Difference Between Pressure Treated Wood and Regular Wood: Essential Guide

Pressure treated wood is chemically infused to resist rot, insects, and moisture, making it ideal for outdoor projects, while regular wood is untreated and best for indoor use. Understanding this difference is key to choosing the right material for your woodworking projects.

Hey there, fellow woodworkers! Ever stood in the lumber aisle, scratching your head, wondering which wood is right for that outdoor deck or that indoor bookshelf? It’s a common puzzle, and choosing the wrong wood can lead to a project that quickly succumbs to the elements or just doesn’t last. But don’t worry, we’re going to clear up the confusion today! I’m Md. Meraj, and I’m here to guide you through the essential differences between pressure treated wood and regular wood. We’ll break down what makes them tick, where to use them, and how to handle them safely, so you can build with confidence. Let’s get your projects built right from the start!

Understanding the Core Differences

At its heart, the primary distinction between pressure treated wood and regular wood lies in their resistance to decay, insects, and moisture. Regular wood, often called “natural” or “untreated” wood, is just that – wood in its natural state. Pressure treated wood, on the other hand, undergoes a specialized process that significantly enhances its durability and longevity, particularly in environments where it will be exposed to the elements.

What is Regular Wood?

Regular wood, also known as untreated lumber, is wood that has not been chemically or physically altered to improve its resistance to external factors. It’s the wood you’d typically find in its natural state, straight from the forest and processed into usable lumber. The type of tree the wood comes from plays a significant role in its natural durability. For instance, woods like cedar and redwood have natural oils and compounds that offer some resistance to decay and insects, making them suitable for certain outdoor applications without treatment, though they are generally more expensive.

Common types of regular wood include:

- Pine

- Fir

- Spruce

- Oak

- Maple

These woods are fantastic for a wide range of indoor projects. Think furniture, trim, cabinetry, and decorative pieces. Their natural beauty and workability are major advantages. However, when exposed to moisture, fungi, and insects, they can deteriorate relatively quickly. This is why you’ll rarely see untreated pine used for an outdoor deck without some form of protective finish, and even then, its lifespan will be significantly shorter than treated wood.

What is Pressure Treated Wood?

Pressure treated wood is lumber that has been impregnated with chemical preservatives under high pressure. This process forces the preservatives deep into the wood’s cellular structure, providing long-lasting protection against wood-destroying organisms like fungi, termites, and other insects. The most common preservative used in the United States is alkaline copper quaternary (ACQ), but other chemicals like copper azole (CA) and micronized copper quaternary (MCQ) are also used. These chemicals are typically copper-based, giving the wood a greenish or brownish hue, although it can also be stained to match desired aesthetics.

The pressure treatment process is quite ingenious. Wood is placed in a large, sealed steel cylinder. Then, a vacuum is applied to remove air from the wood cells. After that, the cylinder is filled with the wood preservative solution, and pressure is applied. This pressure forces the preservative deep into the wood. Finally, the excess preservative is removed, and the wood is dried.

According to the Forest Products Laboratory, this treatment significantly extends the service life of wood, especially in demanding applications.

Key Differences at a Glance

To make it super clear, let’s look at the main points of divergence:

| Feature | Regular Wood | Pressure Treated Wood |

|---|---|---|

| Treatment Process | None | Impregnated with chemical preservatives under pressure |

| Resistance to Decay & Insects | Low (depends on wood species) | High |

| Moisture Resistance | Poor (absorbs moisture easily) | Good (preservatives help repel water) |

| Typical Uses | Indoor furniture, trim, cabinetry, non-structural elements | Outdoor decks, fences, pergolas, structural framing, garden beds, docks |

| Appearance | Natural wood grain, various colors | Often greenish or brownish tint, can be stained |

| Cost | Generally lower for common species, higher for naturally resistant species | Slightly higher than common untreated woods, but cost-effective for longevity |

| Workability | Generally easier to cut and shape | Can be harder on tools due to preservatives; dulls blades faster |

| Safety Considerations | Standard woodworking safety | Requires specific safety precautions during cutting and handling due to chemicals |

When to Use Which: Project Applications

Choosing the right wood is crucial for the success and longevity of your woodworking projects. Here’s a breakdown of where each type shines:

Ideal Projects for Pressure Treated Wood

If your project is going to be outdoors, or in contact with the ground, or in any situation where moisture is a significant factor, pressure treated wood is almost always the best choice. Its inherent resistance to rot and insects means your project will stand up to the elements for years to come.

Consider pressure treated wood for:

- Decks and Patios: This is the classic application. Treated wood handles constant exposure to rain, sun, and ground contact beautifully.

- Fences: Posts set in the ground and fence pickets benefit immensely from the rot and insect resistance.

- Pergolas and Arbors: These outdoor structures are exposed to the weather and need durable materials.

- Play Structures: Safety and durability are paramount, and treated wood provides both for outdoor play equipment.

- Garden Beds and Planters: Direct contact with soil and moisture makes treated wood a practical choice.

- Dock Pilings and Marine Structures: Its resistance to waterborne pests and decay is essential here.

