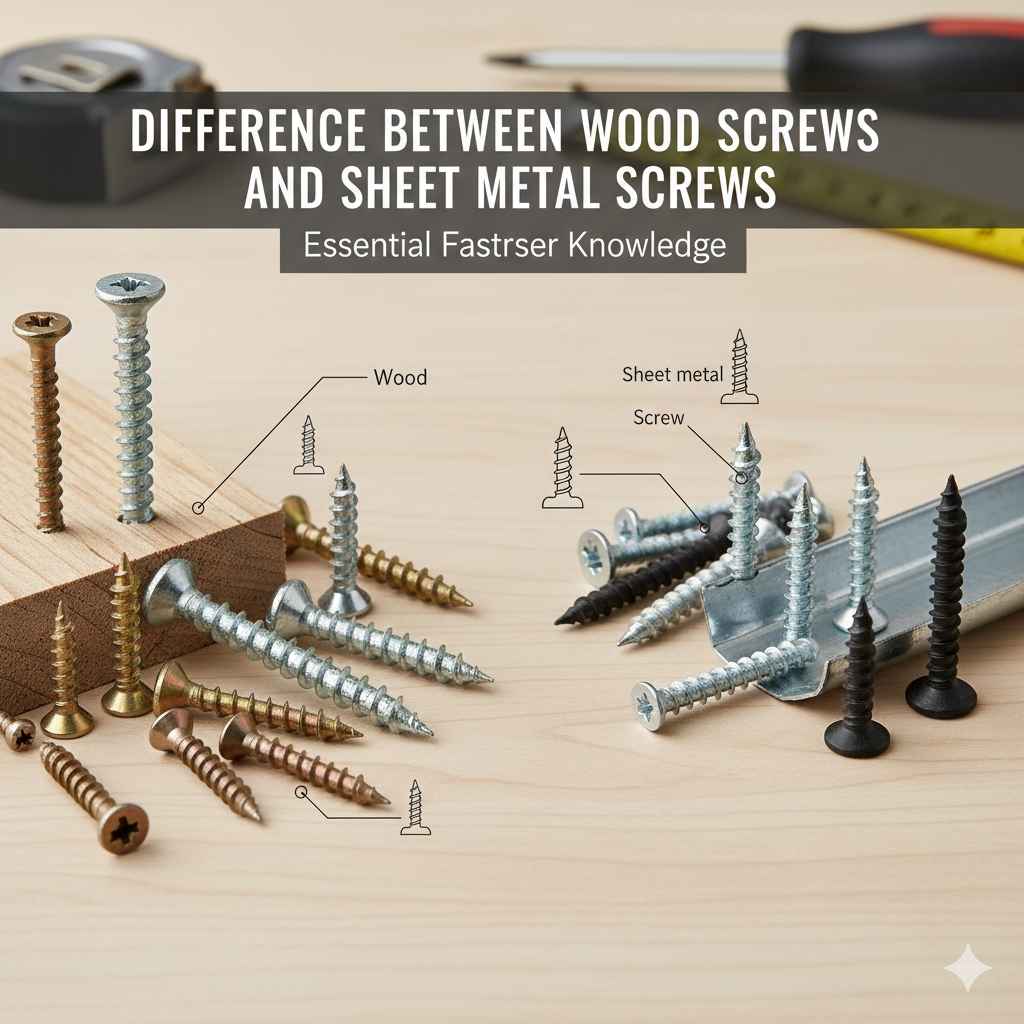

Difference Between Wood Screws And Sheet Metal Screws: Essential

Wood screws are designed primarily for soft materials like wood, featuring deep, wide threads that grip wood fibers. Sheet metal screws, conversely, have sharper, finer threads suitable for penetrating thin metals and hard materials. Choosing the wrong one can strip wood or fail to grip metal securely.

