Treated Wood Shims: Essential for Precision Leveling

Treated wood shims are specially designed pieces of wood that resist moisture and pests. They are commonly used for leveling structures and ensuring stability.

Treated wood shims offer durability and strength, making them ideal for various construction projects. These shims are typically made from pressure-treated lumber, providing resistance against rot and insects. Builders often use them to adjust door frames, windows, and cabinets, ensuring a precise fit.

Their versatility extends to outdoor applications, such as leveling decks and fences, where exposure to the elements is a concern. Choosing the right shim can significantly improve the quality of your project. With proper installation, treated wood shims enhance both structural integrity and longevity, making them an essential tool for DIY enthusiasts and professionals alike.

The Role Of Wood Shims In Construction

Wood shims are essential tools in construction. They help create a stable and level surface. Builders often use them to support doors, windows, and cabinets. Treated wood shims resist moisture and insects. This makes them perfect for outdoor projects.

Precision Leveling Explained

Precision leveling is crucial in construction. It ensures structures are stable and safe. Wood shims offer a simple solution for this task.

- They fit into small gaps.

- They adjust height easily.

- They provide firm support.

Using shims helps maintain the right angles. This prevents future issues like sagging or misalignment. Builders can quickly add or remove shims as needed. This flexibility saves time and effort.

Wood Shims Vs. Alternative Materials

Other materials can replace wood shims, but they often fall short. Below is a comparison of wood shims and alternatives:

| Material | Advantages | Disadvantages |

|---|---|---|

| Wood Shims |

|

|

| Plastic Shims |

|

|

| Metal Shims |

|

|

Wood shims remain a popular choice for many projects. They combine affordability with effectiveness.

Treated Wood Shims: What Sets Them Apart

Treated wood shims are essential tools for construction and home improvement. Their unique treatments enhance durability and resistance. This makes them a popular choice for various projects.

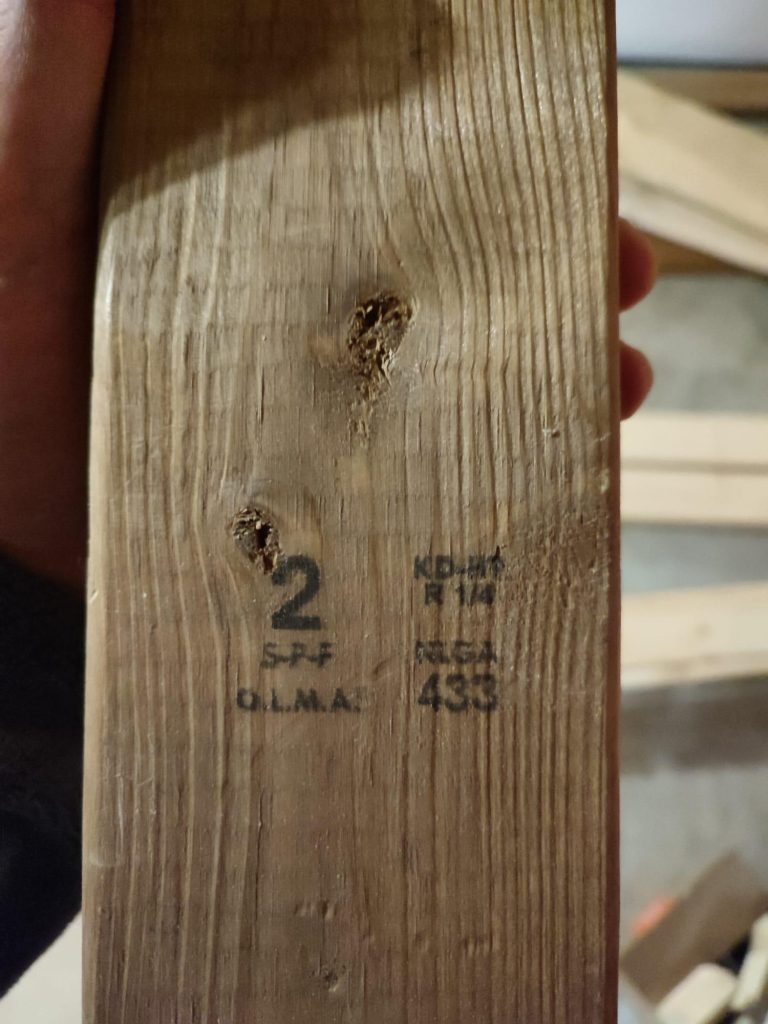

Types Of Treatment Processes

Treated wood shims undergo several treatment processes. Each process aims to increase their longevity and effectiveness. Here are the main types:

| Treatment Process | Description |

|---|---|

| Pressure Treatment | Wood is placed in a chamber and treated under high pressure. |

| Surface Treatment | Chemical solutions are applied directly to the wood surface. |

| Vacuum Treatment | Wood is treated with chemicals in a vacuum chamber. |

Benefits Of Using Treated Wood

Using treated wood shims offers numerous advantages. Here are the main benefits:

- Weather Resistance: Protects against moisture and extreme weather.

- Insect Protection: Resists damage from pests like termites.

