Machine Screw Vs Wood Screw: Key Differences Explained

Are you staring at a pile of screws, wondering which is the right one for your project? Choosing between machine screws and wood screws can feel like a daunting puzzle, but it doesn’t have to be.

Imagine the satisfaction of selecting the perfect screw, knowing your project will stand the test of time. You’ll uncover the distinct characteristics of machine screws and wood screws, and learn how to make the best choice for your needs. Dive in to discover how the right decision can transform your DIY projects into masterpieces.

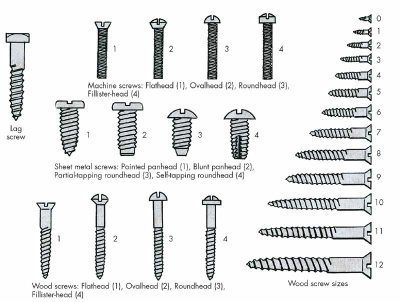

Types Of Screws

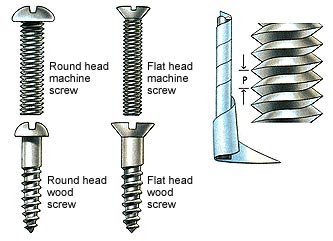

Machine screws have a uniform thread. They connect metal parts. They fit into tapped holes or nuts. They can be flat-headed or round-headed. Some are Phillips or slotted. They come in many sizes and lengths. Stainless steel is common for these screws. They resist rust. They are strong and durable. Easy to use with tools.

Wood screws have a sharp point. They dig into wood easily. Threads are not uniform. They are coarse for better grip. They hold wood pieces together. Flat-head or oval-head types are popular. Brass and steel are common materials. They come in many lengths. Choose the right size for your project. They are easy to use without special tools.

Credit: www.lpscrew.com

Material Composition

Machine screws, made of metal or alloy, are designed for fastening metal parts. Wood screws, crafted from steel or brass, are suited for wood applications. Each screw type has a distinct material composition tailored to its specific use, ensuring optimal performance in varied projects.

Metal Alloys

Machine screws are made from strong metal alloys. These include steel, brass, and aluminum. Steel is very strong and hard. Brass is shiny and does not rust. Aluminum is light and resists corrosion. Metal alloys are used for their strengthand durability. They help machine screws hold tight. These screws are good for metal surfaces.

Wood-friendly Materials

Wood screws use different materials. Many are made from softer metals. Soft metals include brassand zinc. Some screws are coated with zincto stop rust. Others have a coatingto glide through wood easily. These materials help the screws go into wood without splitting it. Wood screws are perfect for wooden surfaces.

Thread Design

Fine threads have tiny ridges. These ridges are close together. Machine screws often have fine threads. They are great for metal surfaces. The tight fit holds parts together well. Fine threads make it hard to loosen screws. But, they can strip easily if not careful. So, using them needs patience and care.

Coarse threads have big ridges. These ridges are spaced out more. Wood screws mostly have coarse threads. They grip wood surfaces tightly. Coarse threads make it easy to drive screws in. They are strong and hold well in soft materials. Easy to use, they are great for many projects.

Purpose And Application

Machine screws are vital in factories. They hold heavy machines together. These screws fit into metal parts. They have a smooth body. This body makes them strong. Perfect for heavy-duty tasks. They come in many sizes. Some are tiny, for small machines. Others are big, for large machines. Safety is important. Machine screws keep machines safe.

Wood screws are for carpenters. They join wood pieces. Their sharp tip helps in easy fixing. They do not need a pre-drilled hole. This saves time. Carpenters love them for this. Wood screws have a wider head. This gives a better grip. They are great for making furniture. Also used in building wooden houses.

Strength And Durability

Machine screws are strong. They hold heavy loads. Wood screws are less strong. They hold lighter loads. Their design helps in wood. Machine screws are perfect for metal. They connect parts tightly. Wood screws are good for furniture. Machine screws are used in machines. Both have their uses. Choose based on your need.

Machine screws resist wear. They last long. Wood screws wear out faster. They are for wood. Machine screws handle tough jobs. Wood screws are for softer tasks. Durability is key for machines. Wood screws suit less tough tasks. Pick the right screw for your project.

Credit: www.thepipefittings.com

Installation Techniques

Using the right tools makes the job easier. A screwdriver is needed. It fits the screw head. Drill can be useful too. Wood screws need a special driver. Machine screws use a different one. Pliers can help with grip. Clamps hold pieces steady. Safety goggles protect eyes. Gloves keep hands safe. Prepare all tools before starting.

Pre-drilling helps screws go in straight. It prevents wood from splitting. Machine screws often need holes first. Wood screws might need it for hard wood. Pilot holes guide screws. Use a drill for this step. Bit size must match screw size. Small holes for small screws. Large holes for big screws. This step is important.

Cost Considerations

Machine screwsoften cost more than wood screws. They need special materials. This makes them pricier. Wood screws are cheaper. They use common materials. This keeps their price low.

Machine screws offer better value. They last longer. Their durability is high. Wood screws may wear out faster. They might need replacing. Machine screws are worth the money. Wood screws fit a tighter budget. They are good for simple projects.

Credit: blog.thepipingmart.com

Choosing The Right Screw

Understanding project requirementsis crucial. Each project needs specific screws. Machine screws are best for metal or plastic. Wood screws work well with wood. The choice depends on the material. Consider the size and length of the screw. Ensure it matches your project needs. Check the screw’s strength. It should hold the materials firmly.

Environmental factorsaffect screw choice. Indoor projects need regular screws. Outdoor projects need screws resistant to weather. Moisture can cause screws to rust. Choose stainless steel or coated screws for wet areas. Temperature changes can impact screws. Some materials expand or contract. Ensure the screw can withstand these changes. Think about the surroundings when selecting screws.

Frequently Asked Questions

Can I Use Metal Screws Instead Of Wood Screws?

Using metal screws instead of wood screws is possible but not ideal. Metal screws may damage wood fibers. Wood screws are designed to grip wood securely, offering better strength and durability. For optimal results, choose screws specifically designed for the material you’re working with.

How To Tell If A Screw Is A Wood Screw?

Wood screws have a tapered shank and sharp threads. Their pointed tip easily penetrates wood. They often feature a flat or oval head for countersinking. Typically, they are made of softer metals to prevent wood damage during installation. Look for coarse threads that grip wood securely.

When Would You Use A Machine Screw?

Use a machine screw for fastening metal parts together. It’s ideal for securing components in machinery. Machine screws fit into tapped holes or nuts, providing strong, reliable connections. They are used in electronics, automotive, and construction applications. Choose them for precision and durability in assembly tasks.

How To Tell The Difference Between A Sheet Metal Screw And A Wood Screw?

Sheet metal screws have a sharper point and finer threads than wood screws. Wood screws have a tapered head and coarse threads for gripping wood.

Conclusion

Choosing the right screw ensures your project succeeds. Machine screws and wood screws serve different purposes. Machine screws work best with metal and plastic. Wood screws excel in timber applications. Consider material, strength, and environment for your decision. Both types offer unique benefits.

Understand your needs before buying. Proper selection leads to stronger and safer constructions. Always match screw type with your project requirements. This avoids unnecessary complications later. Each screw has a special role. Knowing these differences makes tasks easier. Happy building and crafting!