How to Seal Whitewash Wood: Expert Tips for Long-Lasting Finish

Sealing whitewash wood protects it and enhances its appearance. Whitewash gives wood a rustic charm, but sealing is crucial for durability.

Whitewash wood has a timeless, shabby-chic appeal. But to keep it looking fresh, you need to seal it properly. Sealing whitewash wood prevents moisture damage and enhances its longevity. Without sealing, whitewashed surfaces can deteriorate quickly, losing their charm. This guide will show you how to seal whitewash wood effectively.

Follow these steps, and your whitewash finish will stay beautiful for years. Whether you’re a DIY enthusiast or new to home projects, sealing whitewash wood is a skill worth mastering. Let’s dive into the process and protect your whitewashed treasures.

Choosing The Right Whitewash

There are two main types of whitewash: lime-based and paint-based. Lime-based whitewash is natural and safe. It lets wood breathe. Paint-based whitewash covers wood well. It lasts longer than lime-based.

| Type | Pros | Cons |

|---|---|---|

| Lime-based | Eco-friendly, breathable, natural look | Needs reapplication, may wear off |

| Paint-based | Durable, easy to apply, good coverage | Not breathable, can crack |

Preparing The Wood Surface

First, remove all dust and dirt from the wood. Use a damp cloth to wipe the surface. Make sure the cloth is not too wet. Too much water can damage the wood. Dry the surface with a clean towel. Let the wood dry completely.

Use fine-grit sandpaper to smooth the wood. Sand in the direction of the wood grain. Do not press too hard. Gentle pressure works best. Wipe away the sanding dust with a dry cloth. Check for any rough spots. Sand again if needed.

Applying The Whitewash

Gather your tools first. You will need a brush, a bucket, and water. Also, get a cloth, sandpaper, and a sealer. Make sure all tools are clean. Dirty tools can ruin the finish.

Start by sanding the wood. This makes the surface smooth. Then, mix water and paint in a bucket. Use a 1:1 ratio. Next, dip the brush in the mix. Apply it on the wood. Use long, even strokes. Let it dry for 10 minutes.

Wipe the wood with a cloth. This removes extra paint. Let it dry for one hour. Finally, apply the sealer. This protects the wood. Your whitewash is now complete.

Credit: www.pinterest.com

Drying And Curing

Drying and curing help seal whitewash wood effectively. Ensure the surface is clean and dry before applying a sealing coat. This process preserves the whitewashed look and protects the wood.

Drying Time

The drying time for whitewash wood varies. It depends on the wood and the environment. Typically, it takes 24 to 48 hours to dry. Use fans to speed up the process. Make sure the area has good air flow. Avoid touching the wood while it’s drying.

Curing Process

Curing makes the whitewash strong. It can take up to 30 days. Keep the wood in a dry place. Avoid heavy use during this time. This ensures the whitewash lasts long.

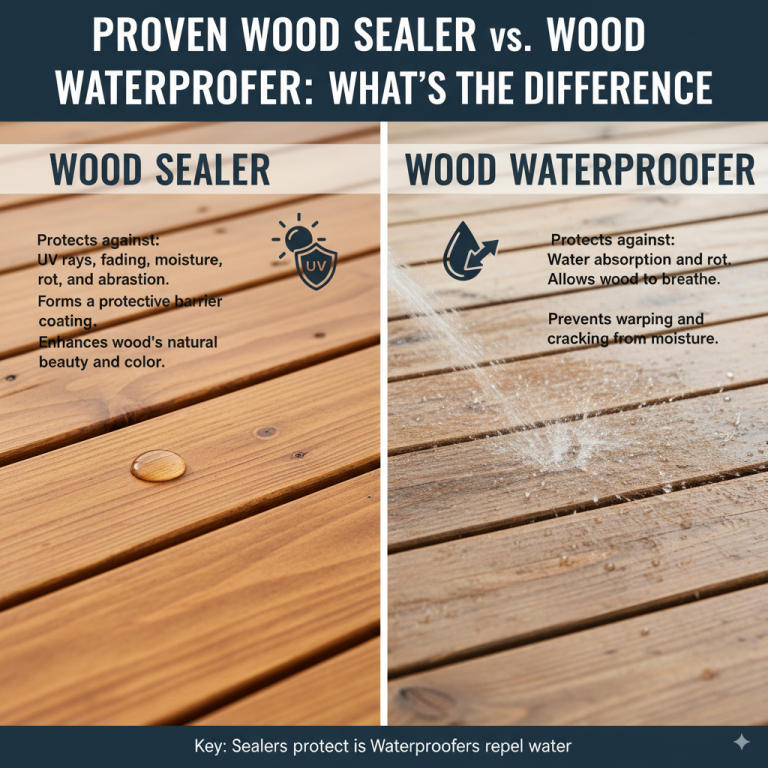

Selecting The Right Sealant

There are many sealant types. Polyurethane is strong and durable. Wax gives a soft finish. Varnish adds a glossy look. Polycrylic dries fast and is water-based.