- Longevity: Lasts longer than untreated wood.

- Cost-Effective: Reduces the need for frequent replacements.

These benefits make treated wood shims an excellent choice for any project.

Selecting The Right Wood Shims For Your Project

Choosing the right treated wood shims is essential for your project. The correct shims help with leveling and support. They ensure stability and durability. Here’s how to select the best wood shims.

Size And Thickness Considerations

Size and thickness play a crucial role in shim selection. The right dimensions provide better support. Consider these factors:

- Length: Common lengths range from 6 to 12 inches.

- Width: Typical widths vary from 1 to 4 inches.

- Thickness: Shims usually come in thicknesses of 1/8 to 1 inch.

Measure your space carefully. Ensure the shim fits snugly. Too thick can cause instability. Too thin may not offer enough support. Use a variety of sizes for flexibility.

Compatibility With Various Surfaces

Wood shims must match the surface they support. Compatibility ensures effectiveness. Here are some surfaces to consider:

| Surface Type | Recommended Shim Type |

|---|---|

| Wood Floors | Treated Wood Shims |

| Concrete Slabs | Plastic or Composite Shims |

| Metal Framing | Metal Shims |

Always check compatibility. Use treated wood shims for outdoor projects. They resist moisture and decay. For indoor use, choose shims based on the surface material.

The Installation Process: A Step-by-step Guide

Treated wood shims are essential for leveling and supporting structures. This guide helps you install them correctly. Follow these steps for a smooth installation process.

Preparation Steps Before Installation

Proper preparation ensures a successful shim installation. Here are the key steps:

- Gather Your Tools: You will need a hammer, level, tape measure, and treated wood shims.

- Inspect the Area: Check for any debris or obstacles.

- Measure the Gaps: Use the tape measure to find uneven spots.

- Choose the Right Shim Size: Select shims that fit your gaps.

Follow these steps to ensure you have everything ready.

Expert Tips For Effective Shim Placement

Correct shim placement is vital for stability. Use these expert tips:

- Start at the Lowest Point: Begin shim placement where the structure is lowest.

- Place Shims Under Load-Bearing Areas: Ensure shims support heavy loads.

- Use Multiple Shims: Stack shims for larger gaps.

- Check Level Frequently: Use a level to ensure even placement.

- Secure Shims: Tap shims gently with a hammer to secure them.

By following these tips, you ensure a strong and stable installation.

Common Applications For Treated Wood Shims

Treated wood shims are versatile tools in construction and repair. They help achieve precise leveling and support. Here are two common applications:

Leveling Doors And Windows

Doors and windows often need adjustment. Treated wood shims help level them properly. Use shims to:

- Support door frames during installation.

- Fill gaps under windows for a snug fit.

- Ensure doors swing open and close smoothly.

Follow these steps for leveling:

- Insert shims under the door frame.

- Check with a level tool.

- Adjust shims as needed.

Treated wood shims provide the strength and stability needed for these tasks.

Foundation Repairs And Adjustments

Foundations may settle over time. Treated wood shims offer a quick fix. They help restore stability in various ways:

- Support sagging beams.

- Fill gaps in uneven floors.

- Enhance load distribution on weak spots.

To use shims for foundation repairs:

- Identify the low spots in the foundation.

- Insert treated wood shims carefully.

- Check for levelness regularly.

Treated wood shims ensure a solid, level foundation.

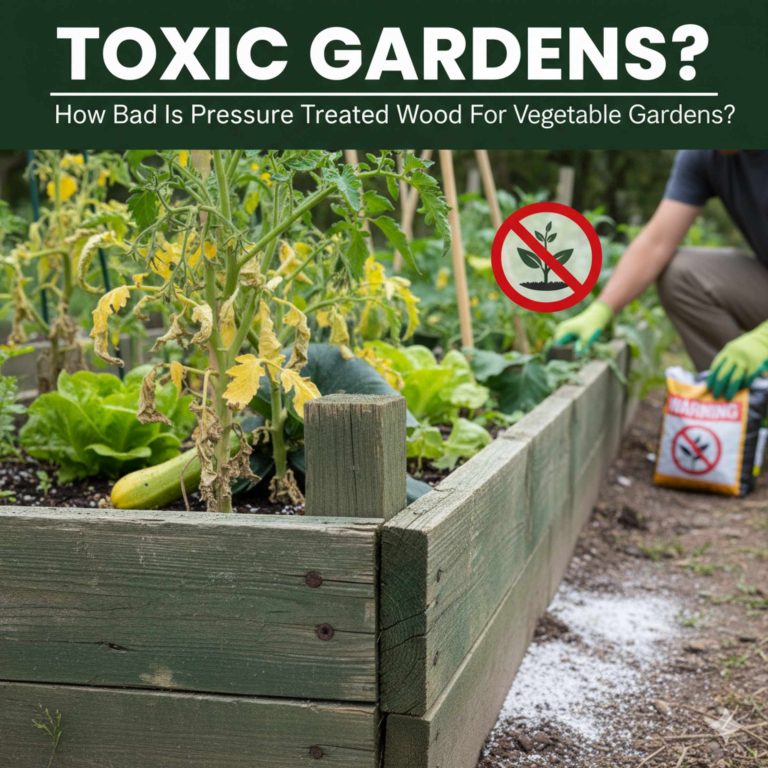

Safety Considerations When Handling Treated Wood

Treated wood shims are useful but can pose safety risks. Proper handling is essential. Understanding safety protocols protects you from harmful chemicals.

