Do You Need to Seal Pressure Treated Wood? Ultimate Guide

Yes, you need to seal pressure treated wood to protect it from moisture and mildew. Pressure treated wood requires sealing to prevent moisture damage and mildew growth.

Sealing helps maintain the wood’s integrity and prolong its lifespan, especially in outdoor settings where it is exposed to the elements. Additionally, sealing can prevent swelling, cracking, and discoloration, ensuring the wood remains in good condition over time. Properly sealed pressure treated wood also minimizes the risk of warping and cupping, making it a crucial step in preserving its quality and appearance.

Whether for decks, fences, or other outdoor structures, sealing pressure treated wood is essential for long-term durability and aesthetic appeal.

The Importance Of Sealing Pressure Treated Wood

Pressure-treated wood is a popular choice for outdoor projects due to its ability to resist rot and insect damage. However, despite its natural resistance, pressure-treated wood still requires sealing to ensure long-term durability and protection against the elements.

Benefits Of Sealing

- Enhances Longevity: Sealing pressure-treated wood extends its lifespan by protecting it from moisture, which can lead to rot and decay.

- Prevents Cracking: Sealing helps to minimize the risk of cracking and warping, maintaining the structural integrity of the wood.

- Minimizes Discoloration: Sealing preserves the natural appearance of the wood by preventing discoloration caused by UV rays and moisture.

- Reduces Maintenance: Properly sealed wood requires less frequent maintenance, saving time and effort in the long run.

Consequences Of Not Sealing

- Increased Decay: Without sealing, pressure-treated wood is susceptible to moisture infiltration, leading to decay and deterioration over time.

- Structural Damage: Unsealed wood is more prone to cracking, warping, and splintering, which can compromise the structural integrity of the project.

- Aesthetic Deterioration: Exposure to UV rays and moisture can cause the wood to fade, discolor, and develop unsightly stains if left unsealed.

- Higher Maintenance Needs: Neglecting to seal pressure-treated wood may result in the need for more frequent repairs and replacements.

Types Of Pressure Treated Wood

To maintain the durability of pressure-treated wood, it’s essential to seal it to protect against moisture and mildew. Sealing prevents swelling, cracking, and discoloration, ensuring longevity. Softwoods like pine and cedar commonly benefit from proper sealing to enhance their lifespan.

When it comes to pressure treated wood, there are various types available in the market. The most commonly used pressure-treated woods are softwoods such as pine and cedar. However, hardwoods like oak and maple can also be treated with pressure for added durability. In this section, we will discuss the common wood varieties used for pressure treatment and cutting and sealing considerations.

Common Wood Varieties

Pine and cedar are the most commonly used woods for pressure treatment. Pine is known for its affordability and availability, making it a popular choice for building decks and outdoor structures. Cedar, on the other hand, is more expensive than pine but is naturally resistant to decay and insects.

Apart from softwoods, hardwoods like oak and maple can also be treated with pressure for added durability. These hardwoods are often used for outdoor furniture and decorative elements in the yard.