Hello there! I’m Md Meraj, and I know that standing in the hardware aisle staring at two nearly identical-looking screws—one labeled “wood” and one “sheet metal”—can feel overwhelming. It is a super common sticking point for new DIYers. Picking the wrong fastener can mean a wobbly shelf, a stripped hole, or worse, a project that falls apart later. Don’t worry! Understanding the basic differences between wood screws and sheet metal screws is simple once you see what makes them unique. I’m here to clear up the confusion so you can grab the right screw every time, ensuring your home projects are strong and built to last. Let’s look closely at what sets these two crucial fasteners apart.

The Essential Difference Between Wood Screws and Sheet Metal Screws

When you’re working on a home improvement project, the screw you choose is just as important as the tool you use to drive it. While both wood screws and sheet metal screws share a common goal—fastening things together—their designs are specialized for different materials. Think of it like using a shovel versus a trowel; both move dirt, but one is much better for a specific job.

The main distinction boils down to the threads and the shaft. Wood screws need aggressive, coarse threads to bite deeply into wood fibers without tearing them apart. Sheet metal screws, on the other hand, need fine, sharp threads to cut cleanly through thin metal sheets or hard plastics.

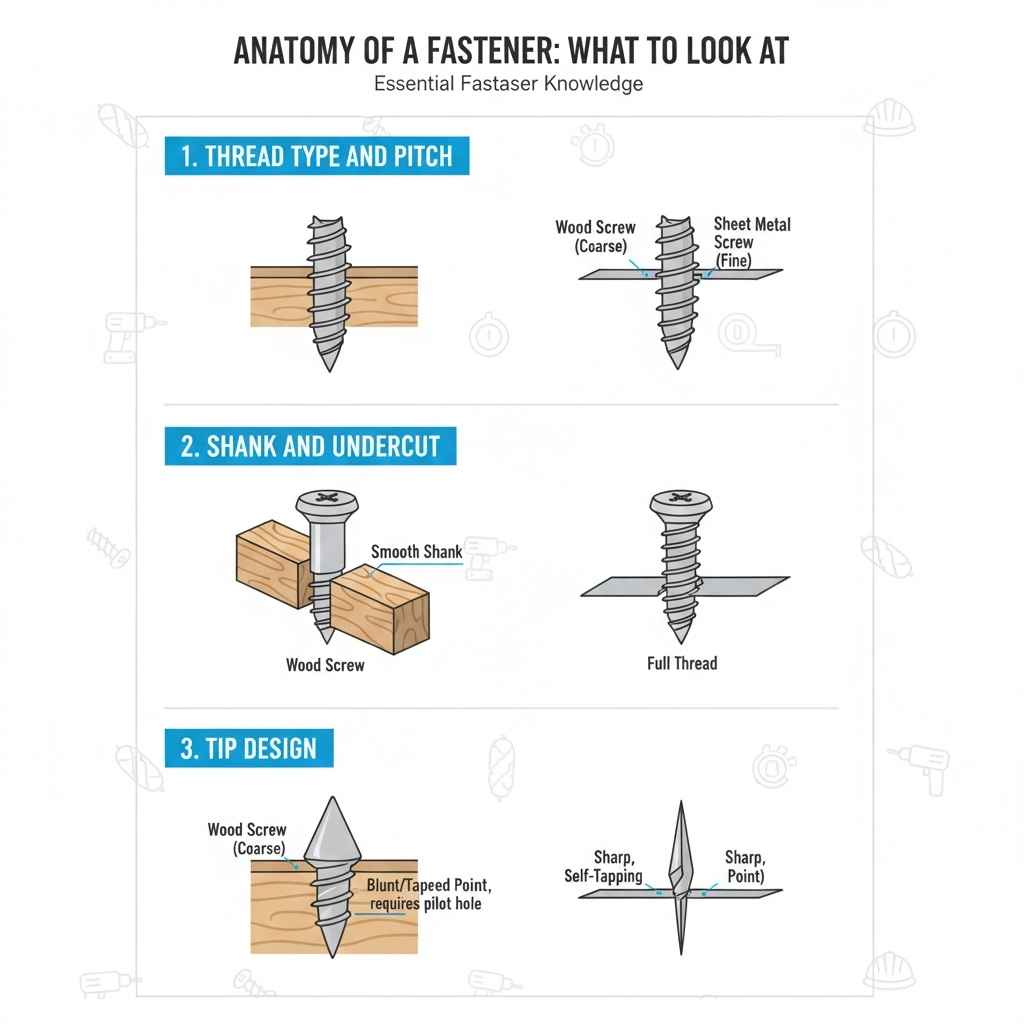

Anatomy of a Fastener: What to Look At

To really understand the difference, we need to break down the parts of the screw. Even though they look similar to the untrained eye, small variations in these components make a big difference in performance.

