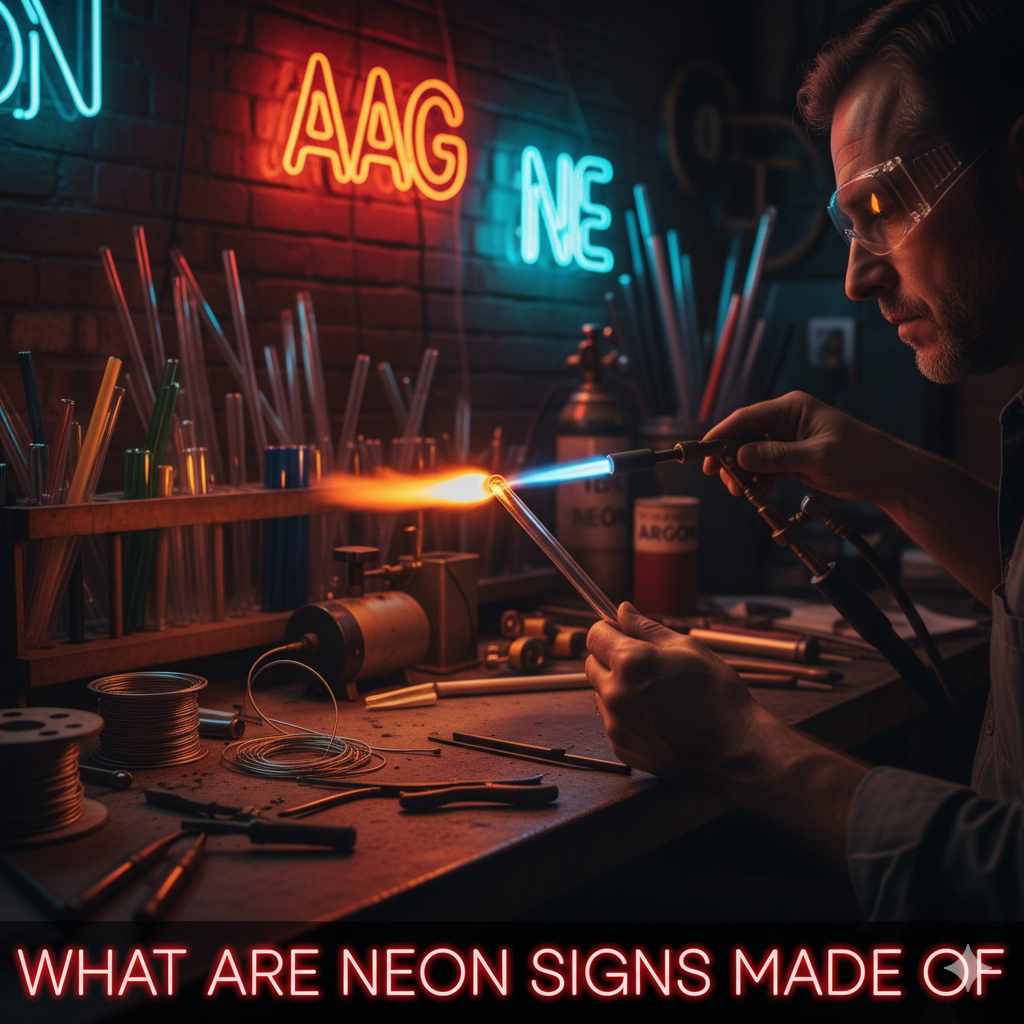

What Are Neon Signs Made Of: Essential Guide

Neon signs are primarily made of glass tubes filled with noble gases, typically neon or argon, which glow when an electric current passes through them. These tubes are then shaped and mounted onto a backing for display.

Ever admired those vibrant, glowing signs in shop windows or at your favorite diner and wondered what magic makes them light up? You’re not alone! The glow of a neon sign is captivating, but understanding what goes into making one can seem a bit mysterious. Many people think “neon” signs are always red, or that they’re incredibly fragile and complicated. But the truth is, the materials and process are more straightforward than you might think. Don’t let the glowing spectacle fool you; we’re going to break down exactly what makes these signs tick. Ready to discover the secrets behind the glow? Let’s dive in!

