Engineered Hardwood vs LVP: Essential Guide

Quick Summary: Engineered hardwood offers genuine wood beauty and increases home value, while LVP provides superior water resistance and durability, making it ideal for high-traffic, moisture-prone areas. Choosing between engineered hardwood flooring vs LVP depends on your budget, lifestyle, and aesthetic priorities.

Picking the right flooring for your home can feel like a big decision, and it’s easy to get lost in all the options! You want something that looks great, lasts a long time, and fits your budget. Two popular choices that often get compared are engineered hardwood and LVP (Luxury Vinyl Plank). They both mimic the look of real wood, but they’re quite different under the surface. Don’t worry, though! We’re going to break it all down in a way that’s easy to understand, just like preparing a piece of lumber for a beautiful project. By the end of this guide, you’ll know exactly which one is the perfect fit for your space.

Why This Choice Matters for Your Home

Think of your flooring as the foundation for your home’s style. Just like choosing the right wood for a sturdy table, the flooring you select sets the tone for every room. It impacts how your space feels, how easy it is to maintain, and even how much your home is worth. When you’re comparing engineered hardwood flooring vs LVP, you’re really looking at how well each material will stand up to daily life, what kind of upkeep it needs, and the overall ambiance it creates.

Many homeowners find themselves scratching their heads when faced with these two options. One seems more “real,” while the other boasts incredible practicality. It’s a common dilemma! But with a little guidance, you can confidently make the best choice for your needs. We’ll explore everything from their construction to their performance, helping you feel as comfortable with this decision as you are with your favorite woodworking tool.

Understanding Engineered Hardwood

Engineered hardwood is a clever construction that gives you the best of both worlds: the authentic beauty of real wood on top, with a stable base underneath. It’s like layering a beautiful veneer on a strong, reliable core. This makes it a fantastic option for those who love the warmth and character of natural wood but need a floor that can handle more than just a formal dining room.

The way it’s made is key to its performance. Unlike solid hardwood, which is a single piece of wood from top to bottom, engineered hardwood is built in layers. This layered construction gives it a distinct advantage in certain environments.

How Engineered Hardwood is Made

The construction of engineered hardwood is quite ingenious, designed for stability and performance. It’s typically made with three or more layers of wood products, often plywood or high-density fiberboard (HDF), pressed together. The top layer, or “wear layer,” is a thin slice of premium hardwood, like oak, maple, or walnut. This is the part you see and walk on, providing that genuine wood look and feel.

The core layers are cross-grained, meaning the wood grain runs in different directions for each layer. This crisscross pattern is what makes engineered hardwood more dimensionally stable than solid hardwood. It resists expanding and contracting with changes in humidity and temperature, which is a common problem with solid wood floors, especially in areas with fluctuating moisture levels.

The result is a floor that looks and feels like solid hardwood but is less prone to warping, cupping, or gapping. This makes it suitable for installation in more places within your home, including basements and areas prone to moisture, though it’s still important to note it’s not completely waterproof.

Pros and Cons of Engineered Hardwood

Like any material, engineered hardwood has its strengths and weaknesses. Knowing these will help you decide if it’s the right fit for your project.

| Pros | Cons |

|---|---|

| Authentic Wood Appearance: The top layer is real hardwood, offering genuine beauty and grain patterns. | Susceptible to Deep Scratches: While durable, the real wood wear layer can be scratched or dented by heavy furniture or sharp objects. |

| Increased Home Value: Real wood flooring is a significant selling point and can increase your home’s resale value. | Limited Refinishing: The wear layer can only be sanded and refinished a limited number of times (often 1-3), depending on its thickness. |

| More Stable in Humid Conditions: Its layered construction makes it more resistant to moisture-related expansion and contraction than solid hardwood. | Can be More Expensive: Generally, engineered hardwood is more costly than LVP. |

| Versatile Installation: Can be installed as a “floating” floor, glued down, or even stapled, and is suitable for installation over concrete slabs and radiant heating systems. | Not Waterproof: While more stable than solid wood, it can still be damaged by prolonged exposure to standing water. |

| Environmentally Friendly Options: Many engineered wood floors use less premium lumber and are made with sustainable practices. | Can be Damaged by Excessive Moisture: Prolonged exposure to moisture can still cause swelling and damage to the core layers. |

Understanding LVP (Luxury Vinyl Plank)

LVP, or Luxury Vinyl Plank, is a modern flooring solution that has gained immense popularity for its impressive durability, water resistance, and realistic wood (or stone) aesthetics. It’s a synthetic material designed to mimic the look of natural materials at a fraction of the cost and with significantly less maintenance. Think of it as a high-performance composite material built for tough conditions.

