Nitrocellulose Vs Polyurethane: Ultimate Finish Showdown

Are you trying to choose between nitrocellulose and polyurethane finishes for your next project? The decision might seem daunting, but understanding these two popular options can make it much easier.

Each has its own unique qualities that can significantly impact the look, feel, and durability of your finished product. Whether you’re restoring a cherished piece of furniture, crafting a musical instrument, or working on any wood-related project, the finish you choose matters.

Dive into this article to uncover the differences, benefits, and potential drawbacks of nitrocellulose and polyurethane. By the end, you’ll have the insights you need to make a decision that perfectly aligns with your needs and preferences. Let’s explore which finish will bring your vision to life!

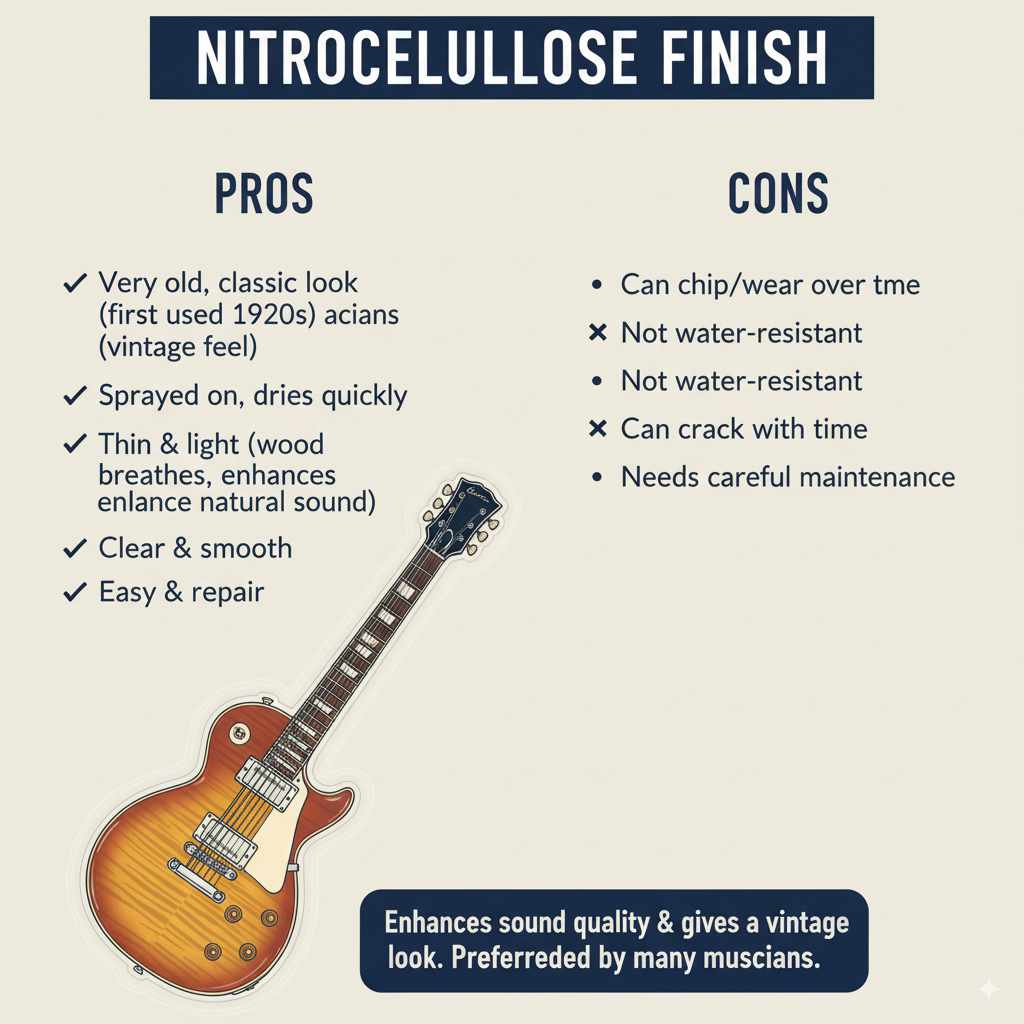

Nitrocellulose Finish

Nitrocellulose finish is very old. It was first used in the 1920s. Many guitars used this finish. It gives a classic look. This finish is popular with musicians. They like the vintage feel.

Nitrocellulose is sprayed on surfaces. It dries quickly. More layers can be added. Each layer makes it shiny. Care is needed during application. Too much can crack.

