To calculate wood shrinkage, subtract the final moisture content from the initial moisture content, then divide by the initial moisture content and multiply by 100. Wood shrinkage is an important consideration in various industries such as construction and furniture manufacturing.

It refers to the decrease in dimension of wood caused by the loss of moisture. Understanding wood shrinkage is crucial for ensuring the proper fit and durability of wooden structures and products. By accurately calculating wood shrinkage, professionals can anticipate and account for any changes in the size and shape of wood during the drying process.

This calculation involves determining the difference between the initial and final moisture content of the wood. In this guide, we will explore the process of calculating wood shrinkage and its significance in various applications.

Credit: kmtools.com

Understanding Wood Shrinkage

Wood is a natural material that has been used for centuries in various applications. Whether you are building furniture, constructing a house, or working on a woodworking project, understanding wood shrinkage is crucial.

Wood shrinkage refers to the changes in the dimensions of wood as it dries and loses moisture content. This phenomenon occurs due to the cell walls of wood cells contracting, resulting in a reduction in overall size. Factors such as moisture content, species of wood, and the direction of the grain influence the degree of shrinkage.

Factors Affecting Wood Shrinkage

Several factors contribute to the degree and rate of wood shrinkage. These factors include:

- Moisture Content: The moisture content of wood significantly impacts shrinkage. As wood dries and loses moisture, the cells in the wood contract, causing shrinkage. Higher moisture content results in more significant shrinkage.

- Species of Wood: Different species of wood have varying shrinkage properties. For instance, some species, like oak and mahogany, have relatively high shrinkage rates compared to others.

- Grain Direction: The direction in which the wood grain runs also affects shrinkage. Radial shrinkage occurs when the wood shrinks perpendicular to the grain, while tangential shrinkage occurs parallel to the grain. Understanding the grain direction is crucial when working with wood to control shrinkage.

- Initial Moisture Content: The initial moisture content of wood affects the rate of shrinkage. Wood with a higher moisture content will shrink more compared to wood with a lower moisture content.

- Temperature and Humidity: Temperature and humidity levels in the environment play a role in wood shrinkage. Fluctuations in temperature and humidity cause wood to expand and contract, leading to changes in dimensions.

Types Of Wood Shrinkage

There are three primary types of wood shrinkage:

- Longitudinal Shrinkage: This type of shrinkage occurs along the length of the wood and is minimal compared to other types. Longitudinal shrinkage is the least noticeable and has minimal impact on the overall dimensions of wood.

- Tangential Shrinkage: Tangential shrinkage occurs parallel to the growth rings of the wood and is the most significant type of shrinkage. This shrinkage usually results in a decrease in width and thickness of the wood.

- Radial Shrinkage: Radial shrinkage occurs perpendicular to the growth rings of the wood, resulting in a reduction in diameter or radius. It is more noticeable than longitudinal shrinkage but less significant compared to tangential shrinkage.

Importance Of Calculating Wood Shrinkage

Wood shrinkage is an essential factor to consider when working with wood in various projects. Understanding how much a piece of wood can shrink allows woodworkers to anticipate and plan for the changes in dimensions that occur over time. Calculating wood shrinkage helps prevent potential structural issues and ensures the long-term stability of woodworking projects. Moreover, it ensures that the final product remains intact and free from any deformities caused by shrinkage.

Impact On Woodworking Projects

Wood shrinkage can have a significant impact on the overall quality and appearance of woodworking projects. When wood shrinks, it can cause joints to loosen, resulting in gaps or misalignments. This can compromise the structural integrity of the project and lead to its eventual failure. It is vital to calculate wood shrinkage beforehand to account for these dimensional changes and make necessary adjustments.

Preventing Structural Issues

Calculating wood shrinkage is crucial for preventing structural issues in woodworking projects. By accurately estimating how much a piece of wood will shrink, woodworkers can take appropriate measures to mitigate potential problems. This may include using the appropriate fasteners, allowing for proper expansion and contraction, or using specific woodworking techniques to account for the anticipated shrinkage. By considering these factors, woodworkers can ensure the long-lasting strength and durability of their creations.