What makes LVP stand out is its innovative construction, which allows it to be incredibly versatile. It’s not just a simple sheet of vinyl anymore; LVP is engineered to replicate the visual and textural qualities of wood planks with remarkable accuracy.

How LVP is Made

LVP is a multi-layered synthetic product. The exact composition can vary slightly between manufacturers, but most LVP floors consist of four main layers, plus a protective wear layer and often an attached underlayment.

1. Wear Layer: This is the top, transparent layer that protects the plank from scratches, stains, and wear. A thicker wear layer (measured in mils) generally indicates better durability and is a key factor in LVP quality.

2. Design Layer: This is a high-resolution photographic layer that replicates the look of wood or stone. Advanced printing techniques allow for incredibly realistic patterns and textures.

3. Core Layer: This is the heart of the LVP plank. It’s typically made from a blend of PVC (polyvinyl chloride) and other materials, often including limestone or wood plastic composite (WPC) or stone plastic composite (SPC). These cores provide stability, rigidity, and impact resistance.

4. Backing Layer: This is the foundation of the plank, providing additional stability and sometimes an integrated underlayment for sound dampening and moisture resistance.

The combination of these layers results in a flooring material that is highly resilient, waterproof, and easy to maintain. Many LVP products also feature a click-lock installation system, making them a popular choice for DIYers.

Pros and Cons of LVP

LVP offers a compelling set of benefits, especially for busy households. However, it’s good to be aware of its limitations too.

| Pros | Cons |

|---|---|

| 100% Waterproof: LVP is completely impervious to water, making it ideal for kitchens, bathrooms, laundry rooms, and basements. | Can be Less Appealing to Some Buyers: While realistic, it doesn’t have the same inherent value or aesthetic depth as real wood to all consumers. |

| Highly Durable: The wear layer provides excellent resistance to scratches, stains, and fading, making it great for high-traffic areas. | Can Fade in Direct Sunlight: Prolonged, intense UV exposure can still cause some fading over time, though many products have UV inhibitors. |

| Affordable: LVP is generally more budget-friendly than engineered hardwood, both in material cost and installation. | Not Environmentally “Natural”: It’s a synthetic product, which might be a concern for those prioritizing natural materials. |

| Easy to Install: Many LVP products feature click-lock systems that are very forgiving for DIY installation. | Can be Damaged by Extreme Heat: Very high temperatures can potentially cause expansion or warping. |

| Low Maintenance: Easy to clean with regular sweeping and damp mopping. | Can be Difficult to Repair Seamlessly: If a single plank is severely damaged, replacing it might be noticeable if not done carefully. |

| Comfortable Underfoot: Often feels warmer and softer underfoot than tile or laminate, especially with an attached underlayment. | Potential for Off-Gassing: Some lower-quality vinyl products may release VOCs (volatile organic compounds), so choosing reputable brands with low-VOC certifications is important. |

Key Differences: Engineered Hardwood vs LVP

When you’re weighing engineered hardwood flooring vs LVP, it’s helpful to see how they stack up against each other in the most important categories. This comparison can really clarify which material is better suited for your specific needs and your home’s environment.