1. Thread Type and Pitch

This is the most significant visual difference.

Wood Screws (Coarse Threads): These screws have threads that are widely spaced (a low thread count per inch, or coarse pitch). These wide valleys between the threads are designed to scoop up and compress the soft wood fibers, providing excellent holding power in timber.

Sheet Metal Screws (Fine Threads): These screws have threads that are much closer together (a high thread count, or fine pitch). This allows them to cut a tight, self-tapping hole into thin, dense materials like aluminum or steel without stripping the thin material away.

2. Shank and Undercut

The shank is the smooth area just below the head.

- Wood Screws: Many wood screws (especially traditional types) have a smooth shank directly under the head. This is crucial because it allows the screw to pull two pieces of wood tightly together as the threads bury themselves in the lower piece.

- Sheet Metal Screws: These generally have threads running the entire length of the screw, right up to the head. This maximizes grip in thin, hard materials where a long, clean pull-through isn’t necessary.

3. Tip Design

The very end of the screw matters for starting the hole.

Wood Screws: Typically end in a relatively blunt or tapered point, designed to start easily in wood fibers but not usually intended to drill through very hard material without a pilot hole.

Sheet Metal Screws: Often feature a very sharp, almost needle-like point. This allows them to puncture metal skins easily. Some specialized versions (Type A or Type B) are “self-tapping,” meaning they create their own mating threads as they are driven in.

Wood Screws vs. Sheet Metal Screws: At a Glance

To make things crystal clear, here is a side-by-side comparison. Keep this handy next time you are at the hardware store!

| Feature | Wood Screw | Sheet Metal Screw |

|---|---|---|

| Primary Material | Wood, composite decking, particleboard | Thin metal, aluminum, plastic, drywall (sometimes) |

| Thread Pitch | Coarse (wide spacing) | Fine (close spacing) |

| Holding Power In Wood | Excellent (designed to grip fibers) | Poor (threads often strip wood) |

| Tip Point | Tapered or blunt | Sharp, often self-tapping |

| Shank Design | Often has a smooth section near the head | Threads usually run the full length |

When and Why to Use Wood Screws (Your Go-To for Woodworking)

If your project involves lumber, plywood, MDF, or any wood-based material, the wood screw is your best friend. Their design is optimized for the structure of wood.

Why Wood Screws Excel in Wood

Wood is an organic material made up of fibers. When you drive a standard wood screw:

The coarse threads displace these fibers but also anchor themselves firmly within the surrounding wood grain.

If the screw has a smooth shank, it allows the head to pull the top piece of wood snugly down onto the bottom piece without the top threads binding against it. This clamping action is what makes strong wooden joints.

Common Applications for Wood Screws

You will use wood screws for virtually any basic construction project around the house:

Assembling furniture (dressers, tables).

Attaching hinges or drawer slides to wooden cabinets.

Securing deck boards to joists (though specialized deck screws are better for outdoor use).

Building wooden frames or basic carpentry joints.

Pro Tip for Wood Screws: Always check the material you are drilling into. For hardwoods like oak or maple, or when driving screws near the edge of a board, drilling a pilot hole slightly smaller than the screw’s body is vital. This prevents splitting, a frustrating issue for all DIYers!

When and Why to Use Sheet Metal Screws (The Metal Masters)

Sheet metal screws, sometimes called tapping screws, are engineered for materials where wood screws simply won’t work well—materials that are thin, dense, or non-fibrous.

