How to Attach Wood to Concrete No Drilling

Many people want to attach wood to concrete but dread the idea of drilling. It can seem like a tough job, especially if you’re new to DIY projects. You might worry about making a mess or not having the right tools.

But don’t worry! Attaching wood to concrete without drilling is totally achievable. We’ll show you simple ways to get the job done right, step by step.

Secure Wood to Concrete Without Drilling

This section explores practical methods for joining wood to concrete surfaces without the need for drilling. Many projects, from building shelves to adding decorative elements, require a stable connection between these two common building materials. Traditional methods often involve drilling into concrete, which can be time-consuming, messy, and require specialized equipment.

Fortunately, several effective alternatives bypass this step entirely, making the process more accessible for DIY enthusiasts and professionals alike. We will discuss the core principles behind these non-drilling methods, highlighting their strengths and when each might be the best choice for your specific needs. Understanding these approaches will empower you to complete your projects with confidence and ease, achieving a durable bond that looks great.

Adhesive Solutions for Wood to Concrete

Adhesives offer a clean and straightforward way to bond wood directly to concrete. These specialized glues are formulated to create a strong, lasting bond between dissimilar materials, providing structural integrity without physical fasteners. The key is selecting the right type of adhesive for the job, as different formulations offer varying strengths, curing times, and resistance to environmental factors.

Understanding the properties of these adhesives, such as their tensile strength, shear strength, and flexibility, is crucial for a successful application. We will look at the most common and effective adhesive types available and how to use them properly.

