Do You Need Underlayment for Engineered Hardwood

When you’re getting ready to put down a new engineered hardwood floor, one question pops up a lot: Do You Need Underlayment for Engineered Hardwood? It might seem a bit confusing at first, especially if you’re new to flooring projects. Don’t worry, though! We’ll break it down super simply so you can get your beautiful new floor installed with confidence.

Stick around, and we’ll figure this out together, step by step. You’ll know exactly what to do next.

Installing a new floor is exciting! Engineered hardwood looks amazing and adds value to your home. But before you start clicking planks together, you might wonder about an extra layer called underlayment.

Is it really necessary? Let’s clear things up. You want your new floor to look great and last a long time.

Figuring out if you need underlayment is a key part of making sure that happens.

The simple answer is: often, yes! While some engineered hardwood can be installed without it, using the right underlayment can make a big difference. It’s not just about padding; it’s about protecting your floor and making it feel better underfoot.

We’ll explore why this layer is so important and what it does for your new floors.

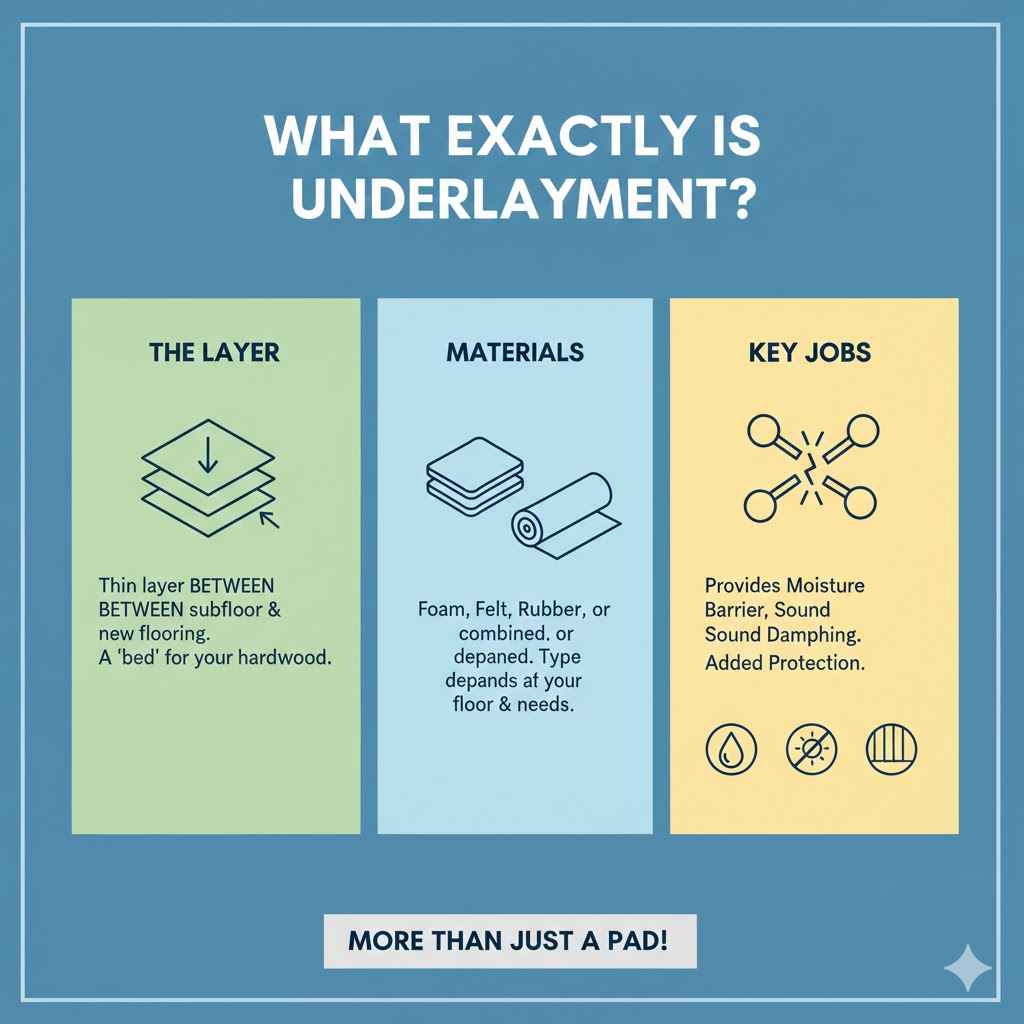

What Exactly Is Underlayment?

Underlayment is a thin layer that goes between your subfloor and your new flooring. Think of it as a bed for your hardwood. It’s not the same as the flooring itself.

It’s a separate material that serves several important jobs.

It’s usually made of foam, felt, rubber, or a combination of materials. The type you choose depends on your flooring and what you need it to do. Some are very basic, while others offer advanced features like moisture barriers or sound dampening.

Why Use Underlayment for Engineered Hardwood?