Cutting And Sealing Considerations

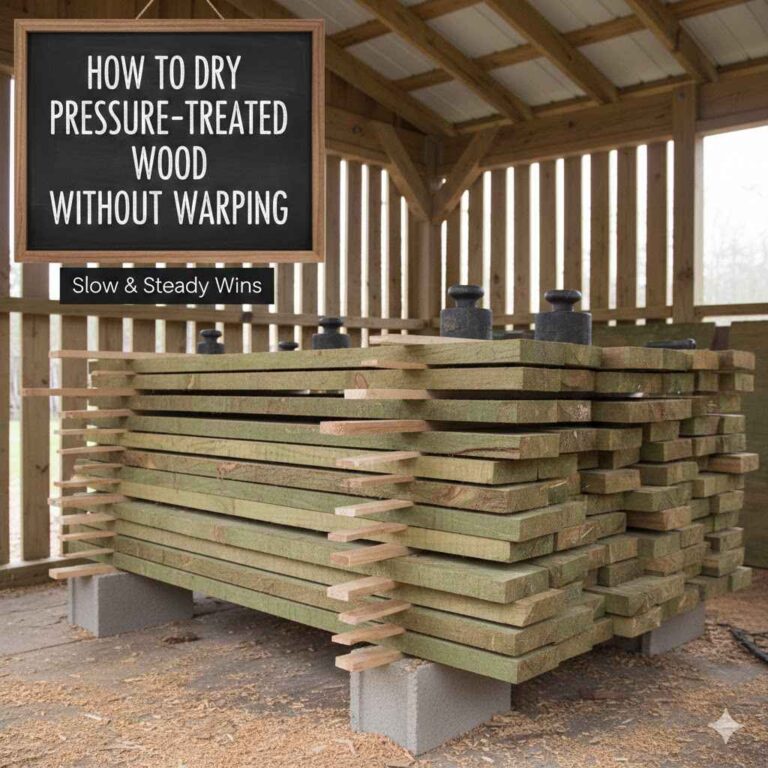

One important thing to keep in mind while working with pressure-treated wood is that it should not be cut or drilled immediately after treatment. The wood needs time to dry out before it can be cut, drilled, or fastened. The drying time can vary depending on the type of wood and the weather conditions, but it is typically recommended to wait at least 48 hours before cutting or drilling.

Sealing the pressure-treated wood is necessary to protect it from moisture, mildew, and UV rays. It is recommended to wait at least 30 days after installation before applying any sealant or stain to allow the wood to dry out completely. When sealing the wood, it is important to apply the sealant evenly and follow the manufacturer’s instructions for best results.

In conclusion, pressure-treated wood is an excellent choice for outdoor structures due to its durability and resistance to decay and insects. However, it is important to consider the type of wood and cutting and sealing considerations to ensure the longevity of the structure.

Moisture And Pressure Treated Wood

When it comes to pressure treated wood, moisture can have a significant impact on its durability and longevity. Understanding the effects of moisture on pressure treated wood and how to prevent moisture damage is crucial for maintaining the quality of your outdoor wood structures.

Effects Of Moisture

Moisture can cause pressure treated wood to swell, crack, warp, and become discolored. It can also lead to the growth of mold and mildew, which can further deteriorate the wood over time.

Preventing Moisture Damage

To prevent moisture damage, it’s essential to seal pressure treated wood regularly. Sealing the wood creates a protective barrier that helps repel water and inhibit the growth of mold and mildew. Additionally, using proper installation techniques, such as leaving gaps between deck boards and using stainless steel fasteners, can help promote proper drainage and reduce moisture retention.

Sealing Vs. Staining

Sealing pressure treated wood is essential to protect it from moisture and mildew, even though the pressure treatment already guards against insects and rot. It is recommended to seal the wood annually to prevent swelling, cracking, cupping, warping, and discoloration.

When it comes to protecting your pressure-treated wood, there are two main options: sealing and staining. Both methods have their benefits, but it’s important to understand the differences before making a decision.

Visual and Protective Differences

Sealing your pressure-treated wood will provide a clear, protective layer that prevents moisture from penetrating the wood. This will help prevent the wood from warping, cracking, and rotting. However, sealing will not change the appearance of the wood. If you want to enhance the natural look of the wood while still providing protection, staining is the way to go. Staining will add color to the wood while also providing a layer of protection against moisture and UV rays.

Choosing the Right Product

When it comes to selecting a product for sealing or staining your pressure-treated wood, there are a few things to keep in mind. First, make sure the product is specifically designed for use on pressure-treated wood. Second, consider the level of protection you need. If you live in a humid or rainy climate, you may want to opt for a product with a higher level of water resistance. Finally, consider the look you want to achieve. If you want a natural wood look, choose a clear or lightly tinted product. If you want to add color, choose a stain that matches your desired shade.

In conclusion, sealing and staining are both effective ways to protect your pressure-treated wood. It’s important to understand the differences between the two methods and choose the right product for your needs. With the right protection, your pressure-treated wood will last for years to come.

Preparing Wood For Sealing

Before you proceed with sealing pressure treated wood, it is important to properly prepare the surface. This involves cleaning the surface and testing the moisture content. By following these steps, you can ensure that the wood is ready for sealing and will provide long-lasting protection against moisture, mold, and UV rays.

Cleaning The Surface

In order to achieve optimal results when sealing pressure treated wood, it is essential to start with a clean surface. This involves removing any dirt, dust, or debris that may be present. Here are a few steps you can follow to clean the surface:

- Begin by sweeping the wood with a broom to remove loose dirt and debris.

- Next, use a mild detergent mixed with water to scrub the surface using a brush or sponge.

- Rinse the wood thoroughly with clean water to remove any residue.

- Allow the wood to dry completely before proceeding with the next steps.