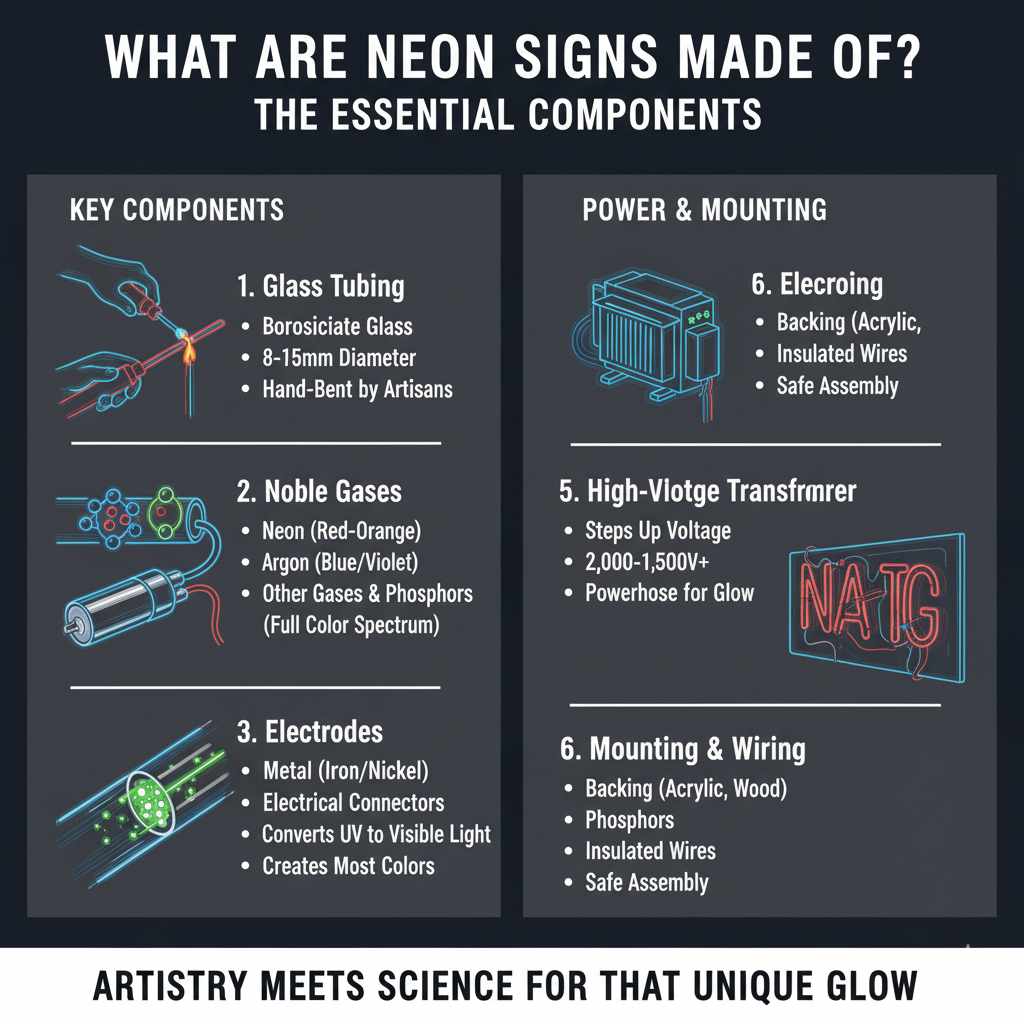

What Are Neon Signs Made Of? The Essential Components

At its heart, a neon sign is a beautiful blend of science and artistry. The glowing effect comes from a carefully orchestrated interaction between electricity and specific gases trapped within shaped glass tubes. While the term “neon sign” is often used broadly, not all signs that use this technology actually contain neon gas. Let’s explore the key ingredients:

1. Glass Tubing: The Foundation of the Glow

The most visible component of a neon sign is the glass tubing itself. This isn’t just any ordinary glass; it’s specifically designed to be bent and worked with at high temperatures without breaking easily. Think of it like a delicate but strong conduit for the light.

- Material: Typically, borosilicate glass is used. This type of glass is known for its thermal shock resistance and durability, making it suitable for the heating and bending process involved in sign making.