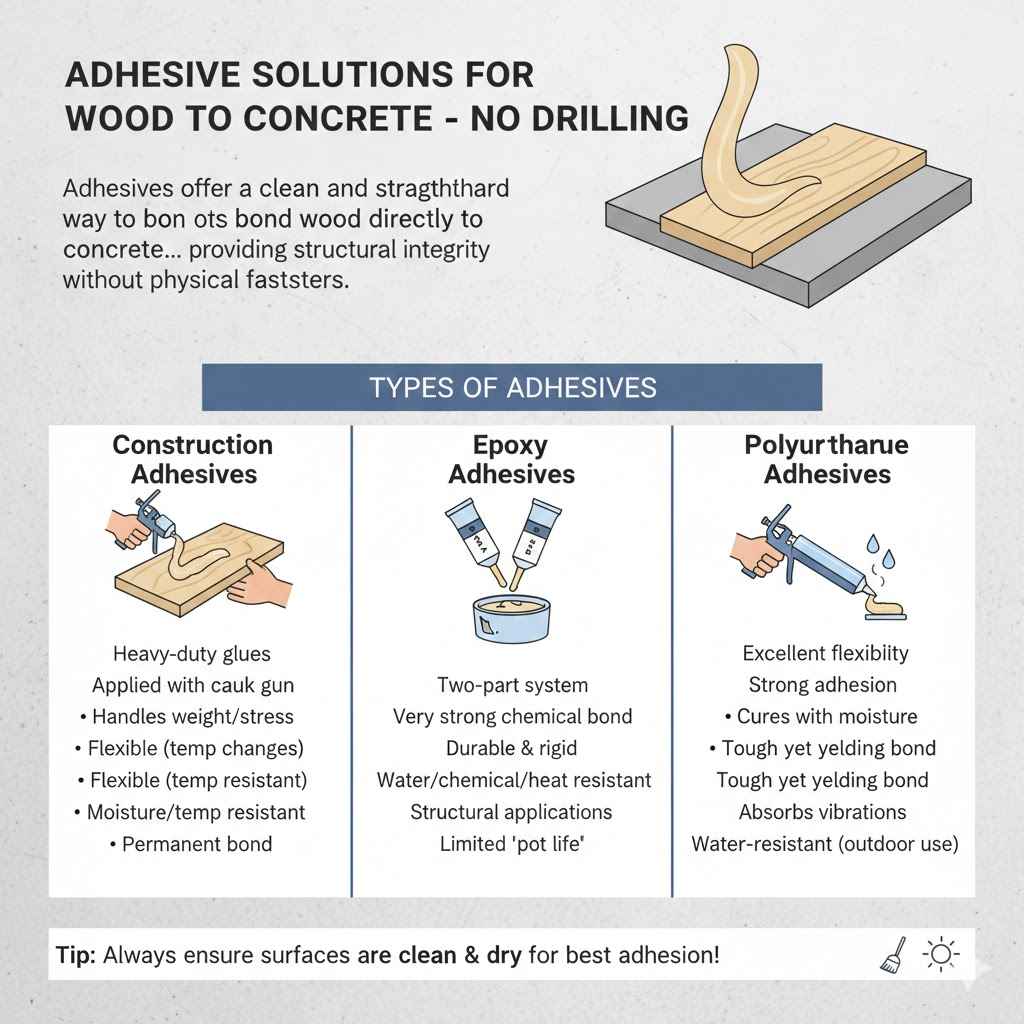

Types of Adhesives

When you’re looking to attach wood to concrete without drilling, adhesives are your best friend. There are a few main types that work really well for this kind of job. Each has its own strengths, so picking the right one is important for a lasting hold.

Construction Adhesives

Construction adhesives are heavy-duty glues designed to hold building materials together. They are excellent for bonding wood to concrete because they can handle significant weight and stress. Think of them as super-strong liquid nails.

They are often applied using a caulk gun, making them easy to spread evenly. These adhesives are flexible enough to accommodate slight movements between the wood and concrete, which can happen due to temperature changes. They create a permanent bond that is resistant to moisture and extreme temperatures once cured.

You can find them in tubes that fit standard caulk guns, and they usually require a clean, dry surface on both the wood and concrete for best adhesion.

Epoxy Adhesives

Epoxy adhesives are a two-part system that, when mixed, create a very strong chemical bond. They are incredibly durable and resistant to water, chemicals, and high temperatures. Epoxies are often used when a very strong, permanent bond is needed, making them suitable for structural applications.

They typically come in a dual-cartridge system or two separate containers that you mix together just before application. The curing process can vary, but once fully hardened, they form a rigid, super-strong connection. It’s important to work quickly once the epoxy is mixed, as it has a limited pot life.

Surface preparation is key for epoxy; both surfaces need to be clean and free of dust or grease for maximum bond strength.

Polyurethane Adhesives

Polyurethane adhesives are known for their excellent flexibility and strong adhesion to a wide range of materials, including wood and concrete. They cure with moisture from the air, forming a tough yet slightly yielding bond. This flexibility is a significant advantage, as it helps to absorb vibrations and accommodate the natural expansion and contraction of materials caused by temperature fluctuations.

Polyurethane adhesives are also very water-resistant once cured, making them a good choice for outdoor applications or areas that might experience dampness. They are typically applied with a caulk gun and are relatively easy to work with, offering a good balance of strength and resilience for attaching wood to concrete.

Application Techniques for Adhesives

Getting the most out of your adhesive means applying it correctly. Here’s how to do it for the best results when attaching wood to concrete without drilling.

Surface Preparation

This is the most critical step. Both the wood and the concrete surfaces must be clean, dry, and free from dust, grease, oil, or any loose debris. For concrete, you might need to sweep it thoroughly and then wipe it down with a damp cloth to remove fine dust.

If there’s any old paint or sealant on the concrete, it might need to be scraped or sanded off. For wood, ensure it’s smooth and free of splinters or loose fibers. A clean surface allows the adhesive to form a direct, strong bond with the material, ensuring it doesn’t just stick to dirt or grime.

Applying the Adhesive

Most construction and polyurethane adhesives come in tubes for caulk guns. Apply the adhesive in a zig-zag pattern or in beads along the surface of the wood or concrete that will be in contact. This pattern ensures good coverage and allows air to escape when the pieces are pressed together, preventing air pockets.

For epoxy, you’ll mix the two parts as directed and then apply the mixed adhesive immediately to one surface. Don’t spread it too thin; a generous but even layer is best. The goal is to have enough adhesive to create a continuous bond line when the wood and concrete are joined.

Joining the Surfaces

Once the adhesive is applied, carefully position the wood onto the concrete. Press down firmly and apply even pressure across the entire surface of the wood. This action helps to spread the adhesive and ensure maximum contact.

For heavier pieces or when using adhesives that require a specific clamping time, you may need to use clamps or weights to hold the wood in place while the adhesive cures. Check the adhesive’s packaging for recommended curing times and whether any temporary support is needed during this period. Allowing the adhesive to cure fully is vital for achieving its maximum strength.

