How Long to Wait Before Staining: Quick Deck Prep Guide

You should wait for several weeks for pressure-treated wood to dry before staining it. If the wood is kiln-dried, you can stain it immediately; otherwise, you may need to wait a bit longer.

When it comes to creating a beautiful and long-lasting deck, staining pressure-treated wood is essential. However, knowing the right time to apply the stain can be crucial to ensure the best results. Pressure-treated wood is infused with preservatives, and allowing it to dry out is vital before applying any stain or sealant.

The drying time can vary based on factors such as the type of treatment and weather conditions. Understanding these considerations can help you make an informed decision on when to stain your pressure-treated wood deck, ensuring a stunning and durable finish.

Introduction To Deck Preparation

When staining pressure-treated wood decks, the drying time varies. Kiln-dried lumber can be stained immediately, while others may require weeks to dry properly. Staining too soon can affect absorption and adhesion, so it’s crucial to ensure the wood is adequately dry before proceeding with staining.

Before staining a pressure-treated wood deck, it is crucial to properly prepare the surface to ensure optimal results and long-lasting protection. Deck preparation involves setting the stage for staining by allowing the wood to dry adequately and gathering the necessary materials and tools. This blog post will guide you through the essential steps of deck preparation, including setting the stage for staining and the materials and tools you will need.

Setting The Stage For Staining

The first step in preparing your pressure-treated wood deck for staining is determining when it is ready. Due to the pressure-treating process, which involves forcing chemical preservatives into the wood, the lumber needs time to dry out. If the wood is kiln-dried, it can be painted or stained immediately. However, if it is not kiln-dried, you may have to wait a little longer for the wood to dry properly.

Materials And Tools Needed

Preparing your deck for staining requires gathering the necessary materials and tools. Here is a list of what you will need:

- Pressure washer or deck cleaner

- Deck brush or broom

- Sandpaper or a deck sander

- Drop cloths or plastic sheeting

- Painter’s tape

- Stain or paint of your choice

- Paintbrush or paint sprayer

- Protective clothing, gloves, and goggles

These materials and tools will help you clean, sand, and protect your deck, ensuring a smooth and successful staining process.

By following these steps and properly preparing your pressure-treated wood deck, you can ensure that the stain adheres well and provides the desired protection and aesthetic appeal. Stay tuned for the next section, where we will dive deeper into the deck cleaning process.

Understanding Pressure-treated Wood

Pressure-treated wood is a popular choice for outdoor projects such as decks and fences due to its resistance to decay and insects. The pressure-treating process involves impregnating the wood with preservatives to protect it from environmental damage, making it a durable and long-lasting option for outdoor structures.

The Pressure Treating Process

The pressure treating process involves placing the wood in a pressure chamber and forcing preservatives into the wood fibers. This helps to protect the wood from decay, rot, and insect infestation, extending its lifespan and ensuring its durability in outdoor environments.

Types Of Pressure-treated Lumber

There are different types of pressure-treated lumber available, categorized based on the treatment process and the intended use. These include:

- Wet Pressure-Treated Wood: This wood is saturated with preservatives and typically needs to dry out before staining or painting.

- Kiln-Dried Pressure-Treated Lumber: This type of wood has been dried in a kiln after the pressure treatment, allowing it to be painted or stained immediately.

Understanding the type of pressure-treated lumber you have will help determine how long you should wait before staining or painting your deck.

Initial Waiting Period

Before staining a pressure-treated wood deck, it is important to wait for the wood to dry out. The drying process can take several weeks, especially if the wood is not kiln-dried. Staining too soon can result in the finish not adhering properly to the wood surface.

Time Frames For Various Wood Types

When it comes to staining a pressure-treated wood deck, the initial waiting period is crucial. The pressure-treating process, where water forces chemical preservatives into the wood, can cause the lumber to retain a lot of moisture. Therefore, it is essential to allow the wood to dry out before applying any stain. The length of time you should wait before staining your pressure-treated wood deck depends on various factors, such as the type of wood and the drying conditions.