Personal Protective Equipment

Wearing the right Personal Protective Equipment (PPE) is crucial. This gear helps keep you safe from potential hazards. Here’s a list of recommended PPE:

- Gloves: Use chemical-resistant gloves.

- Mask: Wear a mask to avoid inhaling dust.

- Safety goggles: Protect your eyes from splinters.

- Long sleeves: Wear long-sleeved shirts to cover skin.

Always inspect your PPE before use. Replace any damaged gear immediately.

Disposal Of Treated Wood Shims

Disposing of treated wood shims requires care. These materials contain chemicals that can harm the environment. Follow these steps for safe disposal:

- Check local regulations on treated wood disposal.

- Do not burn treated wood. It releases harmful toxins.

- Use designated disposal sites for treated wood.

- Consider recycling options if available.

Never throw treated wood in regular trash. Proper disposal protects the community and environment.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from chemicals and splinters |

| Mask | Avoid inhaling harmful dust |

| Goggles | Shield eyes from wood debris |

| Long Sleeves | Cover skin from direct contact |

Maintenance And Longevity Of Treated Wood Shims

Treated wood shims provide support for various structures. They help in leveling and stabilizing. Proper maintenance ensures their longevity and effectiveness.

Routine Check-ups For Shim Integrity

Regular inspections keep your treated wood shims in top shape. Check the following:

- Physical Damage: Look for cracks or splits.

- Moisture Levels: Ensure shims remain dry.

- Position: Verify they stay in place.

Inspect shims at least once a year. Use a flashlight for a detailed view. Replace any damaged shims immediately.

When To Replace Wood Shims

Know when to replace your treated wood shims. Consider these signs:

| Sign | Action |

|---|---|

| Visible Cracks | Replace immediately |

| Significant Warping | Replace promptly |

| Moisture Damage | Replace right away |

| Shifts in Position | Reassess and replace if needed |

Keep a close eye on your shims. Timely replacements save time and money.

Environmental Impact Of Treated Wood Shims

Treated wood shims play a role in construction and woodworking. Their environmental impact is an important topic. Understanding their sustainability helps consumers make better choices. This section explores the sustainability of wood shim production and their recycling options.

Sustainability Of Wood Shim Production

Wood shims come from natural resources. Sustainable practices in wood production are essential. Here are some factors to consider:

- Source of Wood: Choose wood from certified forests.

- Responsible Harvesting: Minimizing tree loss is crucial.

- Processing Methods: Eco-friendly processes reduce pollution.

Using renewable resources promotes sustainability. Many manufacturers focus on reducing waste. This leads to a smaller carbon footprint. Eco-conscious brands often use:

| Eco-Friendly Practices | Description |

|---|---|

| Recycled Wood | Wood from old structures is repurposed. |

| Low-Impact Chemicals | Using safer chemicals during treatment. |

| Energy Efficiency | Reducing energy use during production. |

Recycling And Reusability Options

Treated wood shims can often be reused or recycled. This reduces waste and conserves resources. Here are some options:

- Reuse: Wood shims can serve multiple purposes.

- Repurposing: Use them in crafts or garden projects.

- Recycling: Check local facilities for recycling options.

By choosing recycled materials, consumers can lessen environmental harm. Many communities encourage recycling wood products. Always verify local regulations for disposal methods. Responsible choices contribute to a healthier planet.

Frequently Asked Questions

What Are Treated Wood Shims Used For?

Treated wood shims are primarily used for leveling, supporting, and stabilizing structures. They can also fill gaps in construction projects. Their resistance to moisture makes them ideal for outdoor use, such as deck and fence installations. This durability ensures long-lasting performance in various applications.

Are Treated Wood Shims Safe For Outdoor Use?

Yes, treated wood shims are designed specifically for outdoor applications. They undergo a chemical treatment that protects them from rot and insect damage. This makes them suitable for use in environments exposed to moisture. Always ensure you’re using them in accordance with safety guidelines for optimal performance.

How Long Do Treated Wood Shims Last?

The lifespan of treated wood shims can vary based on usage and environmental conditions. Generally, they can last several years, especially when used in protected areas. Proper installation and maintenance can further extend their lifespan. Regular inspections help ensure they remain effective in supporting structures.

Can I Paint Treated Wood Shims?

Yes, you can paint treated wood shims. However, it’s essential to allow them to dry completely after treatment. Using a primer designed for treated wood will enhance paint adhesion. This not only improves aesthetics but also adds an extra layer of protection against the elements.

Conclusion

Treated wood shims are essential for ensuring stability and precision in various projects. Their durability makes them a reliable choice for both DIY enthusiasts and professionals. By incorporating these shims, you enhance the quality and longevity of your work. Choose treated wood shims for effective and lasting solutions in your construction needs.