How Long to Dry Pressure Treated Wood? Quick Guide!

Pressure treated wood can take up to 2-3 months to dry completely. Factors such as weather and humidity can affect drying time.

Pressure treated wood requires time to dry before it can be stained, painted, or sealed. This is crucial for ensuring the effectiveness of the treatment and preventing warping or rotting. The drying process typically takes around 2-3 months, although this can vary based on factors such as weather conditions and the thickness of the wood.

Understanding the drying time is essential for planning your woodworking or construction projects involving pressure treated wood. Let’s delve into the details of how long it takes for pressure treated wood to dry and the factors that influence the drying process.

Introduction To Pressure Treated Wood

Pressure treated wood typically takes around 2 to 3 days to dry, but this can vary based on factors like temperature and humidity. It’s important to allow the wood to dry completely before staining or sealing to ensure optimal protection and longevity.

Pressure treated wood is a popular choice for outdoor projects due to its durability and resistance to rot, decay, and insect damage. This type of wood is treated with chemicals under high pressure, which helps it withstand harsh weather conditions and prolong its lifespan. However, before using pressure treated wood for your project, it is important to understand how long it takes to dry.

Benefits Of Using Pressure Treated Wood

Using pressure treated wood for your outdoor projects offers several benefits:

- Enhanced durability: Pressure treated wood is specially treated to resist rot, decay, and insect damage, making it a long-lasting option for outdoor structures.

- Cost-effective: Despite its added durability, pressure treated wood is relatively affordable compared to other types of lumber.

- Wide availability: Pressure treated wood is readily available at most lumberyards and home improvement stores, making it easily accessible for various projects.

- Easy to work with: Pressure treated wood can be cut, drilled, and fastened using standard woodworking tools.

Common Uses Of Pressure Treated Lumber

Pressure treated lumber is commonly used for a wide range of outdoor applications, including:

- Decking: Pressure treated wood is a popular choice for building decks due to its durability and resistance to moisture.

- Fencing: Pressure treated lumber is often used for constructing fences as it can withstand exposure to the elements.

- Outdoor furniture: Pressure treated wood can be used to build outdoor furniture such as benches, tables, and chairs.

- Garden structures: It is commonly used for constructing garden beds, pergolas, and trellises.

- Playgrounds: Pressure treated wood is a safe option for building playground structures, ensuring longevity and resistance to wear and tear.

By understanding the benefits and common uses of pressure treated wood, you can make informed decisions when selecting materials for your outdoor projects. Now, let’s explore how long it takes for pressure treated wood to dry.

Understanding The Drying Process

Understanding the drying process of pressure treated wood is essential to ensure its longevity. It typically takes around 60 days for pressure treated wood to dry completely before you can stain or paint it. Waiting for the wood to dry allows for better absorption and adhesion of the stain or paint, resulting in a more durable and attractive finish.

Reasons Why Wood Needs To Dry

Pressure treated wood is infused with preservatives to protect it from decay and termite damage. However, the wood needs to dry out before it can be used in construction. There are two main reasons for this:

- Moisture content: Pressure treated wood is wet when it comes out of the treatment process, with a moisture content of around 50%. This high moisture content can cause problems when the wood is used in construction, such as warping, splitting, and shrinking.

- Adhesion: If you try to paint or stain pressure treated wood before it has dried out, the paint or stain may not adhere properly, resulting in a poor finish.

Kiln Dried Vs. Air Dried Wood

There are two main ways to dry pressure treated wood: kiln drying and air drying. Kiln drying involves placing the wood in a large oven and heating it to a temperature of around 140 to 170 degrees Fahrenheit. This process typically takes between 24 and 48 hours and results in wood that is dry and ready to use.

Air drying, on the other hand, involves stacking the wood in a dry, well-ventilated area and allowing it to dry naturally. This process can take several months, depending on the climate and humidity levels in your area.

How To Test If Pressure Treated Wood Is Dry

There are several ways to test if pressure treated wood is dry enough to use:

- Water Sprinkle Test: Sprinkle a few drops of water onto the surface of the wood. If the water beads up, the wood is still too wet. If the water is absorbed into the wood, it is ready to use.

- Moisture Meter Test: Use a moisture meter to test the moisture content of the wood. A moisture content of around 15% is ideal for most construction projects.

In conclusion, it is important to let pressure treated wood dry out before using it in construction. Kiln drying is the fastest and most reliable way to dry the wood, but air drying can also be effective if you have the time and space. By understanding the drying process and testing the moisture content of the wood, you can ensure that your construction project is a success.

Factors Affecting Drying Time

When working with pressure treated wood, it’s essential to understand the factors that can impact its drying time. Several elements can influence how long it takes for pressure treated wood to dry, including climate and environmental impact, as well as the level of wood treatment. Let’s delve into these factors in more detail.