You might be asking yourself why you can’t just lay the engineered hardwood straight onto the subfloor. Here are the main reasons why underlayment is usually recommended:

- Sound Reduction: Floors can be noisy! Underlayment helps to soak up the sound of footsteps. This means less creaking and thudding. It’s especially helpful in upstairs rooms or apartments.

- Moisture Barrier: Some types of underlayment have a built-in moisture barrier. This is crucial if you’re installing on a concrete slab or in a basement. It stops dampness from reaching your wood floor.

- Cushioning and Comfort: Walking on a floor with underlayment feels softer and more comfortable. It gives a little bit of give under your feet, making the floor feel nicer.

- Subfloor Imperfection Smoothing: Even good subfloors aren’t perfectly flat. Underlayment can help to smooth out minor bumps and dips. This gives your flooring a more even surface to rest on.

- Insulation: Some underlayments offer a bit of extra warmth. This can make your floor feel less cold in winter.

- Installation Aid: For floating floors, underlayment can help the planks lock together more securely. It provides a stable base for the interlocking system.

When Might You NOT Need Underlayment?

There are a few cases where underlayment might not be strictly required. However, even in these situations, it’s often still a good idea for the benefits it provides. Always check your engineered hardwood manufacturer’s warranty and installation guidelines.

Some engineered hardwood floors come with a pre-attached underlayment. If your flooring already has this layer, you don’t need to add another one. Adding a second layer could actually cause problems.

If your flooring is glued directly down to a perfectly flat and dry subfloor, underlayment might not be part of the recommended system. However, most manufacturers still suggest it for the sound and comfort benefits.

Types of Underlayment

There are several kinds of underlayment, each with its own features. Knowing the differences helps you pick the best one for your project.

Foam Underlayment

This is a very common and affordable choice. It’s lightweight and easy to install. Foam underlayment is great for basic cushioning and some sound reduction.

Pros: Inexpensive, easy to cut and lay, good for basic comfort.

Cons: Limited moisture protection, not the best for sound dampening.

Felt Underlayment

Felt underlayment is made from recycled materials. It’s a bit denser than foam and offers better sound absorption. It also provides a good moisture barrier in some versions.

Pros: Good sound absorption, eco-friendly options, can provide a moisture barrier.

Cons: Can be less common, might require a separate moisture barrier if not designed with one.

Rubber Underlayment

Rubber underlayment is known for its excellent sound reduction and shock absorption. It’s often used in high-traffic areas or where noise is a major concern. It can also offer good moisture resistance.

Pros: Superior soundproofing, great comfort, good durability.

Cons: More expensive than foam or felt, can have a rubber smell initially.

Combination Underlayments

Many products combine materials like foam, felt, and a moisture barrier into one layer. These are often the best all-around choice for engineered hardwood floors.

These offer a mix of benefits – sound, moisture control, and comfort. They simplify installation by providing multiple functions in one product.

What Does Your Engineered Hardwood Need? Check the Manufacturer!

This is the most important step. Before you buy any underlayment, always consult the installation guide or warranty information provided by your engineered hardwood manufacturer.

They will tell you exactly what they recommend or require. Following their instructions ensures your warranty stays valid. Some manufacturers have specific requirements for thickness, material, or even approved brands of underlayment.

Your flooring type matters too. Is it a click-lock system? Is it solid hardwood?

Is it a thinner engineered plank?

Installation Considerations

When installing underlayment, make sure your subfloor is clean and dry. Sweep away all dust and debris. If you’re using a floating floor system, lay the underlayment flat and butt the edges together, but don’t overlap them unless the instructions say to.

If your underlayment includes a moisture barrier, make sure to properly seal the seams with the recommended tape. This is critical for preventing moisture damage.

Underlayment and Different Subfloors

The type of subfloor you have can also influence your decision about underlayment.

Concrete Subfloors

Concrete is prone to moisture. If you are installing engineered hardwood over concrete, especially on a ground floor or in a basement, a good moisture barrier within your underlayment is essential. Look for underlayment specifically designed for concrete.

Plywood or OSB Subfloors

These subfloors are generally more stable. However, minor imperfections can still exist. Underlayment can help smooth these out.

Moisture is usually less of a concern with these materials unless there has been a water leak.