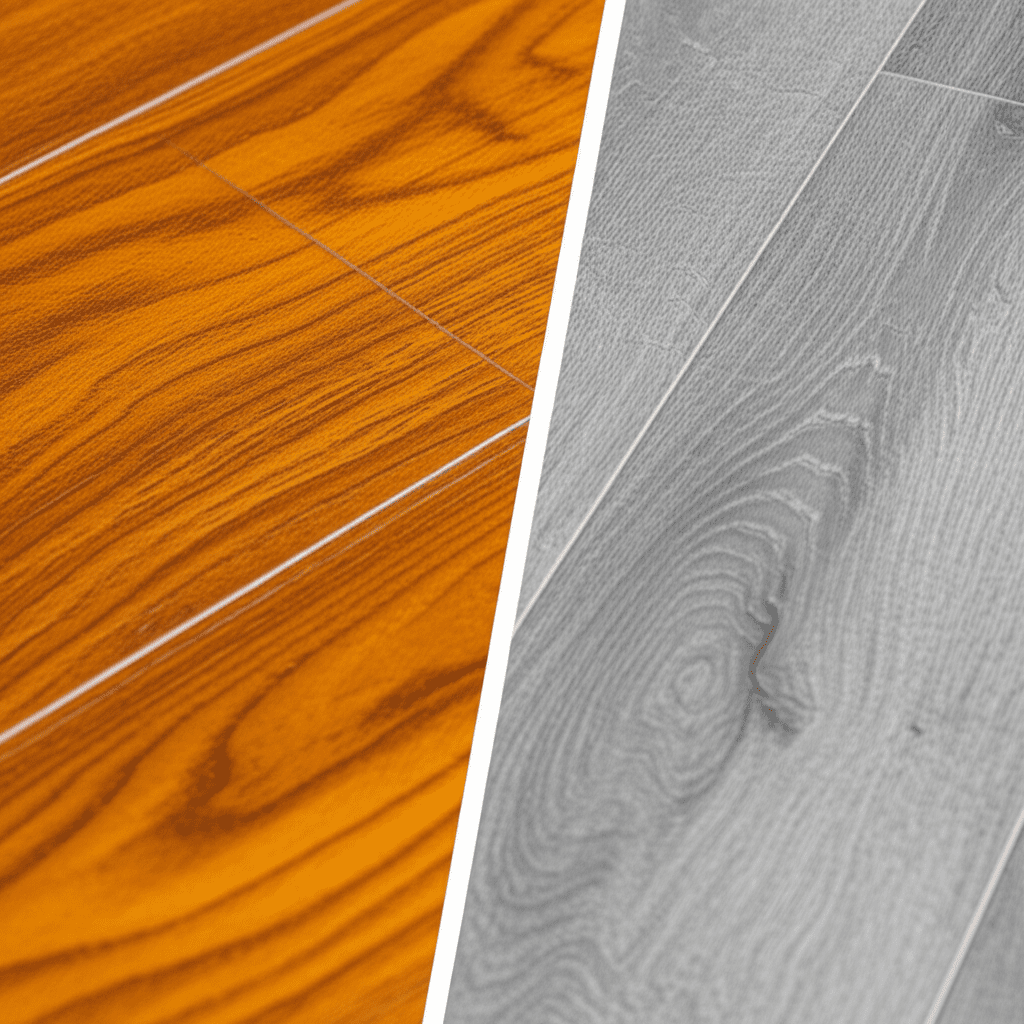

1. Material Composition

Engineered Hardwood: Features a real hardwood veneer on top of multiple layers of plywood or HDF. It’s a composite of natural wood products.

LVP: Is entirely synthetic, made from PVC, limestone, and other plasticizers. It’s designed to mimic the look of wood.

2. Water Resistance

Engineered Hardwood: Is more water-resistant than solid hardwood due to its stable construction, but it is not waterproof. Prolonged exposure to standing water can cause damage, swelling, and warping, especially if water seeps between planks or into the core.

LVP: Is generally 100% waterproof. This makes it an excellent choice for kitchens, bathrooms, basements, and any area where spills or moisture are common. The waterproof nature of LVP is one of its biggest advantages.

3. Durability and Wear

Engineered Hardwood: The durability depends heavily on the thickness of the real wood wear layer. Thicker wear layers can be sanded and refinished once or twice, extending the floor’s life. However, the real wood surface is susceptible to scratches and dents from sharp objects or heavy furniture, just like solid hardwood.

LVP: Is extremely durable, especially those with a thicker wear layer (e.g., 20 mil or higher). It’s highly resistant to scratches, scuffs, dents, and stains. This makes it a very forgiving option for homes with pets and children.

4. Installation

Engineered Hardwood: Can be installed in several ways: glued down, nailed or stapled down (typically to a subfloor), or as a floating floor system where planks lock together and are not attached to the subfloor. This versatility allows it to be installed over various subfloors, including concrete, and it’s often compatible with radiant heating systems.

LVP: Most commonly installed as a floating floor using a click-lock system. This makes it very popular for DIY installations. It can be laid over almost any existing hard surface, including tile, laminate, and even well-prepared concrete, often without needing to remove the old flooring.

5. Aesthetics and Feel

Engineered Hardwood: Offers the unparalleled natural beauty, warmth, and unique grain patterns of real wood. It also feels more substantial and can contribute to a more luxurious feel underfoot.

LVP: Has made huge strides in replicating the look of wood, with realistic textures and varied patterns. However, to a discerning eye, it may still not possess the same depth or character as genuine hardwood. It can also feel slightly less substantial or “warmer” underfoot compared to real wood.