Climate And Environmental Impact

Climate and environmental conditions play a significant role in the drying time of pressure treated wood. The humidity levels and temperature of the surroundings can directly affect the drying process. In humid environments, the wood may take longer to dry, while warmer and drier climates can expedite the drying time. Additionally, exposure to direct sunlight and airflow can aid in the evaporation of moisture, accelerating the overall drying process.

Wood Treatment Levels

Pressure treated wood comes in various levels of treatment, such as Above Ground Contact and Ground Contact. The level of treatment can significantly impact the drying time of the wood. Wood treated for ground contact tends to retain more moisture and may require a longer drying period compared to wood treated for above ground use. The higher the treatment level, the more time it may take for the wood to dry completely.

Testing For Dryness

To determine how long it takes for pressure treated wood to dry, you can use various methods such as testing moisture with a moisture meter or sprinkling water on the surface to see if it beads up or absorbs. It’s recommended to let the wood dry before installing to avoid inconsistent gapping and stress on the fasteners.

However, it could take up to 60 days for the wood to fully dry.

Pressure treated wood is a popular choice for outdoor projects because it is resistant to decay and insects. However, it is important to let the wood dry out before staining or painting. But how do you know when the wood is dry enough? In this section, we will discuss two methods for testing the dryness of pressure treated wood.

Water Sprinkle Test

One simple way to test the dryness of pressure treated wood is to sprinkle a few drops of water onto the surface of the wood. If the water beads up and sits on top of the wood, it is not yet dry enough. But if the water is absorbed into the wood, it is ready for staining or painting.

Using a Moisture Meter

Another method for testing the dryness of pressure treated wood is to use a moisture meter. This tool measures the moisture content of the wood and can give you a more accurate reading than the water sprinkle test. To use a moisture meter, simply press the prongs of the device into the wood and read the moisture level on the display. A moisture level of 15% or lower indicates that the wood is dry enough for staining or painting.

It is important to note that the drying time for pressure treated wood can vary depending on the climate and the conditions in which the wood is stored. In general, it can take anywhere from a few weeks to a few months for pressure treated wood to dry out completely.

In conclusion, testing the dryness of pressure treated wood is an important step in any outdoor project. By using the water sprinkle test or a moisture meter, you can ensure that the wood is ready for staining or painting and will last for years to come.

Installation Concerns

When it comes to installing pressure treated wood, there are a few important factors to consider. Two key concerns are board gapping and the stress placed on fasteners. By understanding these considerations and taking the necessary precautions, you can ensure a successful and long-lasting installation.

Board Gapping

Proper board gapping is crucial when installing pressure treated wood. As the wood dries, it tends to shrink, which can result in gaps between the boards. If wet boards are installed without considering this shrinkage, you may end up with inconsistent gapping once the wood has dried out.

To avoid this issue, it is recommended to allow the pressure treated wood to dry before installation. This will give the wood time to shrink, allowing for more consistent and aesthetically pleasing board spacing. It is generally recommended to wait for the wood to reach a moisture content of around 15-19% before proceeding with installation.

Stress On Fasteners

Another concern when installing pressure treated wood is the stress placed on fasteners. Wet wood is heavier and more flexible than dry wood, which can put additional strain on the fasteners used to secure the boards.

By allowing the pressure treated wood to dry before installation, you can reduce the stress on the fasteners. This will help to prevent the boards from warping or lifting over time, ensuring a more secure and stable installation.

