What Is a Fastener: A Complete Guide for Automotive Enthusiasts

Hey there! If you’ve ever popped the hood of your car or tinkered with a motorcycle, you’ve probably come across a fastener or two. I remember the first time I tried fixing my old pickup truck’s bumper—I was overwhelmed by the variety of bolts, screws, and clips staring back at me. It got me curious: What exactly is a fastener, and why are they so important in the automotive world?

After years of working on cars and learning the ins and outs, I’m excited to share everything I’ve discovered about fasteners with you. Whether you’re a DIY mechanic or just curious about what holds your vehicle together, this guide will break it all down in a simple, friendly way. Let’s dive into the world of fasteners and explore what makes them the unsung heroes of every car on the road!

Understanding Fasteners: The Basics

So, what is a fastener? In the simplest terms, a fastener is a device that holds two or more parts together. In cars, they’re everywhere—keeping your engine components secure, holding your fenders in place, or even attaching your license plate. I like to think of fasteners as the glue that keeps a vehicle from falling apart, except they’re way stronger and usually removable.

Fasteners come in all shapes and sizes, from tiny screws in your dashboard to heavy-duty bolts in your suspension. They’re designed to handle different levels of stress, vibration, and weather conditions. I learned this the hard way when I used a cheap screw to replace a rusted one on my car’s exhaust system—it didn’t last a month! The right fastener makes all the difference, and understanding their types and uses is key to any automotive project.

Types of Fasteners Used in Automobiles

There are tons of fasteners out there, and each has a specific job in your car. I’ve spent countless hours sorting through them at auto shops and junkyards, so let me walk you through the most common ones you’ll encounter.

Bolts

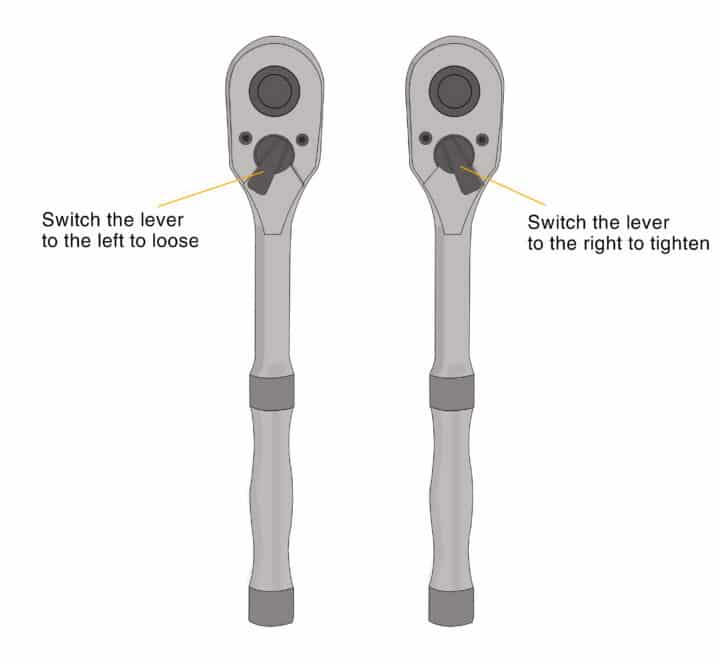

Bolts are the heavy hitters of the fastener world. They’re threaded rods with a head on one end, usually hexagonal, that you tighten with a wrench. I’ve used bolts to secure everything from engine blocks to wheel assemblies. They’re super strong and often paired with nuts to lock parts together. For example, when I replaced my car’s water pump, the bolts had to be torqued just right to prevent leaks.

Screws

Screws are like bolts’ smaller cousins. They’re threaded but usually don’t need a nut—they screw directly into a threaded hole or material. I see screws all over interior panels and smaller components, like the plastic covers under the hood. One time, I stripped a screw trying to remove my dashboard—big mistake! Always use the right screwdriver size to avoid that mess.

Nuts

Nuts work with bolts to create a secure connection. They’re threaded on the inside and come in shapes like hexagonal or square. I’ve used lock nuts on my car’s suspension to keep things tight despite all the road vibrations. Fun fact: Some nuts, like nylon-insert lock nuts, have a plastic ring to prevent them from loosening over time.

Washers

Washers are flat, disc-shaped pieces that sit under a bolt or screw head. They spread out the pressure, protect surfaces, and sometimes help prevent loosening. I always keep a stash of flat washers and lock washers in my toolbox. They saved me once when I was installing a new alternator—the washer kept the bolt from digging into the soft metal.