- Structural Framing in Damp Areas: For foundations or areas prone to moisture within a building, treated lumber can prevent future problems.

Ideal Projects for Regular Wood

Regular, untreated wood is perfect for projects that will be kept indoors and away from excessive moisture. Its natural beauty and ease of working make it a favorite for many projects.

Think about using regular wood for:

- Indoor Furniture: Tables, chairs, cabinets, shelves – all are great candidates for untreated lumber.

- Trim and Molding: Baseboards, crown molding, and door/window casings are typically made from untreated wood.

- Cabinetry and Shelving: Whether for kitchens, garages, or workshops, interior shelving is best with regular wood.

- Decorative Items: Picture frames, wall art, and other decorative pieces that won’t face harsh conditions.

- Woodworking Projects for Practice: When you’re learning new techniques, using less expensive untreated wood is a smart way to practice without worry.

- Interior Doors and Windows: These are protected from the elements and look great with natural finishes.

Safety First: Working with Pressure Treated Wood

While pressure treated wood is fantastic for durability, it’s important to be aware of the chemicals involved and take appropriate safety precautions. The preservatives, while effective, can be harmful if inhaled or ingested. The U.S. Environmental Protection Agency (EPA) regulates these chemicals to ensure they are safe for their intended uses when handled properly.

Here’s how to stay safe:

- Wear a Mask: Always wear a dust mask or respirator when cutting, sanding, or drilling pressure treated wood. This prevents you from inhaling sawdust that contains the chemical preservatives.

- Protect Your Skin: Wear long sleeves, long pants, and gloves to minimize skin contact with the wood. Wash your hands thoroughly with soap and water after handling.

- Avoid Burning: Never burn pressure treated wood. The combustion process can release toxic fumes. Dispose of scraps properly by taking them to a landfill or approved waste disposal site.

- Keep Away from Food: Do not use pressure treated wood for cutting boards or countertops where food will be prepared directly on the surface. While modern treatments are safer, it’s still a good practice.

- Proper Fasteners: Use hot-dip galvanized or stainless steel fasteners when working with pressure treated wood. The chemicals in the wood can corrode standard fasteners over time. Check out resources from organizations like the International Code Council (ICC) for fastener recommendations in building codes.

- Clean Up: Clean up sawdust and scraps promptly. Do not use sawdust from treated wood in garden beds or compost piles, as the chemicals can leach into the soil.

By following these simple safety guidelines, you can confidently work with pressure treated wood and enjoy the benefits of its enhanced durability.

Can You Stain or Paint Pressure Treated Wood?

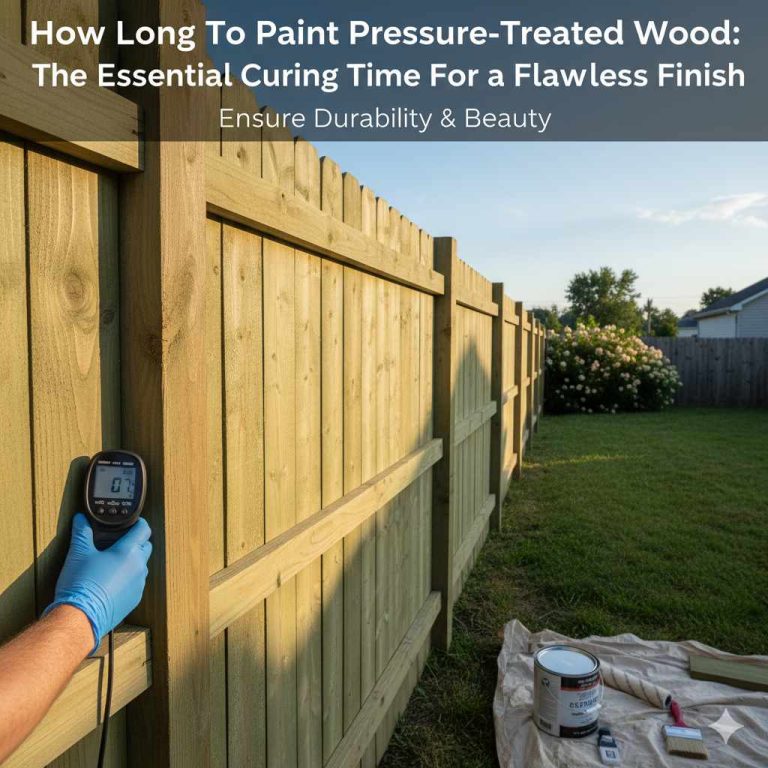

Yes, you absolutely can stain or paint pressure treated wood! In fact, staining or painting can add an extra layer of protection and improve the aesthetic appeal of your project. However, there are a couple of important considerations:

Allow it to Dry: Pressure treated wood is often quite wet when you purchase it due to the treatment process. It’s crucial to let it dry out thoroughly before applying any finish. This can take anywhere from a few weeks to several months, depending on the weather conditions and how the wood was stored. A good test is to sprinkle a few drops of water on the surface. If the water beads up, it’s still too wet. If it soaks in, it’s likely ready.