Here are some general guidelines for how long to wait before staining pressure-treated wood:

| Wood Type | Waiting Period |

|---|---|

| Kiln-Dried Wood | Can be stained immediately |

| Air-Dried Wood | 4-12 weeks |

Factors Influencing Drying Time

The waiting period for staining pressure-treated wood can vary depending on several factors, including the humidity and temperature in your area, the amount of direct sunlight your deck receives, and the ventilation around your deck. Here are some factors that can influence the drying time of your pressure-treated wood:

- Humidity – High humidity can slow down the drying process, so it’s best to wait until the weather is dry and sunny.

- Temperature – Warm temperatures help to speed up the drying process, so it’s best to wait until the weather is consistently warm.

- Sunlight – Direct sunlight can help to dry out the wood, so it’s best to choose a time when your deck receives plenty of direct sunlight.

- Ventilation – Good ventilation around your deck can help to speed up the drying process by allowing air to circulate and evaporate the moisture from the wood.

By taking these factors into consideration, you can determine the best time to stain your pressure-treated wood deck. Waiting for the wood to dry out completely before staining will ensure that the stain penetrates the wood effectively and provides long-lasting protection against the elements.

Moisture Testing Methods

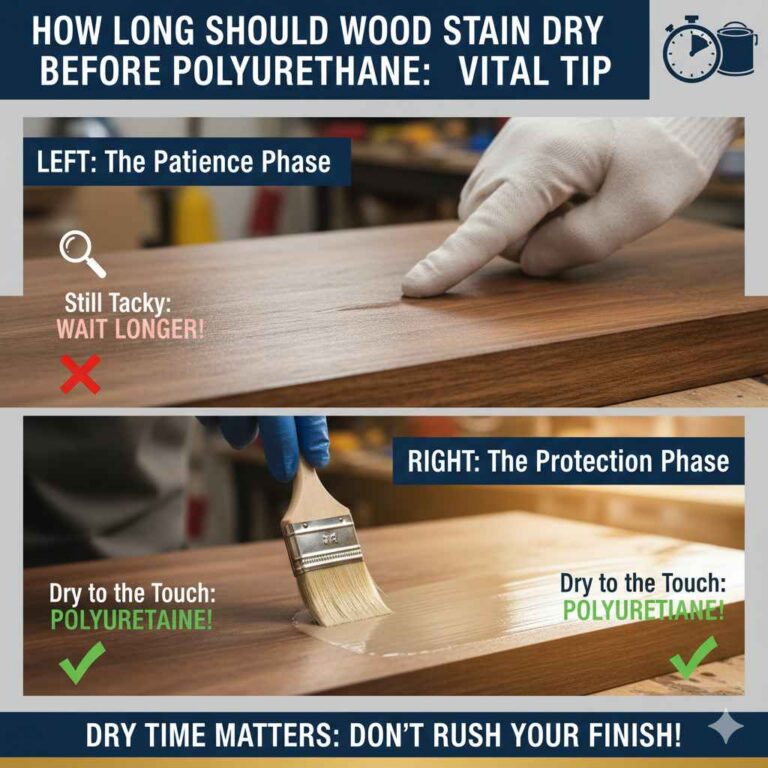

When it comes to staining a pressure treated wood deck, it’s important to know how long to wait before applying the stain. Due to the nature of the pressure-treating process, it can take several weeks for the wood to dry out.

Kiln-dried lumber can be stained immediately, but if not, it’s best to wait a little longer to ensure the stain adheres properly to the wood surface. Testing moisture levels through a moisture meter or water sprinkle method can help determine if the wood is ready for staining.