6. Cost

Engineered Hardwood: Typically costs more than LVP, both for the material and potentially for installation, especially if professional installation is required for certain methods.

LVP: Is generally more affordable. The material cost is lower, and the ease of DIY installation can significantly reduce overall project expenses.

7. Maintenance and Cleaning

Engineered Hardwood: Requires careful cleaning. Sweeping and vacuuming are standard, but for damp cleaning, only a slightly damp mop should be used. Avoid excess water, harsh chemicals, and abrasive cleaners, as these can damage the wood finish and the core layers.

LVP: Is very low maintenance. Regular sweeping or vacuuming is usually sufficient. For deeper cleaning, a damp mop with a pH-neutral cleaner is typically all that’s needed. Its waterproof and stain-resistant nature makes it very easy to clean up messes.

8. Home Value

Engineered Hardwood: Real wood flooring is a desirable feature that can increase your home’s resale value. Buyers often perceive it as a premium upgrade.

LVP: While it enhances the look and functionality of a home, it may not add as much perceived value as genuine hardwood. However, its durability and waterproof qualities can be a significant selling point in certain markets or for specific buyer needs.

For more detailed information on flooring installation and maintenance, you can refer to resources from organizations like the National Association of Home Builders (NAHB), which often provide industry standards and best practices.

Which Flooring is Right for Your Project?

Deciding between engineered hardwood flooring vs LVP really comes down to your priorities. Think about the specific room, who uses it, and what kind of wear and tear it will experience. Let’s look at some common scenarios:

For High-Moisture Areas (Kitchens, Bathrooms, Basements)

Winner: LVP

If you’re flooring a kitchen, bathroom, laundry room, or a basement that’s prone to dampness, LVP is the clear winner. Its 100% waterproof nature means spills, splashes, and even minor flooding won’t damage it. Engineered hardwood, while more stable than solid wood, can still suffer water damage in these environments. Imagine a spill in the kitchen – with LVP, a quick mop-up is all it takes. With engineered hardwood, you might be dealing with a warped plank.

For High-Traffic Areas (Hallways, Living Rooms, Kids’ Playrooms)

Winner: LVP (often) or Engineered Hardwood with a thick wear layer

For areas with constant foot traffic, pets, and children, durability is key. LVP’s scratch and stain resistance make it an excellent choice. However, if you opt for engineered hardwood, choose one with a thicker wear layer (e.g., 3mm or more) and consider a harder wood species like oak or hickory. If you want the most resilient option that’s also easy to clean up after little ones, LVP often has the edge. If the aesthetic of real wood is paramount and you’re willing to be a bit more careful, a good quality engineered hardwood can also work well.

For a Luxurious Aesthetic and Home Value

Winner: Engineered Hardwood

If your primary goal is to achieve the authentic, timeless beauty of real wood and to potentially increase your home’s resale value, engineered hardwood is the superior choice. The natural variations, warmth, and depth of real wood simply cannot be perfectly replicated by synthetics. It offers a premium feel that buyers often seek. For spaces like formal living rooms or dining rooms where the focus is on elegance and character, engineered hardwood shines.

For Budget-Conscious Projects

Winner: LVP

When budget is a major consideration, LVP generally offers more bang for your buck. The material cost is lower, and the ease of DIY installation can save significant labor expenses. You get a stylish, durable floor without breaking the bank.

For DIY Enthusiasts

Winner: LVP (typically)

The click-lock installation systems common in LVP make it incredibly user-friendly for DIYers. Engineered hardwood can also be installed as a floating floor, but some methods (like glue-down or nail-down) require more skill and specialized tools. If you’re new to flooring projects, LVP’s installation process is often more forgiving.

It’s also worth noting that advancements in flooring technology mean that even budget-friendly options can look quite good. However, investing in quality materials, whether it’s a thicker wear layer on LVP or a substantial wear layer on engineered hardwood, usually pays off in the long run with better performance and longevity. For more on choosing materials, check out resources from the Architectural Record, which discusses material trends in construction.

Installation Considerations

Whether you’re a seasoned DIYer or hiring a professional, understanding the installation process for engineered hardwood vs LVP is crucial. Each has its own requirements and best practices.

Engineered Hardwood Installation

Subfloor Preparation: The subfloor must be clean, dry, level, and structurally sound. Any imperfections can translate to the finished floor. For concrete subfloors, a moisture barrier is often required.