Proven Methods For Calculating Wood Shrinkage

Wood shrinkage is a common concern for anyone working with wood, whether it’s in construction, woodworking, or furniture making. Understanding how to calculate wood shrinkage is crucial to ensure the structural integrity and quality of the finished product. By implementing proven methods for calculating wood shrinkage, you can anticipate and account for the dimensional changes that occur as wood loses moisture.

Basic Calculation Formula

One of the most straightforward methods for calculating wood shrinkage is using the basic calculation formula, which involves measuring the initial and final dimensions of the wood and then applying the appropriate formula to determine the shrinkage percentage.

Utilizing Shrinkage Factors

Another effective method for calculating wood shrinkage is by utilizing shrinkage factors specific to the type of wood being used. Shrinkage factors provide a more accurate estimation of how much a particular wood species will shrink under varying moisture conditions, allowing for better precision in project planning and execution.

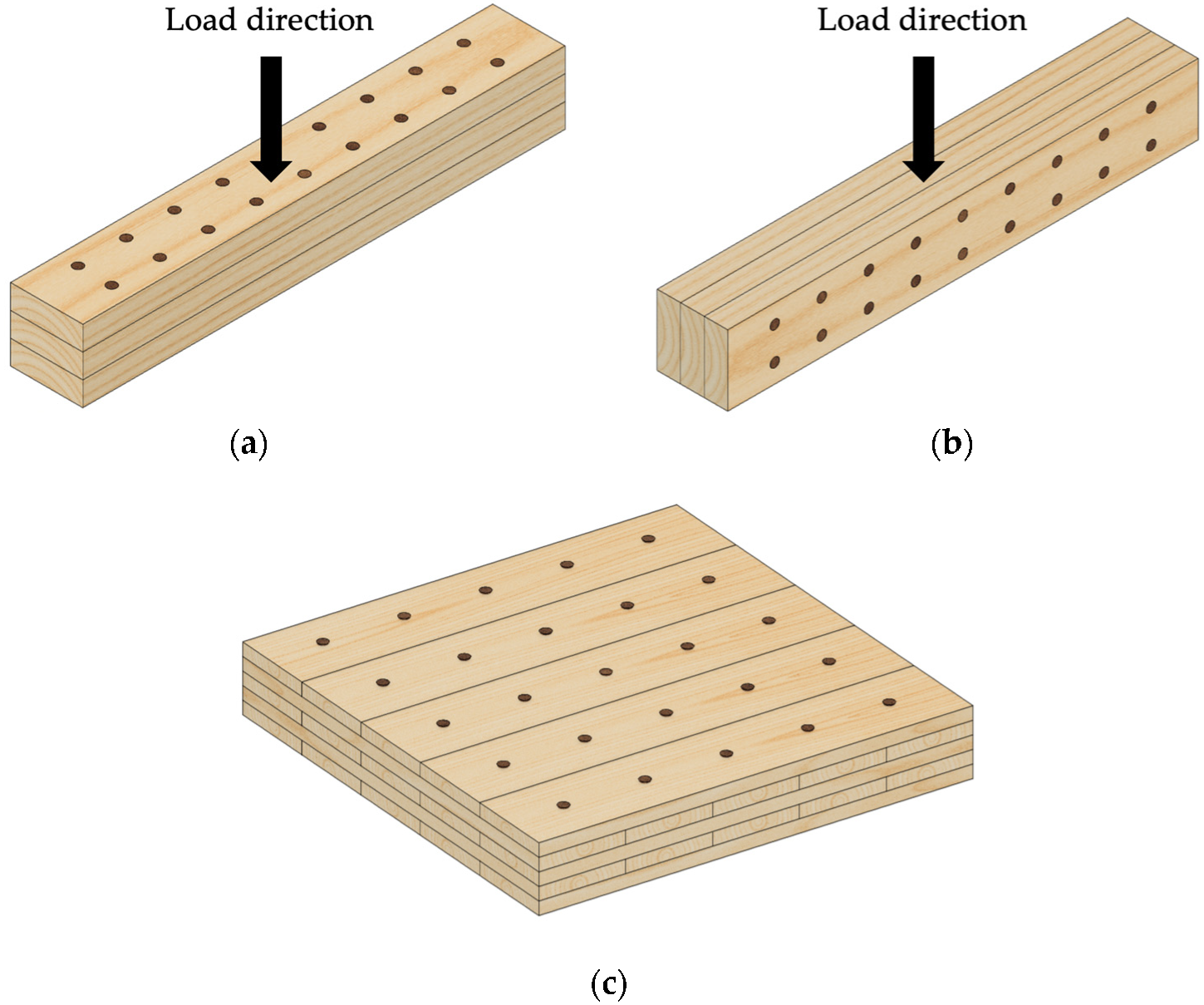

Credit: www.mdpi.com

Measuring Wood Moisture Content

Measuring Wood Moisture Content is crucial in determining wood shrinkage accurately. Wood moisture content is the amount of water present in wood, affecting its dimensional stability.

Use Of Moisture Meters

Moisture meters are handheld devices that measure the moisture content of wood accurately. These meters use electrical resistance or electromagnetic waves to determine the moisture levels in the wood.

Other Moisture Testing Methods

Other methods for testing wood moisture content include using a moisture scale, oven-drying method, and chemical reagents to estimate moisture levels.

Predicting Shrinkage And Expansion

Consideration Of Environmental Conditions

One must consider the humidity levels when predicting wood movement.

Using Wood Movement Calculators

These calculators help in estimating the expected wood shrinkage and expansion.

Application In Woodworking

Wood shrinkage is an essential consideration for anyone working with wood, especially in the realm of woodworking. The process of calculating wood shrinkage becomes particularly crucial in this field given the need for precision and accuracy in creating wooden structures, furniture, and other products. Let’s delve into how the calculation of wood shrinkage is applied in woodworking to ensure the quality and durability of the end products.

