque control. |

Deep Dive: What is an Impact Driver?

The impact driver is the modern champion of fastening. It was designed specifically to drive screws, bolts, and lag bolts quickly and with incredible power without fatiguing your wrist. If you’ve ever struggled to drive a long deck screw by hand or with a standard drill, the impact driver is your answer.

How the Impact Driver Works

This tool is all about rotational force amplified by quick, sharp side-to-side blows (impacts). When the driver meets resistance—like a long screw digging into dense wood—it automatically engages its internal mechanism. This mechanism delivers sharp, high-speed rotational impacts. These impacts are delivered in the same direction as the rotation, essentially helping to push the fastener in while maintaining grip.

The best part for a beginner is that the impacts happen only when resistance is met. This means that when you are just setting the screw or drilling small holes, it operates like a normal, powerful drill. This superior torque control prevents cam-out (when the bit slips out of the screw head).

When You Should Always Choose an Impact Driver

The impact driver shines brightest when repetitive, high-torque fastening is required. It excels in woodworking, decking, framing, and assembly tasks.

- Building a large deck using 3-inch or 4-inch deck screws.

- Assembling IKEA furniture or large shelving units quickly.

- Driving long lag bolts into framing studs for mounting heavy shelves.

- Fastening long screws into dense hardwood materials without stripping the head.

For comparison, experts in construction often cite the difference in how they transfer energy. An impact driver transfers energy torsionally (rotational shocks), which is far more efficient for driving than the pure pushing force of a hammer drill. For more on general tool safety and power tool mechanics, organizations like the Occupational Safety and Health Administration (OSHA) provide excellent resources on power tool operation.

Pros and Cons of the Impact Driver

Impact drivers are champions of driving, but they lack the finesse and pure rotational drilling power needed for masonry work.

| Pros (Impact Driver) | Cons (Impact Driver) |

|---|---|

| Incredible torque makes driving long fasteners easy. | Cannot drill into concrete, stone, or hard brick effectively. |

| Significantly smaller, lighter, and easier to maneuver overhead or in tight spots. | Typically only accepts 1/4-inch hex shank bits; standard round drill bits don’t always fit securely. |

| Reduces fatigue and virtually eliminates stripping screw heads (cam-out). | The driving noise can be much louder and sharper than a standard drill. |

The Key Mechanic: Torque vs. Percussion

This is the technical part explained simply. Understanding torque versus percussion helps lock in the difference:

Torque (Impact Driver Focus)

Torque is rotational force—the twisting power. The impact driver’s mechanism uses a rotational hammer that hits the fastener from the side (rotationally). This means it delivers massive amounts of turning power very quickly. This is what drives a long screw deep into wood without needing you to push hard.

Percussion (Hammer Drill Focus)

Percussion is the up-and-down hammering motion. The hammer drill mechanism uses two discs that bump against each other, pushing the drill bit directly into the material (axially). This breaking action is necessary to fracture hard materials like concrete, but it doesn’t help much when driving a screw.

Can an Impact Driver Drill Wood or Metal?

Yes, an impact driver can drill into wood and metal, but with a few important caveats for the beginner DIYer.

Drilling Wood

Impact drivers are great for drilling wood if you use the right bits. They handle spade bits, Forstner bits, and standard twist bits well, especially if the wood is soft or thin. However, the sudden bursts of rotational impact can sometimes cause the bit to ‘walk’ or skid when you first start the hole. Always keep a firm grip and start slowly.

Drilling Metal

Drilling thin metal is usually fine. For thicker metal, the constant impact bursts can actually cause overheating of the bit or lead to a loss of accuracy, as the driver fights to maintain rotational stability. A regular drill or a dedicated hammer drill in drill-only mode provides smoother, more controllable rotation for precise metal drilling.

A Crucial Note on Bits

Most impact drivers use a 1/4-inch hexagonal (hex) shank. Standard round drill bits will not stay securely in the chuck. You must use bits specifically labeled as “impact-rated” or hex-shank bits for optimal performance and safety in an impact driver. Trying to force a round bit into an impact driver is unsafe and inefficient.

Can a Hammer Drill Drive Screws?

Technically, yes, a hammer drill can drive screws in its standard drill mode. Many homeowners use their old corded hammer drill for light fastening tasks.

The Drawbacks of Using a Hammer Drill for Driving

- Poor Clutch Control: Standard drills often have a clutch (a numbered ring) that allows you to set the maximum torque before the clutch slips. If your hammer drill lacks a good clutch setting or you set it too high, you will easily overtighten and strip the screw head.

- Cam-Out: Without the stabilizing rotational impacts of the impact driver, you have to physically push much harder to keep the bit seated in the screw head, leading to fatigue and increased cam-out.

- Bulky Size: Hammer drills are generally heavier, making them cumbersome for jobs requiring dozens or hundreds of screws.

For small jobs, it works. For big jobs, your wrist will thank you if you use an impact driver instead.