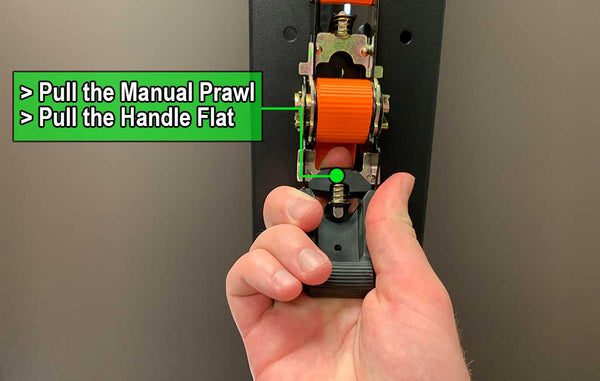

Clips and Retainers

Clips and retainers are the sneaky fasteners you don’t notice until they break. They hold plastic panels, trim, and upholstery in place. I struggled with these when I replaced my car’s door panel—those little plastic clips are tricky to remove without snapping! You’ll find them in places like your bumper or interior trim.

Rivets

Rivets are permanent fasteners that you deform to lock parts together. They’re common in bodywork, like attaching metal panels. I’ve used pop rivets to fix a loose fender on my old Jeep. You need a rivet gun, but they’re super reliable for parts that don’t need to come apart often.

Pins and Cotter Pins

Pins, like dowel pins or cotter pins, keep parts aligned or prevent nuts from turning. I’ve used cotter pins on my car’s tie rods to secure the castle nuts. They’re small but critical for safety—losing one could cause a component to shift while driving.

Here’s a quick table summarizing these fasteners and their common uses:

| Fastener Type | Common Uses in Cars | Tools Needed |

|---|---|---|

| Bolts | Engine, suspension, wheels | Wrench, socket set |

| Screws | Interior panels, small components | Screwdriver |

| Nuts | Paired with bolts for secure connections | Wrench, socket set |

| Washers | Under bolts/screws to spread pressure | None (used with others) |

| Clips/Retainers | Trim, bumpers, upholstery | Trim removal tool, pliers |

| Rivets | Body panels, permanent joints | Rivet gun |

| Pins/Cotter Pins | Securing nuts, aligning parts | Pliers, hammer |

Materials Used in Automotive Fasteners

Fasteners aren’t just about shape—they’re made from different materials to suit their job. I’ve learned to pay attention to this because using the wrong material can lead to rust or failure. Here are the main ones you’ll see in cars:

Steel

Most automotive fasteners are made of steel because it’s strong and affordable. I’ve used steel bolts for heavy-duty parts like axles. However, plain steel can rust, so many are coated with zinc or other finishes to resist corrosion. My truck’s undercarriage bolts were zinc-plated, which kept them rust-free for years.

Stainless Steel

Stainless steel is a step up—it resists rust even in harsh conditions like salty winter roads. I used stainless steel screws when I replaced my license plate holder, and they still look brand new. They’re pricier but worth it for exposed areas.

Aluminum

Aluminum fasteners are lightweight and corrosion-resistant, perfect for parts where weight matters, like in high-performance cars. I’ve seen them in engine components, but they’re not as strong as steel, so they’re used carefully.

Plastic

Plastic fasteners, like clips and retainers, are common in interiors and non-structural parts. They’re cheap and don’t rust, but they can break easily. I keep extra plastic clips on hand because they’re so easy to snap during repairs.

Titanium

Titanium fasteners are rare but awesome. They’re super strong, lightweight, and corrosion-resistant, often used in race cars or high-end vehicles. I’ve never used them myself—they’re expensive!—but I’ve seen them in a friend’s modified Mustang.

Why Fasteners Matter in Automotive Applications

Fasteners might seem small, but they’re critical to your car’s safety and performance. A loose or broken fastener can cause parts to shift, vibrate, or even fail while you’re driving. I once had a loose bolt on my exhaust system that caused a loud rattle—annoying and dangerous! Fasteners also affect how easy it is to repair or maintain your car. The right fastener makes disassembly a breeze, while a rusted or stripped one can turn a quick fix into a nightmare.

In the automotive world, fasteners are designed to handle specific stresses. For example, engine bolts need to withstand heat and vibration, while body panel screws need to resist rust. Choosing the right fastener for the job ensures your car stays reliable and safe.

How to Choose the Right Fastener

Picking the right fastener can feel overwhelming, but I’ve got a simple process that works. First, check your car’s manual or the part you’re replacing to see what fastener is recommended. Look at the size, thread type, and material. For example, when I replaced my brake caliper bolts, I made sure to get the exact size and grade specified by the manufacturer.

Second, consider the environment. If the fastener will be exposed to water or salt, go for stainless steel or coated steel. Third, think about strength. High-stress areas like the suspension need high-grade bolts, usually marked with numbers like 8.8 or 10.9 to indicate their strength. Finally, don’t skimp on quality. Cheap fasteners might save you a few bucks now but can fail faster. I learned this when a bargain-bin screw snapped during a tire change—not worth it!