Proper Material Sourcing

When sourcing wood for woodworking projects, choosing the right type of wood is crucial. Different species of wood exhibit varying levels of shrinkage, and it’s essential to select materials with shrinkage characteristics that align with the design requirements of the project.

Allowing For Shrinkage In Design

In woodworking, designing with the understanding of wood shrinkage is vital for the structural integrity of the final product. Incorporating appropriate joinery techniques and compensating for expected shrinkage can prevent issues such as warping, cracking, or joints coming loose over time. By factoring in wood shrinkage during the design phase, the finished woodworking piece can maintain its quality and stability over the long term.

Minimizing Shrinkage Effects

When it comes to working with wood, one of the challenges many people face is wood shrinkage. As wood naturally loses moisture, it tends to shrink, which can lead to problems such as gaps or cracks in furniture, doors, or other wooden structures.

However, there are strategies you can employ to minimize the effects of wood shrinkage and ensure a more stable and durable end product. In this article, we will discuss some effective techniques for reducing shrinkage and offer guidance on choosing the most suitable wood species for your project.

Strategies For Reducing Shrinkage

Reducing wood shrinkage requires careful planning and consideration. By implementing proper techniques, you can significantly minimize the effects of shrinkage on your wooden projects. Here are some strategies to help you achieve this:

- Use Quarter-Sawn Lumber: When selecting wood, opt for quarter-sawn lumber. This type of lumber is cut in a way that reduces shrinkage and increases stability. It has straight grain patterns that minimize the chance of warping or twisting as the wood loses moisture.

- Allow for Sufficient Drying Time: Before using wood in your project, ensure it has been properly kiln-dried to reduce moisture content. Allowing the wood to acclimate to the environment in which it will be used is essential for minimizing shrinkage. This process can take several weeks or even months, depending on the wood species.