- Shape and Size: The glass tubes come in various diameters, usually ranging from 8mm to 15mm. The thickness and diameter are chosen based on the desired brightness, the complexity of the design, and the specific gas being used.

- Bending Process: This is where the artistry truly comes in. Skilled neon benders heat the glass tubes over a specialized furnace or torch, making them pliable. They then carefully bend the hot glass by hand, following intricate patterns and designs. This requires immense precision and practice to achieve sharp corners or smooth curves.

2. Noble Gases: The Light Source

This is where the “neon” in neon sign comes into play, though it’s often a bit more complex. Noble gases are elements that are naturally unreactive, meaning they don’t easily form chemical bonds. This makes them perfect for use in sealed tubes where they won’t degrade over time.

- Neon Gas: When you hear “neon,” you probably think of that classic, vibrant red-orange glow. That’s exactly what pure neon gas produces when an electric current passes through it. It’s the signature color of true neon signs.

- Argon Gas: For all the other colors you see in “neon” signs, argon gas is usually the primary component. Argon, by itself, produces a soft blue or violet light. However, by mixing argon with other gases and adding a fluorescent powder coating to the inside of the glass tubes, a rainbow of colors can be achieved.

- Other Gases and Mixtures: Sometimes, other noble gases like krypton or xenon are used, or mixtures of neon and argon, to achieve specific hues or brightness levels. The precise combination is a closely guarded secret of many sign makers.

3. Electrodes: The Electrical Connectors

To get the gas to glow, electricity needs to flow through it. Electrodes are crucial for making this connection. They are sealed into each end of the glass tubing.

- Material: Typically made of metal, often iron or nickel, chosen for their conductivity and ability to withstand the electrical discharge and heat.

- Function: When a high voltage is applied, the electrodes help to ionize the gas within the tube, creating a pathway for the electrical current to flow from one end to the other. This flow of electrons excites the gas atoms, causing them to emit light.

4. Fluorescent Coatings (Phosphors): The Color Multiplier

As mentioned, not all colors come directly from the gas. For the vast spectrum of colors beyond red-orange, a special powder is applied to the inside of the glass tubes.

- What they are: These are phosphors, a type of luminescent material.

- How they work: When the excited gas inside the tube emits ultraviolet (UV) light (which is invisible to the human eye), this UV light strikes the phosphor coating. The coating then absorbs the UV light and re-emits it as visible light in a specific color. Different phosphor mixtures produce different colors.

- Common Colors: For example, a blue phosphor coating might be used with argon gas to create a bright blue sign, or a green phosphor with argon to create green. A combination of gases and phosphor coatings allows for almost any color imaginable.

5. High-Voltage Transformer: The Powerhouse

Glass tubes filled with gas need a significant electrical jolt to start glowing. That’s where the transformer comes in.

- Function: Neon signs operate on high voltage, typically ranging from 2,000 to 15,000 volts or even higher, depending on the length and complexity of the tubing. A transformer steps up the standard household voltage (120V or 240V) to the much higher voltage required to ionize the gas and create the glow.

- Safety: These transformers are designed with safety in mind, often enclosed in protective casings. However, due to the high voltages involved, it’s crucial that installation and maintenance are handled by qualified professionals.

6. Mounting and Wiring: Putting It All Together

Once the glass tubes are shaped, filled with gas, and ready to glow, they need to be assembled into a sign and connected to the power source.

- Backing: The bent glass tubes are typically mounted onto a backing material. This can range from clear acrylic or wood to metal or even a custom-designed frame. The backing provides structural support and helps to define the shape of the sign.

- Wiring: High-voltage wires connect the electrodes at each end of the glass tubes to the transformer. These wires are carefully insulated and routed to ensure a safe and functional circuit.

The “Neon” Color Spectrum: Beyond the Red Glow

It’s a common misconception that all “neon” signs use neon gas. While pure neon gas is responsible for the iconic red-orange hue, the vast majority of colorful signs use a clever combination of argon gas and fluorescent coatings.

