What Is The Difference: Genius Wood Sealer vs. Waterproofer

Quick Summary

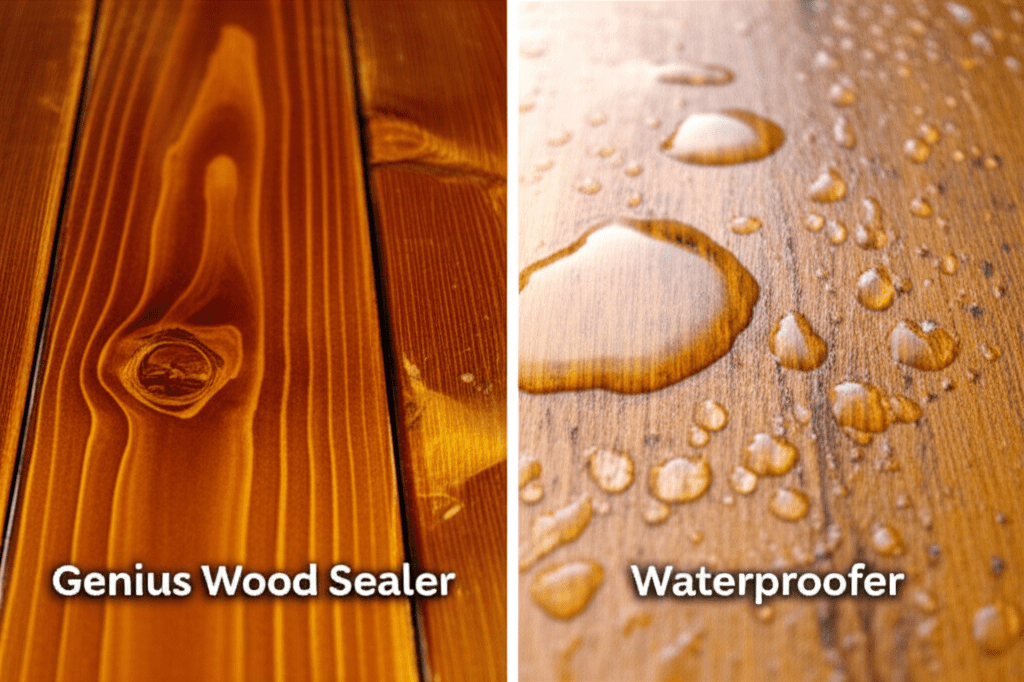

While both wood sealers and waterproofers protect wood, a wood sealer typically forms a protective film on the surface, offering moderate water resistance and UV protection. A wood waterproofer, on the other hand, penetrates deeper into the wood fibers, creating a more robust barrier against water ingress and often offering enhanced durability. Understanding this difference is key to choosing the right protection for your project.

Welcome to the Workshop: Demystifying Wood Protection

Hey there, fellow woodworkers! Ashraf here. Ever stood in the aisle at the hardware store, staring at rows of cans promising to protect your beautiful wood projects, and wondered, “What’s the real difference between a wood sealer and a waterproofer?” You’re not alone! It’s a common question, and getting it right can save your project from moisture damage, warping, and a host of other headaches.

Choosing the wrong product can leave your carefully crafted piece vulnerable. But don’t worry, that’s why we’re here! We’ll break down exactly what makes these products tick, helping you make the best choice for your next creation. Get ready to feel confident in protecting your wood!

Understanding Wood’s Natural Enemy: Moisture

Wood is a fantastic material, full of character and warmth. But it has a weakness: moisture. When wood absorbs water, it swells. When it dries out, it shrinks. This constant cycle of expansion and contraction puts stress on the wood, leading to cracks, warping, and even rot over time. That’s where protective finishes come in.

What Exactly is a Wood Sealer?

Think of a wood sealer as a protective cloak for your wood. It’s designed to create a barrier on the surface of the wood, shielding it from everyday wear and tear, as well as environmental factors. Most sealers offer a good level of water resistance, preventing spills from soaking in immediately, and many also include UV inhibitors to prevent fading from sunlight.