- Seal the Ends: The ends of the wood are particularly prone to moisture loss, leading to more significant shrinkage. To prevent this, apply a sealant or end grain sealer to the ends of the boards. This will slow down moisture loss and help maintain the stability of the wood.

- Control Humidity Levels: Controlling the humidity levels in your workspace or environment where the wood will be used can also help reduce shrinkage. Maintain a consistent humidity level, ideally between 40% and 55%, to prevent excessive moisture loss and minimize wood movement.

- Glue-Up Techniques: When joining wood pieces together, consider using techniques such as doweling, mortise and tenon joints, or biscuit joinery. These methods create stronger, more stable connections that can better withstand shrinkage.

Choosing Suitable Wood Species

Another important factor in minimizing wood shrinkage is selecting the right wood species for your project. Some species naturally have higher shrinkage rates than others. By choosing a wood species with lower shrinkage characteristics, you can mitigate the potential problems associated with shrinkage. Here are some wood species known for their lower shrinkage rates:

| Wood Species | Shrinkage Rate |

|---|---|

| Redwood | Low |

| Cedar | Low to Moderate |

| White Oak | Moderate |

| Cherry | Low to Moderate |

| Maple | Moderate |

Choosing a suitable wood species in combination with the aforementioned strategies can help ensure minimal shrinkage and enhanced stability in your woodworking projects.

Credit: www.stifirestop.com

Conclusion And Best Practices

Calculating wood shrinkage is a crucial step in any woodworking project. By understanding how much wood will shrink, you can ensure that your final piece will fit together properly and withstand the test of time. In this section, we will provide a summary of the key points to remember when calculating wood shrinkage, as well as some guidelines to ensure accurate results.

Summary Of Calculating Wood Shrinkage

Calculating wood shrinkage involves determining the moisture content of the wood before and after it is cut, and then applying appropriate formulas to estimate the dimensional changes. The key factors to consider in the calculation include the type of wood, the initial moisture content, the grain orientation, and the environmental conditions.

Once you have these values, you can use a wood shrinkage calculator or a shrinkage factor chart specific to the type of wood you are working with to determine the expected shrinkage percentage in length, width, and thickness.

Guidelines For Accurate Results

When calculating wood shrinkage, it is essential to follow these guidelines to ensure accurate and reliable results:

- Use a reliable wood moisture meter to determine the initial and final moisture content accurately.

- Measure the grain orientation of the wood accurately to account for any variations in shrinkage.

- Consider the specific gravity of the wood species, as it affects the shrinkage percentage.

- Take into account the environmental conditions where the wood will be used, such as temperature and humidity.

- Apply the appropriate formulas or use online calculators that incorporate all the necessary variables.

- Remember that wood shrinkage is mainly evident in tangential and radial directions, while longitudinal shrinkage is minimal.

By adhering to these guidelines, you can ensure that your calculations are accurate and that any potential wood shrinkage issues are addressed proactively. This will help you avoid problems such as gaps, cracks, or warping in your final woodwork.

Frequently Asked Questions For How Do You Calculate Wood Shrinkage

What Is The Formula For Shrinkage Rate?

The formula for shrinkage rate is: (Initial size – Final size) / Initial size x 100. It calculates the percentage change in size.

What Is The Shrinkage Percentage Of Wood?

The shrinkage percentage of wood varies between species but typically ranges from 7% to 15%.

How Do You Calculate Shrinking?

To calculate shrinking, subtract the final size from the original size and divide by the original size.

How Much Does Wood Shrink And Expand?

Wood typically shrinks and expands based on its moisture content. The amount varies but can be up to 10% in width. Proper drying and acclimation are essential for minimizing these changes in wood.

Conclusion

Understanding wood shrinkage is essential for any woodworking project. By calculating the shrinkage rate with precision, you can anticipate and account for any changes in dimension, ensuring the quality and longevity of your work. With this knowledge, you can confidently tackle any wood project while minimizing the impact of shrinkage.