Why Sheet Metal Screws Excel in Metal

Metal doesn’t compress like wood. When you drive a fine-threaded screw into metal, it needs to cut its own path.

The sharp, fine threads easily cut into the relatively thin material, creating a strong, mating thread profile in the metal surface.

Because the material is thin, there is no need for a smooth shank; full threading ensures maximum grip across the short distance available.

Their hardness means they can resist the twisting forces required to cut through metal.

Common Applications for Sheet Metal Screws

If you’re fastening things that aren’t wood, look here first:

Attaching metal flashing or guttering components.

Securing metal ductwork in HVAC systems.

Mounting thin metal brackets onto wood studs (though a combination might sometimes be used).

Joining thin aluminum or steel panels together in DIY projects or repairs.

Many modern sheet metal screws come with hexagonal heads (Hex Head) for use with impact drivers or wrenches, which is important when a lot of torque is needed to drive them through metal. For more information on proper fastening techniques for structural connections, consulting standards from organizations like the National Institute of Standards and Technology (NIST) can be helpful for understanding load bearing applications.

Specialty Considerations: Variations You Might See

The world of screws expands quickly! It’s important to know that both categories have sub-types that make them even better for specific jobs.

Wood Screw Variations

Don’t be surprised if you see these terms:

Cabinet Screws: Often have a slightly tapered head and an integrated washer or trim head for a smooth, decorative finish in cabinetry.

Deck Screws: Treated or coated specifically to resist corrosion from moisture and treated lumber chemicals. They are wood screws optimized for the outdoors.

Trim Head Screws: Have very small heads, almost disappearing into the surface when countersunk, perfect for attaching thin moulding or trim without splitting the wood.

Sheet Metal Screw Variations

These variations focus on how the screw cuts the hole:

Type A: Features threads that cover the whole shank and a sharp point, excellent for drilling into thin materials like metal studs or aluminum siding.

Type B: Similar to Type A, but the threads are generally a bit deeper, often used for slightly thicker materials or when joining metal to a hard plastic.

Self-Drilling Screws (Tek Screws): These are specialized metal screws that have a drill-bit tip built right onto the end. They eliminate the need for a pilot hole entirely, saving huge amounts of time when working on structural steel or thicker metal panels.

Safety First: Driving Screws the Right Way

No matter which screw you choose, driving it correctly ensures a strong hold and prevents frustration. Safety and technique go hand-in-hand.

Key Steps for Driving Any Screw

Choose the Right Bit: Ensure your driver bit (Phillips, Square/Robertson, or Torx) fits snugly into the screw head recess. A loose fit leads to “cam-out” (the driver slipping out), which strips the head of the screw—a homeowner’s worst nightmare!

Use the Correct Speed: If using a power drill or impact driver, start slow. This gives you control to seat the screw perfectly straight. You can speed up once the threads have fully engaged.

Pilot Holes (Especially for Wood): Drill a pilot hole that matches the shank (the smooth middle part) of the screw, not the threads. This allows the threads to bite securely into the bottom piece of wood while the top piece is pulled flush without splitting.

Do Not Overtighten: This is critical, especially with wood and sheet metal screws. Once the screw head is snug against the material, STOP. Overtightening simply crushes the wood fibers or strips the delicate threads you created in the metal.

Understanding Torque and Material Hardness

When working with metal, you often need more power, but you must be careful not to break the screw. Hardened steel screws are strong, but applying too much torque can cause the head to shear right off.

For driving into metal, it’s wise to use a tool designed for high torque but with clutch settings, like a variable-speed drill, to stop driving when resistance becomes too high. For more detailed instructions on tool usage and preventing damage, resources like the Occupational Safety and Health Administration (OSHA) provide guidelines on mechanical fastener safety that translate well into home workshop practices regarding safe operation.

Cost and Availability: Which is More Accessible?

For most DIY homeowners, both wood screws and sheet metal screws are readily available at any big box store or hardware shop, and they are usually quite affordable.