This finish is thin and light. It lets the wood breathe. It enhances the natural sound of instruments. The finish is clear and smooth. It can chip or wear over time.

Nitrocellulose finish enhances sound quality. It gives a vintage look. This finish is easy to repair. It is preferred by many musicians.

This finish can wear out fast. It is not water-resistant. It can crack with time. Care is needed to maintain it.

Polyurethane Finish

Polyurethane finish offers durable protection and a glossy look, ideal for high-traffic areas. Nitrocellulose provides a warm, vintage feel, perfect for musical instruments. Comparing these finishes reveals varying strengths and applications.

Development And Background

Polyurethane finish was made in the early 20th century. Scientists wanted a strong and shiny coating. Early versions were sticky and hard to use. Over time, they improved the formula. Now it is the favorite for furniture and floors. It is used everywhere. Polyurethane is now seen as a durable option. It is a trusted choice for many projects.

Application Techniques

Use a brush or spray to apply polyurethane. Brushes are easy for beginners. Sprays help cover large areas quickly. Thin layers work best. Wait for each layer to dry before adding more. Sand lightly between layers. This helps smooth the surface. Keep the area clean and dust-free. Dust can ruin the finish. Practice makes perfect with polyurethane.

Key Features

- Shiny and clear surface

- Strong and durable

- Water-resistant

- Protects against scratches

Benefits

Polyurethane finish lasts a long time. It is easy to clean. Protects wood from damage. It can make items look new. Enhances the wood’s natural beauty. Keeps water out. Stops stains and marks. Affordable option for many projects.

Drawbacks

- Can be smelly

- Needs careful application

- Can yellow over time

- May need special tools

Comparative Analysis

Polyurethane is known for its strong durability. It lasts longer than nitrocellulose. Nitrocellulose can wear down faster. This means more repairs over time. Polyurethane can resist scratches and dents better. This makes it a preferred choice for many.

Nitrocellulose gives a warm and glossy look. Many love its vintage charm. It ages beautifully with time. Polyurethane looks more modern. It offers a shiny and clear finish. Some prefer its neat look.

Fixing nitrocellulose is simpler. Small damages can be fixed easily. Polyurethane repairs are tricky. They might need expert help. This can be costly and time-consuming.

Nitrocellulose uses more harmful chemicals. This makes it less eco-friendly. Polyurethane is better for the environment. It has fewer toxic components. This is a plus for those who care about nature.

Choosing The Right Finish

Different projects need different finishes. Nitrocellulose offers a vintage look. It’s perfect for musical instruments. Polyurethane is stronger. It’s ideal for furniture. Think about the project’s end use. This helps in choosing the right finish.

Nitrocellulose is often cheaper. It’s a good choice for small budgets. Polyurethane might cost more. It lasts longer, though. Spend wisely based on your needs. A higher budget can mean a better finish. But plan carefully to avoid overspending.

Nitrocellulose is easier to apply. Beginners might find it simple. It needs multiple coats. Polyurethane needs more skills. It’s thicker and harder to spread. Practice helps in applying it well. Choose based on your confidence and experience.