How Wood Sealers Work

Wood sealers typically work by forming a film or coating on the surface of the wood. This film sits on top of the wood grain, much like paint or varnish, though often with a more transparent or natural finish. When applied, the liquid sealer solidifies into a hard, protective layer. This layer is designed to repel liquids and prevent contaminants from penetrating the wood’s surface.

The effectiveness of a sealer depends on its formulation. Some are oil-based, while others are water-based.

Oil-based sealers: Tend to penetrate slightly into the wood and provide a more durable, often lustrous finish. They are known for their ability to enhance the natural beauty of the wood.

Water-based sealers: Are typically lower in VOCs (Volatile Organic Compounds), easier to clean up, and dry faster. They might offer a more matte finish compared to oil-based options.

Common Uses for Wood Sealers

Wood sealers are excellent for a wide range of indoor and outdoor projects where moderate protection is needed. They are particularly popular for:

Furniture: Protecting tabletops, chairs, and cabinets from spills and general use.

Trim and Molding: Sealing interior wood trim to prevent dust and moisture absorption.

Cabinets: Providing a durable, easy-to-clean surface for kitchen and bathroom cabinets.

Doors and Window Frames: Offering a first line of defense against light moisture and UV rays.

Craft Projects: Sealing small wooden items to give them a finished look and some protection.

Pros and Cons of Wood Sealers

Like any woodworking product, wood sealers have their advantages and disadvantages.

Pros:

Surface Protection: Excellent at preventing stains and minor spills from penetrating the wood.

UV Resistance: Many formulas contain UV blockers to prevent sun damage and fading.

Aesthetic Appeal: Can enhance the natural grain and color of the wood, offering various sheen levels from matte to high gloss.

Ease of Application: Generally easy to apply with brushes, rollers, or sprayers.

Good for Indoor Use: Ideal for furniture and decorative items that aren’t constantly exposed to harsh elements.

Cons:

Surface Film: The protective film can be prone to chipping, scratching, or peeling over time, especially in high-traffic or exposed areas.

Limited Deep Protection: Does not penetrate deeply into the wood, so prolonged submersion or heavy water exposure can still be an issue.

Maintenance: May require reapplication more frequently than more robust waterproofing treatments.

What Exactly is a Wood Waterproofer?

A wood waterproofer is designed to go a step further than a sealer. Its primary goal is to prevent water from penetrating the wood at all. These products often penetrate deeper into the wood’s structure, displacing moisture and creating a more substantial barrier against water damage. They are formulated to handle more demanding environments.

How Wood Waterproofers Work

Wood waterproofers typically work through penetration and displacement. They are often oil-based or silicone-based, allowing them to soak into the wood fibers. As they penetrate, they can displace existing moisture and, upon drying or curing, create a hydrophobic (water-repelling) barrier within the wood itself. This means water beads up and rolls off rather than soaking in.

Think of it like treating fabric with a water-repellent spray. The spray doesn’t just sit on the surface; it bonds with the fibers to make them shed water. Wood waterproofers do something similar, but they are designed for the porous nature of wood.

Some advanced waterproofers might also contain mildewcides and fungicides, which prevent the growth of mold and mildew that often thrive in damp conditions. The Environmental Protection Agency (EPA) offers guidance on controlling mold, and choosing a waterproofer with these additives can be a proactive step.

Common Uses for Wood Waterproofers

Wood waterproofers are the go-to choice for projects that will be exposed to significant moisture or the elements. Their deep-penetrating action makes them ideal for:

Decking and Railings: Protecting outdoor decks from rain, snow, and humidity.

Fences: Extending the life of wooden fences exposed to weather.

Patio Furniture: Keeping outdoor seating and tables safe from the elements.

Sheds and Gazebos: Providing essential protection for outdoor structures.

Boat Docks and Walkways: Areas that are frequently wet or even submerged.

Log Homes: Protecting the structural integrity of log cabins.

Pros and Cons of Wood Waterproofers

Wood waterproofers offer enhanced protection but come with their own set of considerations.

Pros:

Superior Water Resistance: Excellent at preventing water saturation, significantly reducing the risk of swelling, cracking, and rot.

Deep Penetration: Reaches into the wood fibers for long-lasting protection.

Durability: Generally more durable and long-lasting than surface sealers, especially in harsh conditions.