Curing Time

Each adhesive has a specific curing time, which is the period it takes to reach its full strength. This can range from a few hours to several days, depending on the product and environmental conditions like temperature and humidity. Refer to the manufacturer’s instructions on the adhesive packaging.

During the curing process, avoid putting any stress on the connection. It’s also important to ensure the area is well-ventilated, especially with solvent-based adhesives. Properly curing the adhesive guarantees a durable and reliable bond for your wood-to-concrete attachment project.

Mechanical Fasteners Without Drilling into Concrete

While drilling is the most common way to use mechanical fasteners with concrete, there are innovative solutions that bypass this step. These methods often involve using existing structural elements or specialized hardware that doesn’t require you to drill into the concrete itself. This can be particularly useful in situations where drilling is not permitted, or when you need a temporary or easily removable attachment.

Exploring these options provides greater flexibility for various projects, ensuring you can still achieve a secure connection.

Using Clips and Brackets

Some clever clip and bracket systems allow you to attach wood to concrete without drilling. These often work by gripping the edges of the concrete or by utilizing existing features in the concrete structure. They are designed to provide a secure hold without penetrating the surface.

Edge Gripping Clips

These clips are designed to grip the edges of concrete slabs or pre-cast concrete elements. You slide the wood into a channel on the clip, and the clip itself latches onto the concrete edge. They are often used for attaching baseboards or skirting to concrete floors or walls where the edge is accessible.

The strength of the bond depends on the design of the clip and the integrity of the concrete edge. This method is great for temporary installations or where you want to avoid any permanent alteration to the concrete surface. They are usually made of sturdy metal, offering good durability.

Specialized Brackets

There are also specialized brackets that can be integrated into the concrete during its pour or attached to existing concrete features. For instance, some brackets might slot into expansion joints or formwork before concrete is poured, leaving a part exposed to attach wood later. For existing structures, some brackets might use the weight of the concrete or very specific interlocking mechanisms to secure themselves, without needing to drill.

These are less common for typical DIY but exist for specific construction scenarios where drilling is problematic.

Screws with Anchors (for Existing Gaps or Recesses)

This method isn’t strictly “no drilling” in the sense of drilling a new hole, but it cleverly uses existing gaps or recesses in the concrete. If your concrete has pre-existing holes, cracks, or indentations, you might be able to use them to anchor screws.

Leveraging Pre-existing Holes

If your concrete surface already has holes from previous installations or imperfections, you can often use these. You might need to clean them out and then insert a suitable anchor, like a lag shield or a plastic anchor, that doesn’t require drilling. Once the anchor is in place, you can then drive a screw through the wood and into the anchor in the concrete.

This is a smart way to reuse existing concrete features for your attachment needs.

Using Wood or Concrete Spline Anchors

For certain types of installations, particularly where wood is being attached to concrete walls or floors, you might find systems that use wood strips or specialized concrete splines. For example, a wooden furring strip might be secured to the concrete using a non-drilling adhesive, and then the wood you want to attach is screwed into this furring strip. Alternatively, some systems involve a concrete spline that can be wedged or secured into existing cracks or grooves, and then the wood is attached to the spline.

Adhesive Tapes and Strips

In some cases, heavy-duty adhesive tapes and strips can provide a viable solution for attaching wood to concrete, especially for lighter-duty applications. These products are designed with strong, industrial-grade adhesives that can bond to rough surfaces. They offer a quick and easy alternative to traditional methods, eliminating the mess and time associated with drilling or liquid adhesives.

Double-Sided Tapes

High-strength, double-sided tapes are engineered to hold significant weight. Look for tapes specifically designed for construction or outdoor use, as these will have adhesives that can withstand varying temperatures and moisture levels. These tapes often feature a foam core that can conform to slight surface irregularities, ensuring better contact and a stronger bond.

They are excellent for attaching lighter wood elements, like decorative trim or thin wood panels, to concrete surfaces. Ensure both the wood and concrete surfaces are clean and dry for optimal adhesion.

Adhesive Mounting Strips

Similar to double-sided tapes, adhesive mounting strips are often wider and thicker, providing increased holding power. Many are designed to be easily applied and removed without damaging the underlying surface, though this depends on the specific product and surface type. These strips are ideal for projects where you need a secure but potentially temporary attachment.

For wood-to-concrete applications, choose strips rated for heavy-duty use and ensure they are suitable for outdoor or high-moisture environments if necessary.