Here’s a simplified look at how different colors are achieved:

| Gas Used | Inside Coating | Resulting Color (Approximate) |

|---|---|---|

| Neon (Ne) | None | Red-Orange |

| Argon (Ar) | None | Blue/Violet |

| Argon (Ar) + Mercury Vapor | White Phosphor | Bright White |

| Argon (Ar) + Mercury Vapor | Green Phosphor | Green |

| Argon (Ar) + Mercury Vapor | Blue Phosphor | Blue |

| Argon (Ar) + Mercury Vapor | Red Phosphor | Red |

| Argon (Ar) + Mercury Vapor | Yellow Phosphor | Yellow |

| Argon (Ar) + Mercury Vapor | Various Phosphors | Any color in the spectrum (Pink, Purple, Orange, etc.) |

The addition of a tiny amount of mercury vapor to argon gas helps to create ultraviolet (UV) light. This UV light then excites the phosphor coating on the inside of the tube, causing it to glow in its specific color. This technique, known as cold cathode discharge, is what allows for the incredible range of colors we see in modern illuminated signage.

The Neon Sign Making Process: A Glimpse Behind the Scenes

Creating a neon sign is a skilled craft that combines artistic vision with technical expertise. While modern technology has introduced some advancements, the core process remains largely the same, relying on the hands of talented artisans.

- Design and Pattern Creation: It all starts with a design. This can be a simple word, a logo, or a complex illustration. The designer or sign maker will create a full-size pattern on paper or a digital format, showing the exact shape and dimensions of the glass tubing.

- Glass Bending: This is the most critical and artful step. The glass tubes are heated to a pliable state using specialized torches and furnaces. The bender then carefully shapes the glass according to the pattern, often using freehand techniques and various tools to achieve precise curves and angles. This step requires immense skill and practice, as mistakes can lead to cracked glass or an inaccurate shape. You can find some amazing videos online showcasing the artistry of neon bending – it’s truly mesmerizing to watch! For instance, resources from organizations like the International Sign Association often highlight the craftsmanship involved.

- Bombardment and Evacuation: Once the tubes are bent into shape, they are sealed at one end. The other end is connected to a vacuum pump and a gas manifold. The tube is then “bombarded” with electricity while under vacuum. This process cleans the inside of the tube and removes any residual impurities.

- Gas Filling: After evacuation, the desired noble gas (or mixture) is introduced into the tube at a specific pressure. The amount of gas is crucial for achieving the correct brightness and color.

- Sealing and Electrode Attachment: The open end of the tube is then sealed. Electrodes are attached to each end of the tube, often with a special type of glass or cement that can withstand the high temperatures and electrical currents.

- “Aging” or “Burning In”: Before the sign is assembled, each individual tube is tested. This involves applying high voltage to ensure it lights up correctly and achieves its intended color and brightness. This process, sometimes called “burning in,” also helps to stabilize the gas and the phosphor coating.

- Assembly and Wiring: The finished glass tubes are carefully mounted onto their backing material. High-voltage wires are then connected from the electrodes of each tube to the transformer, completing the electrical circuit.

- Final Testing: The complete sign is tested one last time to ensure everything is working perfectly and safely.

The Difference: Neon vs. LED Signs

In today’s world, you’ll often see signs that look like neon but are actually made with LED (Light Emitting Diode) technology. While they offer a similar aesthetic, the materials and how they work are completely different.

Here’s a quick comparison:

| Feature | Traditional Neon Signs | LED “Neon” Signs |

|---|---|---|

| Primary Material | Glass tubes, noble gases (neon, argon), phosphors, electrodes | Flexible plastic or silicone tubes containing LED strips |

| Light Source | Electrical current passing through ionized noble gas | Light Emitting Diodes (LEDs) |

| Colors | Achieved through gas type and internal phosphor coatings | Achieved through the color of the LEDs themselves; often programmable |

| Durability | Glass is fragile; can break if dropped or impacted | More durable; flexible tubes can bend and withstand impacts better |

| Energy Efficiency | Less energy-efficient; requires high voltage | Highly energy-efficient; uses much less power |

| Lifespan | Can last 10-15 years or more with proper care | Can last 50,000+ hours (often longer than traditional neon) |

| Heat Emission | Can generate some heat | Generate very little heat |

| Installation | Requires professional installation due to high voltage | Often easier to install; lower voltage requirements |

| Cost | Generally more expensive upfront | Often more affordable, especially for custom designs |

| Maintenance | Can be prone to breakage; gas can leak over time | Low maintenance; LEDs are solid-state components |

LED “neon” signs are becoming increasingly popular because they are more energy-efficient, durable, and often less expensive. However, traditional neon signs have a unique, warm glow and a certain nostalgic charm that many people still prefer. Understanding the materials helps you appreciate the unique qualities of each.