Mold and Mildew Resistance: Many formulations include additives to inhibit the growth of mold and mildew.

Preserves Wood Integrity: Helps maintain the structural strength and appearance of wood over time.

Cons:

Appearance Change: Can sometimes darken the wood or alter its natural appearance, depending on the product. Some can leave a slightly oily or waxy feel.

Application Nuances: May require specific application methods or conditions (e.g., dry wood) for optimal penetration.

Less Emphasis on Surface Scratches: Primarily focused on water repellency, so they might offer less protection against physical abrasion or surface scratches compared to a hard-surface sealer.

Reapplication Strategy: While durable, reapplication might involve stripping the old product or applying a specific maintenance coat, rather than just a light re-coat.

Key Differences at a Glance: Sealer vs. Waterproofer

To make things crystal clear, let’s lay out the core differences in a way that’s easy to digest. Understanding these distinctions will help you pick the perfect product for your project.

| Feature | Wood Sealer | Wood Waterproofer |

|---|---|---|

| Primary Function | Forms a protective film on the surface. | Penetrates wood fibers to repel water. |

| Protection Level | Moderate water resistance, stain resistance, UV protection. | High water resistance, prevents saturation, guards against rot and warping. |

| Method of Protection | Surface barrier. | Deep penetration and fiber treatment. |

| Durability | Good for moderate use; may require more frequent reapplication. | Excellent for harsh conditions; longer-lasting protection. |

| Appearance Impact | Can enhance wood grain; available in various sheens. | May darken wood; can alter natural feel; usually a more natural, matte finish. |

| Ideal Use Cases | Indoor furniture, cabinets, trim, light-duty outdoor items. | Decks, fences, outdoor furniture, sheds, boat docks, log homes. |

| Common Ingredients | Acrylics, polyurethanes, oils, waxes. | Oils (linseed, tung), silicones, silanes, siloxanes. |

| Maintenance | Can often be recoated directly after light cleaning. | May require specific prep or maintenance coats for optimal performance. |

Choosing the Right Product for Your Project

The “best” product isn’t universal; it entirely depends on what you’re trying to achieve and where your project will live. Here’s a quick guide to help you decide:

When to Choose a Wood Sealer:

Indoor Projects: If your project will stay inside, like a new bookshelf or a refinished dining table, a good sealer is often all you need. It will protect against spills, dust, and general wear.

Light Outdoor Use: For items that might be on a covered porch or get occasional light rain, a sealer can offer adequate protection.

Preserving Natural Appearance: If you love the exact color and sheen of your wood and want to maintain it with minimal alteration, a clear or lightly tinted sealer is a great choice.

Ease of Application & Cleanup: For beginners, sealers are generally forgiving and easier to clean up.

When to Choose a Wood Waterproofer:

Outdoor Exposure: For anything that will live outside and face the full force of the weather – decks, fences, garden benches – a waterproofer is essential.

High Moisture Areas: If your project will be near water, like a boat dock, or in a very humid environment, go for a waterproofer.

Preventing Structural Damage: When the longevity and structural integrity of the wood are paramount, and you need to prevent warping, cracking, or rot, a waterproofer is the way to go.

Minimizing Maintenance Cycles: While initial application might be slightly more involved, a good waterproofer often means less frequent maintenance compared to a sealer that might fail under harsh conditions.

A great resource for understanding wood properties and how they react to different environments can be found through university extension services, such as those offered by the U.S. Forest Products Laboratory, which provides detailed information on wood science.

Application Tips for Both Sealers and Waterproofers

No matter which product you choose, proper application is key to its effectiveness. Here are some general tips that apply to both sealers and waterproofers:

Preparation is Paramount:

1. Clean the Wood: Ensure the wood surface is clean, dry, and free from dust, dirt, grease, or old finishes. Sanding is often a good first step to create a smooth, receptive surface.

2. Check Moisture Content: For many waterproofers, it’s crucial that the wood is dry. Use a moisture meter if unsure. For sealers, while dryness is good, they can sometimes tolerate slightly more residual moisture than deep penetrating waterproofers.