Considerations for Adhesive Tapes

While convenient, adhesive tapes have limitations. Always check the weight rating of the tape or strip to ensure it can support the wood piece. Also, the concrete surface should ideally be smooth and clean for best results.

Rough or very porous concrete may not provide enough surface area for the adhesive to grip effectively. For extreme temperature fluctuations or constant moisture exposure, adhesive tapes might not be the most durable long-term solution compared to liquid adhesives or mechanical fasteners.

Weight-Bearing Capacity and Durability

When choosing a method to attach wood to concrete without drilling, it’s vital to consider how much weight the wood needs to support and how long the connection needs to last. Different methods offer varying levels of strength and durability.

Adhesives

Most high-quality construction adhesives and epoxies can support substantial weight, often equivalent to or even exceeding that of mechanical fasteners. They excel in shear strength, meaning they resist forces pushing parallel to the surface. The durability of an adhesive bond is also quite high, provided the correct adhesive is used for the environment and application.

However, extreme temperature changes or constant flexing can degrade some adhesive bonds over time.

Mechanical Fasteners (without drilling)

Methods using clips and brackets rely on the mechanical strength of the hardware and the integrity of the concrete’s edge or existing features. Their weight-bearing capacity can be very high, but it’s dependent on the specific design and how well they grip the concrete. They are often very durable, as they are typically made from robust materials like steel.

However, they might be more susceptible to loosening if subjected to significant vibration.

Adhesive Tapes and Strips

These are generally best suited for lighter loads. While some heavy-duty tapes can hold a surprising amount of weight, they are typically not recommended for structural applications or situations where the wood will bear significant, continuous stress. Their durability can be lower than adhesives or mechanical fasteners, especially in harsh environmental conditions like direct sunlight, extreme heat, or prolonged moisture exposure.

They are often chosen for decorative or non-load-bearing purposes.