Surface Preparation: Before painting or staining, ensure the wood is clean and free of any surface residue. Lightly sanding the wood can help the finish adhere better.

Choose the Right Finish: For best results, use exterior-grade stains and paints designed to withstand the elements. Both solid stains and semi-transparent stains work well, allowing the wood grain to show through to varying degrees. If you’re painting, a good quality exterior primer is recommended.

Color Considerations: Keep in mind that pressure treated wood often has a greenish or brownish tint. If you’re aiming for a very light or specific color, you might need to use a primer or a solid stain to achieve the desired look.

The Lifespan and Value Proposition

When we talk about the “difference between pressure treated wood and regular wood,” one of the most significant differentiating factors is lifespan and, by extension, long-term value. While regular wood might be cheaper upfront for certain species, its susceptibility to rot, decay, and insect infestation means it will likely need replacement much sooner, especially in outdoor applications.

Consider a deck built with untreated pine versus one built with pressure treated lumber. The untreated deck might look great for a year or two, but it will quickly start to show signs of wear, rot, and potential structural issues if not meticulously maintained with protective finishes. A pressure treated deck, on the other hand, can last 15-25 years or even longer with proper care and maintenance, thanks to the deep-seated protection against the elements.

This extended lifespan makes pressure treated wood a more economical choice in the long run for projects exposed to the outdoors. You invest a little more upfront, but you save significantly on replacement costs and ongoing repairs. It’s a classic case of paying for durability and peace of mind.

Environmental Considerations

It’s natural to wonder about the environmental impact of the chemicals used in pressure treated wood. Modern wood preservatives have undergone rigorous testing and regulation by agencies like the EPA. They are designed to be highly effective at low concentrations and to bind tightly to the wood, minimizing leaching into the environment. The EPA’s registration process ensures that these products can be used safely without causing unreasonable adverse effects on human health or the environment when used according to label directions.

The use of pressure treated wood also has positive environmental implications. By extending the life of wood products, it reduces the need for frequent replacement, which in turn conserves forest resources. Using treated wood for outdoor structures means less demand for alternative materials like concrete or steel, which often have a higher embodied energy and environmental footprint.

For the most current information on wood preservatives and their environmental impact, you can refer to resources from the U.S. Environmental Protection Agency (EPA).

Frequently Asked Questions (FAQ)

Q1: Can I use pressure treated wood for indoor furniture?

While you can, it’s generally not recommended or necessary. Pressure treated wood has a distinct odor and a greenish tint that might not be desirable for indoor furniture. Plus, the chemicals are unnecessary for indoor use where moisture and pests aren’t a concern. Regular hardwoods or softwoods are much better suited for indoor furniture, offering better aesthetics and easier finishing.

Q2: Does pressure treated wood rot?

Pressure treated wood is highly resistant to rot, decay, and insect infestation due to the chemical preservatives forced into its structure. While no organic material is completely impervious to degradation over extremely long periods or under extreme conditions, pressure treated wood is designed to last for decades in environments where untreated wood would fail quickly.

Q3: How long does pressure treated wood last?

The lifespan of pressure treated wood can vary depending on the specific treatment, the quality of the wood, and the environmental conditions it’s exposed to. However, for most outdoor applications like decks and fences, properly installed and maintained pressure treated lumber can last anywhere from 15 to 25 years, and often much longer.

Q4: What kind of fasteners should I use with pressure treated wood?

You should use hot-dip galvanized, stainless steel, or other corrosion-resistant fasteners. The copper compounds in many wood preservatives can cause standard steel fasteners to corrode prematurely. Always check the fastener manufacturer’s recommendations for use with treated lumber.

Q5: Is pressure treated wood safe to touch?

Yes, modern pressure treated wood is considered safe to touch when handled with basic precautions. Always wash your hands after handling. Avoid ingesting the wood or sawdust, and wear a dust mask when cutting or sanding to prevent inhalation of chemical particles. It is not recommended for use where it will come into prolonged direct contact with food, such as cutting boards.

Q6: Can I use sawdust from pressure treated wood in my garden?

It’s best not to. While modern treatments are designed to bind tightly to the wood, there’s still a risk of chemicals leaching into the soil, which could affect plant growth or be absorbed by edible plants. It’s safer to dispose of the sawdust from treated wood in the trash.

Q7: How do I dispose of old pressure treated wood?

Never burn pressure treated wood, as the smoke can be toxic. The best way to dispose of it is to take it to a licensed landfill or an approved waste disposal facility. Check with your local waste management services for specific guidelines in your area.

Conclusion

So there you have it! The difference between pressure treated wood and regular wood boils down to durability and application. Regular wood is your go-to for beautiful indoor projects where it’s protected from the elements. Pressure treated wood, with its enhanced resistance to decay and insects thanks to a specialized treatment process, is the champion for any project facing the challenges of outdoor exposure, ground contact, or high moisture. By understanding these distinctions and following safety guidelines when working with treated lumber, you’re well-equipped to make the right choice for every project, ensuring your creations are not only beautiful but also built to last. Happy building!