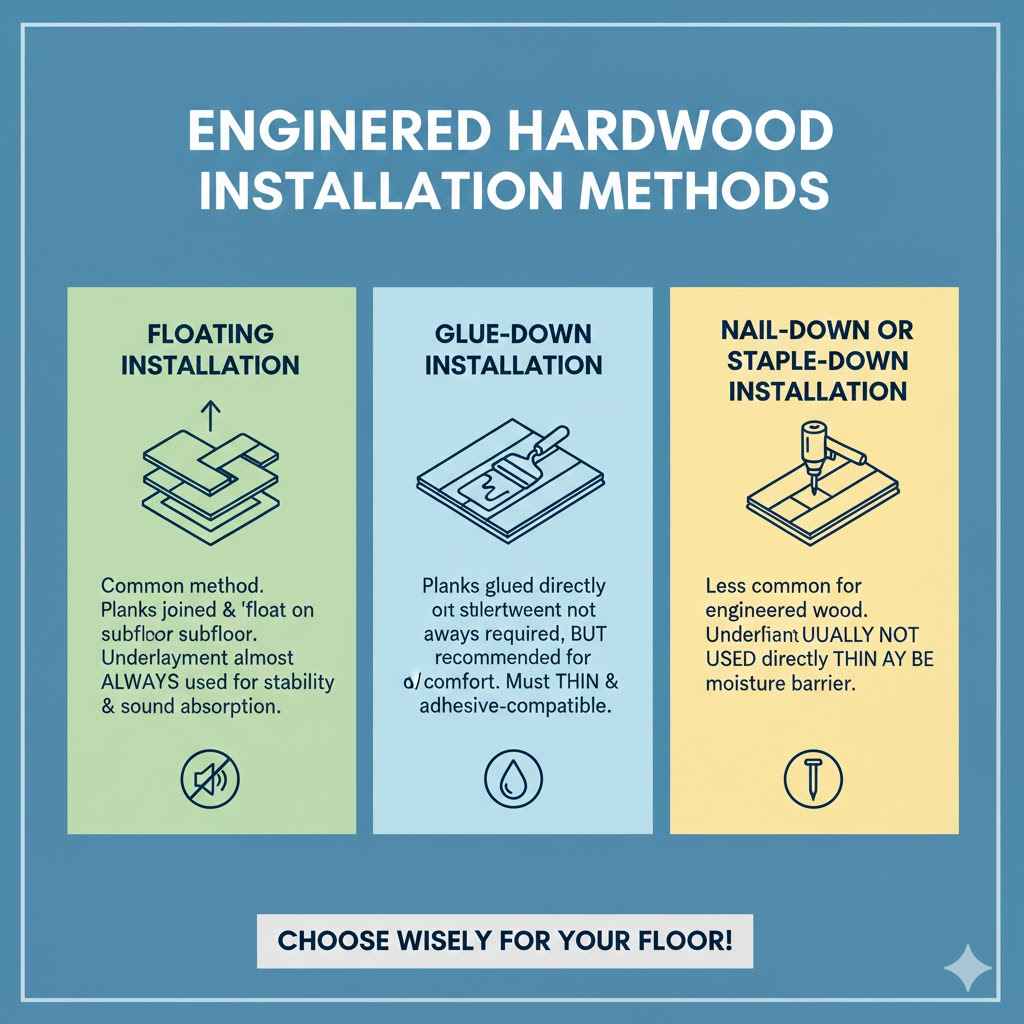

Engineered Hardwood Installation Methods

Engineered hardwood can be installed in a few ways, and this can affect underlayment needs.

Floating Installation

This is the most common method for engineered hardwood. The planks are joined together and “float” on top of the subfloor. Underlayment is almost always used with floating floors to provide a smooth, stable surface and absorb sound.

Glue-Down Installation

In this method, the planks are glued directly to the subfloor. While underlayment isn’t always required by the adhesive manufacturer, many still recommend a thin, compatible underlayment for sound and comfort. The key is that the underlayment must be thin and allow the adhesive to bond properly.

Nail-Down or Staple-Down Installation

This method is less common for engineered hardwood, especially thinner planks. If you are nailing or stapling, underlayment is usually not used directly underneath because the fasteners need to go through the flooring and into the subfloor. However, sometimes a thin, permeable felt is used as a moisture barrier.

Frequently Asked Questions

Question: Does engineered hardwood always need underlayment?

Answer: Not always, but it’s highly recommended in most situations for sound, comfort, and moisture protection. Always check your flooring manufacturer’s guidelines.

Question: Can I skip underlayment if my flooring has a pre-attached pad?

Answer: Yes, if your engineered hardwood comes with a pre-attached underlayment, do not add another layer. This can cause installation problems and void your warranty.

Question: What is the best underlayment for basement installations?

Answer: For basements, especially over concrete, you need an underlayment with a good moisture barrier. Look for products specifically rated for moisture protection and concrete subfloors.

Question: How thick should underlayment be?

Answer: The thickness varies, but generally 1/8 inch to 1/4 inch is common. Your engineered hardwood manufacturer will usually specify acceptable thickness ranges.

Question: Can I install engineered hardwood without underlayment on a concrete slab?

Answer: It is not recommended. Concrete slabs can emit moisture. Using an underlayment with a reliable moisture barrier is essential to protect your engineered hardwood floor.

Final Thoughts

So, Do You Need Underlayment for Engineered Hardwood? The answer is usually yes, and it’s a smart choice. Underlayment adds comfort, dampens noise, and protects against moisture. Always check your flooring manufacturer’s specific recommendations and warranty requirements before you buy or install anything.

Choosing the right underlayment ensures your beautiful new floor looks great and lasts for years to come.