Common Fastener Problems and How to Fix Them

Fasteners can cause headaches if they’re not handled right. Here are some issues I’ve run into and how to deal with them:

Rust and Corrosion

Rust is the enemy of fasteners, especially in older cars or ones driven in snowy areas. I’ve had bolts so rusted they wouldn’t budge. Spray them with a penetrating lubricant like WD-40 and let it sit for 10 minutes. Use a wire brush to clean off rust, and if the fastener is too far gone, replace it with a corrosion-resistant one.

Stripped Threads

Stripped screws or bolts happen when you use the wrong tool or too much force. I stripped a screw on my car’s air filter housing once—frustrating! Use a rubber band over the screw head for extra grip, or try a screw extractor kit. To prevent this, always use the right tool and don’t overtighten.

Loose Fasteners

Vibration can loosen fasteners over time. I noticed this with my license plate screws rattling after a long drive. Use lock washers, thread-locking fluid (like Loctite), or lock nuts to keep things tight. Check critical fasteners, like those on wheels, regularly.

Broken Clips

Plastic clips break easily, especially in cold weather. I’ve snapped plenty while removing trim. Keep spares on hand and use a trim removal tool instead of a screwdriver to avoid damage.

Tools You’ll Need for Working with Fasteners

Having the right tools makes working with fasteners so much easier. Here’s what I keep in my garage:

- Wrench and Socket Set: For bolts and nuts. A ratcheting wrench saves time.

- Screwdrivers: Phillips and flathead in various sizes for screws.

- Pliers: Needle-nose pliers are great for cotter pins and clips.

- Torque Wrench: To tighten bolts to the right specs, especially for engine or suspension work.

- Trim Removal Tool: For plastic clips and retainers without breaking them.

- Penetrating Lubricant: To loosen rusted fasteners.

- Wire Brush: To clean rust and grime off old fasteners.

I also recommend a good organizer for your fasteners. I used to toss them in a jar, but now I sort them by size and type in a tackle box—it saves so much time!

Maintenance Tips for Automotive Fasteners

Keeping fasteners in good shape extends your car’s life and makes repairs easier. Here’s what I do:

- Check for rust regularly, especially in winter. Replace rusted fasteners before they seize.

- Use thread-locking fluid on critical bolts to prevent loosening.

- Lubricate moving fasteners, like hood latch bolts, with a light oil.

- Inspect clips and retainers when removing panels and replace any that look brittle.

- Store spare fasteners in a dry place to avoid corrosion.

I check my car’s fasteners every oil change, just to catch small issues before they become big ones.

When to Replace Fasteners

Not every fastener needs replacing, but some definitely should. If a bolt is rusted beyond cleaning, replace it. Same goes for stripped screws or broken clips. I always replace fasteners in critical areas, like brakes or suspension, with new ones to ensure safety. For example, when I did a brake job last year, I used new caliper bolts to avoid any risk of failure. If you’re unsure, compare the old fastener to a new one—if it looks worn or damaged, swap it out.

When to Call a Professional

Most fastener-related tasks are DIY-friendly, but some situations call for a pro. If you’re dealing with a seized bolt in a critical component like the engine or transmission, a mechanic has the tools to remove it without damage. Same goes for rivets in structural parts—if you don’t have a rivet gun or the know-how, it’s worth the cost. I called a pro once when a rusted manifold bolt broke off in my engine block—it was a job I couldn’t handle alone.

Conclusion

Fasteners might not be the flashiest part of your car, but they’re the backbone of every repair, modification, and assembly. From the bolts holding your engine together to the clips keeping your bumper in place, these little heroes make your vehicle safe and reliable. I’ve spent years learning their quirks, from wrestling with rusted bolts to mastering the art of not snapping plastic clips. With the tips I’ve shared, you can confidently tackle fastener-related projects, choose the right ones for the job, and keep your car in top shape. So, next time you’re under the hood or swapping out a part, give a nod to those trusty fasteners—they’re holding it all together! Happy wrenching!

Frequently Asked Questions

What is a fastener in a car?

A fastener is a device that holds car parts together, like bolts, screws, nuts, or clips. They keep everything from your engine to your trim secure.

What’s the difference between a bolt and a screw?

A bolt usually needs a nut and is used for heavy-duty parts. A screw threads directly into a material or hole, often for smaller components.

How do I know what fastener to use for a repair?

Check your car’s manual for the recommended size, type, and material. Match the old fastener or consult a parts store for help.

Why do fasteners rust, and how can I prevent it?

Fasteners rust from moisture and salt exposure. Use stainless steel or coated fasteners and check for rust regularly to prevent corrosion.

Can I reuse old fasteners?

You can reuse them if they’re not rusted, stripped, or damaged. For critical parts like brakes, it’s safer to use new fasteners.

What tools do I need to work with fasteners?

You’ll need a wrench, socket set, screwdrivers, pliers, and a torque wrench. A trim removal tool helps with clips, and lubricant is great for rusted bolts.

How do I remove a stripped screw?

Place a rubber band over the screw head for extra grip, or use a screw extractor kit. Always use the right screwdriver size to avoid stripping.