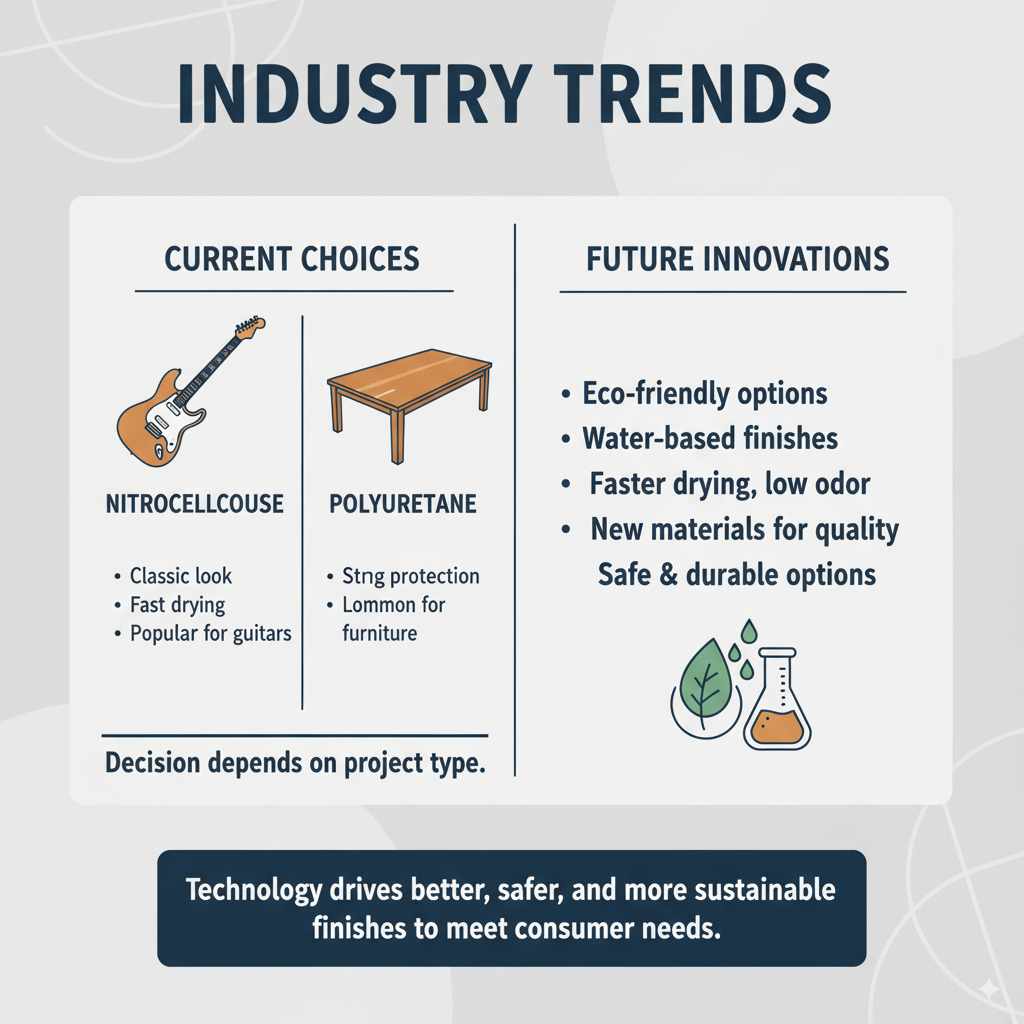

Industry Trends

Many companies like to use nitrocellulose and polyurethane. Nitrocellulose gives a classic look. Polyurethane offers strong protection. People choose finishes based on needs. Nitrocellulose is popular for guitars. Polyurethane is common for furniture. It is important to pick the right one. Both have unique features. Nitrocellulose dries fast. Polyurethane lasts longer. The choice depends on the project.

Technology is changing finishes. New eco-friendly options are here. They are safer for the environment. Water-based finishes are now available. They dry quickly. They do not smell bad. Companies are testing new materials. The goal is to improve quality. Better finishes mean better products. Consumers want safe and durable options. Innovation helps meet these needs.

Frequently Asked Questions

Is Poly Finish Better Than Nitro Finish?

Poly finishes offer durability and resistance to scratches. Nitro finishes provide a vintage look and tonal warmth. Choose poly for longevity and nitro for classic aesthetics.

What Are The Cons Of Nitrocellulose Lacquer?

Nitrocellulose lacquer scratches easily and offers limited durability. It can yellow over time and is flammable. The application requires proper ventilation due to strong fumes. It often requires multiple coats for a smooth finish, increasing labor and time. Environmental regulations may limit its use in some areas.

What Finish Is Best For Guitars?

Nitrocellulose and polyurethane finishes are popular for guitars. Nitrocellulose provides a vintage look and superior resonance. Polyurethane offers durability and protection. Both finishes have their unique benefits, depending on personal preference and playing style. Consider the guitar’s usage and desired aesthetics when choosing.

What Are The Advantages Of Nitrocellulose?

Nitrocellulose offers quick drying, excellent adhesion, and superior gloss. It is versatile for coatings and finishes. Its lightweight nature enhances ease of application. This compound ensures durability and resistance, providing long-lasting protection for surfaces. Ideal for various industries, nitrocellulose enhances aesthetic appeal and performance efficiently.

Conclusion

Choosing between nitrocellulose and polyurethane can be challenging. Both have unique strengths. Nitrocellulose offers a vintage feel and quick drying. Polyurethane provides durability and a smooth finish. Your choice depends on your needs and preferences. Consider the environment where you’ll use the product.

Think about maintenance and longevity too. Musicians might prefer nitrocellulose for its classic appeal. Woodworkers might lean towards polyurethane for protection. Both finishes have their place in different projects. So, weigh the pros and cons carefully. Make your decision based on what suits your project best.