Safety Considerations When Dealing with Neon

While neon signs are beautiful, it’s important to remember they involve high voltages and glass. Safety should always be your top priority.

- High Voltage: The transformers used to power neon signs generate very high voltages. Never touch any part of the sign or its wiring while it is plugged in or if you suspect it might be live. If you need to move or service a neon sign, ensure it is completely disconnected from the power source. For any repairs or installations, always hire a qualified electrician or a professional neon sign technician. Organizations like the Occupational Safety and Health Administration (OSHA) provide extensive guidelines on electrical safety, which are relevant here.

- Glass Fragility: The glass tubes are susceptible to breakage. Handle them with extreme care. If a tube breaks, it’s important to shut off the power immediately and clean up the glass shards carefully. The gases inside are generally inert and not harmful if released in small amounts, but the broken glass itself is a hazard.

- Professional Installation: Unless you have experience with high-voltage electrical systems and neon sign construction, it’s best to leave the installation and any maintenance to professionals. They have the right tools, knowledge, and safety equipment to do the job correctly.

- Proper Ventilation: While the gases are sealed, in very rare cases of leaks or during maintenance, ensure the area is well-ventilated.

Frequently Asked Questions About Neon Signs

Q1: Can I make a neon sign myself?

A: While it’s possible to learn the craft of neon bending and fabrication, it requires specialized tools, extensive training, and a deep understanding of high-voltage electricity and glasswork. For most homeowners, it’s safer and more practical to purchase a professionally made neon sign or opt for an LED alternative if you’re looking for a DIY-friendly project.

Q2: What does “neon” gas actually look like?

A: Pure neon gas, when excited by electricity, emits a distinct red-orange light. This is the iconic color associated with traditional neon signs. Other colors are achieved using different gases (like argon) and phosphor coatings.

Q3: Are neon signs dangerous?

A: Neon signs operate at high voltages, which can be dangerous if mishandled. However, when properly manufactured, installed, and maintained by professionals, they are safe for everyday use. The glass itself can break, so care must be taken to avoid impacts.

Q4: How long do neon signs last?

A: A well-made neon sign can last for many years, often 10 to 15 years or even longer, depending on usage, the quality of materials, and environmental conditions. The lifespan is primarily determined by the electrodes and the integrity of the gas seal.

Q5: What’s the difference between neon and LED signs?

A: Traditional neon signs use electrified glass tubes filled with noble gases. LED signs use light-emitting diodes housed in flexible tubes, offering greater energy efficiency and durability. While they can mimic the look of neon, their internal components and operation are entirely different.

Q6: Can neon signs be used outdoors?

A: Yes, neon signs can be designed for outdoor use. This typically involves using weather-resistant glass, specialized sealing techniques, and protective enclosures for the transformer and wiring to withstand the elements. Proper installation is crucial for outdoor signs.

Q7: Do neon signs use a lot of electricity?

A: Compared to LED signs, traditional neon signs are less energy-efficient. They require high voltage to operate, which can consume more electricity. However, they are still relatively efficient for the amount of light they produce, and their unique aesthetic is often worth the energy cost for many.

Conclusion: The Enduring Glow of Craftsmanship

So, there you have it! What are neon signs made of? They’re a fascinating combination of carefully shaped glass, energized noble gases, and a touch of electrical wizardry. From the pliable glass tubes bent by skilled hands to the precise mix of gases that ignite with a spark, each element plays a vital role in creating that iconic, captivating glow. Whether you admire the classic red of pure neon or the dazzling array of colors achieved with argon and phosphors, understanding the materials demystifies the magic.

While modern LED alternatives offer efficiency and durability, the art of traditional neon signage continues to shine. It’s a testament to craftsmanship, a blend of art and science that has illuminated our world for decades. Now, the next time you see a glowing neon sign, you’ll have a much clearer picture of the materials and the artistry that bring it to life. It’s a reminder that even in our high-tech age, some beautiful things are still best made by hand, with a deep understanding of the materials themselves.