Comparison Summary Table: The Practical Checklist

To help you make a quick decision before you head out to buy, here is a head-to-head comparison covering the most common homeowner needs.

| Application | Best Tool | Why? |

|---|---|---|

| Drilling into cured concrete foundation | Hammer Drill | Requires powerful axial impact action to break up masonry. |

| Driving 3-inch deck screws into pressure-treated wood | Impact Driver | High rotational torque drives screws deep without straining your wrist. |

| Assembling cabinets or furniture (short screws) | Impact Driver | Excellent control with low settings prevents stripping small fasteners. |

| Drilling holes in hard wood studs (no metal studs) | Either (Impact Driver slightly better) | Impact drivers drive quickly, but standard drill bits work well in either tool on wood. |

| Drilling a clean hole through ceramic tile | Hammer Drill (Tile Setting) | The initial slow, gentle tapping helps break the surface glaze without cracking the tile body. |

| Fastening hardware into metal studs | Impact Driver | Superior power for pushing self-tapping metal screws. |

The Right Accessory Matters: Bits and Chucks

A major functional difference that beginners often overlook is how the bits connect to the tool.

Hammer Drill Chucks

Most hammer drills use a traditional 3-jaw chuck that tightens down onto the shank of the bit. This mechanism is designed to securely hold round-shank drill bits (for wood, metal, and masonry), ensuring they don’t slip during the continuous forward rotation.

Impact Driver Quick-Release Collet

Impact drivers feature a spring-loaded collet mechanism. You pull down on the outer sleeve, insert a bit, and release. It locks the bit instantly and securely. This is designed only for 1/4-inch hex shank bits. This quick-change system is super convenient for swapping between driving and drilling tasks rapidly.

If you want to use a standard round drill bit in your impact driver, you must purchase a specialized impact-rated chuck adapter that has a hex shank base. This adapter converts the tool to accept round bits.

A Note on Safety and Fatigue

As your friendly DIY guide, I want to make sure you stay safe and enjoy the process. Both tools are powerful, and managing that power is key.

Managing Force

The impact driver is fantastic because it reduces wrist fatigue. You don’t have to fight the torque. However, because it is so much faster, you must be mindful of controlling the depth. Always wear safety glasses—the high-speed impacts can send chips flying.

The Importance of Depth Control

If you are driving screws with an impact driver, always start on a lower speed setting if your tool has variable speed control. Speed gives you power, but low speed gives you control. With a hammer drill, be very aware of how much pressure you are applying axially (straight in) when drilling masonry. Pushing too hard can dull the bit prematurely or damage your tool.

When Should You Buy Both?

For the serious DIY homeowner, having both tools offers unmatched versatility. If you frequently tackle projects like:

- Building decks and fences (Impact Driver needed).

- Hanging shelves or securing shelving systems (Impact Driver needed).

- Doing basic home repairs, like assembling furniture (Impact Driver).

- Doing any kind of tile removal, basement finishing, or anchoring into brick/concrete (Hammer Drill needed).

If your budget allows, purchasing a two-tool combo kit is often the most economical and practical route. You get the specialized power of the impact driver and the masonry capability of the hammer drill, all running off the same battery platform.

Frequently Asked Questions (FAQ) for Beginners

Q1: Can I use an impact driver to drill into brick?

A: Not effectively. An impact driver spins, but it lacks the strong, direct hammering action needed to break up the hard material of brick or concrete. It will wear out your bit quickly.

Q2: Is a hammer drill a substitute for a regular drill?

A: Yes, generally. Since a hammer drill has a switch to turn the hammer function off, it functions perfectly as a high-power standard drill for wood and metal applications.

Q3: Which tool is better for installing drywall anchors?

A: The hammer drill is better if the anchor goes into masonry or concrete. For installing plastic expansion anchors into drywall, a standard drill or the impact driver on a low torque setting is ideal, as you don’t want to crush the plastic anchor.

Q4: What is the main risk if I use the wrong tool?

A: If you use an impact driver on concrete, you’ll make no progress. If you use a hammer drill for driving many screws, you risk stripping the heads (cam-out) and causing unnecessary fatigue in your wrist.

Q5: Do I need special batteries for these tools?

A: Modern cordless versions typically share the same battery system (like 18V or 20V systems), so buying a kit where the batteries are interchangeable is a huge plus for saving money and convenience.

Q6: Which tool is generally lighter?

A: The impact driver is almost always lighter and smaller than a comparable hammer drill because it has fewer internal moving parts required for the masonry function.

Conclusion: Confidence in Your Tool Choice

Congratulations! You now have a clear understanding of the difference between a hammer drill and an impact driver. Remember this simple rule: if you are drilling through rock-hard material like concrete or brick, you need the pounding power of the Hammer Drill. If you are driving a fastener deep and fast into wood or metal, you need the rotational punch of the Impact Driver.

Don’t let confusing tool names slow down your home projects any longer. Whether you are mounting shelves, building a new garden bed, or finally tackling that concrete patio repair, choosing the right tool the first time builds confidence. Go ahead, pick up the right tool for the job, and enjoy the satisfaction of making beautiful, lasting improvements to your home yourself. You’ve got this!