How to Ground a Dust Collector: Essential Tips for Safety

To ground a dust collector, connect the metal parts to a ground rod with a wire. Properly grounding a dust collector is essential to ensure safety and efficiency in your workspace.

By following the correct steps to ground the unit, you can minimize the risk of static electricity build-up, which can lead to fire hazards. Implementing the proper grounding techniques also helps to protect the integrity of the dust collector’s components, extending its lifespan and ensuring optimal performance.

We will provide a straightforward guide on how to ground a dust collector, outlining the necessary steps and emphasizing the importance of this process. Whether you are setting up a new unit or improving the grounding of an existing one, understanding the fundamentals of grounding your dust collector is crucial for a safe and productive work environment.

Grounding A Dust Collector: An Overview

Grounding a dust collector is a crucial aspect of ensuring safety and efficiency in industrial and woodworking operations. Proper grounding helps to minimize the risks of fire, explosion, and electrical hazards by effectively dissipating static electricity and ensuring a safe path for electrical currents. In this section, we will delve into the importance of grounding in dust collector safety and the steps to ensure effective grounding.

Importance Of Grounding In Dust Collector Safety

Preventing static electricity buildup: Grounding the dust collector helps in preventing the accumulation of static electricity, which can lead to hazardous sparks or discharge when combustible dust is present in the air.

Reduction of fire and explosion risks: Effective grounding significantly reduces the potential for fire and explosion in the dust collection system by providing a safe discharge path for any static charges and preventing electrical arcing.

Protection against electrical hazards: Proper grounding ensures the safety of personnel by minimizing the risk of electric shocks and other electrical hazards associated with the operation of dust collection equipment.

Ensuring Proper Grounding

When it comes to grounding a dust collector, certain key steps must be taken to ensure its effectiveness. These include:

- Using conductive materials for ductwork and fittings

- Installing grounding rods and cables to create a path for static dissipation

- Regularly inspecting and maintaining the grounding system to ensure its integrity

Additionally, proper bonding between all components of the dust collection system is essential for effective grounding. This involves connecting all metal components to create a continuous path for electrical currents, minimizing the likelihood of static discharge or electrical hazards.

Understanding The Basics Of Dust Collection System

Dust collection systems play a crucial role in maintaining a safe and clean working environment in various industrial settings. Proper grounding of a dust collector is essential to prevent the risk of fire or explosion due to electrical discharge. This article will provide a comprehensive understanding of the basics of dust collection systems, including their components and potential electrical hazards.

Components Of A Dust Collection System

A dust collection system consists of various components that work together to effectively capture and remove airborne particulates, minimizing the risk of respiratory issues and maintaining a clean workspace. The primary components of a dust collection system include:

- Dust Collector Unit: The core component responsible for collecting and filtering airborne particles.

- Ductwork: Channels that facilitate the movement of air and particles from the source to the collector.

- Hood/Capture Device: Positioned at the source of dust generation to capture airborne particles effectively.

- Air Handling Unit: Manages the airflow within the system, ensuring efficient collection and filtration.

- Collection Bags or Bins: Where the filtered particles are collected for disposing of or recycling.

Electrical Hazards In Dust Collection Systems

Understanding and addressing electrical hazards in dust collection systems is critical for ensuring the safety of the work environment. Electrical hazards can arise from various sources, such as static electricity buildup, electrical shorts, or improper grounding. Neglecting these hazards can lead to devastating consequences, including fires or explosions. Proper grounding, regular maintenance, and adherence to safety standards are essential in mitigating electrical risks in dust collection systems.

Safety Precautions For Dust Collector Grounding

When it comes to operating a dust collector, safety is of utmost importance. Properly grounding your dust collector is critical in preventing the buildup of static electricity, which can lead to dangerous sparks and potential fire hazards. In this section, we will discuss the safety precautions and grounding requirements necessary to mitigate the risks of static electricity in a dust collector environment.

Identifying Static Electricity Risks

Static electricity poses a significant risk in environments where dust and particles are constantly being moved through a dust collection system. Consequently, it’s vital to identify the potential areas where static electricity build-up is most likely to occur. To effectively mitigate these risks, dust collector operators must be vigilant in recognizing the following key areas of concern:

- Powder and dust accumulation in the dust collector and ductwork

- The movement of air and materials through the ducting system

- The creation of friction from high-velocity airflow

Grounding Requirements For Dust Collectors

Grounding a dust collector effectively involves several key requirements to ensure the safe dissipation of static electricity. To prevent sparks and subsequent fire hazards, adhere to the following essential grounding requirements:

- Utilize grounding systems that are compliant with local electrical codes and regulations.

- Confirm that all components of the dust collection system are electrically bonded and grounded to each other.

- Regularly inspect and maintain the grounding connections to ensure their effectiveness.

- Implement a monitoring system to alert operators of any potential grounding failures or anomalies.

How To Ground A Dust Collector

When setting up a dust collector in your workshop, ensuring proper grounding is vital to maintain a safe and effective working environment. Properly grounding a dust collector prevents the build-up of static electricity, which can lead to hazardous situations. In this article, we will explore the essential methods and techniques for grounding a dust collector and the selection of suitable grounding materials.