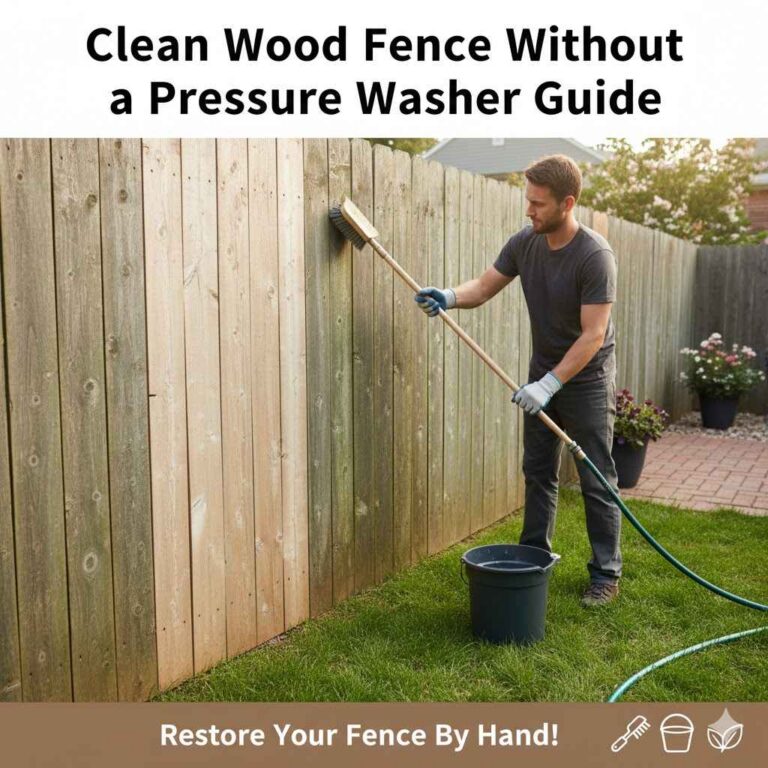

Before installing pressure treated wood, it is important to properly prepare the wood to ensure optimal results. Here are a few steps to follow:

- Inspect the wood: Check for any defects, such as cracks or splits, that may affect the structural integrity of the boards. Replace any damaged pieces before installation.

- Clean the wood: Remove any dirt, debris, or mold that may be present on the surface of the wood. This can be done using a mild detergent and water, followed by thorough rinsing and drying.

- Apply a sealer: To further protect the wood from moisture and potential damage, consider applying a sealer or water repellent. This will help to extend the lifespan of the pressure treated wood.

By following these steps, you can ensure that the pressure treated wood is in the best possible condition for installation, enhancing its longevity and overall performance.

Painting And Staining

Before painting or staining pressure treated wood, it’s crucial to let it dry thoroughly. The drying time can vary based on factors like the climate and the wood’s initial moisture content. Generally, it may take several months for pressure treated wood to dry completely before you can apply paint or stain.

Timing Your Stain Or Paint Application

Allow pressure-treated wood to dry for at least 30 days before painting or staining.

Risks Of Premature Application

Painting too soon can lead to poor adhesion and premature peeling of the finish.

Accelerating The Drying Process

Pressure treated wood usually takes around 2-3 days to dry completely. However, factors like humidity, temperature, and ventilation can affect the drying process. To speed up the process, you can use a moisture meter or kiln drying. It is important to let the wood dry before staining or painting to ensure proper penetration and protection from weather damage.

Techniques For Faster Drying

Accelerating the drying process of pressure treated wood can be achieved through various techniques.

- Use a moisture meter to monitor drying progress.

- Expose the wood to direct sunlight and good air circulation.

- Elevate the wood off the ground to enhance airflow.

Do’s And Don’ts For Acceleration

When trying to speed up the drying of pressure treated wood, it is important to follow certain guidelines.

- Do: Check moisture levels regularly.

- Do: Ensure proper ventilation for faster evaporation.

- Don’t: Rush the process by using excessive heat sources.

Long-term Care And Maintenance

When it comes to pressure treated wood, it is important to allow it to dry before using or staining it. The drying time can vary depending on factors such as weather conditions and the thickness of the wood, but it typically takes about 60 days for pressure treated wood to fully dry.

Regular checks for moisture are crucial to ensure the longevity of pressure treated wood. Ensure it remains dry to prevent issues like rot or decay.

Regular Checks For Moisture

Regularly inspect the wood for signs of moisture, such as dark spots or a damp feel. Use a moisture meter for accurate readings.

Seasonal Considerations For Treated Wood

In humid seasons, monitor the wood closely and consider applying a water repellent to maintain its durability.

Frequently Asked Questions

How Do You Know When Pressure Treated Wood Is Dry?

To determine if pressure-treated wood is dry, there are a few indicators to look for. Firstly, check the color of the wood – if it has turned from a greenish hue to a grayish color, it is likely dry. Additionally, you can use a moisture meter to measure the moisture content of the wood.

A reading below 15% is generally considered dry. Lastly, you can conduct a simple water test – sprinkle a few drops of water on the wood’s surface, and if the water beads up rather than soaking into the wood, it is most likely dry.

Should I Let Pressure Treated Wood Dry Before Installing?

Yes, you should let pressure treated wood dry before installing to ensure consistent gapping and reduce stress on fasteners.

What Is The Fastest Way To Dry Pressure Treated Wood?

The fastest way to dry pressure treated wood is to let it air dry for at least 2 to 3 months.

What Happens If You Stain New Pressure Treated Wood Too Soon?

Staining new pressure treated wood too soon prevents proper absorption, reducing its weather protection. Wait until the wood fully dries.

Conclusion

The drying time for pressure-treated wood varies depending on factors like climate and wood thickness. It’s crucial to allow the wood to dry thoroughly before staining or painting to ensure a proper finish. By following recommended drying guidelines, you can achieve optimal results for your woodworking projects.