Installation Methods:

- Floating: Planks interlock and are not attached to the subfloor. This is common for DIYers and can be installed over many subfloors. An underlayment is typically used.

- Glue-Down: Planks are adhered to the subfloor using a special adhesive. This provides a very secure and stable installation, often preferred for larger areas or for a more solid feel.

- Nail/Staple-Down: Planks are fastened to a wooden subfloor using nails or staples. This method requires a solid wood subfloor and specialized tools.

Acclimation: Engineered hardwood needs to acclimate to the room’s temperature and humidity for 48-72 hours before installation to prevent expansion or contraction issues after the floor is laid.

LVP Installation

Subfloor Preparation: Similar to engineered hardwood, the subfloor needs to be clean, dry, and level. LVP is more forgiving of minor subfloor imperfections than engineered hardwood, but a smooth surface is still important for a good finish.

Installation Methods:

- Click-Lock (Floating): This is the most common method. Planks have interlocking edges that snap together. Many LVP products come with an attached underlayment, simplifying the process.

- Glue-Down: Some LVP products are designed for glue-down installation, offering extra stability.

Acclimation: While LVP is less sensitive to humidity changes than wood, it’s still a good practice to let the planks acclimate in the room for at least 24-48 hours before installation to ensure they settle and don’t shift.

For detailed installation guides, manufacturers’ instructions are always the best resource. You can also find helpful visual guides and tips from reputable home improvement stores and woodworking communities.

Frequently Asked Questions (FAQ)

Q1: Can LVP be refinished like hardwood?

A1: No, LVP cannot be refinished. Its decorative layer is a printed film, and sanding it would remove the design. If LVP is significantly damaged, individual planks can sometimes be replaced, but it cannot be restored through sanding and refinishing.

Q2: Which flooring is better for pets: engineered hardwood or LVP?

A2: LVP is generally better for pets. Its durable wear layer is highly resistant to scratches from pet claws, and its waterproof nature makes cleaning up accidents much easier. While some engineered hardwoods can be quite scratch-resistant, LVP typically offers superior performance in a pet-friendly household.

Q3: Is engineered hardwood always more expensive than LVP?

A3: In most cases, yes. Engineered hardwood flooring typically has a higher per-square-foot cost than LVP. However, very high-end LVP with thick wear layers and premium designs can sometimes approach the cost of lower-end engineered hardwood.

Q4: Can I install engineered hardwood in a basement?

A4: Yes, engineered hardwood can be installed in basements, especially if it’s a floating installation with a proper moisture barrier. However, LVP is a safer and more recommended choice for basements due to its 100% waterproof quality, as basements are more prone to moisture issues.

Q5: Does LVP feel cold underfoot?

A5: LVP can feel cooler than carpet or some wood floors, but it is generally warmer and softer underfoot than tile or laminate. Many LVP products come with an attached underlayment, which adds insulation and comfort. For even more warmth, an additional compatible underlayment can be used.

Q6: How long does engineered hardwood typically last?

A6: With proper care and maintenance, engineered hardwood can last anywhere from 25 to 100 years. The lifespan is heavily influenced by the thickness of the wear layer, the quality of the wood species, and how many times it can be refinished.

Q7: What is the best wear layer thickness for LVP?

A7: For residential use, a wear layer of 12-20 mil is generally considered good to excellent. For commercial applications or extremely high-traffic residential areas, 20 mil or higher is recommended. A thicker wear layer provides better resistance to scratches, scuffs, and daily wear and tear.

Conclusion

Choosing between engineered hardwood flooring vs LVP is a decision that impacts the look, feel, and functionality of your home. Both offer compelling benefits, but they excel in different areas. Engineered hardwood provides the genuine, natural beauty and warmth of real wood, offering a classic aesthetic and potential for increased home value. It’s a fantastic choice for living spaces where elegance and character are priorities, and where moisture isn’t a primary concern.

On the other hand, LVP stands out for its exceptional durability, 100% waterproof capabilities, and affordability. It’s the practical champion for busy households, high-moisture environments like kitchens and bathrooms, and for those seeking an easy-to-maintain, DIY-friendly flooring solution. Its ability to mimic wood realistically means you don’t have to sacrifice style for performance.

Ultimately, the best choice depends on your specific needs, lifestyle, and budget. By understanding the construction, pros, and cons of each material, you can confidently select the flooring that will best serve your home for years to come. Whether you choose the natural elegance of engineered hardwood or the resilient practicality of LVP, you’