The Water Sprinkle Test

One of the simplest ways to test if your pressure-treated wood is ready for staining is the water sprinkle test. Sprinkle a few drops of water onto the surface of the wood and observe what happens. If the water droplets are absorbed into the wood within 10 to 15 minutes, it indicates that the wood is dry enough for staining. If the water beads up or sits on the surface, it means that there’s still too much moisture in the wood, and you need to wait a little longer.

Using A Moisture Meter

Another effective way to test the moisture content of your pressure-treated wood is by using a moisture meter. This device helps measure the amount of moisture within the wood, giving you an accurate reading of how dry or wet the wood is. You can purchase a moisture meter at your local hardware store. Once you have the device, use it to test several areas of the wood to ensure that the moisture content is uniform throughout.

It’s essential to wait until your pressure-treated wood is dry enough before staining it. Failing to do so can result in the stain not adhering properly to the wood surface. Additionally, staining too soon can interfere with the pressure treatment protection, reducing the wood’s lifespan. By using the water sprinkle test or moisture meter, you can ensure that your pressure-treated wood is dry enough for staining, ensuring a long-lasting and beautiful finish.

Prepping Your Deck For Staining

Pressure treated wood decks need to be prepped before staining. It’s important to know that the wood needs to dry out for several weeks after pressure treatment, and if it’s kiln-dried, it can be stained immediately. Testing the wood’s moisture content and ensuring it’s dry enough is crucial for a successful staining job.

Cleaning The Surface

Before you can start staining your pressure-treated wood deck, it’s crucial to clean the surface properly. Over time, dirt, grime, and mildew can accumulate on the deck, which can hinder the stain’s ability to penetrate the wood effectively. Cleaning the surface will ensure that the stain adheres properly and provides long-lasting protection.

To clean your deck, you can follow these simple steps:

- Start by sweeping off any loose debris, such as leaves or twigs, using a broom or leaf blower.

- Next, use a deck cleaner or a mixture of warm water and mild detergent to scrub the surface. This will help remove any dirt or stains.

- For stubborn stains or mold, you may need to use a pressure washer. Be sure to use a low-pressure setting and keep the nozzle at least 12 inches away from the wood to avoid damaging it.

- After cleaning, rinse the deck thoroughly with clean water to remove any residue.

- Allow the deck to dry completely before moving on to the next step.

Sanding: Is It Necessary?

While sanding is not always necessary for staining pressure-treated wood, it can help smoothen rough surfaces and remove any splinters. If your deck has rough patches or visible imperfections, sanding can improve the overall appearance of the wood and ensure a more even application of the stain.

Here are a few key points to consider when deciding whether to sand your deck:

- If your deck has rough or splintered areas, sanding can help smooth them out.

- Sanding can also remove any previous stain or paint, allowing the new stain to penetrate the wood better.

- For newer decks with minimal imperfections, light sanding with a fine-grit sandpaper may be sufficient.

- However, if your deck has significant damage or deep scratches, you may need to use a coarser sandpaper or a power sander to achieve the desired results.

- After sanding, be sure to remove any dust or debris from the surface before proceeding with staining.

Remember, proper deck preparation is essential to achieve a beautiful and long-lasting stain. By cleaning the surface thoroughly and, if necessary, sanding away imperfections, you’ll create an ideal canvas for applying the stain, ensuring optimal results and protecting your pressure-treated wood deck for years to come.

Choosing The Right Stain Or Sealant

Before staining a pressure treated wood deck, it’s crucial to wait for the lumber to dry out, which can take several weeks due to the preservative treatment process. Kiln-dried wood allows immediate staining, while wet wood may require a longer wait.

Testing moisture levels is essential to ensure the wood is ready for staining.

Types Of Stains And Sealants

When selecting a stain or sealant for your pressure-treated wood deck, consider options like transparent, semi-transparent, or solid stains. Waterproof sealants are also available.

Match Stain To Wood Type

Match the stain type to the wood; for example, use oil-based stains for pressure-treated wood to ensure proper adhesion and longevity.