Grounding Methods And Techniques

There are various methods and techniques for effectively grounding a dust collector. This not only ensures the safety of the equipment but also helps in safeguarding the overall working environment. Some commonly used grounding methods and techniques include:

- Direct metal contact with the earth

- Utilizing grounding rods or plates

- Implementing conductive flooring or mats

- Using bonding straps to connect metal components

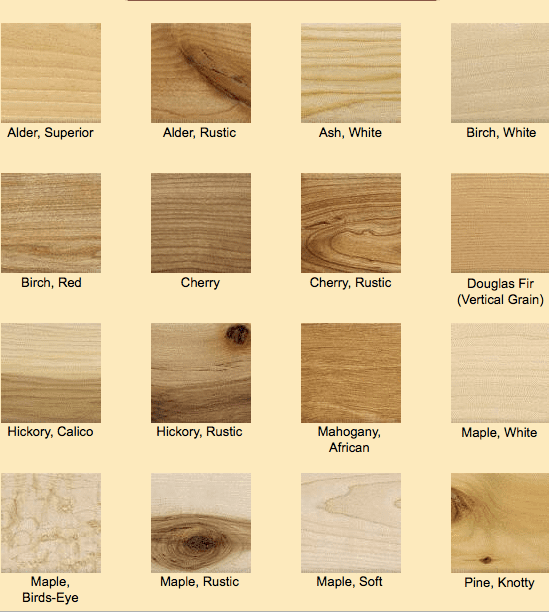

Selecting Suitable Grounding Materials

Choosing the right grounding materials is crucial for the effectiveness of the grounding system. When selecting suitable grounding materials, the following factors should be considered:

- Conductivity: Ensure the material has high conductivity to efficiently dissipate static electricity.

- Corrosion resistance: Select materials that are resistant to corrosion, especially in industrial settings.

- Durability: Opt for durable materials to maintain long-term effectiveness.

Common Mistakes In Dust Collector Grounding

Pitfalls To Avoid In Grounding Process

When grounding a dust collector, it’s essential to avoid common pitfalls that can compromise its effectiveness and safety. Improper grounding can lead to electrical hazards, poor performance, and non-compliance with regulations. Therefore, it’s crucial to be aware of the potential pitfalls and ensure that the grounding process is carried out correctly.

Addressing Common Grounding Errors

Grounding errors in dust collectors are often overlooked but can have serious consequences. To prevent these errors, it’s important to understand the common grounding mistakes and how to address them effectively. By identifying and rectifying these errors, you can ensure the proper functioning and safety of your dust collector system.

Maintenance And Monitoring Of Grounded Dust Collectors

When it comes to maintaining a safe and efficient working environment, the maintenance and monitoring of grounded dust collectors play a critical role. Proper maintenance and monitoring ensure that the dust collector continues to operate effectively, minimizing health and safety risks associated with airborne particulate matter. In this article, we will delve into the essential aspects of maintaining and monitoring grounded dust collectors, focusing on regular inspections for grounding continuity and troubleshooting grounding issues.

Regular Inspections For Grounding Continuity

Regular inspections for grounding continuity are crucial to ensure that the dust collector remains effectively grounded. It is essential to conduct visual checks and perform electrical measurements to verify the integrity of the grounding system. A reliable grounding continuity testing procedure should be established to identify any potential issues promptly.

Troubleshooting Grounding Issues

When troubleshooting grounding issues, it is important to follow a systematic approach. Inspect the grounding connections to identify loose or damaged components. Utilize electrical testing equipment to measure the resistance and continuity of the grounding system. It is essential to address any grounding issues promptly to maintain the safety and efficiency of the dust collector.

Frequently Asked Questions On How To Ground A Dust Collector

Why Is Grounding A Dust Collector Important?

Grounding a dust collector is crucial to prevent static electricity buildup which can lead to fire hazards in a woodshop or industrial setting. Proper grounding ensures safety and reduces the risk of explosions caused by static discharge.

How Does Grounding A Dust Collector Work?

Grounding a dust collector involves connecting it to the earth to neutralize any static charge, typically through a grounding rod or wire. This ensures that any built-up static electricity is dissipated safely, reducing the risk of fire or explosion.

What Are The Steps To Ground A Dust Collector?

To ground a dust collector, start by installing a grounding rod or wire and connecting it to the earth. Ensure all components are properly bonded and use a continuity tester to verify an effective ground connection. Regularly inspect and maintain the grounding system to ensure its effectiveness.

Can I Use A Grounding Wire For My Dust Collector?

Yes, a grounding wire is essential for effectively grounding a dust collector. It provides a path for the dissipation of static electricity and ensures that any potential charge is safely transferred to the earth, reducing the risk of fire and explosions in the workspace.

Conclusion

Grounding a dust collector is crucial for safety and efficiency. By following the steps outlined in this guide, you can ensure a successful grounding process for your dust collector. Remember to prioritize safety measures to prevent hazards and maintain optimal performance.

With proper grounding, you can enhance the longevity and functionality of your dust collector, making it a valuable asset in your workspace.