Think about durability. Will the wood be in high traffic areas? Choose a sealant that protects against wear. Consider appearance. Different sealants give different looks. Check if the sealant is easy to apply. Some are simpler than others.

Lastly, think about drying time. Some sealants dry quickly. Others take longer. Choose what fits your schedule.

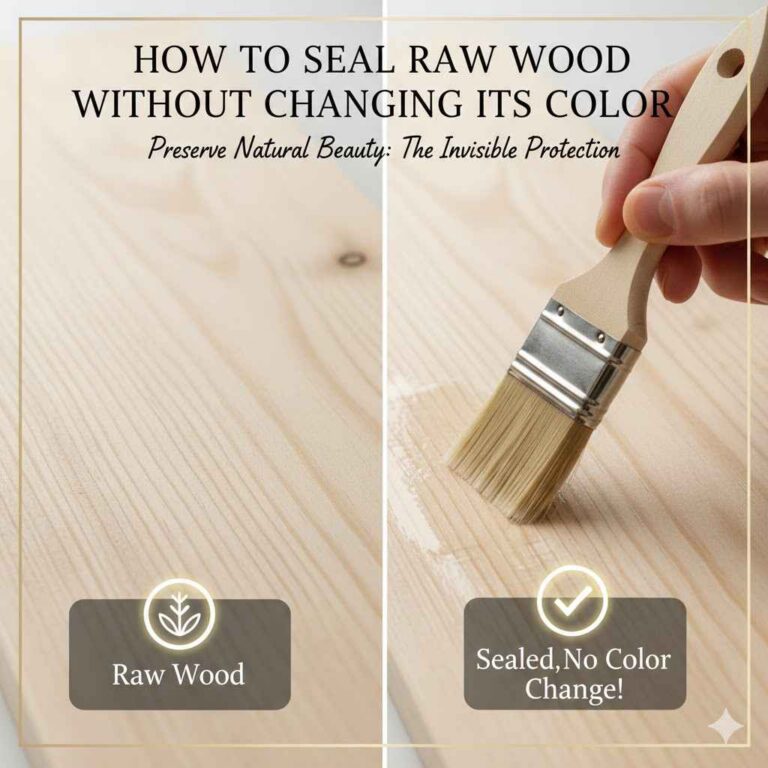

Applying The Sealant

Applying the sealant ensures the whitewash stays protected. Gently brush or spray the sealant over the wood surface. Allow it to dry completely for a durable finish.

Preparation Steps

Make sure the wood is clean and dry. Sand the surface lightly with fine-grit sandpaper. Remove any dust with a damp cloth. This ensures better adhesion of the sealant.

Application Methods

Use a brush or roller to apply the sealant. Apply a thin, even coat. Let it dry completely before adding another coat. Usually, two coats are enough. Each coat should dry for at least 24 hours.

Maintaining The Finish

Dust the wood often. Use a soft cloth. Avoid harsh cleaners. They can damage the finish. A damp cloth works well. Dry the wood right away. This keeps the finish looking good.

Small scratches can be fixed. Use a matching touch-up pen. Apply it gently. Let it dry. For deeper scratches, use wood filler. Sand it smooth. Then, repaint the whitewash. This keeps the wood looking new.

Credit: www.justthewoods.com

Common Mistakes To Avoid

Applying too much sealant can be a mistake. This makes the surface sticky. It also takes longer to dry. Less is more with sealant. Use a thin coat. Thin layers work better.

Sealing too soon can cause problems. The wood needs to be dry first. Patience is key. Let the whitewash dry fully. This helps the sealant stick well.

Credit: www.justthewoods.com

Frequently Asked Questions

What Is Whitewash Wood?

Whitewash wood is a technique where wood is coated with a diluted white paint. This gives it a rustic, weathered look.

Why Seal Whitewashed Wood?

Sealing whitewashed wood protects it from moisture, stains, and wear. It enhances durability and maintains the aesthetic appeal.

How To Seal Whitewashed Wood?

Apply a clear polyurethane or polycrylic sealer. Use a brush or spray for even coverage. Allow it to dry completely.

Can You Seal Whitewashed Wood With Wax?

Yes, you can use furniture wax to seal whitewashed wood. It provides a soft sheen and added protection.

Conclusion

Sealing whitewashed wood preserves its beauty and durability. Use the right sealant for best results. Apply evenly and allow proper drying time. Your wood will look stunning and last longer. Follow these steps and enjoy your beautifully sealed whitewashed wood.

Happy sealing!