Top Tips For Staining Pressure-treated Lumber

– Ensure the lumber is adequately dried before staining.

– Test the wood’s readiness by sprinkling water; if it absorbs, it’s ready.

– Avoid staining too soon to prevent adhesion issues.

– Choose the appropriate stain type for pressure-treated wood.

Common Questions About Staining Pressure-treated Wood

– How long should I wait before staining pressure-treated wood?

– What happens if I stain pressure-treated wood too soon?

– How do I know if the wood is ready for staining?

Remember, the key to a successful staining job is choosing the right stain or sealant and ensuring the wood is adequately prepared.

Application Techniques

When it comes to staining a pressure treated wood deck, it’s important to wait for the lumber to dry out. The drying time can vary, but typically it can take up to several weeks. If the wood is kiln-dried, you can stain it immediately, but if not, you may need to wait a little longer.

Best Practices For Staining

When staining pressure-treated wood, follow these best practices:

- Ensure the wood is thoroughly dry before staining.

- Use a high-quality stain and sealer for longevity.

- Apply the stain evenly with a brush or roller.

- Consider applying two coats for optimal protection.

Avoiding Common Mistakes

To avoid common staining mistakes:

- Avoid staining wood that is still wet.

- Don’t rush the process; allow adequate drying time.

- Choose the right weather conditions for staining.

- Follow manufacturer’s instructions for best results.

Post-staining Tips

When it comes to staining a pressure-treated wood deck, it is important to wait for the wood to dry out completely before applying the stain. Depending on whether the wood is kiln-dried or not, it can take several weeks for the lumber to dry.

Waiting ensures that the stain will properly adhere to the wood surface and provide the desired protection.

Maintenance For Longevity

When To Reapply Stain Or Sealant

After staining your pressure-treated wood deck, it’s crucial to follow these post-staining tips to ensure its longevity and appearance.

Maintenance For Longevity

– Regularly sweep the deck to prevent dirt buildup.

– Inspect for damage and repair any issues promptly.

– Clean the deck with a mild detergent and water solution.

– Apply a fresh coat of stain or sealant every 2-3 years.

When To Reapply Stain Or Sealant

– Check for fading or wear on the stain/sealant.

– Perform a water test – sprinkle water on the deck; if it absorbs, it’s time to reapply.

– Observe the color – if it looks dull or worn, it’s time for a new coat.

– Consider the deck’s exposure – more exposed decks may need reapplication sooner.

Frequently Asked Questions

How Long Should You Wait To Stain A New Pressure Treated Deck?

You should wait for the pressure treated wood to dry out, which can take several weeks. If it’s kiln-dried, you can stain it immediately; otherwise, wait a little longer. Ensure the wood is dry enough by sprinkling water on it.

If it absorbs, it’s ready for staining.

What Happens If I Stain Pressure Treated Wood Too Soon?

Staining pressure treated wood too soon can result in poor absorption and adhesion of the finish. It can also interfere with the wood’s pressure treatment protection. Allow several weeks for the wood to dry. Use a moisture test to ensure it’s ready for staining.

How To Tell If Pressure Treated Wood Is Ready To Stain?

Before staining pressure treated wood, ensure it’s fully dried. Use a moisture meter or sprinkle water – if it absorbs, it’s ready. Staining too soon can lead to poor adhesion. Kiln-dried wood is ready immediately; otherwise, wait a few weeks.

How Do I Know If My Deck Is Dry Enough To Stain?

You can check if your deck is dry enough to stain by sprinkling water on the surface. If the water absorbs, it’s ready. If it beads up, it’s too moist and needs more drying time.

Conclusion

The drying time for pressure-treated wood before staining can vary. Kiln-dried wood can be stained immediately, while wetter wood may need several weeks. Staining too soon can affect the finish and the wood’s protection. Test the wood’s dryness by sprinkling water.

Patience is key for a successful staining job.