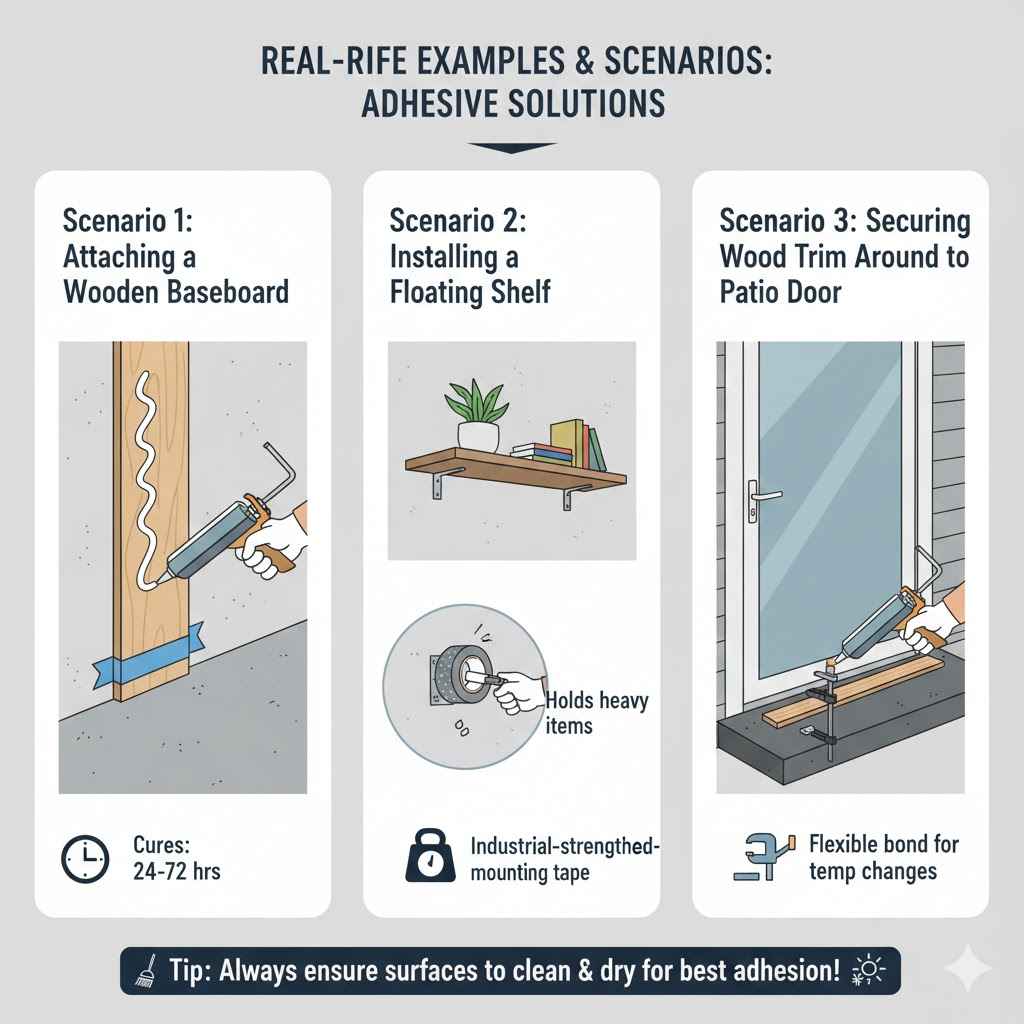

Real-Life Examples and Scenarios

Let’s look at how these methods are used in real situations.

Scenario 1: Attaching a Wooden Baseboard to a Concrete Floor

Imagine you’ve just laid a new concrete floor in your basement or garage. You want to add wooden baseboards around the perimeter for a finished look. Drilling into the concrete for every baseboard can be time-consuming and messy.

A great solution here is using a high-strength construction adhesive. You would apply beads of the adhesive to the back of the wooden baseboard and then press it firmly against the concrete wall. You might use painter’s tape or temporary props to hold it in place while the adhesive cures, which typically takes 24-72 hours.

This method results in a clean, secure attachment without any visible fasteners on the wall or floor.

Scenario 2: Installing a Floating Shelf on a Concrete Wall

You want to add a stylish floating shelf to a concrete wall for displaying decor. Drilling into concrete walls can be challenging and often requires a hammer drill and masonry bits. Instead, you could use a very strong industrial double-sided mounting tape or a powerful construction adhesive.

For a floating shelf, the support brackets would typically be attached to the wood shelf itself, and then the entire unit is mounted to the wall. If the shelf isn’t too heavy, a robust mounting tape designed for heavy items might suffice. For heavier shelves, a construction adhesive applied to the back of the mounting bracket (if the bracket is designed to be glued) would be a better choice.

Ensure the wall and bracket surfaces are meticulously clean before application.

Scenario 3: Securing Wood Trim Around a Concrete Patio Door

After installing a new patio door with a concrete threshold, you want to add some wood trim for a smoother transition and aesthetic appeal. Instead of drilling into the concrete threshold or frame, you can opt for a strong polyurethane adhesive. Apply the adhesive to the back of the wooden trim pieces and press them into place against the concrete.

The flexibility of polyurethane adhesive is beneficial here, as it can absorb minor expansions and contractions between the wood and concrete. Clamps might be needed to hold the trim firmly while the adhesive cures.

Frequently Asked Questions

Question: Can I really attach wood to concrete without any drilling at all

Answer: Yes, absolutely. There are several effective methods, primarily using strong adhesives like construction adhesive, epoxy, or polyurethane glue. Heavy-duty double-sided tapes and specialized clips are also options for certain situations.

Question: What is the strongest way to attach wood to concrete without drilling

Answer: For maximum strength, high-quality construction adhesives or two-part epoxy adhesives are generally considered the strongest options for permanently bonding wood to concrete without drilling.

Question: Will adhesive work on rough concrete surfaces

Answer: Many construction adhesives can bond to moderately rough concrete surfaces. However, the rougher the surface, the less contact area there is, which can weaken the bond. For best results, smooth out any very rough spots or fill deep voids if possible.

Question: How long does it take for adhesives to fully cure when attaching wood to concrete

Answer: Curing times vary greatly depending on the specific adhesive product and environmental conditions like temperature and humidity. Typically, it can range from 24 hours to several days for a full, strong bond to be achieved.

Question: Are there any methods that are easily reversible

Answer: Yes, some heavy-duty adhesive mounting tapes or strips are designed to be removable without damaging the surfaces, making them a good choice for reversible attachments. Mechanical clips can also sometimes be removed without leaving permanent marks.

Summary

Attaching wood to concrete without drilling is simpler than you might think. You can achieve strong, reliable bonds using various adhesives or specialized tapes. Always prepare surfaces well and choose a product suited for your project’s weight and environment.

These methods offer excellent results without the need for drills.