Testing Moisture Content

Testing the moisture content of pressure treated wood is crucial before sealing, as excess moisture can prevent the sealer from properly adhering to the surface. Here are two methods you can use to test the moisture content:

- Water Sprinkle Method: Sprinkle a few drops of water onto the wood surface. If the water beads up, it indicates that the wood is still too wet and needs more time to dry. If the water is absorbed into the wood, it is ready for sealing.

- Moisture Meter: Use a moisture meter specifically designed for wood to measure the moisture content. Follow the instructions provided with the meter to obtain an accurate reading. Ideally, the moisture content should be below 15% before sealing.

By cleaning the surface and testing the moisture content, you can ensure that the pressure treated wood is properly prepared for sealing. This will result in a more effective seal and enhanced protection against moisture, mold, and UV rays. Remember to follow the manufacturer’s instructions when applying the sealer for best results.

Application Techniques For Sealants

When it comes to sealing pressure-treated wood, proper application techniques are crucial to ensure long-lasting protection. Below are the essential tools and materials, best practices for application, and key tips to follow:

Tools And Materials

- Quality paintbrush or roller

- Spray applicator for larger areas

- Protective gear: gloves, goggles, and mask

- Clean cloth for wiping excess sealant

- Appropriate sealant for pressure-treated wood

Best Practices For Application

- Clean the wood surface thoroughly before applying the sealant.

- Ensure the wood is completely dry to allow better penetration of the sealant.

- Apply even coats of sealant to avoid drips or uneven coverage.

- Follow the manufacturer’s instructions for drying times between coats.

- Avoid sealing in direct sunlight to prevent premature drying of the sealant.

- Apply sealant along the wood grain for optimal coverage and protection.

- Reapply sealant annually to maintain protection against moisture and UV rays.

Maintenance Of Sealed Surfaces

Regularly inspecting sealed pressure-treated wood is crucial to ensure its longevity. Look for signs of wear or damage that may compromise the sealant.

Regular Inspection

- Check for any cracks or peeling of the sealant.

- Inspect for moisture penetration or mold growth.

- Address any issues promptly to prevent further damage.

Reapplication Interval

- Reapply sealant every 1-2 years for optimal protection.

- Consider more frequent reapplications for high-traffic areas.

- Follow the manufacturer’s recommendations for the specific sealant used.

Special Considerations

When working with pressure treated wood, there are some special considerations to keep in mind:

Treating Cut Ends

- Sealing cut ends is crucial for all treated lumber products.

- It is especially important for in-ground installations like fence posts.

- Properly sealed cut ends help prevent moisture penetration.

Working With In-ground Installations

- Use pressure treated wood for in-ground installations.

- Seal the ends of the wood to protect against moisture and decay.

- Maintain sealed ends for longevity of fence posts and retaining walls.

Sealing pressure treated wood is essential to protect it from moisture, mold, and UV rays. Regular sealing helps prevent swelling, cracking, and discoloration, ensuring the durability of your wood structures.

Frequently Asked Questions

What Happens If You Don’t Seal Treated Wood?

Sealing pressure treated wood is necessary to protect it from moisture, mold, mildew, and UV rays. While pressure treatment protects against insects and rot, it does not protect against these other elements. Failure to seal the wood annually can result in swelling, cracking, cupping, warping, and discoloration.

Softwoods such as pine and cedar are commonly used for deck building in the US.

How Long Do You Have To Wait To Seal Pressure Treated Wood?

Seal pressure treated wood after 6 months to a year to ensure it’s fully dried.

Is It Better To Stain Or Seal Pressure Treated Wood?

Yes, it is better to seal pressure treated wood. While pressure treatment protects against insects and rot, sealing is necessary to protect the wood from moisture, mold, mildew, and UV rays. Sealing your pressure-treated wood annually can prevent swelling, cracking, cupping, warping, and discoloration.

For a natural look, you can skip the stain and apply a clear or lightly tinted sealer for waterproofing and UV protection. Clean and dry the treated boards before sealing.

Should I Seal Cut Ends Of Pressure Treated Wood?

Yes, it’s important to seal cut ends of pressure treated wood to protect it from moisture and mildew.

Conclusion

It is essential to seal pressure-treated wood. While pressure treatment provides protection against insects and rot, sealing is necessary to safeguard the wood from moisture and mildew. By sealing the wood, you can prevent swelling, cracking, cupping, warping, and discoloration.

Whether it’s a deck, fence posts, or landscaping projects, sealing the cut ends and applying a clear or lightly tinted sealer will help maintain the wood’s natural look and provide waterproofing and UV protection. Don’t overlook the importance of sealing pressure-treated wood to ensure its longevity and durability.