However, wood screws tend to have a broader range of finishes and specialized types readily stocked (like exterior-grade bronze or ceramic coatings). Sheet metal screws are more utilitarian, though you will find more specialty options like self-drilling tips.

Affordability Note: For simple, non-structural projects, screws are inexpensive. Do not try to save a dollar by using a sheet metal screw in a crucial wood joint; the difference in holding power will cost you time and material later on.

Quick Troubleshoot Guide: What Went Wrong?

Ever driven a screw and immediately knew it wasn’t right? Here is how to diagnose common problems based on the screw type:

| Symptom | Likely Screw Used | Fix/Reason |

|---|---|---|

| Screw spins freely in the wood, not tightening down. | Wood Screw (or pilot hole too large) | The hole is stripped. Use a slightly thicker screw or use wood glue and a dowel rod to plug the hole before re-drilling. |

| Wood splits while driving the screw. | Wood Screw (no pilot hole or too close to edge) | The wood fibers couldn’t move aside easily. Drill a proper pilot hole next time. |

| Head snaps off during driving. | Sheet Metal Screw (in wood or overtightened in metal) | Too much torque or the screw material was too brittle for the resistance. Reduce torque setting. |

| Screw won’t bite into the thin metal. | Wood Screw (used on metal) | Wood threads are too coarse to cut into metal. Switch to a sharp, fine-threaded sheet metal screw. |