3. Repair Damage: Fix any cracks or loose joints before applying any finish.

Application Process:

Read the Label: This is the most important tip! Each product has specific instructions for application, drying times, and recoating. Always follow the manufacturer’s recommendations.

Test First: Always test the product on a small, inconspicuous area or a scrap piece of the same wood. This helps you see how it affects the color and finish, and practice your application technique.

Apply Evenly: Use a good quality brush, roller, or sprayer, depending on the product and your preference. Work in the direction of the wood grain.

Avoid Over-Application: Applying too much product can lead to uneven drying, drips, or a gummy surface. It’s usually better to apply multiple thin coats than one thick one.

Allow Proper Drying Time: Rushing the process can compromise the finish. Ensure each coat is dry to the touch and, if required, before applying the next.

Ventilation: Always work in a well-ventilated area, especially with oil-based products.

Frequently Asked Questions About Wood Sealers and Waterproofers

Let’s tackle some common questions beginners have about protecting their wood projects.

Can I use a wood sealer on my outdoor deck?

While a wood sealer can offer some protection for outdoor items, it’s generally not recommended for high-exposure areas like decks. Decks are constantly subjected to rain, sun, and foot traffic, which can quickly break down a surface sealer. A dedicated wood waterproofer or deck stain with waterproofing properties will provide much more durable and effective protection against moisture and UV damage.

Will a waterproofer change the color of my wood?

Yes, many wood waterproofers, especially oil-based ones, can darken the wood or give it a richer, deeper tone. This is often considered a desirable effect as it enhances the wood’s natural beauty. However, it’s always best to test the product on a scrap piece first to see exactly how it affects the color of your specific wood species.

How often do I need to reapply wood protection?

This depends heavily on the product used and the environment it’s in. For indoor furniture with a good sealer, it might be years. For outdoor projects like decks or fences treated with a waterproofer, reapplication could be needed every 1-3 years, or when you notice water no longer beads up on the surface. Always inspect your wood regularly and reapply as needed.

Can I put a sealer over a waterproofer, or vice versa?

Generally, you can apply a sealer over a properly cured waterproofer if the sealer is compatible. However, applying a waterproofer over a surface sealer is usually not recommended because the waterproofer needs to penetrate the wood fibers. If there’s a surface film, it will prevent proper penetration. Always check product compatibility or test on a scrap piece. Some manufacturers offer specific topcoats designed to go over their waterproofers.

What’s the difference between a wood sealer and a wood stain?

A wood stain’s primary purpose is to add color to wood. Many stains also contain sealants that offer a degree of protection, but their main job is aesthetic. A wood sealer’s primary purpose is protection, and while some offer tinting, they are not typically designed to be as deeply pigmented or as varied in color as stains. Some products are stains with built-in sealants, and some are sealers that offer a tint.

Can I use a waterproofer on treated lumber?

Yes, you can use a waterproofer on treated lumber. Treated lumber is already resistant to rot and insects due to the chemicals infused into it. However, it can still absorb moisture from the surface, which can lead to weathering and graying. A waterproofer will help maintain its appearance and further protect it from water damage. Ensure the treated lumber is dry before application.

What does VOC stand for and why is it important?

VOC stands for Volatile Organic Compound. These are chemicals released into the air as a gas while the product is applied, drying, or curing. High VOCs can be harmful to your health and the environment. Many water-based sealers and some newer waterproofer formulations have lower VOCs, making them a safer choice for your workshop and home. Always check the product label for VOC content and safety information. For more details on VOCs, you can refer to resources from the EPA.

Conclusion: Protecting Your Creations with Confidence

So, there you have it! We’ve journeyed through the world of wood sealers and waterproofers, uncovering their unique roles in protecting our beloved wooden creations. Remember, a wood sealer acts like a protective shield on the surface, offering good defense for indoor items and lighter outdoor use, while a wood waterproofer penetrates deep into the wood’s fibers to create a robust barrier against the elements.

Choosing between them isn’t about which is “better,” but which is right for your specific project and its environment. By understanding their differences, how they work, and where they’re best applied, you can confidently select the product that will ensure your woodworking projects look great and last for years to come. Keep building, keep protecting, and most importantly, keep having fun in the shop!