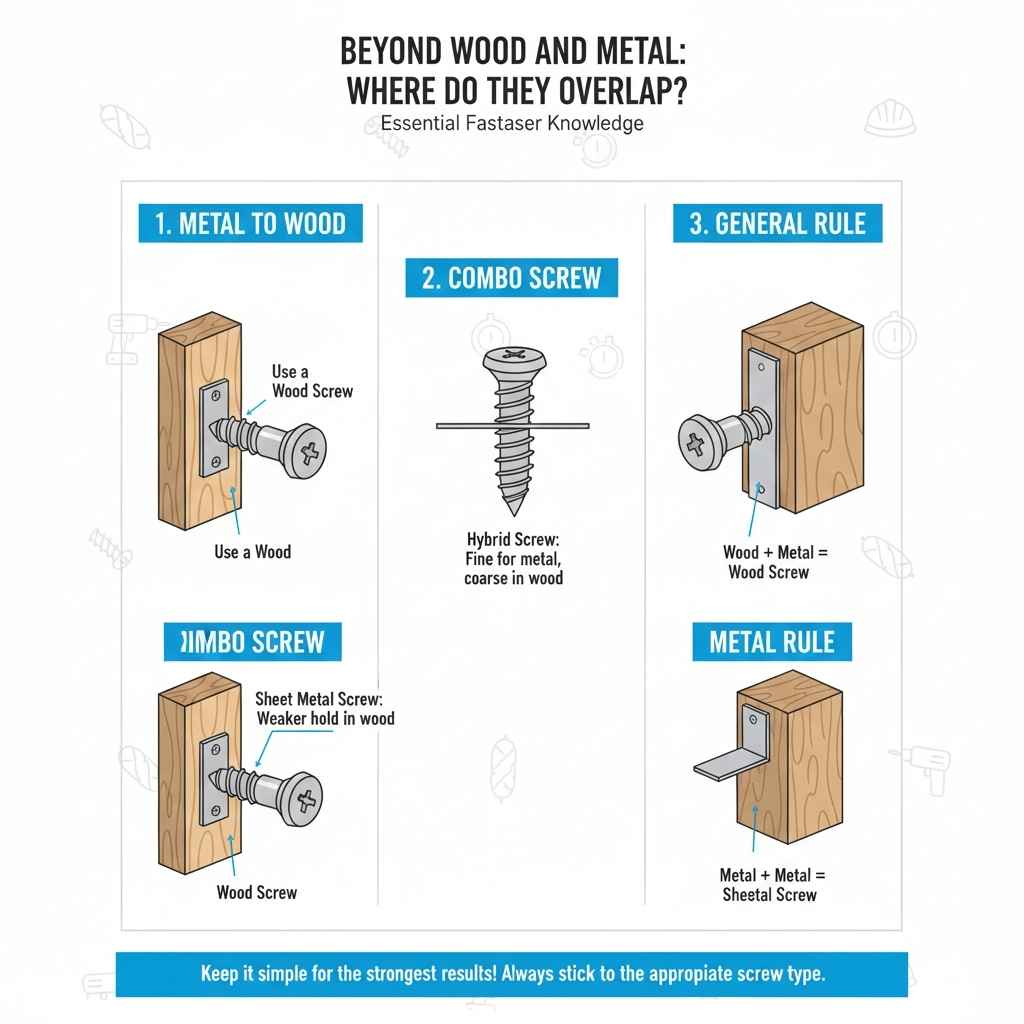

Beyond Wood and Metal: Where Do They Overlap?

Sometimes a project demands hybrid solutions. For instance, when securing something metal to wood (like mounting a metal bracket onto a wooden wall stud), you have options:

Use a Wood Screw: Drive a good, sturdy wood screw through the metal bracket and into the wood stud. The wider threads will hold firmly in the wood stud.

Use a Sheet Metal Screw: You can sometimes use a Type B sheet metal screw to go through a thin metal plate and bite into a wood stud, but the pull-out strength in the wood will be significantly weaker than a true wood screw.

Use a Combo Screw: Some manufacturers make hybrid screws that feature finer threads near the head (for the metal) and coarser threads lower down (for the wood), often used in manufactured housing assembly.

For general home repairs, if one side of the connection is wood, stick to a wood screw. If both materials are thin metal or plastic, stick to the sheet metal screw. Keep it simple for the strongest results!

Conclusion: Building Confidence with the Right Fastener

You’ve done great work understanding the core differences between wood screws and sheet metal screws. Remember this simple guide: Wood screws have wide, deep threads to grab wood fibers, and sheet metal screws have fine, sharp threads to cut into thin metal.

This knowledge is one of those little secrets that instantly makes you feel more competent on the job site. Next time you need a fastener, you won’t just be grabbing a screw; you’ll be selecting the correct screw for the job. That means stronger connections, less frustration, and projects that look professional and stand the test of time. Keep practicing, keep learning, and enjoy the confidence that comes with knowing your tools!

Frequently Asked Questions (FAQ) for Beginners

Q1: Can I use a sheet metal screw instead of a wood screw in a soft piece of wood like pine?

A: You can, but it’s not ideal. The fine threads on the sheet metal screw will tend to chew up or strip the soft wood fibers rather than gripping them firmly, resulting in a weaker hold and potential stripping of the hole.

Q2: Are wood screws ever used on metal?

A: Only in very specific, heavy-duty applications where the wood screw passes through a metal piece and securely anchors into a thick wooden structure underneath. Even then, a true sheet metal screw is better for the thin metal part of the connection.

Q3: Do I always need to drill a pilot hole for wood screws?

A: Not always for very soft woods like pine or cedar, but it is always the safest practice, especially near the edges of boards or when working with hardwoods (like maple or cherry). A pilot hole prevents splitting.

Q4: What is the main reason sheet metal screws are so sharp?

A: They are designed to be “self-tapping,” meaning they cut threads into the metal as you drive them. This sharpness is necessary to pierce the dense surface of the metal material effectively.

Q5: Which screw is better for securing hinges on a wooden cabinet door?

A: A wood screw is the correct choice. Hinges need the high holding power provided by coarse threads biting deeply into the wood to handle the repeated stress of opening and closing the door.

Q6: Why are some wood screws black or gray?

A: Those are usually coated for corrosion resistance. Black phosphate coatings offer minimal moisture protection, while specialized bronze, ceramic, or stainless steel coatings are required for outdoor or high-moisture environments.

Q7: What happens if I use a wood screw in thick steel?

A: The wood screw’s threads will be too coarse to cut into the steel, and you will likely snap the head off the screw immediately because the threads will bind up and snap before they can penetrate the material.